Pellet Machine - Manufacturer and Supplier in China

- We Are Leading Pellet Machine Manufacturer

- 15+ Years Factory With CE IS09001 Certificate

- 1000+ Happy Customers Worldwide

- Shipped To Over 60+ Countries

- Pellet Machine Made With Enhanced Top Level Steel

- Easier To Start Your Pellet Production Plant

- 24*7 Hours Online Service

Privacy Policy: Security and Privacy Guaranteed 100%

TCPEL Pellet Machine Introduction

Our pellet machine offers all the benefits of both a flat die pellet machine and a horizontal ring die pellet mill machine. It can work with all kinds of materials, including rice or sunflower husks, crop straws, rubber, ash, cement, branches, peanut and other fruit shells, trunks, branches, bark, and much more.

It uses German alloy steel in its construction for a more secure, reliable build. The die has a fixed and vertical installation that allows easy maintenance and repairs, and the pellet modeling system operates silently and efficiently. This offers a greater life of work along with a more efficient user experience.

Widely used in industry and recommended by experts, the pellet mill can be used in fertilizer, MSW processing, wood processing, power, biomass energy fuel, and chemical plants. For low investment and high profit, the TCPEL Pellet Mill is the way to go.

| Model | Power(kw) | Pellet Size(mm) | Capacity(t/h) | Size(mm) | Weight(t) |

|---|---|---|---|---|---|

| TCZL400 | 37 | 6/8/10/12 | 0.3-0.5 | 1300*5300*1250 | 1.5 |

| TCZL560 | 90 | 6/8/10/12 | 1-1.5 | 2630*1300*2300 | 5.8 |

| TCZL700 | 160 | 6/8/10/12 | 1.5-2.5 | 2900*1300*2400 | 7.8 |

| TCZL850 | 220 | 6/8/10/12 | 2.5-3.5 | 3300*1400*3100 | 12 |

This machine is our flat die pellet machine, power from 15kw to 55kw ,the capacity from 100kgs/hour to 1000kgs/hour. This machine can be used for making biomass pellets and animal feed pellets, suitable for small scale pellet production.

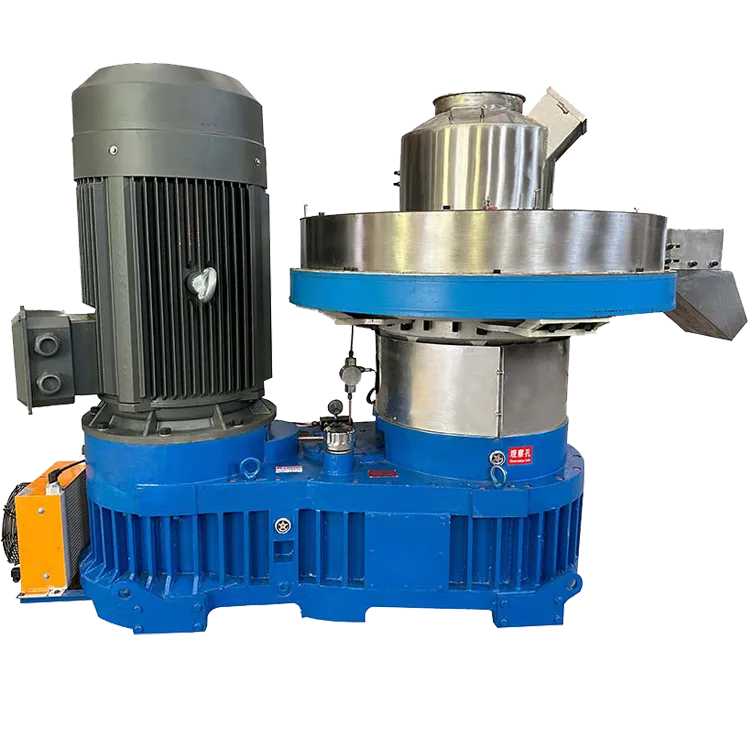

This pellet machine is our hot selling model, with 90kw motor, TCZL560 can reach capacity 1-1.5t/h. This machine structure is vertical ring die, with reasonable price and reliable performance, we can make 200sets this model annually.

With 160kw strong power ,this pellet making machine model TCZL700 can process various biomass materials such as wood sawdust, rice husks,corn straws into solid pellets.

This model TCZL850 single set capacity can reach 3-3.5t/h, with big power 220kw. This is our biggest model for single set pellet mill. Widely used for big pellet production plant.

Advantages Of Our Pelleting Machine

Heavy duty structure ensure durable and long-lasting, 24 hours of work time without stop and less maintenance.

Suitable for various materials, including wood, sawdust, rice husk, EFB, palm shell, olive waste, fruit straw beech etc. and more.

Enhanced stainless steel dies have a service life of 1000 to 1500 hours, less power to achieve higher capacity.

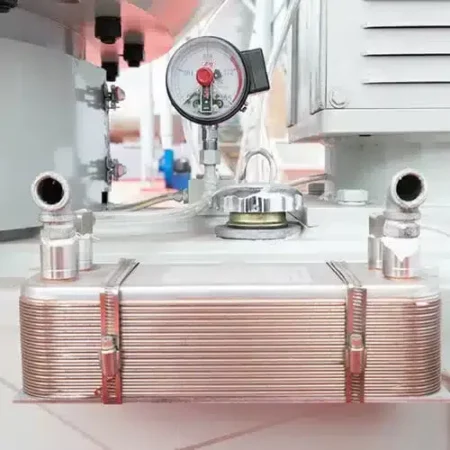

Built-in cooling system and fan blower to help cool down the pelletizing area, ensure continuous high quality output.

The main shaft inside our pellet machine is also wear-resistant, which can ensure produces wood pellets with a smooth, consistent surface.

The vertical laying dies feed directly with a broad range of applications and excellent heat dissipation. It offers improved efficiency with reduced cost.

TCPEL a professional pellet machine manfuacturer in China since the year 2004.Our factory integrate research and development, production, sales and service, we have modern equipment for manufacturing and excellent technical research and development team.

We have experienced and skilled aftersales service team. Based on detailed customers requirements, we can always offer satisfying solutions for pellet production projects.

Quality and service is our soul for company development, we will try our best to support customers on pellet making, to achieve win-win cooperation.

We employ highly skilled, professional engineers devoted to researching and improving all our products. Our experienced and skillful R&D engineers can help solve your pellet mill problems and assist with after-sales service.

Quality is important to us. We are IS0 9001, CE, and SGS certi-fied. All components used in our pellet mills pass our strict quality inspection. We carry out a trial run for each machine and wearing testing before shipment.

Manage your budget in a smart way and minimize your man-ufacturing costs. We offer competitive prices for all our pellet machines. Contact our sales team for support for custom solutions.

We have a highly qualified international sales team that will reply to you within 24 hours regarding any pre-sales ques- tions you may have. After sales, we offer 24/7 email and phone communications, and can arrange onsite support.

Full 24/7 support both before and after your purchase. We offer free testing to develop the manufacturing process and are dedicated to find the best solution for your specific needs. If you are interested in partnering with us to sell our machines, we will offer 100% support.

Ordering with us is fast and convenient. Our professional sales team replies quickly to inquiries and strives to solve your problems, both pre-sales and after-sales. We securely accept all forms of payment including T/T transfer, LC at sight, PayPal, and Western Union.

Successful Projects

We Have 500+ Sets Pellet Machine Offered Per Year For Customers Domestic And Aborad

Our Manufacturing Facilities

To get the best performance of our pellet machine, we always use advanced facilities for manufacturing, more than 90% parts of pellet machines are made from our own factory.

Which Industries Needs Wood Pellets?

Wood pellets are a suitable option for Home Heating, Industry Boiler,and Power Generation as they are efficient, clean. Unlike gas and oil-fired furnaces and boilers, wood pellets are environmentally-friendly.

Pellets Stove

Industry Boiler Using Pellets

Power Plant Using Pellets

Drum Chipper

Processing big size materials into smaller chips size, 3-5cm lengh and width ,10mm thickness

Rotary Dryer

Drying the sawdust to standard 15% moisture con-tent, prepared for next pelletlizing section.

Pellet Cooler

Cooling down the hot pellets into standard tem-perature, 30- 40° normal hot.

Hammer Mill

Further crushing the chips size material into smaller sawdust size, 3-5mm size sawdust

Pellet Machine

Pelletizing the ready dried sawdust into pellets. Single set machine capacity can reach 3t/h.

Pellet Packing Machine

Packing the pellets into bags, small 50kgs/bag or jumbo bag.

Various Materials For Making Pellets

Our pellet machine is suitable to process various materials from agricultural and forest waste, we can customized solutions based on customers different materials available, to maximize your pellet making profit.

Wood Pellet Making

Straw Pellet Making

Shells Pellet Making

Sawdust Pellet Making

EFB Pellet Making

Bamboo Pellet Making

FAQs About Pellet Production Before Cooperation

Which kind of materials can your pellet machines process?

Our pellet machine can process various materials from forest and agricultural waste. For example wood logs, branches, wood chips, tree leaves, log stump, waste furniture, sawdust, mushroom, rice husk ,rice straw, corn stalk, peanut shell, EFB, bamboo etc. We have different machines and specification which can meet your various materials production requirements, you can contact with your experts team to know more.

What's the process to cooperate with your company?

The process for cooperation is below :

1. Negitation

We will negotiate with you about your requirement, including what's your material for making pellets,?how much moisture content? how much capacity per hour? budget for the project? plant landing size available etc. Based on them we will customize the solution with our experience and introduce to you.

2. Order Confirmation

After we conclude the production line solution and quotation, we will sign contract and proceed with payment. We accept 30%T/T after confirm the order, and 70%T/T balance before shipment.

3. Manufacturing Process

After we get your deposit payment, we will arrange production accordingly, based on different capacity, our manufacturing time are different. Normally speaking we need 30-45days for whole line capacity under 5t/h, and 45-60days for capacity over 5t/h. For single set machine need about 25-30days based on our manufacturing plan.

4. Machine commission and delivery

After all the machines finished manufacturing, we will test and run all the machines before delivery ,make sure the machine can achieve best performance before delivery, during that time we will send customers the testing videos for confirmation

5. Balance payment and delivery arrange

After customer accept the machines performance, customer should arrange the balance payment to us, after we get the balance, we will arrange to book the ship and arrange delivery for customers. All the machines will be well packed for long distance shipment.

6. Customs documents handover

After all the machines arranged customs in China, we will send all the documents to customers including Bill Of Lading ,Invoice, Packing List, Country Of Orign etc. We will help customers on the customs clearance smoothly.

Are you are a manufacturer or trader?

We are pellet machinery manufacturer since the year 2004, we can offer complete pellet production machinery based on your requirement. Factory landing size 40000㎡ and 350+working staff. And more than 1000+ happy customers domestic and abroad. We have seperate team to arrange sales and after-sales service.

What information do you need to customize pellet line for me?

In order to serve you better, please try to provide the below information:

- What is the material to make pellets? Better if you can share us some pictures

- Hardness of your material?

- Moisture content?

- Maximum diameter of the material to be processed?

- The capacity per hour you want to get for the pellet production.

Then we will recommend suitable model based on your actual needs.

What's the moisture requirement to make pellets?

To make pellets, we should control the sawdust entering the pellet mill moisture content 10-15%, too wet or too dry will affect the pelletizing result. If you material is too wet, you need a dryer machine to remove the moisture.

What's your warranty for your pellet production line?

Our warranty for pellet production machinery are one year after sale, not including the wear parts. The main wear parts are the ring die and roller.

How to arrange the installation of your pellet line?

Because of COVID-19 since 2020, we can not send our engineers to abroad for on site installation, we can offer video help installation after customer receive machines. Before delivery, we will also test all the machines to make sure it can achive best performance, and we will make detailed video to show customers how to install them, and the installation manual will be sent together with the machine. Our after-sales will be ready 24hours to support customers for the whole installation process.

Pellet Machine Maker - The Beginner's Guide

Pellet machine is a great way to make your own pellets from various materials like wood, rice husk, sawdust, bamboo, waste veneer, corn stalk and more. If you’re new to pellet machines, this beginner’s guide is for you. We’ll go over the basics of how pellet machine works, pellet machine price and how to make wood pellets. Plus, we’ll provide some tips for using your pellet maker safely and effectively. So whether you’re just starting out or you’ve been using pellets machine for a while, this guide will help you get the most out of your pellet mills. What are you waiting for? Let’s dive in it.

What is a Pellet Machine?

Pellet machine, also known as pellet mill, wood pellet machine, pellet makers, pellet making machine. It is a machine that used to press crushed trees, wood boards, bark, shavings, furniture factory scraps, and other raw materials into rod-shaped solid pellets with a diameter of 6-12 mm by physical press.

The density of the pressed pellets is 0.8-1.3t/m3 according to the different raw materials, which are more convenient for transportation and storage, and the combustion performance is greatly improved.

According to the different die structures, pellet machines can be divided into flat die pellet machine and ring die pellet machine. According to different usage scenarios, pellet machines can be divided into home use pellet machine and industrial pellet machine. According to the different uses of pellets, pellet machine can be divided into biomass pellet machine and animal feed pellet machine.

Because the pressing process is a physical process, there is no need to add any chemical ingredients. The extruded pellets can be used as fuel to replace coal, which is a clean and environmentally friendly new energy.

What Does a Pellet Machine Do?

A pellet machine is a machine that takes raw materials and shape them into pellets. The process of doing this is called pelletizing.

The raw material can be anything from agricultural to forest waste. Pellet machines can be big or small depending on their use. Some pellet machines are used to make animal feed while others are used to make fuel for wood stoves. There are many different types of pellet machines, but they all work in basically the same way.

First, the raw material is fed into the machine. Then, a die presses the raw material into the desired shape. Finally, the pellets are cut to the desired size and then ejected from the machine.

Wood Pellet Machine Prices?

Based on different materials and different capacity, the wood pellet machine prices vary from $4000 to $48000, below is the price range for your reference:

| Capacity | Price Range |

| 300-500kgs/h | $4000-8000 |

| 500-1000kgs/h | $7000-10000 |

| 1000-1500kgs/h | $15000-23000 |

| 1500-2000kgs/h | $23000-28000 |

| 2000-2500kgs/h | $33000-38000 |

| 2500-3500kgs/h | $42000-48000 |

For detailed final price list, please contact with our experts.

How Does a Pellet Machine Work?

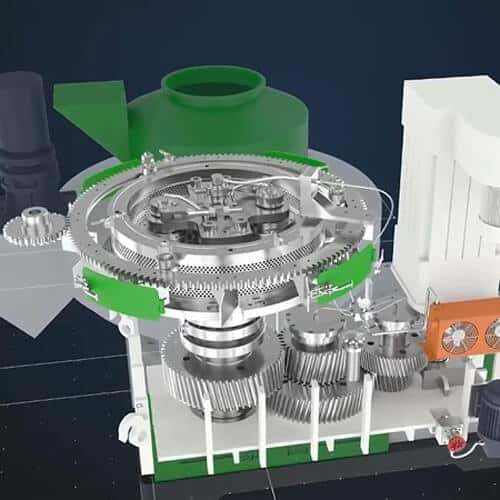

The pellet machine consists of a main machine base, a reducer, a bearing chamber, a feeding cover, a discharging port, a motor, a pressing roller assembly, a ring die etc.

The motor is connected with the reducer shaft through a gear coupling. The rotation of the motor drives the main shaft to rotate, and the main shaft drives the roller to roll the inner surface of the ring die to complete the pressing process. When working, the ready sawdust is sent to the feeding port above the pellet machine through the screw conveyor. The material is stirred and compressed under the dual action of the rotation of the main shaft and the rotation of the roller, and through the action of centrifugal force, the material is continuously attached to the inner surface of the ring die in circular motion, forming a uniform annular material layer, and the attached material is pressed again and again by the rotating roller and forced to extruded out from the ring die hole continuously, and then cut into the required length by the rotating cutter, and then the spreader plate gradually pushes these final pellets out from the discharge port.

It should be reminded that there are no auxiliary raw materials in our processing process, and it is completely made by physical compression.

How Many Types of Pellet Machines Are There?

There are several types of pellet machines out there. They can be grouped into large-scale and small-scale types. You will also find a ring die pellet machine and a flat die pellet machine within the large-scale category. These are the two main types of pellet mills.

The flat die pellet machine was created in the late 1900s to produce animal feed but is now one of the most popular ways of producing wood pellets, too.

A flat die machine uses a flat die with a few slots, with powders introduced to the very top of the die. As the die rotates, a roller compresses the material through the die’s holes, and it is then freed out of the other side.

In the ring die pellet mill, radial slots exist around and throughout the die. The powder is fed through the interior of the die with spreaders distributing it evenly.

How to Choose the Best Pellet Machine for Pellet Production?

Here are a few tips to help you buy the best possible pellet machine for wood pellet production for your home or business.

What is the application of your pellets?

For choosing the suitable pellet machine, you need to confirm your pellets applications first, for animal feed pellets or biomass pellets. No single pellet machine can make both pellets for feed and for biomass. The type of pellet machine that you buy will depend on which type of pellets you want to produce.

The main difference between animal feed and biomass pellets is their energy density and moisture content. Animal feed pellets have a lower energy density, lower ash content, and higher moisture content than biomass pellets. Biomass pellets have a much higher energy density than animal feed pellets. They also have a lower ash content than animal feed pellets because they don’t contain any digestible proteins or carbohydrates that could be burned by microbes during digestion by ruminant animals like cattle or sheep.

Confirm your capacity requirement for pellet making.

To choose the best pellet machine for your needs, you should to confirm your capacity requirement also. How much capacity do you need? This will affect your budget of course. The more capacity of your pellet mill, the higher price will be.

The capacity of a pellet machine is measured in terms of ton per hour (TPH). A TPH rate indicates how many pellets can be processed by the pellet machine within an hour.

A small scale pellet mill may be enough for an individual farmer who wants to produce wood pellets in limited quantities. However, if you have plans to expand your business, or if you are planning to sell wood pellets commercially, then you may need a larger sized industrial pellet machine that can produce more pellets per hour.

The final pellets requirement for making, including density, length, hardness

The pellets requirement is also very important before you made the purchasing plan, including pellets density, pellets length, pellets hardness etc.

Density

The density of the pellets is the main factor that can affect the pellet production. If you want to produce low-density pellets with a high moisture content, flat die pellet machine can be your best choice. The low-density pellets are suitable for feeding animals and also for using in animal feed processing plants. If you have high density pellets as biomass fuel, the vertical ring die wood pellet machine can be your best choice.

Length

The length of pellets depends on your local market requirement, whether 1cm or 5cm, you should confirm that in advance then you can choose the suitable pellet maker machine accordingly.

Space required for installation and working floor area of the plant

For choosing the suitable pellet press machine, you need to confirm your local working site size, you can not put elephant into the fridge, big capacity pellet mill means bigger size for operation, so before you make the purchase plan, think about your plant size for operation, not only for the machine ,but also for the storage of materials and final pellets.

Make sure your moisture of material suitable for making pellets

The moisture content in the material which you want to make into pellets should be between 8% and 12%. If it is too low or too high, then your wood pelleting machine will not work properly.

Confirm which kind of power will you use for pellet making, electric motor or diesel power?

Consider your local power supply before buying pellets machine, you need to confirm which kind of power is available around your site, and then proceed with the next purchasing step.

If you are looking for a large-scale pellet production, then it is necessary to look at electric motors that have a high output capacity. Diesel engines are also good but they have higher maintenance costs and they tend to be more expensive than electric motors. The advantage with diesel engines is that they can be used in remote areas where there is no electricity supply or in areas where there is no easy access to electricity supply.

Think more about the pellet machine parts quality, especially ring die and roller.

Pellet press machine parts quality is very important to the production process. Therefore, in order to ensure the quality of the product, the selection of pellet mill parts should be done carefully.

At the top of my list is ring die and roller quality – these are the two most critical parts in making pellets and if they break down then your entire production process will stop cold. That’s why it’s important to look for machines that use high quality steel or stainless steel parts instead of low cost materials like aluminum or cast iron.

Pellets machine manufacturer after-sales service and technical support

Pellet machines require regular maintenance and servicing due to their constant use, so it’s important that you choose a company with good after-sales service and technical support who can assist with any problems you encounter with your machine while also providing spare parts if they become necessary over time.

What Are the Advantages of a Ring Die Pellet Machine?

Ring die pellet machines have several advantages over other types of pellet mills, some of which include:

Larger Capacity Available

The main advantage of using ring dies is that they can produce large quantities of pellets very quickly. This makes them ideal for commercial use, where time is money and you need to make your product as quickly as possible.

Relatively Affordable Price

The average price for a new ring die machine is around $10,000. This includes everything from the hopper to the conveyor belt system that transports your pellets out of the building, this will help save budget for pellet making business.

More Efficient

Another advantage of using ring die pellet mill is that they’re more efficient than other types of dies. This means that you can produce more pellets per hour with a ring die pellet machine than you could with other types of dies.

More Durability

The durability of the ring die is one of its advantages. The machine is made with high quality materials that can withstand use in a steel mill environment. This means that it will last longer than other machinery and will not need to be replaced often.

High Quality Output

A ring die pellet machine produces high quality output because it can process all types of raw material into pellets without any damage to the product or loss of quality. The process is efficient and produces consistent results every time

Ease Of Maintenance

Ring die pellet machines do not require much maintenance because there is only all the parts are fixed like module. Also, these machines are easy enough for anyone to operate without special training or certification from an outside source like some other types of mills might require before use.

How to Buy An Affordable Pellet Machine?

While you should always look at quality over price, you have a bottom line to stick to. Therefore, it’s important to look at specific details about buying an affordable pellet machine.

Flat die pellet machines tend to be less expensive than ring die pellet mills. Although the output capacity is different and may not suit your business, a flat die pellet machine is the way to go if you are trying to save money. Of course, if you want to maximize your efficiency and the money you have available, you can always get a machine like the TCPEL Pellet Machine that offers the best of both worlds!

Remember that sticker price isn’t the only factor that needs to be considered as you’re shopping for an affordable pellet machine. You also need to consider spare part supply, after-sale service, and ease of operation.

If your machine isn’t easy to use, service, or maintain, then it’s going to cost you more money in the long run. Consider these factors to buy an affordable pellet machine that will last as long as your business does.

How to Use a Pellet Machine for Beginners?

With regard to the pellet mill operation for beginners, you need to pay attention to several points before you start running.

1. Ensure your pellet mill is properly installed on solid ground

2. Always follow the safety protocols and rules of using a pellet mill

3. Pay attention to the quantity of raw materials and moisture content of them, make sure your materials for feeding to pellet mill do not contain foreign materials

4. Open the top cover of the pellet mill and check the bearing, gearbox and oil level, learn the lubricating parts regularly

5. Check if there’s any foreign matter in the hopper and clean it up. Then check if there are coal or residual material inside the pellet mill.

6. It is necessary to check whether the bolts of the die and roller are loose or not. If they’re loose, tighten them and then you can use them.

7. Start pellet mill engine and check whether all the nuts on the machine are tightened. Check whether there is something stuck at inlet pipe or outlet pipe and clean them if necessary. If there is an emergency shut-off button, you should know where it is, just in case a safety emergency comes up.

8. Observe production condition when pellet mill is running for about 15 minutes, it is still not working well; you need to stop it immediately and check why it goes wrong, then adjust

9. Clean The Filter Bag Of Electric Cabinet In Time

How to Maintain a Pellet Machine?

To keep your pellet machine working in tip-top shape, you will need to take certain steps to maintain it.

Be sure to regularly add oil to the parts in the transmission. These should be lubricated to ensure a long lifespan. Change the lubricating oil of the gearbox regularly and be sure to undergo a monthly inspection of the parts in the pellet machine. This might include everything from the bearings to the gears, the roller and the die.

If you notice anything wrong at any time, you must repair or replace them instantly. Also, check that no parts are loose. After each use, take the roller out and wash it carefully.

Finally, be sure to read the operation instructions before every time you use the pellet mill. If any kind of malfunction occurs, shut it down immediately for maintenance and inspection. This can prevent damage to the machine as well as injury to your operators.

Complete Process For Pellet Making

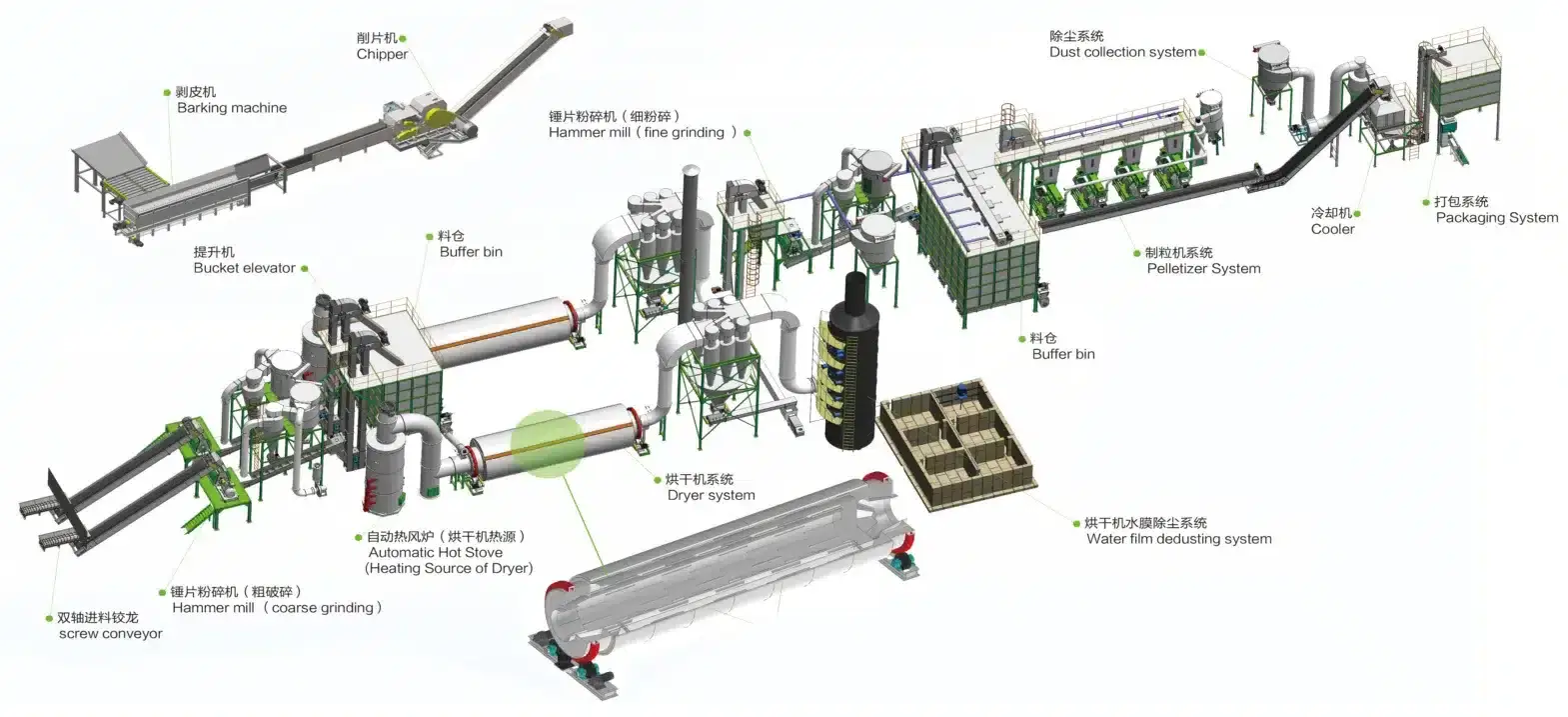

Based on different materials, we have suitable pellet making process. The whole process include Material Crushing Section, Drying Section, Pelletizing Section, Pellets Cooling Section and Pellets Packing Section. The production capacity can be 500kgs/h to max 20ton/h, below is our project we customized for our customers capacity 10t/h.

Useful Articles For Pellet Making

Before You Buy A Pellet Machine

You should know everything well before you buy a pellet machine, including pellet machine manufacturers in the world, how much money canI earn for pellet making, how many types of pellet machines, what is a good pellet machine, how to choose a suitable pellet machine for yourself.

- Top 10 Pellet Machine Manufacturers in The World 2022

- Types Of Pellet Making Machines & Their Pros and Cons

- 7 Questions You Need To Ask Yourself Before You BuyA ellet Machine

- How to Choose The Best Pellet Machine For Yourself?

- Pellet Die, How to Choose?

- What A Good Pellet Machine Stands For?

- How to Start A Wood Pellet Business Successfully in 2022?

- Pellet Making Business Profit Analysis

Beginner's Guide For Making Pellets

Once you have figured out all the questions for pellet making, you should know clearly how to make wood pellets, how to operate pellet machine and how to achieve top performance of your pellet machine, how to choose raw materials for wood pellet production.

- How to Make Wood Pellets-The Ultimate Beginner' S Guide

- Biomass Materials For Pellets and Pellets Calorific Value

- How to Setup A Pellet Machine?

- How to Keep Pellet Machine High Efficiency?

- How to Install A Pellet Machine?

- How To Make Wood Pellets from Sawdust?

- How to Make Hardwood Pellets?

- How to Choose Raw Materials For Pellet Production?

- How to Make High Quality Wood Pellets?

- How to Maintain You Pellet Machine?

Pellet Machine Troubleshooting

When you come across any problems while operating pellet maker, you should know where it is and how to fix them, find out the main pellet machine problems and how to fix them, what’s the reason for your pellet mill unstable current, why your pellet machines low capacity etc.

- 10 Common Pellet Maker Problems and How to Fix Them

- Pellet Machine Current Unstable and Solution

- Why Your Pellet Machine Low Capacity?

- 3 Tips to Extend Pellet Mills Life

- Everything You Need to Know About Pellet Line

- How to Make High Quality Wood Pellets With Pellet Machine?

- How to Achieve Highest Performance of Pellet Mill?