Professional Wood Pellet Press Manufacturer and Supplier in China

- Automatic lubricating system ensure longer work time without stopping

- More than 90% parts are self made, quality controlled by ourselves

- Lower power consumption and higher efficiency

Wood Pellet Press - The Beginner's Guide

Are you considering purchasing a wood pellet press? If you are in the biomass fuel pellet business or looking to start it, you'll need a cutting-edge wood pellet press. Unfortunately, with so many options in the market, finding a suitable wood pellet press machine is a tough row to hoe. Don't worry, in this detailed beginner's guide, we’ll answer all the possible questions a first-time buyer may have.

This tutorial aims to provide you with enough information about wood pellet press so that you can make the best decision.

What is a Wood Pellet Press?

A wood pellet press, also known as a wood pellet mill, is a machine that helps in the pelletization of powdered material. The raw material could be crushed wood shavings, sawdust, wood chips, and other wood biomass material.

Many people associate it with a grinding machine. However, like a grinding machine, it does not grind. On the contrary, it turns powdered wooden material into a large uniform mass.

What Does a Wood Pellet Press Do?

As we mentioned above, a wood pellet press machine makes equal-sized pellets from wooden powder. Companies and individuals manufacturing biomass fuel pellets can invest in this machine.

Alone in the United States, about 1.4% of people use wood pellets to keep their homes warm in winters. So, you can save some dollars by investing in a small wood pellet press and making biomass fuel pellets for yourself.

How Much Does a Wood Pellet Press Cost?

There could not be one sure answer for this question. Several factors influence the price of a wood pellet press for sale. For example, the type of machine, country of origin, quality of the machine, and more.

Keep in mind that a commercial wood pellet press is often more expensive than a home-use pellet machine.

An advanced, feature-rich commercial wood pellet press can cost up to USD 50,000. On the other hand, small wood pellet press machines start at around $300.

It is worth noting that Chinese wood pellet presses are less expensive than European pellet presses since the raw material is widely available in the country.

What Is the Working Process of a Wood Pellet Press?

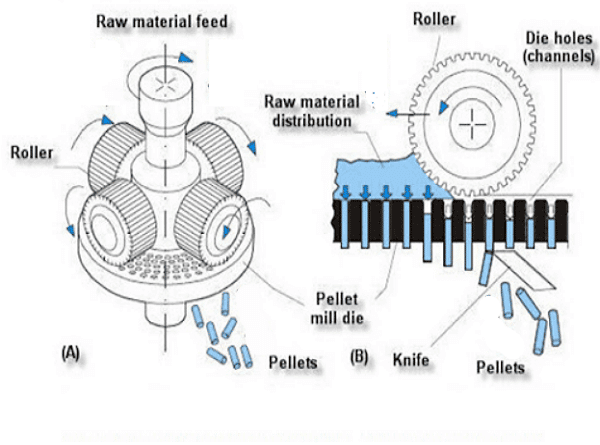

The functioning of a wood pellet press machine differs according to its kind. However, the overall working principle is similar in all wood pellet press machines.

Wood pellet press machines are classified into two types: Ring Die Pellet Machines and Flat Die Pellet Machines.

Flat Die Pellet Machine

As soon as you put the wooden raw material into the feeder hopper, it settles down on a flat die and spreads over it.

When you switch on the machine, the electric motor begins to pull the transmission shaft through the gearbox. There is a pressing roller installed on the shaft that spins around it. Simultaneously, the roller circles around the shaft.

The rotating press applies intense pressure on the raw material so that it can pass through the holes in the flat die. Subsequently, the machine molds the wood material inside these holes and squeezes them out as hard cylinders.

The Ring Die pellet machine further has two types: Roller-Turned and Die turned.

The roller-turned pellet machine has a flat die mounted on the main shaft. When you switch on the machine, only the die rotates while the roller remains still. On the contrary, in the Die-turned machine, the roller rotates along with the shaft whereas the flat die is still.

In both types of machines, you feed raw material through the hopper, and they come out as solid cylinders out of ring die.

How to Choose an Ideal Wood Pellet Press?

When purchasing a wood pellet press, keep the following points in mind.

Find a Reliable Manufacturer

For a first-time buyer, it can be overwhelming to invest in a wood pellet press machine. However, do adequate research to decide the best manufacturer. Since it is going to be a considerable investment, don’t go with any random manufacturer.

Make sure your potential manufacturer fulfills the following requirements.

- The manufacturer must have at least 10 years of expertise.

- They must have a state-of-the-art workshop along with a qualified development team.

- Their wood pellet press machines must pass certifications like CE, ISO, etc.

- You should get full technical support for your purchase.

- The manufacturer must provide after-sales service.

- You must get a legit warranty for manufacturing defects.

- You should be able to test the machine before buying.

Select the Specific Machine

Choose the machine as per the raw material you are going to process through it. If you want to make pellets out of different materials than wood such as rice husk, straw, etc., buy a pellet machine that can process that.

Remember, a pure wood pellet press will not be able to process such raw material. You will need to use only wooden powder to make pellets.

Analyze Exterior and Interior of the Machine

You need to ensure that the outer surface of the machine has smooth, anti-corrosion paint and polishing. Check out if the machine has high-grade metal.

The die of the machine must have uniform holes to produce consistent pellets. Carefully examine the design, thickness, rotation, and hole depth of the pellet die.

Output

It is another crucial thing you must consider when buying a wood pellet press. Generally, a small wood pellet press can produce up to 800Kg pellets per hour. If your requirements are higher, you can look for a commercial wood pellet press. The ring dies pellet machine can produce up to 5000kg pellets per hour.

Safety & User-friendliness

Never compromise on these two factors since they will have a direct influence on your ROI.

There must be a safety linkage in the shaft. In the ring die machine, the compression chamber must have a travel switch connecting the main motor. It will help you avoid getting injured by ring die. Also, check if the hopper has a guard magnet.

Consider the user-friendliness of the machine as well. One should be able to operate it single-handedly.

How to Buy a Budget-friendly Wood Pellet Press?

Below are a few legit methods to save money on your purchase.

Determine Your Needs

Select a wood pellet press based on your needs. Pellet press machines for small, medium, and large-scale production are readily available nowadays. Homemade wood pellet press mills are also available to make pellets on a small scale or for personal usage.

Type of Machine

The type of machine also influences the price of a wood pellet press. For instance, a Ring die pellet machine is comparatively cheaper than a Flat die pellet machine.

However, the flat die pellet machine is better when it comes to output. Fortunately, a modern wood pellet press is a blend of both. You can save a lot by investing in such a machine.

Work with a Chinese Manufacturer

Some buyers are misinformed about Chinese wood pellet presses. They believe they are less expensive because of their poor quality.

However, this is not the case. China is a manufacturing powerhouse, and raw materials are readily accessible in the country. As a consequence, they provide European-standard pellet presses at a reasonable price.

Furthermore, their goods are more affordable due to cheap labor costs and a competitive shipping industry. So you can buy a Chinese wood pellet press to reduce your cost.

How to Use a Wood Pellet Press for Beginners?

The functioning of the pellet machine varies (though slightly) according to its type.

Machine Assembling

Assemble the machine according to the manufacturer’s instructions. Seek their assistance if you do not have an experienced crew for the same. A good company must provide you with all the support required for assembling and operating the machine.

At Tcpel, we provide you with videos, manuals, and drawings for assembling and proper operation. We can also provide on-site assistance on demand.

Lubrication of Machine

Several first-time users make this mistake. They start operating the machine without lubricating it. Ensure the machine is neither over nor under lubricated.

Examine all the crucial parts before operating the machine, especially the mold roll. Ensure all fastening components are appropriately tight.

Putting the Raw Material

Depending on the kind of machine, only use valid raw materials on the feeder. Do not add anything other than wooden material. Add an appropriate amount of raw material, water, and other abrasive material. Add a bit less raw material than the pellet size.

Since the machine will pass pellets at a fast speed, maintain a distance.

Final Step

When wood pellets come out of the machine, they are hot. It may take some time for them to return to room temperature. If you do mass production, invest in a pellet cooler to turn them cool quickly.

The pellets are ready to transport once they have cooled. Depending on your business scale, you can buy a pellet packing machine to pack them in plastic wraps.

How to Care for a Wood Pellet Press?

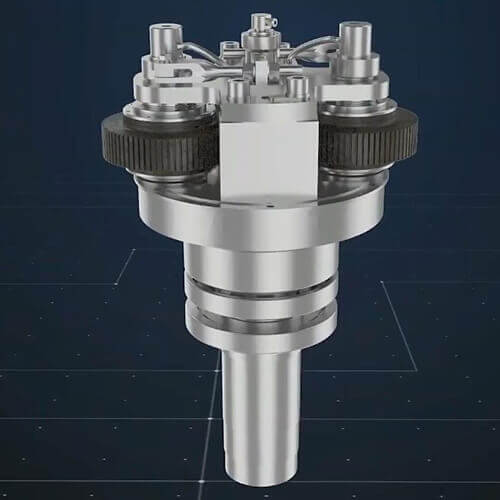

Maintenance regularly may considerably increase the life of your wood pellet press. First, you must know its parts to maintain them. A wood pellet press machine consists of a feeder, die, roller, bearings, transmission shaft, and more.

Give your staff training for the maintenance. If required, seek your manufacturer’s help and go through drawings, videos, manuals provided by them. You may incorporate the following things into your regular maintenance routine.

- The die and roller are two critical machine components. They have a significant influence on product quality and your job efficiency.

Take special care of these two because they wear out soon.

- Clean the roller and die holes regularly so that pellets can come out in a proper shape.

- Add oil mixture in the die after every use to ensure holes are soft. It will also prevent the die from rusting.

- You should lubricate transmission parts for effortless operation.

- Pay close attention to critical components such as bearings, gears, die, and roller.

- Make sure that there is no stone in the wood powder, as this might harm the die.

- Follow manuals and guidelines from your manufacturer for operation. In case of malfunction, shut down the machine immediately. After that, call professionals for inspection and necessary repairs. If you need to change a specific part, replace it with genuine only.

- Along with mechanical components, inspect electrical parts as well.

So this is our detailed guide to wood pellet press. We hope it assists you in making the best decision when purchasing a wood pellet press machine. You can contact us if you have any further queries on the issue.

Tcpel Wood Pellet Press Introduction

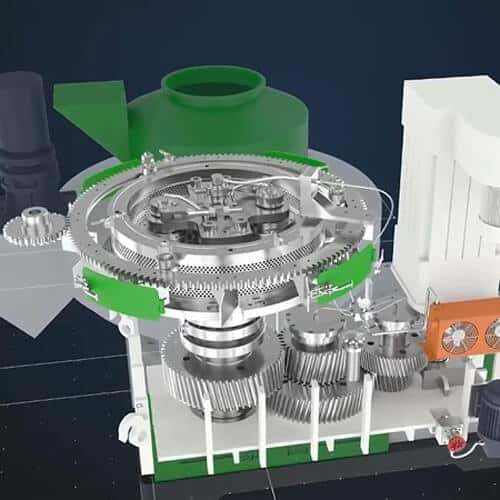

If you want to save energy, increase productivity, and make your business ten times more efficient, you need to consider the Tcpel Wood Pellet Press.

This biomass pellet press offers all the benefits of both a flat die pellet machine and a horizontal ring die pellet mill machine, allowing you to truly get the best of both worlds.

You’ll save money and enjoy a better quality product. It can work with all kinds of materials, including rice or sunflower husks, crop straws, rubber, ash, cement, branches, peanut and other fruit shells, trunks, branches, bark, and much more. It’s not just wood waste that this pellet machine can handle – it can handle just about anything.

It uses alloy steel in its construction for a more secure, reliable build. The die has a fixed and vertical installation that allows easy maintenance and repairs, and the pellet modeling system operates silently and efficiently. This offers a greater life of work along with a more efficient user experience.

Widely used in industry and recommended by experts, the wood pellet press can be used in fertilizer, MSW processing, wood processing, power, biomass energy fuel, and chemical plants. For low investment and high profit, the Tcpel wood pellet press is the way to go.

TcpelWood Pellet Press Features

Tcpel is a professional company that specializes in the production, research, and development of wood pellet press machine. We’ve been around for more than a decade and employ a team of talented engineers and designers. We are ISO 9001, CE, and SGS certified, meaning our products are manufactured under the strictest quality control standards

Based in China, we offer quality machines – guaranteed. Our products are manufactured under these strictest quality control standards. We offer complete installation service for a turn-key experience. We’ll even help train your operators so that they fully understand how to use the new pellet machine onsite.

And after your product has been installed, we’ll provide you with quick, reliable, and responsive after-sale service. From 24/7 email to phone communication or even onsite visits, we’ll be here to help you out.

This heavyweight machine is durable and long-lasting, offering 24 hours of work time with no need to stop and perform maintenance. It has automatic intermittent lubrication to reduce your workload and extend the life of the machine’s parts, too.

It can be used on all kinds of materials, including peanut and fruit shells, branches, stems, and other food waste, sunflower and rice husks, and more. It can be used in chemical plants, fuel plants, wood processing plants, feed mills, and more.

The vertical-laying flat dies to feed directly with a broad range of applications and excellent heat dissipation. It offers improved efficiency for a reduced cost and the best possible performance. Die materials are made out of alloy steel for a longer life span.

The main shaft on this compact, easy-to-operate machine is also wear-resistant and produces wood pellets with a smooth, consistent surface.

This kind of machinery has all the benefits of a horizontal ring die pellet machine combined with a flat die pellet machine. Its double layer die is uniquely assembled with high-quality rolls made out of wear-resistant alloy steel.

The stainless steel dies have a service life of 1000 to 1500 hours, meaning you’ll save money and energy while remaining more efficient. It comes with a built-in cooling system and fan blower to help cool down the pelletizing area. The cooling system of the gearbox helps to extend the internal bearing life and improve the functioning of the machine.

It has a high-strength transmission box and allows you to vertically feed the machine right in place – centrifugal force will take care of the rest. It resists blockages and has wear-resistant bearings.

Its independent frequency conversion discharge device ensures an even and consistent rate of pellet formation.

Tcpel Wood Pellet Press Parameter

| Model | Power(kw) | Pellet Size(mm) | Capacity(t/h) | Size(cm) |

|---|---|---|---|---|

| TCZL560 | 90 | 6-12 | 1-1.5 | 263x130x230 |

| TCZL650 | 160 | 6-12 | 1.5-2.5 | 290x130x240 |

| TCZL850 | 220 | 6-12 | 2.5-3 | 330x140x310 |

| TCZL315 | 315 | 6-12 | 3-4.5 | 380x168x340 |

| TCZL315-450 | 315-340 | 6-12 | 4.5-6 | 410x185x380 |

| TCZL550-660 | 550-660 | 6-12 | 6-10 | 430x198x395 |

Tips When Buying a Wood Pellet Press

In order to serve you better, please try to provide the below information:

1) What is the material to make wood pellets? Better if you can share us some pictures

2) Hardness of your material?

3) Moisture content?

4) Maximum diameter of the material to be processed?

5)The capacity per hour you want to get for the pellet production.

Then we will recommend suitable model based on your actual needs.