How to Make Quality Pellets with a Pellet Machine?

Whether you want to make pellets for personal use or commercial purposes, they should be high quality. They must have the appropriate size, ash content, and moisture size. When you make quality pellets, you get tons of benefits. You reduce waste, safeguard the environment, and improve profits simultaneously. This post will guide you to make good-quality wood pellets using a professional pellet machine.

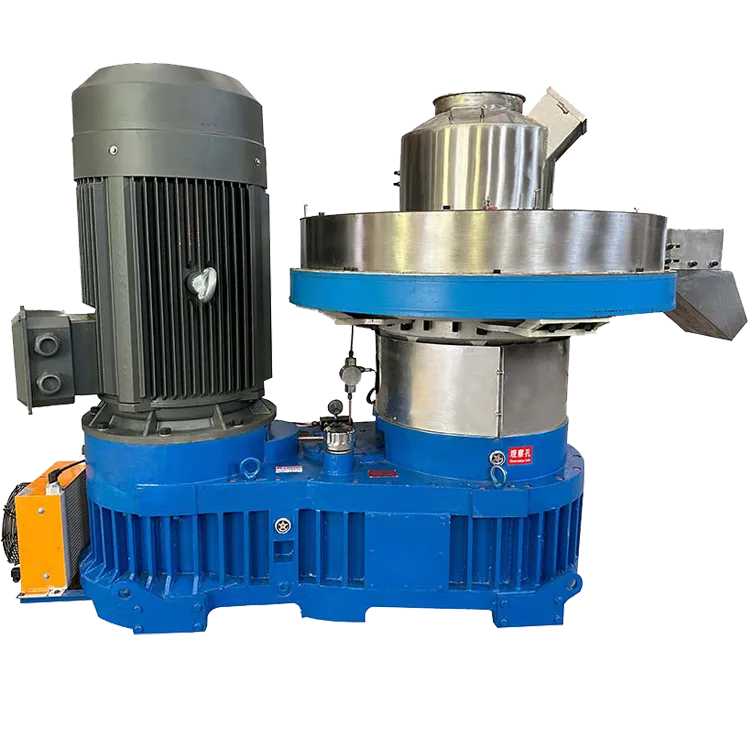

Choose a High-Quality Pellet Machine

You cannot expect to get high-grade pellets until you have a professional and premium quality pellet machine. The quality of pellets depends on the mill and raw material you use to a large extent. Choose a pellet machine that meets international quality standards.

Buy a pellet mill having a top-quality die and roller. The holes of the die should be symmetrical and uniform. Also, make sure the machine you choose has a branded electric motor. Do not forget to check the overall artistry of the machine.

If you want an international-standard, professional machine at a low price, consider the Tcpel pellet mill. Features like alloy steel die, built-in lubrication, and double-layered roller makes it the best option.

Choose the Right Raw Material

To get quality wood pellets, you must choose the raw material carefully. You can use sawdust, the forest remains, wood chips, etc. Be sure the raw material you select is consistent in size. You can crush them to 5mm. Nevertheless, the crushing of raw material depends on the hole diameter of the die mold. Do not crush material too fine or thick as it will affect the quantity and quality of the output.

Drying

Once you have ground all the raw material, you need to dry it. The process plays a crucial role in determining the quality of pellets. If you want your wood pellets to burn perfectly and emit less smoke, they must have low moisture content. The moisture content should be around 10 to 15%.

Dry your raw material until it has a suitable moisture level. If you are making pellets for commercial purposes in large quantities, you can use a professional rotary dryer.

Your pellet machine will not be able to pelletize raw material into pellets if the moisture content is too low. The raw material will block the die if the moisture content is too high. So make sure the raw material is appropriate.

Eliminate Unwanted Objects from Raw Material

Before you pelletize source material, it must be free of plastic, metal, stone, and other hard materials. These hard objects can break your pellet machine. You can remove metals with a magnet.

Hammering

You won’t be able to get smooth, shiny, and crack-free pellets until your raw material has the appropriate size. Hammering is the process of making the base material even. It would remove dead knots and wood lumps so that raw material can smoothly pass through the die hole.

Pelletizing

After you have dried raw material, it is time to make pellets. As soon as material falls into the pelletizing chamber, the mill applies pressure to the raw material to help it pass through the die holes and take on a consistent shape.

First, produce pellets in small quantities, then test the quality of your pellets according to the following factors.

Appearance

If you want to produce pellets for commercial purposes, you cannot neglect the appearance of your pellets. After all, in the business world, the first impression is everything. The uniform shape and size of pellets ensure that the performance of a pellet machine is consistent and stable. The ideal size for wood pellets is 6-12mm.

If you notice that your machine produces pellets of different sizes, there could be a problem with its cutting knife. Do not forget people like to buy pellets of similar lengths.

Smooth Texture

Good quality pellets have smooth surfaces. If you find some cracks over them, chances are the raw material is not properly conditioned. Maybe it has less water.

Smell

Besides the feel, the aroma of pellets helps you determine if your pellet machine is producing quality pellets or not. Make sure you can smell the fresh wood flavor. There should be no adhesive in the raw material to make it stickier. If you have not prepared it yourself, pay particular attention to it.

Sinking of Pellets

Fill a cup with water and add some pellets. If they sink, it suggests they have a higher density than water. They will float if they do not have the good quality raw material. Wood pellets of high grade must dissolve quickly in water.

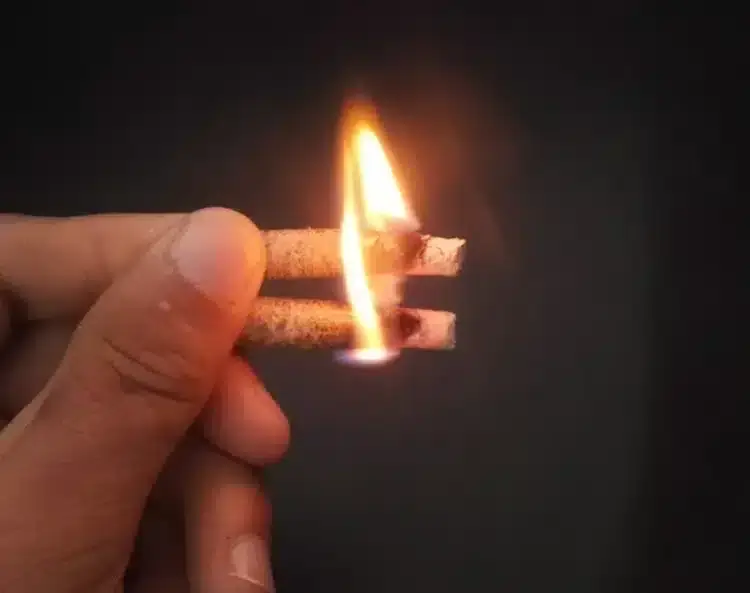

Try Burning Your Pellets

A good quality pellet must burn quickly. The color of the flame should be either yellow or brown. If the quality of raw material is not okay, you will notice dark flame.

Check the Ash

Last but not least, examine the remaining ash. Good quality pellets often have less ash comparatively. Notice these small things to find out if your pellet machine is making quality pellets or not. If everything is okay with pellets, you can start pelletizing further.

Cooling

As soon as pellets are released from the pellet mill, they are hot. Let them cool so that they do not lose their shape and size. Keep them in the open air for some time until they are cool.

Packaging

Pack your pellets properly. Packaging also plays a crucial role in deciding how your pellets will look when they reach your customers’ place. Depending on your requirements, you can use bags and plastic wraps for the packaging. If you are shipping pellets to a remote area, you should use a plastic wrapper to avoid moisture. On the other hand, bags are suitable for local deliveries.

Storage

Keep all your pellets in storage facilities where there is no moisture. It should be water-tight.

So these are steps to make quality pellets out of a pellet machine. We hope the guide helps you take your pellet-making business to the next level.

Talk to An Expert

SHARE THIS POST

Talk to An Expert