2022 Best Animal Feed Pellet Machine Manufacturer, ISO9001 Certificated

- Поголем капацитет и помали трошоци за делови за абење

- Широк опсег на соодветност на апликацијата

- Стабилни перформанси и лесно ракување

Animal Feed Pellet Machine- The Beginner's Guide

As a leading animal feed pellet machine manufacturer, we always suggest our clients to learn more before buying one. If you are looking for products or information, you are in the right place. Feed pellet machine, fodder pellet mill, feed mill, or pellet feed mill, It doesn't matter which name you call this machine. The result of this machine will bring your business to the next level. But before you buy, you should consider many things such as the Animal pellet machine quality, Animal feed pellet machine price, etc.

As a top leader, we receive many questions from our clients every day.

This beginner’s guide will provide the information you should know before buying an animal feed pellet machine.

What is an Animal Feed Pellet Machine?

Animal feed pellet machine make animal feed from raw materials. Using an animal feed pellet machine, you can make feed maintaining proper nutrition level, which is crucial for an animal’s growth.

You can use these machines for any animal and fish.

While firming, you want your animals to have the proper nutrition to grow properly. It is nearly impossible to provide balanced food for your animals using the conventional manual process.

Type of Animal Feed Pellet Machine?

Small and large production – these are the two types of animal feed pellet machines. Flat die machines are used for small production and ring die for large production.

Animal feed pellet machines also can be categorized for the purpose you will use them. Some machines are used for cattle, some for fish. You can buy machines for rare animals such as goats, pigs, rabbits, etc.

DO NOT choose a manufacturer that builds only one type of machine because there are many types and categories for animal feed pellet machines.

How to Make Animal Feed Pellets?

Animal feed pellets are animal feeds made with an animal feed pellet machine with the help of a wide variety of raw materials. Here are the steps to follow:

мелење

Crushing the raw materials is the first step to creating an animal feed. You have to grind the raw materials into tiny pieces of particles so that you can mix them with other materials easily. The primary crusher is the place where you perform this step. The hammer bill breaks down the raw materials into tiny particles, and once the step is finished, you can move them to the next step.

Мешање

Mixing is the second step of how to make animal feed. You can mix the crushed materials inside the mixer, and that manufactures a homogenous mixture.

It first churns the basic raw materials together before it mixes well. And then, you can add other minerals and vitamins you want to add to the mixture. Please continue this step for some time so that all the contents mix very well.

Making Feed Pellets

After mixing, it’s time for pelletization. Follow the procedure according to the pellet type.

Ладење

Drying the pellets is the final step of making animal feed pellets. The moisture level of pellets that comes from the pelletization level is around 17%, but the required moisture level for animal feed is 11 to 12%. If the animal feed leaves the manufacturing firm with more moisture than 12%, the feed will not sustain.

Here we have provided methods for cattle feed but for other fishes or other special animals that can vary.

Where to Buy an Animal Feed Pellet Machine?

Animal farming is a profitable business these days, and this process is fulfilling the increasing need for food for us. But animals need to take proper care to grow on time with proper nutrition. And you can not provide proper nutrition using old-fashioned feeding techniques.

There are so many animal feed pellet machine manufacturers in the market. You can find them on Aliexpress, Indiamart, and many other B2B marketplaces. But it is never a good idea to purchase one random animal feed pellet machine for sale.

Machines are delicate items, and you should choose the manufacturer properly before buying an animal feed pellet machine for yourself.

TCPEL is one of the leading animal feed pellet machine manufacturers in China. We exported our machines to over 50 countries all over the world. We have the certifications, and every machine is tested, maintaining the industry standard.

So, our suggestion is to talk to the manufacturer, ask for the experience and compare several animal feed pellet machine manufacturers before making decisions.

How to Make an Animal Feed Pellet Machine?

You can make an animal feed pellet machine at your home. Here are some important considerations for you:

Raw Material’s Size

The size of raw materials should be 5mm after crushing. How much the crushing size will be will depend on the size of the die hole and particle diameter of the animal feed pellet machine. Therefore, that should be your primary concern before building an animal feed pellet machine at home.

Барања за влага

The moisture content of the output material should not be over 8-12%, depending on the feed type. Very dry or wet, both materials are not ideal for pelting and affect the output value as it is tough to control. Both materials have the chance to break while performing the pelting task.

Лепила

Standard animal feed pellet machines can deliver adhesives. However, in special cases, you may need to add some adhesive for better outputs.

Now let’s talk about other aspects of making animal pellet machines at your home.

опрема

For small production, an animal feed pellet machine, you will need a crusher/hammer drill, dryer, pellet cooler, etc. You can select different hardware according to your requirements

Though a homemade Pellet machine for animal feed can not produce large quantities of pellets, that certainly reduces your costs, and you can easily make your pellets at your home.

If you don’t know how to make an animal feed pellet machine at your home, you can ask any colleague or friend to help you out. If you need information or a demonstration, there are many resources available online.

You can watch videos from YouTube or read DIY articles, and hopefully, you will be able to make one for yourself easily.

If you are an owner of an animal firm or fish firm, we will advise you to buy a machine for small production. That may cost you a fair amount of money, but that will help you in many ways in the long run.

In TCPEL, we hear requirements from our clients first and provide the best affordable solution for them. Our small animal feed pellet machine cost is affordable. You can send us a message, and our sales team will help you buy one at an affordable price.

How to Buy an Affordable Animal Feed Pellet Machine?

The first suggestion that we want to provide is to never consider quality over price. Yes, there are many animal feed pellet machine manufacturers around you. But a low-quality animal pellet machine will just increase your costing in the long run.

More and more people have started to buy animal feed pellet machines these days for both business and in-house purposes. But how to buy a cost-effective animal feed pellet machine?

Квалитет

Like we told you in the first section, quality is the first thing to consider before buying a pellet machine for animal feed. A lower quality machine will not sustain a long time and increase fuel costs, increasing the investment in the long run.

Buy that suits your Budget

A good animal feed pellet machine is not simply “The best” for you. Like we said earlier, there are many types of animal feed pellet machines in the market. You have to consider many things before buying one—first, the type of machine you need.

You have to consider what type of animal you are going to feed. Then you need to consider the production requirement. You don’t want a machine for large production if you don’t need that. On the other hand, a small production machine can not handle the load of large production and will damage soon.

So, find out your needs and environment first. If you can’t decide, you should consult an expert. You can send us a message, and we will help you to find out which machine you need.

Други Цена

Fuel consumption, operational and maintenance costs are very crucial aspects of an animal feed pellet machine. You may think that is not connected to the large or small animal feed pellet machine cost. But they are.

Over energy consumption, operational, and maintenance cost will increase the production cost, which will affect your overall business cost.

Поддршка

It doesn’t matter how good a machine you cost; an animal feed pellet machine needs servicing and support. Therefore, before purchasing a machine for your firm, please consider the support service quality of the company. In TCPEL, we have a dedicated after-sales team and never make delays when supporting our customers.

How to Use an Animal Feed Pellet Machine for Beginners?

Whether it is an animal feed pellet machine or a smartphone, beginners need to have some pre-knowledge before using a new device. For a machine like an animal feed pellet machine, you need to know the prerequisites or hurt yourself or damage the raw materials.

Here are some of the steps you must consider before using your animal feed pellet machine:

Подмачкување

Lubricate the shaft, gearbox, and roller with oil before running the machine. Enough lubrication is mandatory every time you start your animal feed pellet machine. One thing to remember is that the lubricating process is not the same for all machine parts.

Flat Die And Roller Checking

Many beginners sometimes miss this but checking roller and flat die is very important. Make sure nothing is blocking the road.

Прилагодување

You have to adjust the clearance between the die and the roller for the feed you will produce. Please use the reference for the feed you will produce for reference. This adjustment also affects the longevity of the machine. So, please make sure you use the right number.

Checking the Connecting parts

There are cap bolts at the end of every roller of the animal feed pellet machine. You MUST make sure that you tighten them at the optimum level. Because if they fall off, that will damage the roller. You should also check other connecting parts to make sure everything is fine before you run the machine.

Насока на ротација

Checking the indicative sign and the rotating direction and consistency is vital, and that is a very handy suggestion, especially for beginners. If the rotating direction is not consistent, adjust the drive engine.

Сигурност

Safety is crucial when you are dealing with machines like animal feed pellet machines. If the wire has any power leakage in the wire, the electric cabinet will stop your animal feed pellet machine from working. Power and voltage issues can also damage the machine or parts. So, make sure everything is okay before you hit the start button.

Good animal feed pellet machine manufacturers arrange training sessions and provide sufficient documentation. We suggest you attend that session and appoint an expert man to operate the machine. That will expand the lifespan of your animal feed pellet machine.

How to Maintain an Animal Feed Pellet Machine?

When it comes to using a machine, maintaining it is very crucial. Proper maintenance will not only expand the lifespan of your animal feed machine but also reduce fuel consumption. So, make sure you always maintain the correct procedure to maintain your animal feed machine.

Here are some of the maintaining processes you should follow:

Maintaining an Animal Feed Pellet Machine

- Lubrication is very important for both the proper operation and longevity of an animal feed pellet machine. Read the manual carefully and use proper lubrication to various parts of your machine.

- You should change the lubricating oil and gearbox at regular intervals. That will increase the lifespan of your animal feed pellet machine.

- You should run a monthly inspection of every part. You should cover the roller, gear, die, bearing while inspecting your animal feed pellet machine. If you find any problem with any part, immediately change the part. Remember, a bad part will damage the other parts also.

- NEVER overload your animal pellet machine with more than its capacity. That might give you additional production for the time being but will damage your feed pellet machine shortly.

- Before every use, please carefully wash and clean your animal feed pellet machine. Cleaning is a fundamental maintenance process you should consider doing after everyday work.

- There could be times; you will not use your animal feed pellet machine for some time. Preserve the machine in good condition when you are not using it. Cover the machine with a tarpaulin. Use a dry area to store your animal feed machine.

- Always read the instructions carefully before using your animal feed pellet machine. Most companies arrange a free training session. Attending that session is also a very good idea to learn how to maintain an animal feed pellet machine.

- Appointing an experienced person to operate your machine is always a good investment. Single Handed use is always better for animal feed pellet machines.

In TCPEL, we offer free training sessions and have a dedicated support team. You can contact us anytime if you feel any confusion about your animal feed pellet machine.

TCPEL Animal Feed Pellet Machine Introduction

TCPEL is one of the best animal feed pellet machine manufacturers in China. We have been running a solid research and development team, and our research has produced some of the finest machines in the industry.

We have been in the industry for one decade, and by this time, we have established ourselves as one of the leading manufacturers in China and all over the world. We are an ISO9001, CE, and SGS certified company, and all of our machines are well tested before delivery.

Every product that comes out from our factory is guaranteed. Because we have our in-house QC (Quality Control) team. Our quality team ensures the quality of every machine that comes out from our factory.

We offer complete installation service for turn-key service. We also provide a free training session for our clients.

We also have a world-class after sales service that provides 24/7/365 after-sales services around the globe. We are not limited to receiving service requests from our clients. You can call or email us or simply send us a message using our website.

Animal Feed Pellet Machine Parameters

| модел | капацитет | Нотка ролери | Моќ | Приклучна моќ (V) | Тежина | димензија |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg / ч | Двоен валјак | 2.2kw | 220V / 380V | 95kgs | 68 * 42 * 53cm |

| TFC150 | 150-200kg / ч | Двојни ролери | 7.5kw | 220V / 380V | 100kgs | 72 * 45 * 65cm |

| TCF200 | 300-400kg / ч | Двојни ролери | 11kw | 380V | 180kgs | 126 * 53 * 92cm |

| TCF250 | 600-800kg / ч | Двојни ролери | 15kw | 380V | 320kgs | 131 * 54 * 93cm |

| TCF300 | 800-1000kg / ч | Двојни ролери | 22kw | 380V | 400kgs | 146 * 59 * 110cm |

| TCF350 | 1000-1200kg / ч | Двојни ролери | 30kw | 380V | 580kgs | 186 * 70 * 128cm |

| TCF400 | 2000kg / h | Двојни ролери | 37kw | 380V | 680kgs | 206 * 76 * 137cm |

| TCF450 | 2000-2500kg / ч | Двојни ролери | 45kw | 380V | 780kgs | 218 * 79 * 140cm |

TCPEL Animal Feed Pellet Machine Advantages

We used chromium-manganese steel to build the pressure roller and the grinding disc of this animal feed pellet machine. That material made this machine more durable even after using it under high-temperature quenching treatment. 10-20 times wear resistant for ordinary materials.

User friendly and easy to refuel. You should use GL-5 heavy-duty gear oil before use.

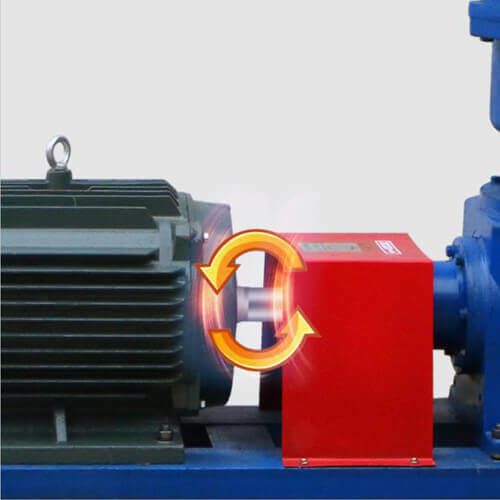

The installation process is pretty convenient. Direct docking, simple operation and electric coupling. The coupling is made of stainless steel, which has advanced durability properties than regular materials. Compared to the old belt drive, the upgraded coupling drive comes with less transmission ratio loss and wear resistance, resulting in more durability.

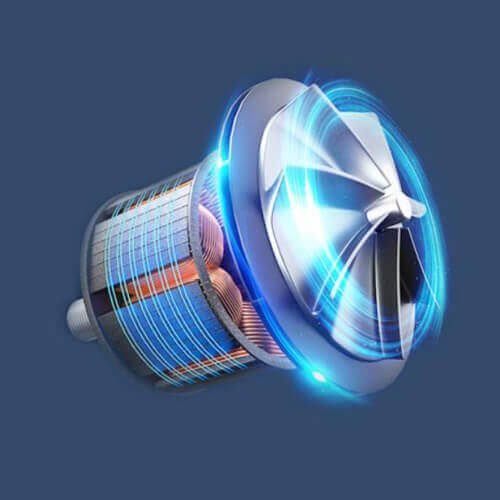

Larger horsepower, extended lifespan with 100% copper wire motor. The heat sink, every copper coil confirms longer service life and stable operation without any noise. It has a power-off functionality at a high temperature to reduce malfunction.

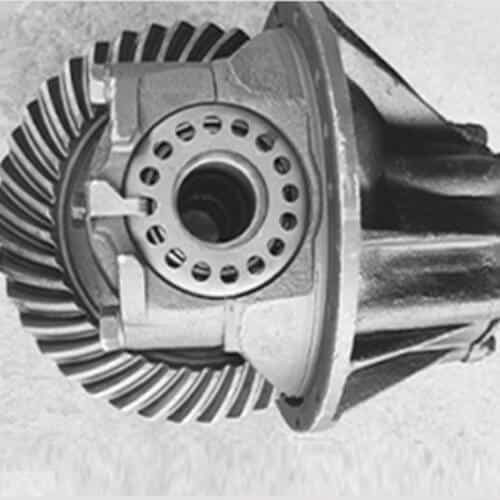

We adopted an automobile rear axle differential assembly design. This new design has an advanced gear combination, reduces the engine’s loading time, and provides advanced stability.

You will get a more convenient feeding environment and enhanced work efficiency with a larger feed inlet, and higher Widened discharge port design. Both-sided baffles design ensures feed spilling, widened enlarged discharge port, discharge faster and smoother.

Wear resistant, durable, and adopts nylon sliding casters.