Professional Cattle Feed Pellet Machine Manufacturer, ISO9001 Certificated

- Daha yüksek kapasite ve daha az aşınan parça maliyeti

- Geniş uygulama uygunluğu yelpazesi

- İstikrarlı çalışma performansı ve kolay kullanım

Cattle Feed Pellet Machine-The Beginner's Guide

Do you manage cattle/livestock farming? Purchasing a Sığır Yemi Pelet Makinesi is that solution you need to produce the best quality cattle feeds with balanced nutrients. It’s economical and saves unnecessary cost of buying feeds. The pellet machine for cattle feed is also easy to operate. Read on to learn more about the cattle pellet machine and all you need to know before buying.

What is cattle feed pellet machine?

Cattle feed pellet machine is a multi-component equipment that comprises a feeding system, pelleting system and a drive system that helps to create cattle feed pellets from crushed soybean meal, wheat, grass, corn, etc.

What is cattle feed pellet machine used for?

Cattle feed pellet machine is used to process dry powdered feed into small or medium-sized pellets. The powdered/crushed feed includes cereals, soybean meal, additives, minerals, vitamins, feed preservatives and other necessary trace nutrients.

How does a cattle feed pellet machine work?

Getting the best out of your cattle pellet machine requires that you understand how it works. There are two types of pellet machine for cattle feed: the ring die pellet machine and the flat die pellet machine.

Remember that the cattle pellet machine processes powdered material into pellets. Hence, the first step involves crushing the feed materials like your soybean meal, grass and corn into powder. The powdered materials are then introduced into the cattle feed pellet machine, where a centrifugal component does the mixing.

For the flat die machines, a roller presses upon the mixed materials till they form pellets. The pellets are cooled and there is a cutting knife to get them to the desired shape.

The process is also similar to that of ring die machines, except that the powdered feed forms pellets by being squeezed through the holes of the rolling ring die.

How much does a cattle feed pellet machine cost?

There is no fixed cattle feed pellet machine cost and the price range depends on the production capacity you plan to achieve. The cattle feed pellet machine price for an average setup starts from about $1000 to $2000. Such feed mills are suitable for small businesses with low market demand.

However, you can still get a budget-friendly pellet machine for cattle feed. Some could be as low as $500, but with minimal function because of the price.

Purchasing a cattle feed pellet machine with complete functionality should cost about $2500 or more. The higher cost should not scare you. It only means higher utilization and higher production rate.

How to choose the best cattle feed pellet machines for pellet production?

The cattle feed pellet machine price is not all that matters when purchasing one. There is more to choosing the best pellet machine for cattle feed.

Here, we have highlighted some of the essential factors to consider.

Raw material type

Both the flat die and ring die pellets are compatible with any type of feed material you choose to use. The ring die is the more preferred option for grass feed materials. It is more efficient and meets the compression ratio requirements.

Percentage of grass powder

The percentage of powder in feed material should affect your choice of pellet machine for cattle feed. Use the flat die machine for small production involving feed materials with a high proportion of powder. Larger production outputs require the ring die pellet mill because it has the mechanism to prevent blockage caused by the powders.

Hayvan türü

The animal type determines the type of feed pellet machine you will buy. That is because the feed pellet mill must be able to produce the required diet concentration. A thinner die is enough to produce cattle feed pellets, while we recommend a thicker one for pigs and chicken.

Üretim kapasitesi

The cattle pellet machine has an instructional manual or book that should contain the production capacity. Make sure your desired choice of cattle pellet mill meets your targeted production level. It is even more advisable to choose a machine with slightly higher capacity than is required. If you are going to be having 24/7 production schedules, check for ring die pellet machines instead.

Power

Asides from the name of the cattle feed pellet machine manufacturer, the power rating is another information on the manual. It helps to choose the best cattle feed pellet machine for cattle production because it indicates the output capacity.

How to make cattle feed pellets?

Learn the practical procedures to make the best cattle feed pellets in easy steps.

Step 1. Gather your raw materials

Depending on the cattle diet formula, there are some set of nutrients that must be available. The expected nutrients are present in your corn, wheat, grass, soybean meal, fish meal, and so on. Source for these raw materials from the market or get a supplier to send them to you at a cheaper rate.

Step 2. Get a balanced nutritional formula

Ensure the composition of nutrients from your raw materials matches the recommended nutritional formula for your cattle. For example, a matured cow in the mid-trimester of pregnancy would require about 7% protein and 48.8% TDN. It is slightly different for a 2-year-old heifer that needs more of protein and TDN (8.6% and 59.3% respectively) in the last pregnancy trimester. Verify the specific diet formula for your cattle breed.

Step 3. Prepare the premix

The premix is a combination of all your powdered raw ingredients, such as your fish meal. Measure and record their combined proportions. It’s a premix, so you can decide to store them until it is time to make the pellets.

Not: use minimal fat as possible. Excess fat has the potential to reduce the feed’s quality and might even affect the cattle pellet machine.

Step 4. Crush the whole grains

You can use a stone for crushing during minimal production. However, we recommend a feed grinder. Uniformly crush the raw grains before adding them to the premix. Do the mixing with hand or a feed mixer, depending on the production volume.

Step 5. Introduce the mixed raw materials into the cattle pellet machine

Safety first! Read the instructional manual before getting started. The pellet machine automatically helps to compress the raw feeds into pellets. Although you might need to use a pellet drying machine to remove left-over moisture after production. It’s optional anyway.

Step 6. Store in a cool, dry place

This step is important for those that do not plan using the pellets immediately. Store them in a dry container free from moisture.

Step 7. Clean up after use

Properly clean the pellet machine and periodically lubricate the moving parts to keep the machine in good working condition.

How to use a cattle feed pellet machine for beginners?

We have broken down some of the cattle feed pellet procedures for beginners to understand quickly.

1. Sort the raw materials

You probably do not want to end up having strange items like metals or tiny plastics in your cattle feed. That’s why it is essential to sort the raw materials before introducing them to the pellet machine.

2. Crush the raw materials

Crushing or grinding the sorted raw materials ensures that proper mixing is done. It also hastens the pellet production process. The crushed materials should be smaller than the die holes to avoid clogging.

3. Pre-treat the raw materials feed

This step includes checking for excess moisture. Wet raw materials affect the pellets’ quality while the ones that are too dry do not properly form.

4. Consider the adhesive properties of raw mix

Some of the raw materials combine better to form pellets. For example, rice husk alone will not properly mash unless we mix it with a secondary binder like sawdust. Try making enquiries to avoid wasting raw materials. You can also carry out small production samples before starting large-scale production.

5. Aim for uniform pellet length

The settings for the pellet machine’s slicer determine the length of the produced pellets. That means you can always adjust cattle pellets’ size. However, the thickness of the pellets depends on the hole size of the flat or ring die.

6. Cool the produced pellets

The pellets can be very hot after production and should be allowed to cool before packaging. Also, ensure there is no moisture before storage.

7. Properly clean the machine

It is poor practice to shut down the cattle feed pellet machine immediately after use. Proper maintenance ethics include cleaning off remnants of the raw materials feed. Also lubricate the machine and let it work for a little longer to allow proper oil circulation.

How to maintain a cattle feed pellet machine?

With increasing cattle feed pellet machine cost, keeping your pellet machine in optimal working conditions after every use is vital. The following are some ways to maintain your cattle feed pellet machine:

Her kullanımdan sonra temizleyin

The keyword here is “every”. It is not enough to use the pellet machine and abandon until the next production operation. Dust from the powdered materials gets accumulated between the machine parts until they are cleaned.

Lubricate after prolonged use

If you’re conversant with the cattle pellet mill, you understand that the parts sometimes get hot after long hours of use. That might cause some of the oiled parts to become dry. That is why cattle feed pellet machine manufacturers recommend lubrication after about 7-8 hours of use.

Maintain a fixed maintenance schedule

Create a preventive maintenance schedule. Let’s say every six months to ensure all parts of the cattle pellet machine are fully functional.

TCPEL Cattle Feed Pellet Machine Introduction

TCPEL cattle feed pellet machine is perfect for large, medium, and small companies looking to expand and improve how they process animal feed pellets. Whether you’re an aquaculture plant or a grain factory, or a livestock farm, this pellet feed mill will work wonders for you.

Çiftçiler ve hayvan yemi şirketleri bunu tüm dünyada kullandı. Toz halindeki bileşenler bile silindirik parçacıklar üretebileceğinden, ham maddelerinizin kurutulmasını gerektirmez. İşinizde daha fazla yem (ve daha fazla para) kazanmanızı kolaylaştırarak zamandan ve enerjiden tasarruf etmenizi sağlar.

Güçlü bir motor tarafından tahrik edilen bu makine, hammaddelerin nem içeriği yaklaşık %12 ila 20 olduğu sürece yem peletlerini ve odun talaşı peletlerini presleyebilir. Aralarından seçim yapabileceğiniz çok sayıda kalıp çapı vardır ve malzemeleri her seferinde tek bir granül olarak işlemenize olanak tanır – ancak üretim hattınızı doğru yolda tutmak için hızlı ve daha verimli.

İşte bu ürünün temel özelliklerinden bazıları:

1. Birden fazla güç derecelendirmesi mevcut: Bu makineyi, en küçük modelde 3 KW'tan 15 KW'a veya daha fazlasına kadar birden çok güç değerinde satın alabilirsiniz. Bu, fabrikalar ve her türden işletme için son derece verimli olmasını sağlar. Elektrik, dizel, benzin veya PTO dahil olmak üzere güç seçenekleri ihtiyaçlarınıza göre değişir. Bu seçenekleri, makinenizi daha kolay hareket ettirmek, güç sağlamak ve daha verimli çalıştırmak için uyarlayabilirsiniz.

2. Çalıştırması kolay: Bu yem pelet makinesi, düşük tüketim ve düşük gürültü ile yüksek bir çıktıya sahiptir. Sadece çalıştırması sessiz olmakla kalmaz, aynı zamanda çalıştırması da kolaydır. Yeni operatörleri makineyi kullanmaları için eğitmek kolaydır ve çalıştırması için yalnızca bir kişi gerekir.

3. Minimum bakım gerektirir: Bakım, herhangi bir yem peleti makinesi için esastır, ancak bu üründe, bakımını kolaylaştıran parçalara ve bileşenlere sahip olduğunu göreceksiniz. Yüksek basınçlı filtreleme sistemine ve bağımsız yağlama sistemlerine sahiptir, bu nedenle makineyi yağlamaktan sürekli vazgeçmezsiniz.

4. Uygulamalarında çok yönlü: Bu yem peleti makinesini hemen hemen her türden tür için yem peletlerini işlemek için kullanabilirsiniz. Pirinç kabukları, yer fıstığı kabukları, ayçiçeği kabukları, ahşap parçalar ve çok daha fazlası gibi şeylerle çalışabilir, bu da onu satın alabileceğiniz en çok yönlü ürünlerden biri yapar. Yüksek yoğunluklu ve düşük yoğunluklu malzemelerle, düşük nem içeriğiyle ve benzer şekilde yüksek nem içeriğiyle çalışır.

5. Çoklu açıklıklar mevcuttur: Farklı hayvan türlerinin ihtiyaçlarına ve gerekli yemlerine uyacak şekilde birkaç farklı açıklık mevcuttur. Tüm yemler aynı düz kalıpta işlenemez, bu nedenle bu makine onları değiştirmeyi kolaylaştırır.

Cattle Feed Pellet Machine Parameters

| Model | Kapasite | pinch Merdane | Power | Gerilim (V) | Ağırlık | Boyut |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg / saat | Çift silindir | 2.2kw | 220V / 380V | 95kgs | 68 * 42 * 53cm |

| TFC150 | 150-200kg / saat | Çift silindirler | 7.5kw | 220V / 380V | 100kgs | 72 * 45 * 65cm |

| TCF200 | 300-400kg / saat | Çift silindirler | 11kw | 380V | 180kgs | 126 * 53 * 92cm |

| TCF250 | 600-800kg / saat | Çift silindirler | 15kw | 380V | 320kgs | 131 * 54 * 93cm |

| TCF300 | 800-1000kg / saat | Çift silindirler | 22kw | 380V | 400kgs | 146 * 59 * 110cm |

| TCF350 | 1000-1200kg / saat | Çift silindirler | 30kw | 380V | 580kgs | 186 * 70 * 128cm |

| TCF400 | 2000kg / h | Çift silindirler | 37kw | 380V | 680kgs | 206 * 76 * 137cm |

| TCF450 | 2000-2500kg / saat | Çift silindirler | 45kw | 380V | 780kgs | 218 * 79 * 140cm |

TCPEL Cattle Feed Pellet Machine Advantages

Basınç silindiri ve taşlama diski, yüksek sıcaklıkta söndürme işleminden sonra daha dayanıklı olan krom-mangan çeliğinden yapılmıştır. Yeni yükseltilmiş öğütme boşluğu, sıradan malzemelerin aşınma direncinin 10-20 katıdır.

Yakıt ikmali kolay, kullanımı basit, GL-5 ağır hizmet dişli yağı kullanımdan önce doldurulmalıdır.

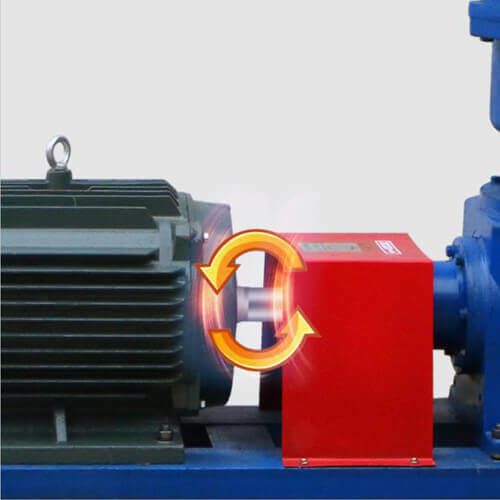

Elektrikli bağlantı, doğrudan yerleştirme, basit kullanım ve uygun kurulum. Kaplin, yüksek sıcaklıkta söndürme işleminden sonra, sıradan malzemelerden daha dayanıklı, paslanmaz çelikten yapılmış, sağlam ve dayanıklıdır. Yeni yükseltilmiş kaplin tahriki, eski kayış tahrikine kıyasla daha az aktarım oranı kaybına sahiptir ve daha dayanıklı ve aşınmaya dayanıklıdır

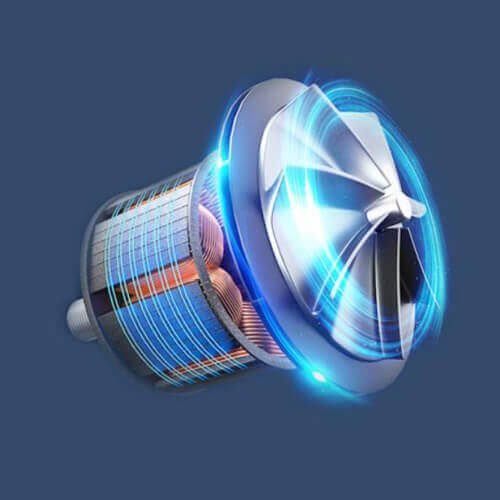

%100 bakır tel motor, uzun kullanım ömrü, büyük beygir gücü, güç tasarrufu. Tamamen bakır bobin, ısı emici, uzun hizmet ömrü, sessiz yatak, kararlı çalışma ve düşük gürültü. Yüksek sıcaklıktan kaynaklanan arızaları önlemek için yüksek sıcaklıkta gücü kapatın

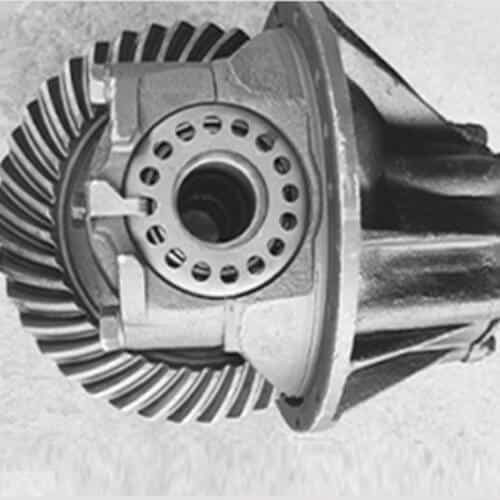

İyi bir dişli kombinasyonuna sahip olan, ana motor üzerindeki yükü azaltan ve iyi bir dengeye sahip olan otomobil arka aks diferansiyel tertibatı tasarımını benimser.

Daha büyük yem girişi tasarımı, beslemeyi daha rahat ve iş verimliliğini daha yüksek hale getirir Genişletilmiş tahliye portu tasarımı, yemin dökülmesini önlemek için her iki tarafta bölmeli tasarım, genişletilmiş ve büyütülmüş tahliye portu, daha hızlı ve daha pürüzsüz tahliye.

Aşınmaya dayanıklı ve dayanıklı naylon sürgülü tekerlekler benimseyin