Best Fish Feed Pellet Machine Manufacturer in China with 14+ Years Experience

- Већи капацитет и мањи трошкови һабајућиһ делова

- Широк спектар погодности за примену

- Стабилне перформансе трчања и једноставан рад

Fish Feed Pellet Machine - The Beginner's Guide

A fish feed pellet machine, also known as a pellet mill or extruder, might be the piece of equipment you need to take your business to the next level. A feed pellet machine may assist in the transformation of items like soybean meal, corn, or rice husks, among other materials, into smaller pellets. These will be given to animals and eventually help save money and time.

As the leading fish feed pellet machine manufacturer, we’ve included all the information you need about this important piece of equipment, and you’ll find everything you need in this guide.

What is a Fish Feed Pellet Machine?

A feed mill that uses a feed mill to press crushed material such as straw soybean meal, corn, straw, grass, and even rice husk into feed pellets is called a pellet machine. It’s commonly utilized in commercial aquaculture farms, livestock farms, poultry operations, and major, medium, and small food processing facilities.

What are Fish Feed Pellet Machines Used For?

In plain words, a fish feed pellet machine is a tool used to transform materials into smaller pieces. They can be fed to animals that either can’t eat big chunks of food or that would be unhealthy to consume due to their size.

How Does a Fish Feed Pellet Machine Work?

Now that we have covered what a fish feed pellet machine is and what it’s used for let’s dive deeper into the subject and explain how it works.

The compression roller spins as a result of the frictional force between the main axis and flat-die. The starch is fermented at a high temperature between the die and the roller, and the protein concentrates.

It then comes out as tiny pieces of fish food (called “pellets”) from the die’s holes. Of course, the size and shape of these pellets are set by the machine per default. However, you may also adjust the angle of cutting by changing it to suit your needs.

Blend 5 or 10 kilograms of mashed grain with an edible oil containing 5% to 10% fat. If the mash feed clogs, we should break it up to keep the feed-in powder form.

Before you turn on the mill, put the feed into it to get started. Then, until the food can be extruded without difficulty, adjust the press roller bolt.

Before adding dry powder into the machine, we recommend you test the machine and the results with the oily mash feed 3 to 5 times to verify if this is the outcome you need.

Last but certainly not least, pellets come out of the mill very hot and should therefore be placed in a ventilated area to cool down before placing them in their packaging.

How Much Does a Fish Feed Pellet Machine Cost?

A fish feed pellet machine is one of the important pieces of equipment in the industry. It can produce large amounts of premium pellets for fish feeding.

Of course, there are a few factors to think about when checking any fish pellet machine price. Other than the fish feed pellet machine manufacturer in question, the type of mill and its quality play a big role.

For those pellet machines with low production capacity or more home-style ones, the price will be between $300 to $3000.

On the other hand, If you want larger output, you should expect to pay more. The average high output pellet machine’s cost ranges from US$5000 to US$7500, but it can get to tens of thousands of dollars for the priciest ones.

How Many Types of Fish Feed Pellet Machines are There?

There are currently two types of fish feed pellet machines on the market:

- Dry Type Fish Feed Extruder

- Wet Type Fish Feed Extruder

Of course, these are the two different types, but you will find endless models available. They can be categorized into big-scale and little-scale versions. The ring dies pellet machine and the flat die pellet machine is two of the most prevalent pellet mills.

In addition, it’s important to highlight the fact that a fish feed pellet machine isn’t the only piece of equipment you need. These are the important machines you will need in your production line:

- Screw Elevator

- Feed Crusher

- Мрежаста трака за сушење

- Feed Peller Cooler

- Oil Spraying Machine

How to Choose the Best Wood Pellet Machines for Pellet Production?

You will need to think about many elements when selecting your pellet machine for fish feed. Let’s list them one by one.

Quality and Duration

First and foremost, you’ll want a stable and durable machine. It’s crucial to choose a sturdy one with a potent die.

Make sure your pellet machine’s die meets all technical criteria and has a high-quality surface finish. To ensure uniform wood pellets, make sure the inner holes are equally distributed and symmetrical. Choose a die that doesn’t contain blind or joint holes.

If you bought a set of pellet-making equipment and spent much of your time maintaining it, your overall production process will slow down and eventually make you waste time and money.

Energy Consumption and Output

When purchasing a pellet mill, consider both its energy use and output. For example, if the output of the pellet mill is extremely high, but the power consumption is significant, profits will be lower. So before buying a machine, you should understand more about per kilowatt-hour of electricity production.

On top of that, pellet machines can produce 50-800 kg/h, but bigger equipment can reach up to 2,000 kg/h or more. Most manufacturers advise selecting a ring die pellet mill with a custom-made die to remain safe if you require a greater output.

Цена

It would be best if you always chose the most suitable equipment for both your budget and your needs. Sure, as discussed previously, a fish feed pellet machine can be extremely pricey, but you should plan to increase your revenue using a bigger one.

Some sellers may advise you to purchase a lot of supplementary equipment that is perhaps unnecessary and adds to the overall price and being accounted for on the plan. As a result, when selecting a floating fish pellet machine for sale, keep an eye on price rather than features.

Одржавање

Maintenance is an often underestimated element when choosing the machine, and most customers frequently neglect these expenses. Every so often, a normal machine would need to be maintained, and the longer it can stay without maintenance, the higher your profits.

Након продаје

Last but not least, the after-sales service is an important thing to observe. Choose a firm with a good corporate culture that has a strong after-sales staff. It’s critical to have prompt, efficient after-sales service that won’t increase the price for you in any way.

Here at TCPEL, we proudly tick all the boxes above, ensuring that you get the best machine for all the steps in the process. Lastly, our after-sales team makes sure that you remain satisfied after purchase which is a factor that makes us stand out from the other organizations on the market.

How to Make Fish Feed Pellets?

A few steps in the process and other pieces of equipment are involved apart from the fish feed pellet machine.

First of all, the grinding step. The size of the particles is determined in the crushing process by a variety of elements. For instance, the rotor speed, the number, and size of hammer blades, the screen size, the hammer strikes.

A screen with mesh holes must be used to keep objects from passing through the discharge hole of a hammer mill. To control particle size reduction, a screen with diverse-sized holes may be utilized.

The speed of the hammer mill has the most influence on the finished particle size. The hammers whirl around rapidly, striking the material with tremendous impact, breaking it down.

Secondly, the mixing part is just as important as grinding. When grinding ingredients, they then should be mixed them homogenously.

During the mixing part, it’s instrumental in remembering two points: every formulation has its mixing time. If you mix the materials for too long, they will start to decompose. Apart from that, incorporate some ingredients like additives as well to fill the mixer.

After that comes the extruding of the pellets. The process is essentially the extrusion part that can create pellets. The sizes range from less than a millimeter to several centimeters, suitable for different species of fish. After that, fatty acids like fish oil are added.

The pellets need then to be dried. The wet or humid pellets will need to be dried to get to a moisture percentage of 10% or even less whenever possible. In the ideal world, you should do this part of the process at lower temperatures – less than 60 ºC. And with sufficient airflow to dry the pellets as fast as possible. This is to ensure that heat-sensitive nutrients like vitamins are not ruined.

At last, the packing part is the easiest yet not the least important. When the pellets are dry, they must be stored in containers or bags to remain safe from insects, rats and keep moisture away. Plastic bags should be avoided since feeds can sweat, and they can encourage the growth of mold.

How to Use a Feed Pellet Machine?

In terms of operation, each pellet machine is different. However, there are a few basic guidelines that apply to all of them.

To start, adjust the clearance between the pressure roller and the flat die according to how tightly packed the pellets are.

Also, the raw material should be smaller than the pellet size. To make the substance smaller, you may need to use a wood chipper or a hammer mill (or sometimes both). The water ratio of the raw ingredients should also be 12% (or possibly less) before starting.

After that, feed the ingredients through your pellet machine. It will come out at a fast speed, so keep clear. The materials fed into the machine will be shaped into pellets by the die’s hole and then pushed out.

Finally, follow the manufacturer’s instructions when assembling your newly purchased pellet machine. If you’re not comfortable doing it yourself or find it complex, TCPEL provides onsite installation services.

How Does the Maintenance of a Fish Feed Pellet Machine Work?

Every fish feed pellet machine requires regular maintenance. The main goal of routine maintenance is to ensure that all equipment necessary for product manufacture is always operating at full efficiency.

To keep your pellet machine in good working order, you must take certain measures to preserve it. Make sure the pieces of the transmission are lubricated regularly. These should be lubricated to increase their longevity. Change the gearbox’s oil every month and conduct a comprehensive examination of the parts every month. This might include everything from bearings to gears, as well as rollers and dies.

If you detect anything incorrect at any time, you must correct it immediately. Also, make sure all of the components are secure and not loose. Remove and clean the roller after each use.

If the machine is not cleaned, metal or other foreign substances may accumulate inside, causing it to break down eventually. To avoid damage to the equipment, clean up the raw materials. Always inspect extruded goods for quality and replacement of worn components.

How are Fish Feed Pellet Machines Made?

The hopper, in which the feed meal is fed into the machine, and the pelleting chamber are two of the most vital components of a fish feed pellet machine. The shaft is driven by a pulley and belt system powered by an electric motor.

Adequate material selection has to be made to achieve the following goals: easy maintenance, reduce noise, produce machinery at a low cost, improve and lessen dimensions, enhance machine aesthetics, increase mechanical strength and resistance to wear, corrosion, and acid medium.

Mild steel, stainless steel, cast iron, and chemical paint are used to construct machines.

TCPEL Fish Feed Pellet Machine Introduction

This flat die pellet machine is perfect for large, medium, and small companies looking to expand and improve how they process animal feed pellets. Whether you’re an aquaculture plant or a grain factory, or a livestock farm, this pellet feed mill will work wonders for you.

Пољопривредници и компаније за сточну храну користе га широм света. Не захтева сушење ваших сировина, јер чак и састојци у праху могу произвести цилиндричне честице. То ће вам уштедети време и енергију, што ће вам олакшати да зарадите више хране (и више новца) у свом послу.

Покренут снажним мотором, може да пресује пелете за храну и пелете од дрвене пиљевине све док је садржај влаге у сировинама око 12 до 20%. Постоји више пречника калупа које можете изабрати, што вам омогућава да обрађујете материјале једну по једну гранулу – али брзо и ефикасније како бисте своју производну линију одржали на правом путу.

Ево неких од главних карактеристика овог производа:

1. Доступне су вишеструке оцене снаге: Ову машину можете купити са вишеструким називним снагама у распону од 3 КВ у најмањем моделу до 15 КВ или више. То га чини веома ефикасним за фабрике и предузећа било које врсте. Опције снаге варирају у зависности од ваших потреба, укључујући електричну, дизел, бензинску или ПТО. Можете да прилагодите ове опције да би вашу машину учинили лакшом за кретање, снагом и ефикаснијом за рад.

КСНУМКС. Једноставан за руковање: Ова машина за пелете има високу снагу уз ниску потрошњу и ниску буку. Не само да је тих за рад, већ је и једноставан за руковање. Лако је обучити нове оператере да користе машину и потребна је само једна особа за покретање.

3. Захтева минимално одржавање: Одржавање је неопходно за сваку машину за пелете за храну, али са овим производом ћете открити да има делове и компоненте које олакшавају бригу о њима. Има систем за филтрирање под високим притиском и независне системе за подмазивање, тако да нећете стално престати да подмазујете машину.

4. Свестран у својим применама: Можете користити ову машину за пелете за храну за обраду пелета за храну за скоро све врсте врста. Може да ради са стварима као што су љуске пиринча, љуске кикирикија, љуске сунцокрета, делови дрвета и још много тога, што га чини једним од најсвестранијих производа које можете купити. Ради са материјалима високе и ниске густине, ниским садржајем влаге и високим садржајем влаге.

5. Доступно је више отвора: На располагању је неколико различитих отвора који одговарају потребама различитих врста животиња и њиховој потребној храни. Не може се сва храна за храну обрадити кроз исту равну матрицу, тако да ова машина олакшава њихову замену.

Fish Feed Pellet Machine Parameters

| модел | Капацитет | Пинцх Роллер | снага | Напон (В) | тежина | Димензија |

|---|---|---|---|---|---|---|

| ТЦФ120 | КСНУМКС-КСНУМКСкг / х | Двоструки ваљак | КСНУМКСкв | КСНУМКСВ / КСНУМКСВ | КСНУМКСкгс | КСНУМКС * КСНУМКС * КСНУМКСцм |

| ТФЦ150 | КСНУМКС-КСНУМКСкг / х | Двоструки ваљци | КСНУМКСкв | КСНУМКСВ / КСНУМКСВ | КСНУМКСкгс | КСНУМКС * КСНУМКС * КСНУМКСцм |

| ТЦФ200 | КСНУМКС-КСНУМКСкг / х | Двоструки ваљци | КСНУМКСкв | КСНУМКСВ | КСНУМКСкгс | КСНУМКС * КСНУМКС * КСНУМКСцм |

| ТЦФ250 | КСНУМКС-КСНУМКСкг / х | Двоструки ваљци | КСНУМКСкв | КСНУМКСВ | КСНУМКСкгс | КСНУМКС * КСНУМКС * КСНУМКСцм |

| ТЦФ300 | КСНУМКС-КСНУМКСкг / х | Двоструки ваљци | КСНУМКСкв | КСНУМКСВ | КСНУМКСкгс | КСНУМКС * КСНУМКС * КСНУМКСцм |

| ТЦФ350 | КСНУМКС-КСНУМКСкг / х | Двоструки ваљци | КСНУМКСкв | КСНУМКСВ | КСНУМКСкгс | КСНУМКС * КСНУМКС * КСНУМКСцм |

| ТЦФ400 | КСНУМКСкг / х | Двоструки ваљци | КСНУМКСкв | КСНУМКСВ | КСНУМКСкгс | КСНУМКС * КСНУМКС * КСНУМКСцм |

| ТЦФ450 | КСНУМКС-КСНУМКСкг / х | Двоструки ваљци | КСНУМКСкв | КСНУМКСВ | КСНУМКСкгс | КСНУМКС * КСНУМКС * КСНУМКСцм |

TCPEL Fish Feed Pellet Machine Advantages

Притисни ваљак и брусни диск су направљени од хром-манган челика, који је издржљивији након третмана каљења на високим температурама. Новонадограђена шупљина за млевење је 10-20 пута отпорнија на хабање од обичних материјала.

Лако се пуни горивом, једноставно за употребу, ГЛ-5 уље за тешка оптерећења мора се напунити пре употребе.

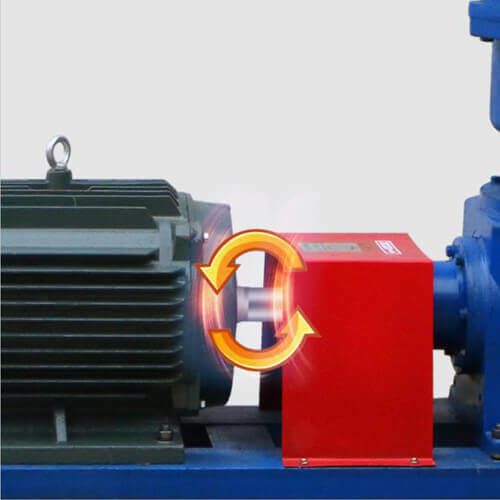

Електрична спојница, директно пристајање, једноставан рад и згодна инсталација. Спојница је стабилна и издржљива, направљена од нерђајућег челика, након третмана гашења на високим температурама, издржљивија од обичних материјала. Новонадограђени погон спојнице, у поређењу са старим ременским погоном, има мањи губитак преносног односа и издржљивији је и отпорнији на хабање

Мотор од 100% бакарне жице, дуг радни век, велика коњска снага, уштеда енергије. Сав бакарни калем, хладњак, дуг радни век, тихи лежај, стабилан рад и ниска бука. Искључите напајање на високој температури да бисте избегли квар узрокован високом температуром

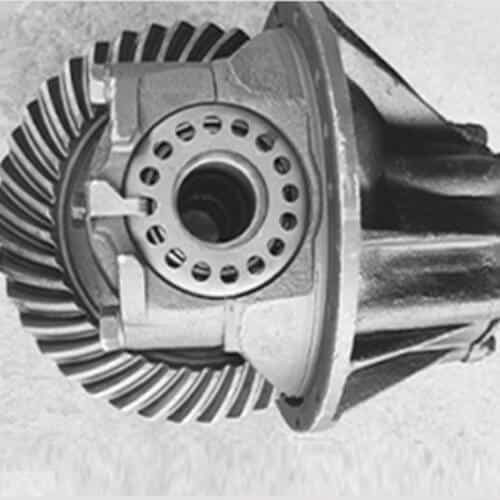

Он усваја дизајн склопа диференцијала задње осовине аутомобила, који има добру комбинацију зупчаника, смањује оптерећење главног мотора и има добру стабилност.

Већи дизајн улаза за довод чини храњење практичнијим, а радну ефикасност већом. Проширени дизајн отвора за пражњење, дизајн са преградама на обе стране како би се избегло просипање хране, проширени и увећани отвор за пражњење, пражњење је брже и глаткије.

Усвојите најлонске клизне точкове, отпорне на хабање и издржљиве