IZVJEŠTAJ ZA INDONEZIJU VERZIJA 2022: Proizvodnja drvenih peleta i drvenih peleta Indonezija

Granulati ogrejnog drveta (Wood Pellet, WP) u gorivo (BB) primadona trenutno posebno u zemlji koja ima 4 sezone kao zamjena za ugalj (djelomično/u potpunosti) u termoelektrani na ugalj, sušilici zraka, peći na biomasu i sušenje na uslugama pranja rublja. U međuvremenu, promet WP-a u zemlji regulisan je modelom pakovanja sa šporetom ili gorionikom za upotrebu u domaćinstvu (zamena TNG), pogonu za preradu biljne hrane kao što su piletina, tofu, gudeg Jogja, restoranu/ štandovi sa hranom, peći za sušenje čaja/duvana/kukuruz/riba, preduzetnici pržene hrane itd. Ovdje nudimo drveni pelet indonezija izvještaj za kupce kojima je ovo potrebno, pročitajte više o vašem poslu proizvodnje peleta.

Velika potražnja za WP u LN uzrokovana zemljama odredišta za izvoz uglja (južna Koreja, Japan, Kina i Indija) koje se polako prebacuju na WP su dobrog kvaliteta, ekološki prihvatljive i obnovljive (vidljivo iz potražnje drvenih peleta u međunarodno tržište se brzo povećava). S druge strane, Kina postepeno počinje da zabranjuje upotrebu uglja (niskokalorični) za svoje građane (zbog zagađenja i emisije visokog sumpora). Australija i SAD da svedu upotrebu uglja na minimum. Indonezija također polako zamjenjuje upotrebu uglja drvenim peletima. (ISO 8021:2014).

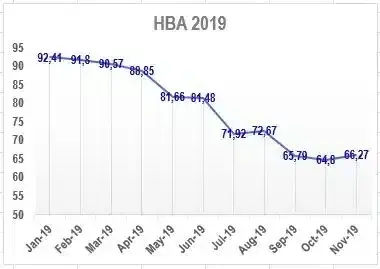

Rastuće cijene uglja zbog pooštravanja proizvodne 2016. godine, uzrokujući da referentna cijena uglja (HBA) Indonezije na međunarodnom tržištu (novembar 2016.) počinje da raste do 84,89 USD/tona ranije, (decembar 2016.) 69,07 USD/ tona, čak i preko 100 USD/tona u decembru 2016. godine, odnosno iznosi 101,69 USD/tona. Međutim, u 2019. godini HBA se vraća kao u 2016. godini, a to se može vidjeti na gornjoj slici (6322 kcal/kg, FOB posuda). To je bilo zbog pada potražnje iz Kine i Indije, te priliva ruskog uglja na tržišta Azije, Kine i Australije. Energetski i mineralni resursi postavili su proizvodnju uglja u 2019. oko 489 jt tona. Ranije 2018. vezano je 485 jt tona, ali realizacija 557 miliona tona.

S druge strane, oko 50 kompanija postaju partneri PT PJB grade elektranu na ušću rudnika (MT) (ukupno 6GW) sa ekološki prihvatljivom tehnologijom podkritičnom na kotlarnici kako bi se smanjio iznos izvoza (što će opet podići cijenu) odjednom ubrzati realizaciju programa snage od 35,000 MW. Primjer: elektrana MT Jambi (2x300MW); Riau (2x300MW); Sumsel 1, 6 (2x300MW, Tanjung Enim, 3jt tona uglja/godišnje, 2026), 8 (2x260MW, Huadian Bukit Asam Power 45% + China Huadian 55%, Muara Enim, 5,4 miliona tona uglja godišnje); Kaselteng 3, 4, 5; Kaltim 3, 5 (200MW), 6, Muara Jawa; i United Tractors (2x15MW, centralni Kalimantan).

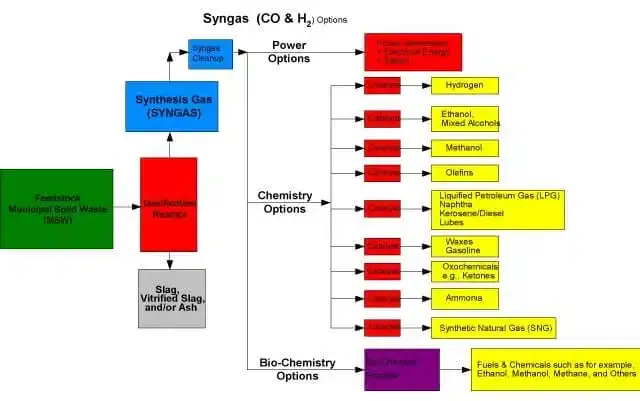

Jedna od upotreba uglja je pretvaranje u sintetički gas (gas sintetički) kroz tehnologiju gasifikacije (gasifikaciona plazma) kako bi se sintetski gas pretvorio u električnu energiju ili druge supstance kao što su metanol, DME, amonijak, itd.

Postoje neki od razloga zbog kojih će se ugalj razbiti drvenim peletima:

- Drveni pelet je BB obnovljivog (uvijek postoji, jednom se može promijeniti položaj uglja u budućnosti), i prijateljskog okruženja, dok ugalj nije obnovljiv (potrošan) i manje je ekološki prihvatljiv. Stoga je korištenje uglja na međunarodnom nivou berkurang za preživljavanje. Dakle, postoje mogućnosti za povećanje opskrbe nacionalnom električnom energijom putem BB drvenih peleta.

- Kalorični drveni pelet je ekvivalentan uglju s niskim kalorijama.

- Proizvodnja nižeg ugljika od uglja.

- Trošak električne energije proizvedenih drvenih peleta za zamjenu uglja jednak je proizvedenom prirodnom plinu koji je naravno jeftiniji od uglja.

- Kadrovi su bili potrebni ELEKTRANI na pelet (uključujući i pripremu infrastrukture drvenih peleta) više (dodati zaposlenje), što je oko 3.480 ljudi, dok TE na ugalj iste snage zahtijeva osoblje od oko 2.540 ljudi. 2 10

- Potražnja za drvenim peletima je dugoročno održiva kako bi se motivirali dionici da očuvaju i poboljšaju upravljanje šumama i razviju kritično zemljište (bivši rudnici uglja, zlata, kalaja, nikla, itd.) u šumu industrijskih biljaka specijalnih drvenih peleta (npr. Kaliandra Mo (KM), Mahang / Macaranga Gigantean, Karamunting / Melastoma Malabatricum)

- Potražnja za drvenim peletima koji dolaze iz svih krajeva svijeta i dalje hrli u Indoneziju. Treba ga iskoristiti za poboljšanje prihoda zajednice

- Indonezija je zapravo sposobna da proizvede električnu biomasu do 49.8 GW (potreba Indonezije za dodatnom nacionalnom energijom 35 GW). Potencijal biomase je bio oko 146.7 miliona tona/godišnje dobijenog od ostatka pirinča (150 GJ/th), gumenog drveta (120 GJ/god), ostataka šećera (78 GJ/god), ostataka palminog ulja (67 GJ/ godine), i ostali organski otpad (20GJ/god).

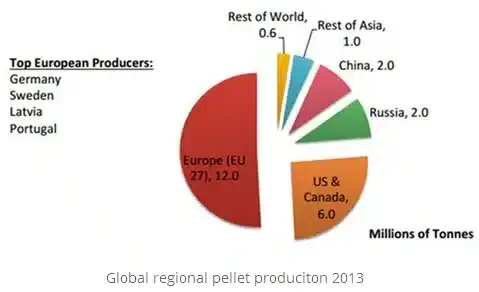

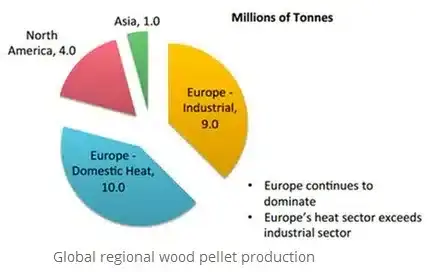

Kao što je poznato, korisnički WP svijet 2013. (23.6 miliona tona) zabilježen je država Japan, Južna Koreja, Kina (2 miliona tona), Evropa (12juta tona) (takođe najveći emiteri, odnosno Njemačka, Švedska, Latvija i Portugal), SAD (3 miliona tona), Rusija (2 miliona tona) i Kanada (3 miliona tona).

Iako su zemlje korisnici WP-a u mogućnosti da proizvode svoje, ali još uvijek nisu u mogućnosti da zadovolje potrebe WP DN koje (moraju uvoziti), zbog rasta drva u zemljama suptropskog sporijeg nego u tropskim zemljama. Primjer: 2013. godine evropske potrebe od 19 miliona tona [10 (vruće) + 9 (industrijske)] (manje 7 juta tona), Kanada (4 tone juta) (manje 1 milion tona), Azija (Japan i Južna Koreja) manje 1 miliona tona. Druga azijska zemlja koja će postati najveći uvoznik WP u narednoj deceniji (procjenjuje se na oko 5 miliona tona 2020.). Japanci u 2016. uvoze WP 400 tona (nakon nuklearne nesreće u Fukušimi 2014.), dok je za Carousel potrebno 1.7 miliona tona.

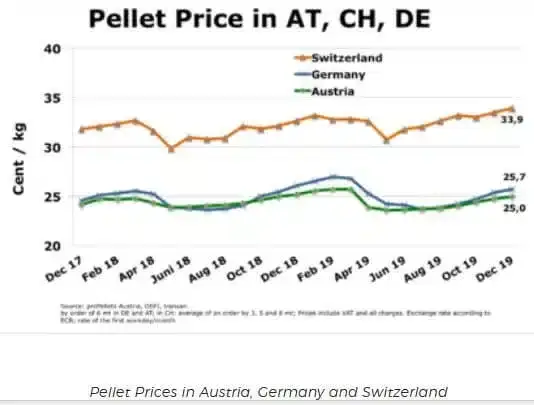

Proizvodnja WP-a u svijetu se približava 28juta tona (2015, za toplinu 15, industrija 13juta). U međuvremenu, marketing WP global za proizvodnju električne i toplotne energije nastavlja da raste za oko 14.1% godišnje. Tahun 2020, očekuje se da će potreba za WP porasti na 80 miliona tona. Stoga su neke zemlje, na primjer južna koreja, Japan, Evropa (uvoz ~14juta tona/2014), SAD i Kanada pokušale da pronađu sirovine za tropsku zemlju od kojih jedna do Indonezije. Sljedeća konto cijena WP u Evropi (Švicarska, Austrija i Njemačka) koja se može vidjeti u Gambaru na vrhu (~centEuro/kg). Mjesec septembar 2018., prosječna cijena WP ENplusA1 u Austriji je 236,5 EUR/toni.

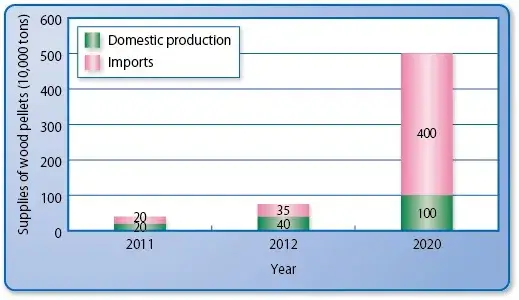

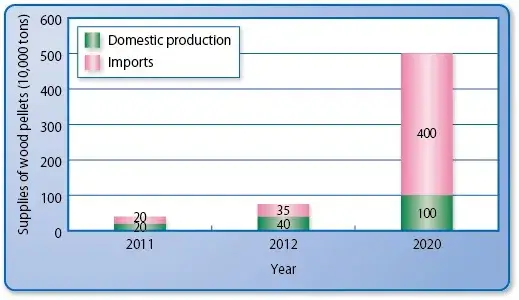

Od 2012. godine Carousel cilja korištenje obnovljive energije od najmanje 2%, a 2022. godine korištenje biomase treba ući u 10%, od čega 60% dolazi iz WP-a. Februara 2015. na tržištu Carousel je potrebno snabdjeti više od 280,000 tona za potrebe domaćinstva i industrije hrane i pića. Oko 70,3% WP Carousel je uvoz peleta (Indonezija isporučuje samo >7% Carousel-u, tačno oko 8.940 tona od 122.447 tona u 2012. godini, a ostatak se uvozi iz Rusije, Malezije i Vijetnama).

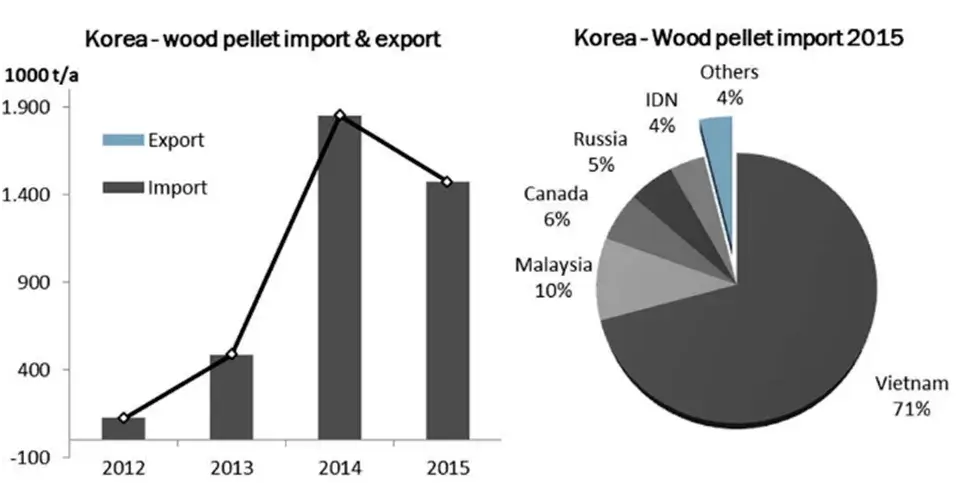

U to vrijeme, cijena CIF WP Indonezija aerodromske takse (131 USD/tona, ispod Vijetnama 144 USD/tona, i Malezije 141 USD/tona). Uvoz iz Indonezije nastavljen je prisustvom kerma kompanije Carousel Depian Co. Ltd. sa državnim PT Inhutani III (razvijanje pogona šumske industrije 5000-8000 Ha u Pelaihari, južni Kalimantan preko PT SL Agri u cilju izvoza WP do 100,000 tona, 2015.). U budućnosti, neke južnokorejske kompanije istražuju mogućnost uvoza WP-a iz Australije, Vijetnama, Indonezije, Filipina, Malezije, Tajlanda, Kanade i SAD-a. Za vrtuljak je potrebna elektrana koja koristi WP.

Import WP Carousel u 2014. i 2015. se vidi na bočnim slikama. Te godine Indonezija je izvezla 150,000 tona WP (Malezija 60,000 tona), od čega samo oko 4%. U međuvremenu, ljuska palminog jezgra (Palm Kernel Shell) dvije zemlje je izvezena u Japan u malim količinama. Sam vrtuljak uvozi WP sa cijenom od oko (109-135) Potražnja za drvenim peletima u Južnoj Koreji Isporuka drvenih peleta za Carousel 2/10/2020 3/31 Euro/ton (2015). U to vrijeme, Vijetnam je izvozio WP u Carousel oko 71%.

Da pemilik zemljište (stotine/hiljade hektara) u Indoneziji i zainteresovani ste za poslovanje WP, molimo vas da pazite na strane poslodavce (skalpere) koji kupuju piljevinu drvo DN po povoljnoj cijeni, jer će izvoziti u obliku WP u Rok ili Japan. Morate proizvesti sam WP u DN-u i izvesti ga u LN.

Spisak: Predstavnici Južne Koreje u Indoneziji, Indonežanski predstavnik u Carouselu, Agencija / Udruženje drvenih peleta u Carouselu i Pengusaha / Importir Carousel možete vidjeti ovdje (maj 2014.).

Korejski konzorcij koji je predstavljao izvršnog direktora GIMCO-a potpisao je saradnju (MoU) sa Kemendes PDTT (i PT Alam Bumi Cemerlang), kako bi se otpadni kukuruz/žižak (3500-4500 kCal/kg) (u 24 okruga) iskoristio u drvo peleti se mijenjaju tako da električno selo u oblasti Transmigracije, Labangka, Sumbawa, NTB. Žižak će biti pomiješan sa drvetom Gamal (4168kCal/kg, sadržaj vode 24%, sadržaj pepela 2.97%) i Calliandra (5000Ha) koji će se koristiti kao drveni peleti i izvoziti u Južnu Koreju za gorivo PLTBm Carousel. Investicija 400 juta ionako zasađena za finansiranje fabrike drvenih peleta 400.000 tona godišnje i PLTBm 30MW u Sumbawi.

Piljevina, pirinčana slama/pšenica, pirinčana ljuska (3300kcal/kg), bagasa/bagasa (sa sadržajem šećera 2.5%, kalorijska vrijednost 1.825 kcal), stabljike kukuruza/sirka, stelja od lišća, trava, grančice, Palm EFB (tankos) palma), a dijelovi biljke koji se smatraju otpadom mogu biti izvor WP. Poduzeća WP počela su uzgajati drvo brzo žetvom, minimalnim održavanjem i visokim energetskim sadržajem kao mješavinom otpada tsb. Na primjer: Petai china (Leucaena leucocephala), crvena kaliandra (KM) (Caliandra calothyrsus) i Gamal (Gliricidia sepium). Svrha izrade WP-a je da će se poboljšati kalorijska vrijednost drvnog otpada kako bi se BB-kalorija približila uglju (5.000 – 6.000 kcal), što je oko 4.200 – 4.800 kcal sa sadržajem pepela oko 0.5-3%.

Kaliandra crvena (KM) je sirovina najboljeg WP u odnosu na kinesku bananu, gamal i sengon dugme sa strane tempa rasta. Energija sadržana u KM 4600kkal/kg, do 7.400 kcal/kg, 1 kg peleta KM je ekvivalent toplotnoj energiji od 5.35 kWh ili električnoj energiji 1,355 kWh. Obogaćivanje tla kroz fiksaciju dušika u tlu, te težine vrste, tako da sadržaj pepela može biti manji. Osim toga, životni vijek KM može biti i do 29 godina sadnje, a može se brati 2 puta godišnje, tako da mu je za proizvodnju električne energije potrebno 1.5 godina. Od jednog ha KM može se proizvesti drvo 20-65m3/god. ili 20-35t/god. Gustina sadnje od minimalno 5000 stabala/Ha (razmak od 1x2m), može se podrezati do 1m iznad nivoa tla na periodičnoj osnovi svaka 4 mjeseca (3x godišnje) kada je plodno i ima mnogo padavina. Pod sastojinama kokosa (svjetlosti 60%), KM se može saditi kao biljno punilo.

Za kapacitet od 100kW, trošak investicije od oko 5.5 milijardi Rp (januar 2017.) uključuje obezbjeđivanje kritičnog zemljišta od 30 Ha (renta zemljišta 1.5 M Rp. za 20 godina, sadnice i sadnju/održavanje 250,000 stabala).

KM ne samo kao sirovina za WP, listovi kao hrana za stoku (visoki proteini), a interes za njih kao stočna polja pčela (proizvodnja meda (med bijela kaliandra) se dobija od nektara cvijeća KM poznatog u Jedan ha KM proizvodi med od najmanje 1 tone/godišnje (1000 kg x 50.000 Rp./kg = 50 miliona Rp/god = 4.17 miliona Rp./mjesečno), dok u Evropi može dostići 2 tone/th) za 15 godine bez sredstava za lečenje. Radijus pčela u potrazi za nektarom oko 5km.

KM dobro rastu na nadmorskoj visini od 400-600m, pH~5 i malo vode. Postrojenje će također funkcionirati kao biljke koje pokrivaju tlo (perdu) (đubrenje tla / očuvanje zemljišta / sidrenje erozije u nagnutom tlu / iskopavanje tla kao što su kalaj, ugalj, zlato, nikl, itd.) kako bi se izbjegle poplave i okrenule zemlja kritična, suva, peskovita i neplodna, jer služi kao đubrivo zemlje, korenje ubijenih štetočina je odletelo u zemlju, a delikatno korenje drugog koje se proteže do površine zemlje. KM služi održavanju održivosti prirode.

Neki primjeri lokacije pn KM:

- Gamal i kaliandra zasađeni u Sumbawa 5000 ha.

- 100 hiljada batanga u kritičnom zemljištu u Wonogiriju u saradnji sa Ministarstvom PDT-a;

- P Singkep (Kep Riau) (u zemlji kritičnih bivših rudnika kalaja);

- Gorontalo Utara (PT Citra Makmur kencana).

- Primjer razvoja KM kao WP (ET) zamjene uglja od strane nevladinih organizacija (bez pomoći vlade) se provodi u Buturu (kab. Buton North, Prov. Southeast Sulawesi). U početku je rasadnik KM samo 100,000 stabala razvijen u Kulbaru (osim Kalisusu West) od strane CHANGE (Pokret ribara Tani Indonezije) Butur, sa ciljem od milion stabala u budućnosti. Potpisan je Memorandum o razumijevanju sa PT Energy Indonesia (tvornički WP) za otkup MILES-a od farmera.

Proces izrade drvenih peleta:

- Pripremite materijale unaprijed

- Stavite u mašinu za sušenje na okretanje kako biste smanjili sadržaj vode dok ne dostigne 10%

- Suvi prah (koji je pomešan sa brašnom od tapioke; ne treba sipati, jer već sadrži šećer) ubaciti u mašinske proizvođače peleta za presovanje i zagrevanje na oko 180 oC sa krajnjim rezultatom WP cilindrično oblikovani berdiamater 6 -10 mm dužine, 1-3 cm i gustine 650 kg/m3. Calliandra Calothyrsus Pčele sišu cvjetnu esenciju KM 2. 10.

- Zamotajte/pakujte, pošaljite drugim stranama

Karakteristike proizvoda BB pelet

Osnovni sastojci ovih peleta su stabljike kukuruza, pšenična slama, pirinčana slama, ljuska kikirikija (4644 kcal/kg), klip kukuruza, grančice pamuka, stabljika soje, korov (divlja trava), grančice, lišće, piljevina i druge biljke. otpad. Nakon što je sirovina zdrobljena, zatim prešana i otisnuta, formirana u obliku peleta kako bi se stvorio pritisak između valjka i kalupa na materijalu. Gustina materijala je prvobitno bila oko 130kg/m3, ali se gustina peleta penje na vrhu 1100kg/m3, tako da je lako skladištenje i ditransport, kao i performanse dizanja goriva.

Piljevina Peleti

Linija za proizvodnju peleta od piljevine: otkup sirovina, sakupljanje materijala, sušenje, peletiranje i pakovanje. Sadržaj vode u piljevini je oko 30-45%, a cijena sirovine oko 21.05 – 24,29 USD/tona. Uvjeti kalorijske vrijednosti mogu doseći 4.000 – 4.500 kcal.

Pellets Twigs

Linija za proizvodnju peleta grančica: otkup sirovina, drobljenje, sušenje, peletiranje i pakovanje. Cijena sirovina ~16,19 USD/tona. Kalorična vrijednost peleta grančica niža od peleta od piljevine.

Procedura izrade:

otkup sirovina, sušenje, peletiranje i pakovanje. Kvaliteta materijala ovisi o periodu sadnje. Svi materijali se mogu efikasno uskladištiti na vrijeme, zatim osušiti i peletizirati. Sadržaj vode u šećernoj trsci je oko 20-25%. Pelet bagasse ima visoku kalorijsku vrijednost 3.400-4.200 kcal (prije peletiranja samo oko 1825 kcal, a kada se sirova bagasa samo zagrijavala izduvnim plinovima iz kotla, sadržaj vode u pulpi je opao za 40%, a kaloričnost vrijednost postaje 2305 kKal).

Pelet bagasse (bagasse) je bioenergija nova. Može se koristiti kao grijač prostora, štednjak, toplovodni kotlovi i industrijski, PLTBm i dr. On služi kao zamjena za ogrevno drvo, ugalj, lož ulje i TNG. Bagasse ima energetski sadržaj i kvalitet goriva je visok. Med, sadržaj pepela od ~6%.

Potencijal bagase u Indoneziji je 30 tona/Ha/godišnje. Dok je zemljište šećerne trske (2014) od 447.000 ha [63,46% je na Javi, ostalo je 36,54% van Jave], onda je potencijal bagasa ukupno oko 13,41 miliona tona godišnje, što je površina useva smanjena za 6% u odnosu na 2013. godinu (470.198 Ha). Stoga je Vlada, da bi zadovoljila potrebe DN šećera i smanjila uvoz sirovog šećera, postavila plantažu šećerne trske od dodatnih čak 500,000 ha u jugoistočnom Sulawesiju, P., Aru i Merauke, kao i izgradnju 10 nove fabrike šećera DN. U budućnosti će biti dodatnog prtljaga od oko 15 tona godišnje.

Čvrsti otpad šećerne trske nastaje iz rezultata naprezanja nira u filteru sa rotirajućim bubnjem naziva se filter kolač. Kada se osuši, filter kolač se može direktno koristiti kao gorivo u kuhinji za kuvanje. Filterski kolač se uglavnom koristi za kompost.

Odabir gazećeg sloja i budžet trošak pelet Bagasse u Drvenim peletima Indonezija

Bagasa za gazište treba da bude locirana na lokaciji gde su sirovine u izobilju, jeftine i blizu aerodroma/luke kako bi se olakšao transport proizvoda, tako da troškovi sirovina i ostali troškovi (radna snaga, najam skladišta, upravljanje troškovima itd.) .) može se sačuvati kao nisko. Potrebno je pripremiti aspekte zakonitosti industrije građevinskih dozvola: TDI, SIUP, HO, IMB itd. Izrađuju se i sertifikat za izvoz (SVLK) i sertifikat proizvoda (npr. Sucofindo i SGS).

Početno ulaganje bagasa u mlin za pelet oko 112.414 USD sa kapacitetom od 1 tona/h (kapacitet se može povećati do 6 tona/sat da bi se dodala potrebna oprema).

Investiciona izgradnja fabrika oko 19.271 USD sa površinom od 6.000m2.

Početna kapitalna ulaganja u opremu oko 72.266 USD uključujući sušare 24.089 USD, kavez za pelet Bagasse 2/10/2020 5/31 1.927 USD, elektro ormar 1.927 USD, mašina za pelete (1 tona/h) 25.695 USD itd.

Obrtni kapital oko 40.148 USD za početno skladištenje sirovina i pretprodaju proizvoda.

Kada je tržište i poslovanje stabilno, možete povećati svoju investiciju. Sušilica 24.089 USD može se koristiti za 3 mlin za pelete, jednostavno možete dodati oba u Stranding kavez, mašinu za pelete i transporter. Kada je mlin za pelete više od tri, onda je potrebno dodati sušaru i neophodan je kamionski viljuškar. Hlađenje motora treba uzeti u obzir u zavisnosti od okolnosti proizvodnje.

Drveni pelet Indonezija Analiza troškova i marže peleta Bagasse

Poslovni cilj: 500 tona/mjesečno (početak). Pri normalnom radu, mjesečna proizvodnja može se povećati do 1,500 tona ili 3,000 tona. Godišnji proizvodi oko 30,000 tona.

ROI Pellets Bagasse:

- Cijena sirovine tone šećerne trske: 19,45 USD/ton

- Troškovi transporta: 3,24 USD/tona [naknada za pakovanje i troškovi van]

- Drobljenje: 0

- Opterećenje električne sušare: 1,39 USD/tona [7,5 kV električna mašina za sušenje 0.7 tona/sat]

- Električno opterećenje peletisasi: 11,67 USD/ton [90kW pelet električnog motora 1 ton/j]

- Pakovanje: 5,19 USD/tona [25kg/džak; 0,13 USD/vreća]

- Radnici-direktno: 8,10 USD/tona [1 alat za 8 radnika, 11,34 USD za 1 radnika u jednom danu]

- Cijena gazećeg sloja: 5,33 USD/tona [19.434 USD za korištenje od 10 godina]

- Cijena alata: 3,25 USD/tona [alat 80.976 USD za 26 dana/mjesečno u 5 dana upotrebe]

- Troškovi njege: 4,86 USD/tona [cijena matrice / oči filca su istrošene]

- UKUPNI trošak: 62,48 USD/tona

Obračun zarade: ukupni trošak: 62,48 USD/tona; prodajna cijena peleta u fabrici: 97,17 USD/tona; neto dobit za jednu tonu 34.69 USD. Ako je mjesečna proizvodnja od 500 tona, neto dobit mjesečno je 17.345 USD.

Dok, ROI piljevine peleta

- Cijena sirovine piljevine: 22,67 USD/tona

- Troškovi transporta: 4,86 USD/tona [pakovanje i troškovi van]

- Drobljenje: 0

- Opterećenje električne sušare: 2,08 USD/tona [7,5 kV električna mašina za sušenje 0.7 tona/sat]

- Električno opterećenje za mlin za pelete: 15,16 USD/tona [90kW pelet za električni motor 1 tona/j]

- Pakovanje: 5,18 USD/tona [25kg/džak; 0,13 USD/vreća]

- Radnici-direktno: 8,10 USD/tona [1 alat za 8 radnika, 11,34 USD za 1 radnika u jednom danu]

- Cijena gazećeg sloja: 5,33 USD/tona [19.434 USD za korištenje od 10 godina]

- Cijena alata: 3,25 USD/tona [alat 80.976 USD za 26 dana/mjesečno u 5 dana upotrebe]

- Troškovi njege: 5,83 USD/tona [cijena matrice / oči filca su istrošene]

- UKUPNI trošak: 72,46 USD/tona

Obračun zarade: ukupni trošak: 72,46 USD/tona; prodajna cijena peleta u fabrici: 137,65 USD/tona; neto dobit za jednu tonu iznosi 65,19 USD. Ako je mjesečna proizvodnja od 500 tona, neto dobit mjesečno je 32.595 USD.

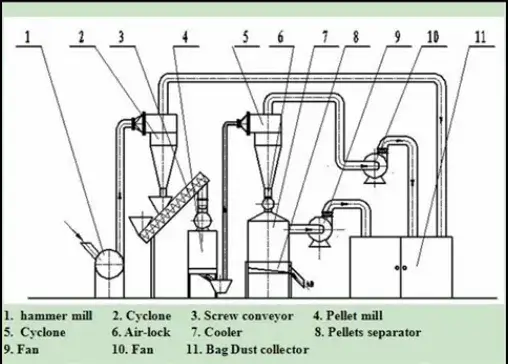

Drvene pelete Indonezija rižina slama/pšenica/trava/slično

Evo primjera sheme alatnih mašina za proizvodnju peleta od pirinčane slame/pšenice kapaciteta peleta 200-300 kg/h. Takve mašine mogu koristiti i razne druge sirovine kao što su drvo, bagasa, stabljike/kožica kukuruza/sirak, ljuska kikirikija, bagasse jatropha, kožica kafe, brzorastuća biljka, stabljika palme (od 8.6 tona/Ha, 3650 kCal/kg) piljevina, komadi papira i strugotine. Mašina se sastoji od mlina sa čekićem, mlina za pelete, hladnjaka, vibriranog separatora peleta opremljenog hvatačem prašine za sprečavanje zagađenja prašinom. Kao što je poznato, sijeno je objekat koji je gladak i teško ceđen. Zbog toga je mašini potreban pužni transporter koji je posebno dizajniran sa dodatnim rezervoarom, tako da korisnik može da dodaje piljevinu i komade papira kako bi poboljšao kvalitet peleta. Ako je mamac previše mokar, potrebno je dodati dodatak za sušenje.

Različiti tipovi primera drugih mašina (začepi, kreni dalje/u kamion, mašina torba, velika i mala) dosta je dostupno na tržištu LN [1, 2, 3, 4, 5, 6, 7 , 8]; DN [1, 2, 3] za izradu peleta od raznih sirovina biomase.

Poređenje pelet slame (sa peletom na pirinčanoj ljusci) su: Sadržaj vode: 8-10% (15-30%); sadržaj pepela 3% (15-20%); kalorijska vrijednost: 18,5 MJ/kg (13,98 MJ/kg) ili 4422 kCal/kg (3341 kCal/kg). Sagorijevanje peleta slame proizvodi ugljični neutralan, koji se može koristiti natrag na rast biomase sljedeće.

Proizvodnja peleta od slame može povećati gustinu pirinčane ljuske, smanjiti troškove transporta, energetski sadržaj uzlaznog (4422kKal/kg), niski sadržaj pepela (3%), a može se smanjiti i pepeo od sagorevanja peleta slame. koristi se kao mineralno đubrivo za rast biljaka.

Koraci u proizvodnji peleta od slame Wood Pellet Indonesia

- Odvajanje slame od drugih objekata.

- Dozing slama. Prije nego što se slama pošalje u hranilicu, mora se smanjiti na ujednačenu veličinu (15%, potrebna je upotreba sušara rotacionog bubnja.

- Sušenje slame. Uglavnom se slama suši na vazduhu sa sadržajem vode od 15%, tako da

sušenje sijena nije potrebno. Međutim, ako je sadržaj vode >15%, upotreba sušilice

rotirajući bubanj je potreban.

- Peletiranje u mašini za peletiranje. Nakon prolaska procesa celuloze i sušenja, slama se transportnom trakom (transporterom) transportuje do mašine za peletiranje slame. Uz pomoć pritiska između kalupa i mašine za performanse valjka, pelet slame se istiskuje i reže prema željenoj dužini (6 mm i 8 mm).

- Hlađenje peleta slame. Kako bi se održala kvaliteta peleta tokom skladištenja i rukovanja, izlaz peleta od slame na visokoj temperaturi treba ohladiti na zraku na sobnu temperaturu ili malo više korištenjem suprotnog smjera zraka za hlađenje motora.

Zemlje koje proizvode pirinač (10) koje potencijalno koriste mašinu za peletiranje slame za recikliranje energije iz slame su Kina, Indija, Indonezija, Bangladeš, Vijetnam, Tajland, Filipini, Mjanmar, Brazil i Japan.

Budućnost drvenih peleta Indonesai (spoj sa PLTPk)

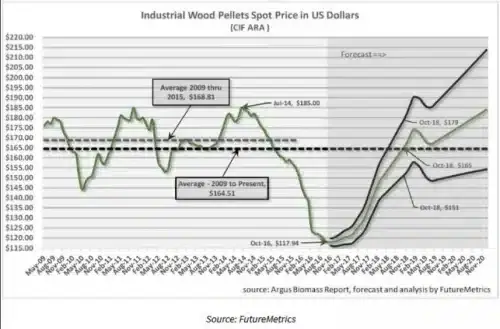

Drveni peleti (WP) počeli su se proizvoditi mnogo. Postoji velika vjerovatnoća da će doći do poplave ponude u DN i LN može se raščlaniti na cijenu. Pogledajte međunarodne cijene ovdje i sliku (sljedeća). Uvoznici LN koji počinju nositi koncepte smatraju da je WP najbolji, ali cijena je jeftina. Stoga je vrijeme da WP biznismeni opremi svoje poslovanje:

- Snabdijevanje WP-a termoelektrani na ugalj radi djelimične/potpune zamjene uglja (potpisan MoU sa elektranom na ugalj).

- GRAĐEVINARSTVO POSTROJENJA drvni peleti (PLTPk; PLTBm = biomasa; primjer u Japanu) u DN / lokalno oko tvorničke WP.

- Sadnja stabla brze žetve, može se uzgajati i kvalitet je dobar na kritičnom zemljištu / rudarstvu (kositar, ugalj, zlato, cirkon, bakar, nikal, itd.) do kvalitetnog WP materijala, kao što je crvena kaliandra (peć za vatru blizu plave).

- Promovirajte socijalizaciju korištenja WP & štednjaka (ratne/ratne) u zajednici (kao zamjenu za 3 kg LPG BBG-a koji je trenutno teško pronaći). Zajednica oko Factory WP je preferirala kupovinu WP-a po tvorničkoj cijeni.

Trebalo je stabilizirati cijenu WP-a odjednom nacionalnu snagu i otvoriti nova radna mjesta koja se traže od ljudi oko fabrike WP, na primjer:

- PT Austral Byna gradi PLTPk 100MW (svakih 10MW košta 150 miliona Rp) u Mantuil Banjarmasin, Muara Teweh (Kab. Barito Utara) u centralnom Kalimantanu i istočnom Kalimantanu.

- PT PLNE (Prima National Engineering Service) aboutandatangani kerma (MoR) sa Distriktom, Morowali, centralni Sulawesi, izgraditi PLTBm 10MW (cijena 30 mil. Rp. za 2 godine, FS 6 mjeseci) sa sirovim materijalom calliandra calothyrsus rasprostranjenog u Morowaali (200. ).

- PT EMI (Energy Management Indonesia) gradi PLTPk oko 5-10MW (energetski WP KM: 4.800 kKal, biougljevlje ~7.500 kcal) u Purworeju, Centralna Java (sa tvornicom luas 10 Ha) koristeći WP od KM sa kapacitetom od 36.000 tona/ godine. Otpad/pepeo WP još uvijek može biti đubrivo za obnovu tresetnog zemljišta koje je veoma rasprostranjeno u Indoneziji (4. svijet). PLTPk je razvijen na nekoliko lokacija u Indoneziji. Sirovina (KM) dobijena od društva Wonosobo, Magelang, Kebumen, Banyumas.

- Korindo grupa planira da izgradi PLTBm (drveni peleti) 10MW u Jayapuri, Papua. Podružnica Korindoa, PT Tunas Sawaerma, u suradnji s vladom provincije Papua i Regency of Jayapura, traži koncesije na zemljište od 12.000 ha od čega približno 7,200 ha za zemljište HTI (Industrijske plantažne šume, u obliku stablo Eucalyptus Pellita i Red Jabon kojim rukuje PT Biomass Papua Lestari) i PLTBm (od PT Bio Green Jayapura). Međutim, naletjeli su na uobičajeno zemljište, a još nisu postigli dogovor sa lokalnom zajednicom.

Cijena drvenih peleta Indonezija (promjena prema ponudi i potražnji):

Domaće (fabrička cijena, ex-Works) (115-125 USD)

- Jakarta Rp.1700/kg,

- Banten Rp.1600/kg

- Zapadna Java Rp.1600/kg,

- Centralna Java Rp.1600/kg

- Istočna Java Rp.1550/kg.

- U inostranstvu: FOB $140/tona; CIF $ 160/tona

Provjerite gdje ima zaliha WP-a u Indoneziji? kontaktirajte kontakt osobu ovog [email zaštićen]

Opasnost od prerade drvenih peleta

Kada proizvodite WP, uzmite u obzir i stvari vezane za zdravlje i sigurnost radnika:

- Opasnosti od prašine drvenih peleta na lokaciji fabrike,

- Trovanje Bd produktima – gas CO u skladištu WP (silos, rezervoar, otvoreni prostor); i

- Bd proizvodi kebakaran u fabrici WP, elektrane itd.

Iskoristite prednosti otpadne biomase u WP oko vas

- Iskoristite sve ostale poljoprivredne proizvode bez vrijednosti, na primjer stabljike klipa i kukuruza, stabljike manioke, bagasa (4476 kcal/kg), bambusa (4105 kcal/kg), pirinčane ljuske i pirinčane slame, prazne grozdove voća palmino ulje, grančice, stelja, piljevina, ljuske mljevenog oraha (4644 kcal/kg), smeđa kosa, sengon buto (3948 kCal/kg, sadržaj vlage 14.21%, sadržaj pepela 1.08 posto) itd. u WP

Ako želite da otvorite zemljište, broj otpadnog drva na raspolaganju se zatim utiskuje u WP, kao dodatni prihod (kao energent PLTBm / domaća elektrana na ugalj, izvozi u LN, gorivo za peći, kućne aparate, restorane, kulinariku centar, itd.); ne spaljivanjem šume, što će značiti pušenje u čitavim krajevima svijeta.

Primjeri proizvođača mašina za peletiranje drveta

u državi (DN)

- PT Toba Green Synergy, Medan, sjeverna Sumatra

- IN (Dahlan Iskan) (preko PT SDI, Sociopreneur za dobro Indonezije) poziva studente SMK mašine za izradu WP (1 tona/h) kako bi iskoristili sadnju drva KM u 30 provincija (istočni Kalimantan, NTB, Riau, Lampung, Bengkulu, itd.). PT SDI građevinska mašina WP i PLTBm, te će otkupljivati KM od stanovništva. Njen moto je da zajednica dobije poslove i prihode (od pripreme WP, goveda i koza, goveda i pčele) kao i da dobije moć.

Mašina Kraljevina (UKM), proizvodne mašine WP za kapacitet od 400-600kg/h i 800-1000kg/h; Malang, istočna Java.

u inostranstvu (LN)

Proizvođač Kina

Informacije o proizvođaču mašina koje se odnose na drveni pelet, bilo individualne opreme ili integrisane sa različitim proizvodnim kapacitetom WP od 1.5 tona/sat do 12 tona/sat se često traže od čitaoca. Informacije o proizvodu TCPEL u nastavku se mogu koristiti kao referenca za početnu pretragu ovih mašina. Ako ste zainteresovani, kontaktirajte [email zaštićen]

- Vertikalna mašina za pelet pored ovih veštačkih Tcpel-a nalazi se u Shandongu u Kini. Kapacitet od 0.8-1 t/h treba da napaja 55kW, dok kapacitet od 3-4 tone/sat treba da napaja 220kW.

Prednosti proizvoda od Tcpel u odnosu na proizvod WP drugi je:

- Kompaktnost je značajno poboljšana dizajnom mašine. Koristi modularni dizajn za povećanje operativne pouzdanosti za 4-6 puta.

- Koristi odličan uređaj za labirintsko brtvljenje bez kontakta i visoke otpornosti na habanje.

- Povećajte površinu reduktora, usvajajući prisilno hlađenje zraka i novi tip deflektorskog štita koji ima dobre performanse odvođenja topline.

- Podmazivanje cijele mašine je projektovano na osnovu niže maksimalno dozvoljene temperature ulja, što poboljšava pouzdanost rada. U međuvremenu, troškovi održavanja su smanjeni zbog produženja ciklusa zamjene ulja.

- Prekinite situaciju kada je mašina za pelete posudila tradicionalni industrijski reduktor. Koristimo specijalni reduktor za mašinu za pelet.

Jedinica kola kao što je prikazano u nastavku:

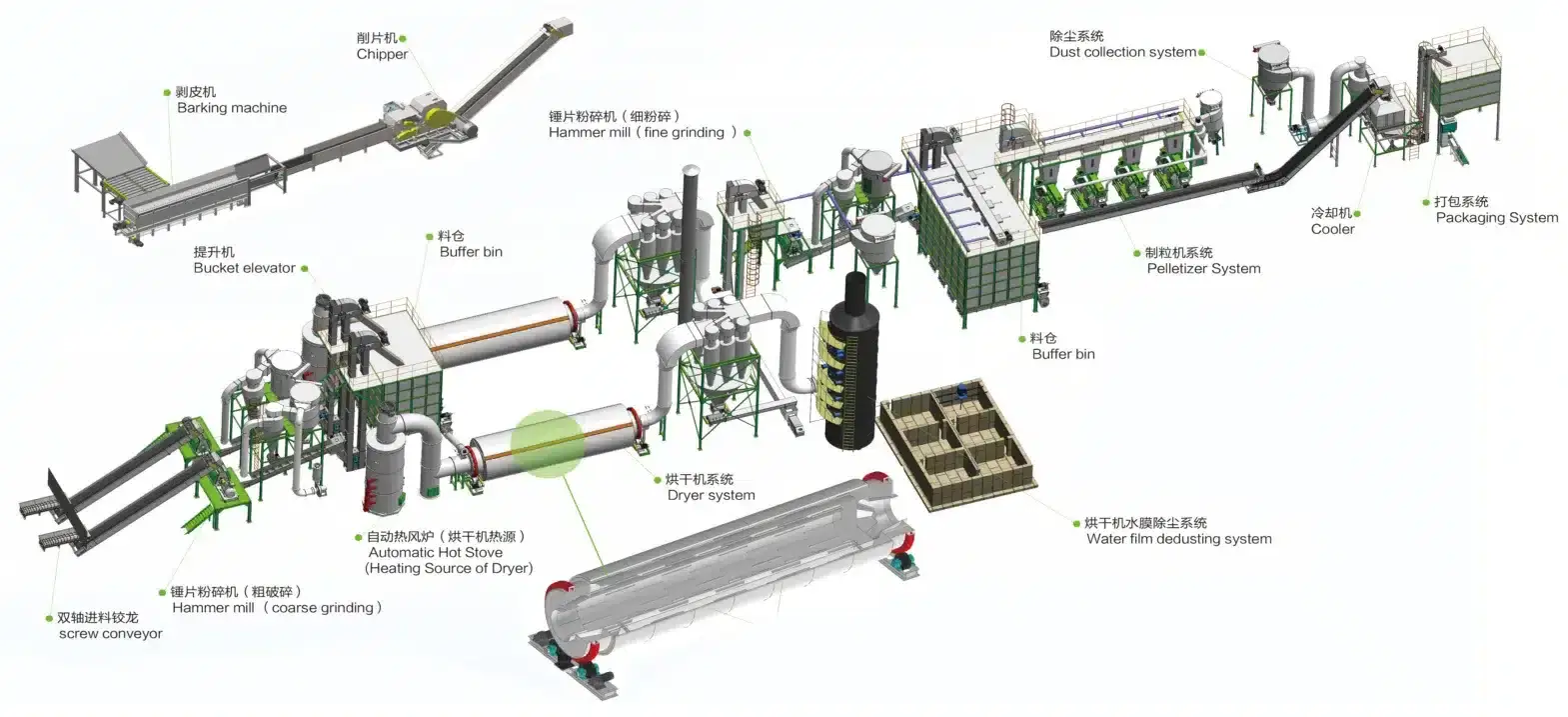

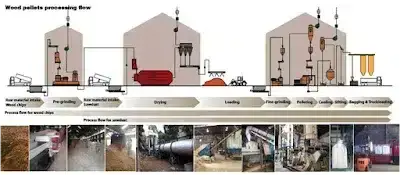

IZGLED PROIZVODNJE PELETA SLAME

LINIJA ZA PROIZVODNJU DRVENIH PELETA RAZLIČITIH PREDMETA

Cijenu mašine za pelet i uređaja drugih proizvođača možete pogledati ovdje.

- Proizvođač evropskog primjera:

Proizvodi WP motora Njemačka (neki proizvodi su korišteni u fabrici drvenih peleta u Surabaji).

Primjer WP proizvođača/tvornice u Indoneziji

Carousel radi na projektima u istočnoj Javi, centralnoj Javi, Sumateri, Kalimantanu i Papui. Indonezija će biti cilj Carousel koji će u budućnosti biti dobavljač WP-a u Aziji, a posebno za biopelet dobijen od otpadnog namještaja, palme uljarica, EFB-a, bagasa od trske, slame, calliandra calothyrsusa, piljevine itd.

- Sjeverna sumatra (Medan) PT Toba Green Synergy posluje krajem 2016. koristeći palmu EFB (EFB, tankos palm) u pelet tankos ulje koje se koristi kao BB alternativa za poštovanje ZAKONA br. 32 godine 2009. Prednosti palme tankos palme je vlažnost niska, energetska efikasnost visoka toplota, lako rukovanje i skladištenje, pogodan za kotlovski sistem na rešetki i proizvodi malo dima. Med, sadržaj pepela >3%. Preradom 1 tone FFB-a (Fresh Fruit Bunches) proizveo je otpad od 0.23 tone EFB; 0,13 tona mezokarpnih vlakana (vlakna); 0,06 tona školjki (palmina školjka), i 0.65 tona LCPKS (Efluent palminog ulja). EFB se za to vrijeme koristi samo kao kompost (malč). Proces koji se koristi uključuje: drobilicu za prazne snopove, hidraulički sistem, presu za praznu grudu, isjeckanu praznu drobilicu, rezač, sušač, mašinu za briket i bunker za briket. Pretpostavke: EFB (u TBS) od 23%, kapacitet ako VFD 30ton/j, EFB proizvodi ~6.9 tona/j. Potrebna je jedna jedinica za usitnjavanje kapaciteta 7 tona/h. Ukratko proces izrade drvenih peleta: EFB usitnjeni (drobljenje), usitnjeni (usitnjeni), slam (tresanje), prešani (prešani) kako bi se smanjio sadržaj vode, te sakupljanje ostatka ulja; zatim se preko transportera šalje u jedinicu za sušenje (sušenje), sečenje (sečenje, max 2 inča) i tako dalje u tankos mašine za pelet. Kapacitet VFD-a 30 kg/h ili 600 kg/dan, EFB 138ribu kg/dan, Pelet EFB (40% EFB) 55.200 kg/dan, Tilapia grijač pelet tankos 17.660 kJ/kg (4.640 kCal/kg), potencijalna toplota peleta 974.832.000 kJ/dan. Tankos od pet kg peleta je ekvivalent 12 kg plinske boce za TNG. Cijena mašina za pelet tankos tečaj proizvedena u Kini ~33.000 USD.

- Kep Riau: IDEAS u saradnji sa PT APP (Achmadi Pasca Perintis) sproveo je istraživanje za uspostavljanje šumskih energetskih usjeva i biljaka WP u Falusu (bilo je oko 604 ostrva velikih i malih).

- Zapadna java: Tvornica WP u Ciamisu, kapacitet 2,500 tona/mjesečno (60% za DN, 40% za LN) IN (Dahlan Iskan) je bio u fabrici WP (2x350kg/j, bahan sirovo KM) Ds Močvara, Kec. Cingambul, Kab. Majalengka; do tempe u Dukuh Semar, Cirebon, koji pokušava WP Anymore.

- IDEAS i PT MBT (Independent Three-Star) u saradnji razvijaju energetsku kaliandru i fabriku WP u Sumedangu, Kuninganu i Bandungu.

- Jawa Tengah: papart drveni peleti najveći PT južnopacifički proizvođači namještaja u Jepari, Centralna java, proizvode WP nego otpad ostatak proizvodnje namještaja proizvodnja WP-a je popularna u Južnoj Koreji (70,000 tona/godišnje), zbog kvaliteta je dobar (visoka kalorija, hemijski sastojci i prilično malo pepela). Planirano je da se u centru vrtne biomase grade četiri postrojenja WP na različitim lokacijama (Max. oko 4 sata od međunarodnog aerodroma).

- U vlasništvu je PT SPI (Solar park Indonesia, u Kalikajaru, Wonosobo, centralna Java) koji je kao pilot projekat prvi predvidio mogućnosti ulaganja drvne baze od biomase (kao i fabrike WP) između Indonezije i Republike Koreje (200,000 ha). lokalno. Sada se prodaje (19,5 milijardi Rp.) drugim stranama (čak je i dio motora već skinut i prodat po komadu).

- Semarang: PT Mahya Bioenergy, kapacitet 2,000 tona/mesečno (max 10,000 tona/mesečno), drvo albazije, 4200-4600 kcal/kg, prečnik 8mm, sadržaj vlage 7-9%.

- Purworejo: PT EMI (Energy Management Indonesia) (u državnom vlasništvu preko svoje podružnice PT EBI) radi kerma sa vladom Purworejoa da izgradi novu fabriku WP izvedenu od drveta calliandra calothyrsus sa kapacitetom od 36.000 tona/godišnje. Njegova proizvodnja kako bi se zadovoljila potražnja WP DN (250 tona/dan) i LN Japan i Južna Koreja koja se povećava svakih 250 tona/dan (10,000 tona/mjesečno) preko LOI. Fabrika površine 10 ha.

- U Yogyakarti: jedan od dobavljača WP (50 tona/mjesečno) za Republiku Koreju (i Japan) je PT Greeno Energy Innovation od Ds. Među, Bangunjiwo, Helpl, DIY. Glavna sirovina je piljevina, koja se dobiva od Jateng & DIY, koja miješa otpadnu drugu biomasu poput ljuske pirinča, pulpe šećerne trske (bagasa), prašine od duhana i starog papirnog novca. Brašno od tapioke dodato mu je kao ljepilo.

- Istočna java (Paiton, Probolinggo): PT Pellet Biomass Indonesia, proizvođač premium WP (kalorije 4600kcal/kg; vlažnost 8%; sadržaj pepela 1.2%; minimalna poruka: 16 tona; luka Surabaya; rok isporuke 1 mjesec L/C, T/T; sposoban za isporuku: 2000 tona/mjesečno).

- Madura: April 2015, CV Gate Lestari je osnovao fabriku WP kojom upravlja Ponpes Darul Ittihad u Ds. Kombangan, Kec. Geger Kab. Bangkalan, Madura sa kapacitetom od 1 tona/h, sa drvnom sirovinom calliandra calothyrsus oko 12 tona/dan (1 dan = 8 sati, vlažna sirovina sadrži oko 40%) vode. Ako je godina = 310 dana, tada se uzima sirovina 12 tona x 310 = 3720 tona/godina, ili treba da se zemljište 3720/20 = 186 ha. Dakle, bašta požnjevena na dan, samo 186 Ha/310 = 0.6 Ha. Prodajna cijena drvenih peleta je 1.6-2.5 miliona KM po toni. Dok je prodajna cijena drveta samo 367.000 Rp/tona. Nakon što proizvodnjom upravlja ISE (IDEAS of the Universe Energy, mašine podmlađene od strane CV SBE, Suryabaja Engineering), WP 2 tona/sat ili 25 tona/dan (u obliku mješavine KM i Kemlandingan) poslat je u Gresik , i PTPN 8 u Pangalenganu, Bandung (za BB sušenje listova čaja). Lokalni korisnici počeli su koristiti WP kao zamjenu za LPG što može uštedjeti trošak od 47% koji dolazi uz korištenje peći WP u jednu paket sa WP. Ta ideja će se razvijati u Mamuju (zapadni Sulawesi) i Sjevernom Lomboku (NTB). Drvo Kaliandra crvena ubrano nakon 14 mjeseci od strane CV Gate Lestari. Optimum proizvodnje od 20 tona/Ha/th. Lokalno stanovništvo koristi projekat bašte Energy kaliandra u šumskom selu površine 214 ha i fabriku WP 200 m2 (pomoć ICCTF, Indonesia Climate Change Trust Fund). Dok se proizvod WP koristi kao BB PLTBm 197kW. ISE dizajn fabrika WP 1.5 tona/h u Bangkalan Maduri, Mamuju (zapadni sulavesi) 2 tone/h, Karangantu, Banten i PLTBm u Ds. Selengen & Salute u Lombok Utara, NTB. Aktuelna mlin za pelet Madura je torpor, nedostatak rezervnih delova-mašina za pelet koja je pokvarena.

- Južni Kalimantan: PT Jhonlin Agro Mandiri (PT JA) gradi fabriku WP na površini od 2 ha kapaciteta 4 tone/sat sa potpuno automatskom mašinom. Sirovina dolazi od drveta Jabon, Gmelina, Sengon i Bagrem zasađeno na zemljištu od 15.000 ha. Cilj: izvoz WP-a u Carousel i Evropu.

- PT Inhutani III snabdeva sirovinom eukaliptusa, sengona i gamala koji su zasađeni na zemljištu od oko 5,000 ha, Pelaihari, Kalsel, fabrici WP koju gradi PT SL Agro Industries (podružnica Carousel, Depian) sa kapaciteta oko 100,000 tona (2015). Nadalje, PT SLAI isporučuje WP iz fabrike južnokorejskim kompanijama Western Power Co. Ltd. Kerma Inhutani III sa Kinom je takođe potpisan, a Inhutani III priprema zemljište od 5,000 ha. PLTBm 2x10MW sa sirovinom drvne sječke (140.000 tona) je također izgrađen za podršku elektrani, dok je ostatak električne energije prodat u PLN.

- Zapadni Sulavesi (Mamuju): fabriku WP će izgraditi MCA-I (Milenijumski izazovni račun-Indonezija) sa kapacitetom od 600 tona/mesečno, a energija bašte dolazi iz HTR (zajednička plantaža šuma) i HR (People's Forest) ) kaliandra crvena pripremljena 748Ha. S druge strane, strani investitori iz Carousel PT Bara Indoco (maj 2018.) ulažu sredstva preko IUPHHK-a (Poslovna licenca za korištenje šumskog proizvoda) (sengon & Calliandra) HTI 27.300 ha (oko 700 m3 drva, WP 200,000 tona/god.) 3 okruga (tapalang potokrug 14.865 Ha, Tommo, Kalumpang) u Mamuju (zapadni sulavesi). Fabrika od 80,000 tona godišnje biće izgrađena u okrugu Dappled. Kalukku.

- Papua: (Merauke) IDEAS u saradnji sa PT SIS (Selaras Inti Semesta, MEDCO Grupa) sproveo je FS (Studiju izvodljivosti) integraciju šumskih energetskih kultura i izgradnju postrojenja WP.

Problem koji se često javlja u Indoneziji od drvenih peleta

Šta treba da uradite ako se pokazalo da proizvod vašeg WP ima sadržaj pepela i nivoe hlora (jon hlorida) iznad specifikacija koje je kupac tražio?

Uraditi proces Torrefakcija (Pečenje vodenom parom), u reaktorskoj šarži na temperaturi od 250-300 oC, pritisak blizu atmosferskog, bez kiseonika/vode, brzina zagrevanja je mala (vreme zadržavanja 30-120 minuta). Nivo hlora se prepolovi čak i do 90%.

Drugi način: drveni prah uglavnom sadrži visoku vodu u prvoj mokroj (Tor pranje, Hidrotermalna karbonizacija) frakciji (hidrotermalni medij, topla voda pod pritiskom 20 bara, s ciljem da se voda održava u obliku tečnosti na temperaturi od 180- 260°c, vreme zadržavanja 5-10 minuta), novo napunjen mlin za pelete, ohladi, a zatim šalje kupcu. Voda koja prodire između čestica biomase će rastvoriti hlorid soli i alkalije. Kao rezultat toga, vrijednost vrućeg WP-a raste, nivoi klora, vode i sadržaja pepela su smanjeni, a priroda WP-a je tvrda. Proizvod je mirisao na drveni ugalj

Svaki Indonežanin zna da zemlja ima dosta drva za gorivo. Stoga Indonezija može biti jedna od zemalja s najvećom industrijom drvenih peleta na svijetu. Ovo je prilika za Indonežane da zarade novac i brzo se obogate osnivanjem fabrike drvenih peleta.

Drveni pelet Indonezija je potreban za smanjenje emisije stakleničkih plinova u očuvanju okoliša. To je način uzgoja drvene palete kao glavne sirovine koja osigurava ekološki prihvatljivu i obnovljivu energiju. Dobra stvar je što je vlada shvatila o ovom pitanju i podržala plantaže poput drvenih peleta Indonezije s više sredstava. Postao je dobar biznis plan potencijalnim privatnim investitorima koji imaju problem da se suoče sa ovim poslom. U svakom slučaju, sretno u odabiru najbolje kompanije za proizvodnju drvenih peleta iz Indonezije.

Takođe pročitajte:

Analiza profita proizvodnje peleta

Razgovarajte sa stručnjakom

PODIJELI OVU OBJAVU

Razgovarajte sa stručnjakom