3 Useful Tips to Extend the Life of Pellet Mills Effectively

Pellet mills are used to grind up all kinds of food wastes into a powder form, and can be made of steel, concrete or ceramic materials. They can be used to grind corn, wheat, rice, soybeans, potatoes and other dry goods into a fine powder that can be sold as a fertilizer. As an important part of the production process, pellet mills need to be taken good care of to prolong their lifespan. Here are 3 useful tips to help keep your pellet mill working well.

First, Remove impurities and iron well before feeding materials for pellet mill

No matter which kind of pellets are you making ,feed pellets or biomass pellets, the raw materials are often mixed with some sand, stone or iron and other impurities. When these impurities enter into the pelleting chamber, the spare parts will wear out soon because of the strong extrusion stress and friction between the ring die, this will lead lower rate of pellet forming and also increase production costs. The worst situation is the whole machine maybe broken just because of the iron filing.

So the iron filing and debris removal must be well done before feeding. Clean up the iron removal device once per work shift, to avoid foreign objects into the ring die working chamber, or it will result in body vibration and collapse of the ring die.

Avoid pellet mills overload work

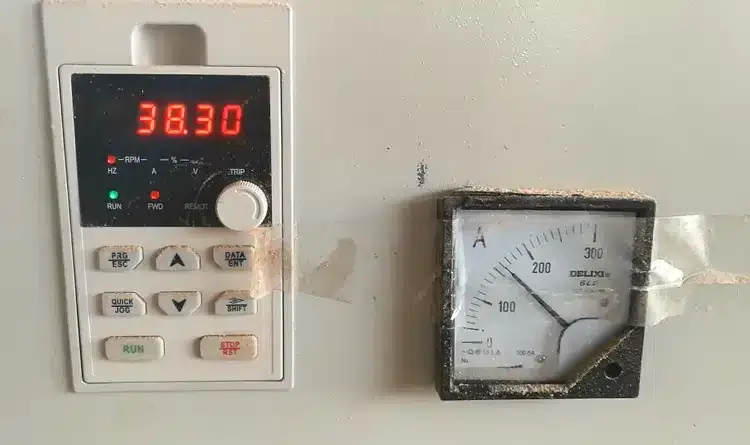

In order to pursue higher production efficiency, some users will choose to fill up the material, or 24-hour continuous rotation. Overload work will also intensify the loss of machine bearings. When the pellet mill starts working, the feeding volume should be increased from low speed to high speed, and the speed should be well controlled, otherwise the ring die and pellet mill will be damaged or blocked due to sudden overload.

When vibration, noise, bearing and body temperature too high, outward spraying material and other situation occur, you should immediately stop work for inspection, troubleshooting before continuing to work.

Do prevention work before pellet machine blockage

To prevent blockage in advance, do not be afraid of the complexity of the work. It is recommended to adjust the ring die and pressure roller gap every shift. The distance between the ring die and roller shell should be adjusted well, better 0.1-0.3mm. But when you press the straw materials, you can adjust the distance at 0.5mm. The distance adjustment is quite important, if too large, it will affect the productivity of the pellet mill, or even worse no pellets come out. If the distance is too small, this will accelerate the wear between the pressure roller and the ring die, reducing the service life of the die.

When the pellet mill is blocked, it is necessary to loosen the pressure roller, eradicate the material inside the ring die and adjust the gap of the die roller from the beginning to prevent the transmission parts and bearings from being damaged because of the violent oscillation. In addition, we should check the fastening of each fastener in time, and tighten it in time if it is loose.

Conclusion

Pellet mill is like our daily use of cars, 30% on use, and 70% on daily maintenance. When you do properly maintenance, the pellet machine production efficiency and machine life will naturally higher and longer.

Talk to An Expert

SHARE THIS POST

Talk to An Expert