un granulu ražošanas risinājumu nodrošinātājs

Profesionāls granulu mašīnu ražotājs un piegādātājs Ķīnā

TCPEL ir profesionāls uzņēmums, kas nodarbojas ar granulu ražošanu un izpēti mašīnas.

- Reģistrācijas gads: 2004

- Reģistrētais kapitāls: 1.4 miljoni USD

- Rūpnīcas zemes platība: 40000 ㎡

- Darbinieki: 350

- Vecākie inženieri: 10

- Mehāniskie dizaineri: 16

- Tehniskais inženieris: 20

- Saņemts sertifikāts: CE, ISO9001-2000, SGS …

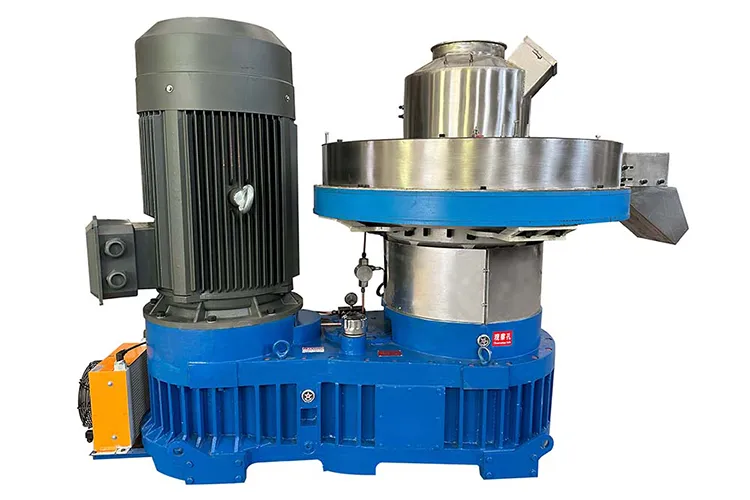

Prece

TCPEL specializējas granulu mašīnu ražošanā. Mēs nodrošinām inovāciju ieviešanu produktu izstrādē un kvalitatīvu granulu rūpnīcu ražošanā.

Kāpēc vairāk nekā 1000 klientu izvēlas mūs?

Mūsu inženieri

Mēs nodarbinām augsti kvalificētus, profesionālus inženierus, kas nodarbojas ar visu mūsu produktu izpēti un uzlabošanu. Mūsu pieredzējušie un prasmīgie pētniecības un attīstības inženieri var palīdzēt atrisināt jūsu granulu rūpnīcas problēmas un palīdzēt nodrošināt pēcpārdošanas pakalpojumus.

Stingra kvalitātes kontrole

Kvalitāte mums ir svarīga. Mums ir IS0 9001, CE un SGS sertifikāti. Visas mūsu granulu rūpnīcās izmantotās sastāvdaļas iziet mūsu stingro kvalitātes pārbaudi. Pirms nosūtīšanas mēs veicam katras mašīnas izmēģinājumu un nodiluma pārbaudi.

konkurētspējīgu cenu

Pārvaldiet savu budžetu gudri un samaziniet ražošanas izmaksas. Mēs piedāvājam konkurētspējīgas cenas visām mūsu granulu rūpnīcām. Sazinieties ar mūsu pārdošanas komandu, lai saņemtu atbalstu pielāgotiem risinājumiem.

Profesionāla pārdošanas komanda

Mums ir augsti kvalificēta starptautiskā pārdošanas komanda, kas 24 stundu laikā atbildēs uz visiem jautājumiem, kas jums varētu rasties pirms pārdošanas. Pēc pārdošanas mēs piedāvājam 24/7 e-pasta un tālruņa sakarus, kā arī varam nodrošināt atbalstu uz vietas.

Pilns tehniskais atbalsts

Pilns 24/7 atbalsts gan pirms, gan pēc pirkuma. Mēs piedāvājam bezmaksas testēšanu, lai attīstītu ražošanas procesu jūsu uzņēmumā, un esam veltīti, lai atrastu labāko risinājumu jūsu īpašajām vajadzībām. Ja vēlaties sadarboties ar mums, lai pārdotu mūsu mašīnas, mēs ar prieku konsultēsim ar jums.

Pasūtīšana un apmaksa

Pasūtīšana pie mums ir ātra un ērta. Mūsu profesionālā pārdošanas komanda ātri atbild uz jautājumiem un cenšas atrisināt jūsu problēmas gan pirmspārdošanas, gan pēcpārdošanas jomā. Mēs droši pieņemam visus maksājumu veidus, tostarp T/T pārskaitījumu, LC at sight, PayPal un Western Union.

Ko mēs varam jums piedāvāt

Vai meklējat uzticamu kokskaidu granulu mašīnu ražotāju?

TCPEL būs jūsu labākā izvēle.

GARANTĒTA KVALITĀTE GRULLU MAŠĪNA

Nodrošinām inovāciju ieviešanu produktu izstrādē un kvalitatīvu granulu mašīnu ražošanā.

PILNĪGS UZSTĀDĪŠANAS PAKALPOJUMS

Mēs piedāvājam pabeigtas uzstādīšanas, atkļūdošanas un ekspluatācijas apmācības pakalpojumus visā pasaulē

ĀTRA PĒCPĀRDOŠANAS APKALPOŠANA

24/7 e-pasts, saziņa pa tālruni vai pārbaude uz vietas, atrisiniet problēmas pēc iespējas ātrāk

Ko saka mūsu klienti

Super kvalitātes granulu mašīna, mums bija raiti diskusija par manu projektu, man ir saplākšņa rūpnīca Austrumjavā, katru dienu daudz atkritumu, to risinājums var lieliski atrisināt mūsu problēmu. Protams, es iepazīstināšu savus draugus.

Ariefs Kresna

Saplākšņa rūpnīca Austrumjavā

Man ir iespēja apmeklēt viņu rūpnīcu, un esmu pārsteigts par to izmēru un augsto kvalitātes kontroles standartu, pēc diviem darbības gadiem viss norit labi, izņemot dažas rezerves daļas, es kopā ar viņiem uzstādīšu jaunu granulu līniju.

Jaini Hoang

Mēbeļu uzņēmums Surabajā

Līdz šim projekts darbojās 3 mēnešus, vissvarīgākais ir pēcpārdošanas serviss, kas liek man neuztraukties turpināt

Quoc Thinh

Kokskaidu plātņu ražošanas rūpnīca Haoni

Sadarbojoties ar viņiem nav par ko uztraukties, viņi atrisinās visas granulu ražošanas problēmas!!!

Staņislavs

Koka paneļu ražošanas rūpnīca Maskavā

Piešķirts CE sertifikāts

Piešķirts ISO9001 sertifikāts

Ķīnas reputācijas sertifikāts

BLOGS | 6

Šī ir visaptveroša cilindru šķeldotāju pirkšanas rokasgrāmata. Šajā pirkšanas rokasgrāmatā jūs atradīsiet visu, kas jums jāzina par cilindru šķeldām.

BLOGS | 5

Šodien mēs jums parādīsim 10 galvenos iemeslus šīm problēmām biomasas granulu mašīnā, cerams, ka tas var jums palīdzēt.

BLOGS | 1

Šis ir pilns koksnes granulu pārskats par Indonēzijas tirgu 2021. gadā

Kā tiek izgatavotas koksnes granulas?

Koksnes granulas tiek izgatavotas no dažādiem koksnes atkritumiem, piemēram, baļķiem, koka zariem, zāģu skaidām, mēbeļu celmiem utt. Lai izgatavotu koksnes granulas, visi koksnes izstrādājumi vispirms ir jāpārstrādā zāģu skaidās ar drupinātāju un āmuru dzirnavām, ja jūsu zāģu skaidas ir slapjš (vairāk nekā 15% mitruma), jums ir nepieciešams žāvētājs, lai noņemtu mitrumu. Kad esat sagatavojis zāģu skaidas, jums ir nepieciešama granulu mašīna, lai zāģu skaidas apstrādātu koksnes granulās. Nav nepieciešams pievienot nekādu līmi vai saistvielu.

Koksnes granulas ir ilgtspējīgs, atjaunojams un pieejamu cietais kurināmais, kas izgatavots no zāģu skaidām, skaidām, koka skaidām un rūpnieciskajiem atkritumiem. Tāpēc koksnes granulas ir ļoti pieprasītas visā pasaulē. Ja vēlaties gūt labumu no šī pieprasījuma, varat ieguldīt granulu iekārtā un sākt granulu ražošanu.

Soli pa solim ceļvedis koka granulu izgatavošanai

Koksnes granulām ir vairāki pielietojumi, sākot no mājas apkures līdz krāsnīm un krāsnīm. Turklāt tiem ir arī dažādi rūpnieciski pielietojumi. Piemēram, uzņēmumi tos izmanto rūpnieciskajos katlos dabasgāzes vai ogļu vietā.

Tā kā koksnes granulām ir augsta siltumvērtība, uzņēmumi tās izmanto kā kurināmo gazifikācijas un siltumenerģijas ražošanai.

Apskatīsim, kā tiek izgatavotas kokskaidu granulas.

1. darbība: granulu mašīnas izvēle

Pirmkārt, jums ir jābūt augstas kvalitātes granulu mašīna.

Kad runa ir par granulu dzirnavu iegādi, ir divas iespējas: gredzenveida granulu mašīna un plakanās granulu dzirnavas.

Flat Die Granulu mašīna ir viegla, kompakta izmēra koksnes granulu ražošanas mašīna, ko izmanto lietošanai mājās. Izmantojot šo mašīnu, jūs varat izgatavot granulas nelielos daudzumos. Gluži pretēji, Ring Die Granulu mašīna ir komerciāla iekārta, kas ļauj izgatavot koksnes granulas lielā skaitā. Šīm divām granulu ražotnēm ir vairākas atšķirības. Tomēr viena galvenā atšķirība ir veids, kā viņi baro izejvielas.

Gredzenveida granulu mašīnai ir izliekta padeve, izmantojot velmēšanas kompresijas padevi. Kamēr Flat diet mašīna ir atkarīga no barības svara. Svara dēļ izejviela presēšanas kamerā nonāk vertikāli.

Abām mašīnām ir savas priekšrocības. Ja vēlaties priekšrocības, ko sniedz divi vienā, ieguldiet TCPEL kokskaidu granulu dzirnavas. Galu galā tas apvieno abu dzirnavu priekšrocības.

Papildus kokskaidu granulu mašīnai jums būs nepieciešams šāds aprīkojums, lai izveidotu visu granulu līniju.

Bungu šķeldotājs

Kā norāda nosaukums, šī iekārta palīdz apstrādāt izejmateriālu, ko izmantojat granulu izgatavošanai. Jūs varat izmantot šķeldotāju, lai lielus koku zarus pārvērstu mazās skaidās.

Lai gan tirgū ir pieejami dažādi cilindru šķeldotāji, bungu šķeldotāji ir ideāli piemēroti granulēšanai, īpaši, ja jums ir maza izmēra koka baļķi.

Rotējošie žāvētāji

Rotācijas žāvētāja mašīna samazina izejmateriāla mitruma saturu, izmantojot uzkarsētu gāzi. Varat arī izmantot zibspuldzes žāvētājus, lai novērstu virsmas mitrumu.

Hammer Mill

Hammer dzirnavas ir koka smalcināšanas mašīna, kas ļauj nodrošināt izejmateriālu ideālā izmērā. Tirgū ir pieejami gan dzīvojamie, gan komerciālie koka āmuri.

2. solis: izejvielu sagatavošana

Kad esat izlēmis par mašīnu, sagatavojiet izejmateriālu. Atkarībā no pieejamības varat izmantot koka plātnes, baļķus, zāģu skaidas, skaidas un pat labības atkritumus. Neatkarīgi no izvēlētā izejmateriāla tā diametram ir jābūt mazākam par 5 mm.

Ja jums ir liela izmēra koka baļķi, izmantojiet šķeldotāju, lai samazinātu to sākotnējo izmēru. Nogrieziet visus zarus, lai izveidotu nelielu koka skaidu. Ja jums ir koka skaidas vai zāģu skaidas, neievērojiet šo procesu.

3. solis: izejvielu žāvēšana

Tas ir viens no būtiskākajiem šīs rokasgrāmatas posmiem – kā tiek izgatavotas koksnes granulas? Šim nolūkam varat izmantot rotācijas žāvētāju. Koksnes granulu izejviela nedrīkst būt ne pārāk sausa, ne pārāk mitra. Vēlams, lai koksnes granulu mitruma saturs būtu no 10 līdz 18%. Pārliecinieties, ka izejmateriālā nav pārāk daudz ūdens. Atcerieties, ka lielais granulu mitrums granulu dedzināšanas laikā var izraisīt dūmus.

4. darbība. Nekoksnes materiāla filtrēšana

Šajā solī jūs atdaliet visus svešķermeņus no izejmateriāla. Tas var būt metāls, akmens un citi piesārņotāji. Šim nolūkam varat izmantot ekrānus un magnētus. Neaizmirstiet, ka šie priekšmeti var kaitēt jūsu granulu mašīnai un granulu līnijai.

5. solis: izejvielu slīpēšana

Kad esat pārliecināts, ka jūsu izejmateriālā nav neviena priekšmeta, sāciet ar slīpēšanas procesu. Tam izmantojiet koka āmuru dzirnavas. Mašīna sastāv no brīvi šūpojošiem āmuriem, kas piestiprināti pie rotējošās vārpstas. Tas sasmalcina cietus un sausus kokus un pārvērtīs tos pulverī. Bez tam šajā procesā izejvielas tiks sajauktas.

6. solis: izejvielu granulēšana

Tas ir faktiskais granulu izgatavošanas process no izejvielām. Atkarībā no izvēlētā iekārtas veida process var nedaudz atšķirties. Tomēr pamata procedūra ir standarta.

Pirms turpināt procedūru, uzsildiet savu granulu mašīna. Temperatūrai jāsasniedz 170 līdz 190 grādi pēc Fārenheita.

Ievietojiet izejvielas granulu dzirnavas padevējā. Sākumā ņemiet nelielu daudzumu izejvielu, lai novērstu sastrēgumus. Turklāt tas palīdzēs jums noteikt, vai granulu kvalitāte un forma atbilst prasībām.

Izejviela sasniegs veidni un veltni, kas iet cauri padevējam. Tērauda presforma un rullīši saspiedīs materiālu un izlaidīs tos cauri matricas caurumiem, lai iegūtu labas formas granulas.

TCPEL granulu mašīnai ir gan horizontālās gredzenveida, gan plakanās granulu dzirnavas priekšrocības. Turklāt iekārtai ir iebūvēta eļļošanas sistēma, kas nodrošina procesu bez berzes.

7. solis: granulu atdzesēšana

Tā kā granulas iziet no granulu dzirnavas, tās ir karstas. Jūs varat pamanīt, ka tie izdala nedaudz mitruma. Pirms lietošanas ļaujiet tiem 24 stundas atdzist brīvā dabā.

Ja jums ir komerciāla granulu ražošanas bizness, izmantojiet profesionālu granulu dzesētāja mašīna. Neievietojiet granulas, kamēr temperatūra nav normalizējusies.

8. solis: Koksnes granulu uzglabāšana

Kad koksnes granulas ir izžuvušas, rūpīgi uzglabājiet tās, izmantojot maisiņu iepakošanas mašīna vai jumbo maisu iepakošanas mašīna. Glabājiet koksnes granulas sausā un vēsā vietā. Pārliecinieties, ka veikalā ir laba ventilācija un nav tiešas saules gaismas.

Tātad tiek izgatavotas koksnes granulas. Ja jums ir jautājumi vai jautājumi par granulu mašīnu, SAZINIETIES AR MUMS.

Vai meklējat apmierinošu risinājumu granulu ražošanai?