What is a chicken feed pellet machine?

A chicken feed pellet machine is the equipment used to manufacture chicken feeds in exact nutritional proportion to ensure they meet market demands.

What is the chicken feed pellet machine used for?

After 5–6 weeks, it is expected that the chicken broilers/layers are matured enough for sale. That entails consistent feeding with the correct chicken diet. However, these standard feeds can be sometimes expensive. That’s where a chicken pellet machine becomes useful.

It’s a more economical feed production method without compromising the standard. There are different chicken feed pellet machine manufacturers. We also have different chicken pellet machines. Therefore, you must know how they work to determine the best for your farm business.

How does a chicken feed pellet machine work?

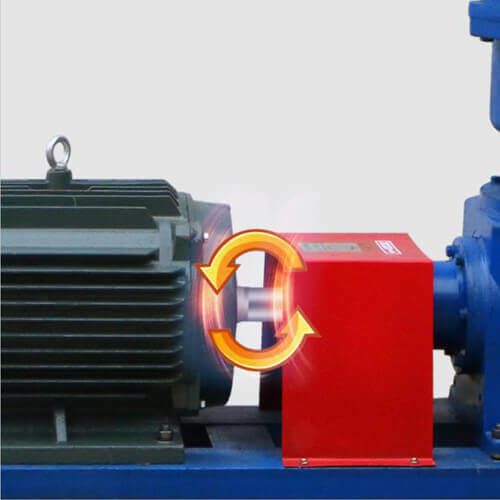

Firstly, understand that we have two basic types of chicken pellet machines. The flat die ones and the ring die pellet machine. The difference lies in how their mechanical parts are arranged. However, they operate in similar ways.

Generally, the operating principle of the machine to make chicken feed is divided into drobljenje, miješanje, I sušenje.

Drobljenje: the pellet machine for chicken feed can only mix powdered-like materials. Therefore, the raw materials like your soybean meal, sorghum, corn, bone meal, and fish meal must be crushed into powder before their introduction to the chicken feed pellet machine.

Miješanje: the feed mill stirs the introduced powdered material and compresses it to form mashes. The added proportions should correlate with the diet you aim to achieve.

Sušenje: although the feed mash is good enough to feed your chickens, especially the baby chicks, it’s possible to continue. Further processing actions will involve drying them for proper storage and sale. Dried pellets should be cut into specific sizes, depending on market demands.

How much does a chicken feed pellet machine cost?

While there is no general price of chicken feed pellet machine for sale, knowing the price range gives an estimate of what your budget should be. For a small chicken feed pellet machine, the average cost can be as low as $300-$400. But such a feed mill would obviously be small with a low output.

Therefore, standard pellet machines for chicken feed production are more expensive. You can prepare a budget of $2000 – $7000. That should serve your basic production needs, except you want to venture into full large-scale chicken feed sales. The machinery for that could be as costly as several thousand dollars. But of course, they provide more value and production capacity.

How to choose the best chicken feed pellet machine for pellet production?

Although you can choose any type of pellet machine for chicken feed, the following are essential consideration factors. They help you make the right decision on the chicken feed machine to buy.

Sirovine

Effective production requires that you use a pellet machine that can manage the type of raw materials that are common in your feed formulations. For example, grass raw materials are more suitable with the ring die machine. It meets basic compression requirements.

Amount of powder in feed

While the ring die pellet machine for chicken feed is suggested for the grass-like feed materials, we can also use the flat die machine. It’s great for those raw materials with much-powdered concentration. However, the flat die is not suitable for large-scale production because of the tendency of the powder to block the flow channel. Instead, we use the ring die when processing a large number of chicken pellets.

Scale of production

One of the important things to decide before buying a chicken feed pellet machine for sale is your proposed production capacity. Are you producing for your chickens alone? Or are you aiming at meeting market demand levels? Some chicken feed pellet manufacturer understands this factor. That’s why there is a production capacity value stated somewhere in the manual. However, the ring die chicken pellet machine is the recommended one for large-scale manufacturing.

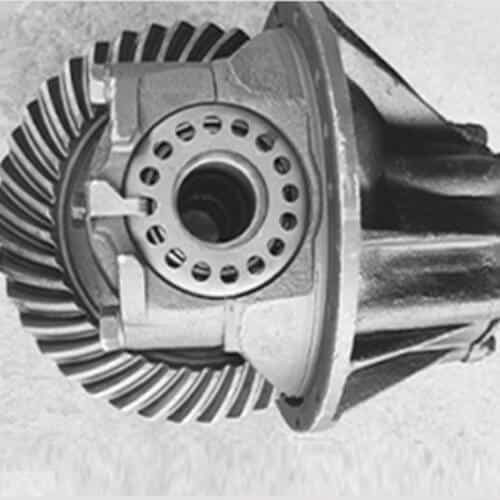

Životinjski tip

The type of livestock farming you practice will determine the type of chicken feed pellet machine you need. For example, a thinner die is suitable for producing feeds for cattle and sheep. That’s not the case for chicken feed. The ring/flat die chicken pellet machine must have a thicker die because of the nature of the chicken diet. It should be one that perfectly mashes it into what the chickens can consume.

moć

Every chicken feed pellet machine for sale has a power rating indicated on the nameplate or manual. It serves as a measure of the production capacity and tells the suitability for large-scale or small-scale production. Whether you need a small chicken feed pellet machine or one that can function throughout the day, always remember to verify the power ratings before purchase.

How to buy an affordable chicken feed pellet machine?

Besides the buying considerations we just evaluated, you will agree that the cost of the chicken pellet machine is also essential. That does not mean you should compromise quality for the purchasing cost. Rather, search for a chicken feed pellet machine for sale that offers the best functions at a reasonable price.

The first thing we recommend you consider is the troškovi održavanja. The cost of the pellet machine for chicken feed must also cover the long-run cost of having to service and repair. Hence, an affordable chicken feed pellet machine is not only budget-friendly but also offers an estimated low maintenance cost.

Drugi važan faktor je proposed production scale. Yes, we already mentioned it before, but getting a big pellet machine for personal feed production might be an economically poor decision in the long run. You can always check the TCPEL page for cost quotations, depending on your specific chicken farm needs.

How to use a chicken feed pellet machine for beginners?

The first step is to go through the chicken feed pellet machine manufacturer guide for basic safety tips. Have you done that? Check out our step-by-step procedures to start making your chicken feed.

1. Collect and sort the raw materials

The raw materials for producing chicken feed pellets include corn, bone meal, fish meal, sorghum, etc. Gather them depending on the specific diet you aim to achieve. Also, remember to sort out unwanted items like metals or plastics.

2. Prepare the premix

The premix is the mixture of all raw feed materials for chicken pellet production. They must be in exact proportions according to the recommended diet plan.

For instance, chicks below 8 weeks require a starter feed with much protein and very low calcium. High calcium is unhealthy for such baby chicks until they are mature enough to lay eggs.

Bilješka: the premixed materials can be prepared and stored ahead of the production day.

3. Crush the raw grains

The cattle feed pellet machine is designed to accept only powdered materials. Use a feed grinder for crushing large quantities of grains. Also, get rid of excess moisture in the crushed feed.

4. Pour the powdered materials into the chicken pellet machine

Before introducing the mixed materials into the machine, understand that some materials like rice husk do not properly compress when added alone. Secondary binders like sawdust are added to increase their adhesive properties for better pellets formation.

5. Cut pellets uniformly

Cutting the produced pellets to uniform sizes is particularly useful if you plan to sell them. The cutting is done through the machine’s slicer/cutter.

6. Čuvati na hladnom i suvom mestu

The produced chicken pellets can be very hot immediately after they are formed. So, allow them to cool and lose excess moisture before packaging it for storage or later sales.

7. Clean up the machine after every use

It is wrong to abandon the machine and turn it off till the next production line. The correct procedure is wiping/blowing off accumulated particles in the machine, and properly lubricating them ahead of the next use.

How to maintain a chicken feed pellet machine?

No matter how rugged a chicken feed pellet machine might be, poor maintenance practices will see it lose its functionality quickly. That’s why we outlined the following maintenance tips to keep your chicken pellet machine always in top working condition.

Don’t abandon, clean after use

Like the saying, “as you lay your bed, so you lie on it”. Leaving residual materials in the pellet die until the next production line means they remain there and probably cause rusting of machine parts later. Rather, the machine to make chicken feed should be wiped regularly nakon svake upotrebe.

Use expected power ratings

There is a specified power rating in the manual by every chicken feed pellet machine manufacturer. Connecting to lower power sources affects the output and machine’s performance. Also, excess power will cause energy waste and is dangerous to the useful life of the pellet mill.

Lubricate after extensive use

Heat-resistant lubricants are the recommended type for oiling the moving parts of the pellet machine for chicken feed. Check the pellet machine manufacturer’s manual for instructions on lubrication. However, we suggest oiling the machine after 6-7 hours of prolonged use. Regular checks for oil leakages should be done too.

Check for worn-out parts

The cutter, press roller, mixing blade, and die are some of the chicken feed pellet machine parts that can wear out. The bolts and screws can also get loose and might lead to factory accidents or damage to machine parts. Therefore, strict periodic maintenance and routine checks should be observed.

Fill the gear oil

Always ensure the GL-5 is filled with sufficient heavy-duty oil before every use.