Nhà sản xuất máy ép viên thức ăn chuyên nghiệp, được chứng nhận CE

- Chúng tôi là nhà sản xuất máy viên hàng đầu

- Nhà máy hơn 15 năm với chứng chỉ CE ISO9001

- Hơn 1000 khách hàng hài lòng trên toàn thế giới

- vận chuyển đến hơn 60 quốc gia

- máy viên được làm bằng thép cấp cao nhất

- dễ dàng hơn để bắt đầu nhà máy sản xuất thức ăn viên của bạn

- Dịch vụ trực tuyến 24 * 7 giờ

Chính sách bảo mật: Bảo mật và quyền riêng tư được đảm bảo 100%

lợi thế của máy Feed Pellet của chúng tôi

Máy ép viên thức ăn chăn nuôi của chúng tôi là lựa chọn hoàn hảo cho các công ty lớn, vừa và nhỏ đang tìm cách mở rộng và cải tiến quy trình sản xuất viên thức ăn chăn nuôi. Cho dù bạn là nhà máy nuôi trồng thủy sản hay nhà máy sản xuất ngũ cốc hay trang trại chăn nuôi, nhà máy thức ăn viên này sẽ mang lại hiệu quả tuyệt vời cho bạn.

Nông dân và các công ty thức ăn chăn nuôi đã sử dụng nó trên toàn thế giới. Nó không yêu cầu nguyên liệu thô của bạn phải được sấy khô, vì ngay cả các nguyên liệu dạng bột cũng có thể tạo ra các hạt hình trụ. Nó sẽ giúp bạn tiết kiệm thời gian và năng lượng, giúp bạn dễ dàng kiếm được nhiều nguồn cấp dữ liệu hơn (và nhiều tiền hơn) trong công việc kinh doanh của mình.

Được điều khiển bởi một động cơ mạnh mẽ, nó có thể ép viên thức ăn chăn nuôi và ép viên mùn cưa gỗ miễn là độ ẩm của nguyên liệu thô khoảng 12 đến 20%. Có nhiều đường kính khuôn mà bạn có thể chọn, cho phép bạn xử lý vật liệu từng hạt một – nhưng nhanh chóng và hiệu quả hơn để giữ cho dây chuyền sản xuất của bạn đi đúng hướng.

Dưới đây là một số tính năng chính của máy ép viên thức ăn chăn nuôi của chúng tôi:

1. Nhiều xếp hạng sức mạnh có sẵn: Bạn có thể mua máy này với nhiều mức công suất khác nhau, từ 3 KW ở kiểu máy nhỏ nhất cho đến 15 KW trở lên. Điều này mang lại hiệu quả cao cho các nhà máy và doanh nghiệp dưới mọi hình thức. Các tùy chọn nguồn khác nhau tùy thuộc vào nhu cầu của bạn, bao gồm điện, dầu diesel, xăng hoặc PTO. Bạn có thể điều chỉnh các tùy chọn này để làm cho máy của bạn dễ dàng di chuyển, cung cấp năng lượng và chạy hiệu quả hơn.

2. Dễ dàng hoạt động: Máy tạo viên thức ăn chăn nuôi này có sản lượng cao với mức tiêu thụ thấp và tiếng ồn thấp. Nó không chỉ hoạt động yên tĩnh mà còn dễ vận hành. Thật dễ dàng để đào tạo những người vận hành mới sử dụng máy và chỉ cần một người để vận hành.

3. Yêu cầu bảo trì tối thiểu: Bảo trì là điều cần thiết đối với bất kỳ máy ép viên thức ăn chăn nuôi nào, nhưng với sản phẩm này, bạn sẽ thấy rằng máy có các bộ phận và bộ phận giúp bạn dễ dàng bảo dưỡng. Máy có hệ thống lọc áp suất cao và hệ thống bôi trơn độc lập, vì vậy bạn sẽ không phải ngừng bôi trơn máy liên tục.

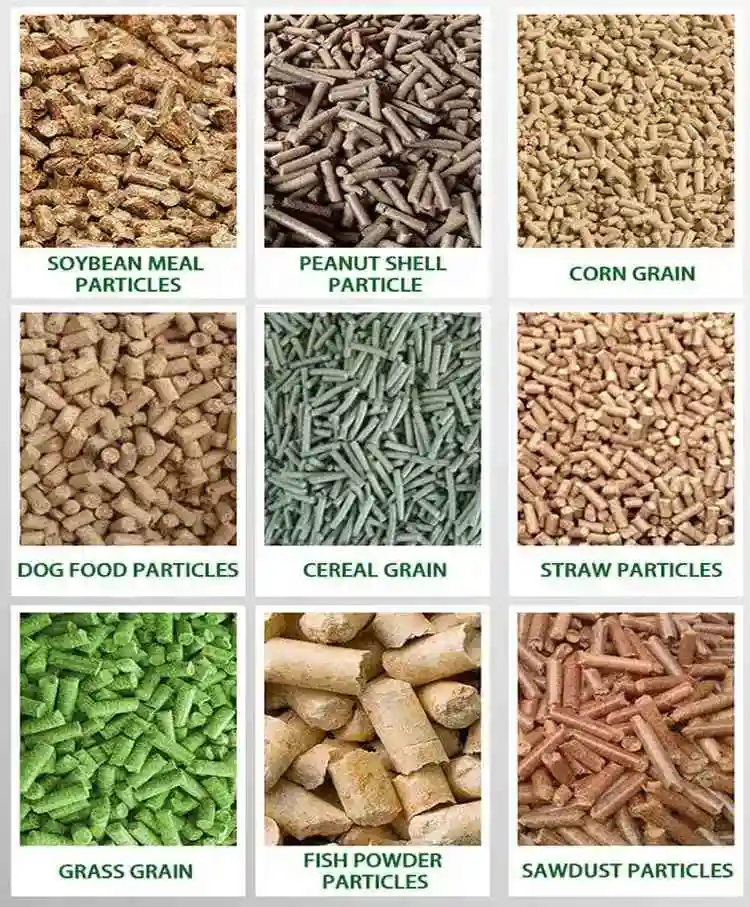

4. Đa năng trong các ứng dụng của nó: Bạn có thể sử dụng máy ép viên thức ăn này để chế biến thức ăn viên cho bất kỳ loại loài nào. Nó có thể hoạt động với những thứ như trấu, vỏ đậu phộng, vỏ hướng dương, các bộ phận bằng gỗ, v.v., khiến nó trở thành một trong những sản phẩm linh hoạt nhất mà bạn có thể mua. Nó hoạt động với các vật liệu có mật độ cao và mật độ thấp, độ ẩm thấp và độ ẩm cao như nhau.

5. Nhiều khẩu độ có sẵn: Một số khẩu độ khác nhau có sẵn để phù hợp với nhu cầu của các loại động vật khác nhau và thức ăn cần thiết của chúng. Không phải tất cả nguồn cấp dữ liệu đều có thể được xử lý thông qua cùng một khuôn phẳng, vì vậy chiếc máy này giúp bạn dễ dàng thay đổi chúng.

Con lăn áp lực và đĩa mài được làm bằng thép crom-mangan, bền hơn sau khi xử lý tôi ở nhiệt độ cao. Khoang mài mới được nâng cấp có khả năng chống mài mòn gấp 10-20 lần so với vật liệu thông thường.

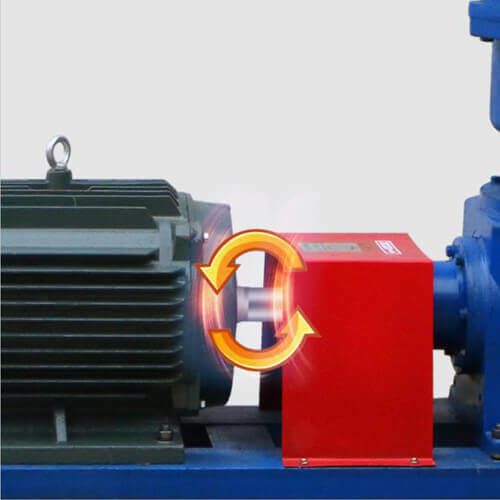

Khớp nối điện, lắp trực tiếp, vận hành đơn giản, lắp đặt thuận tiện. Khớp nối ổn định và bền, được làm bằng thép không gỉ, sau khi xử lý tôi ở nhiệt độ cao, bền hơn vật liệu thông thường. Bộ truyền động khớp nối mới được nâng cấp, so với bộ truyền động đai cũ, ít bị mất tỷ số truyền hơn, bền hơn và chống mài mòn hơn

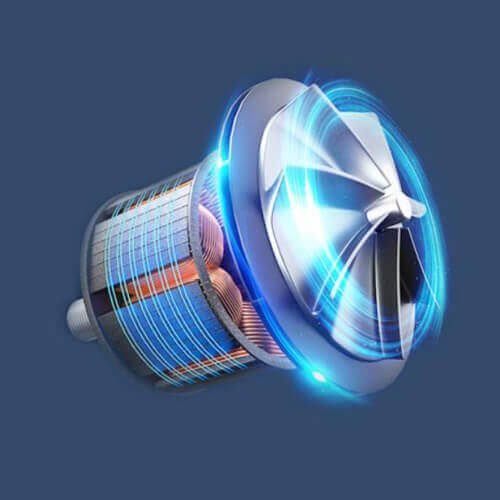

Động cơ 100% dây đồng, tuổi thọ cao, mã lực lớn, tiết kiệm điện năng. Tất cả cuộn dây bằng đồng, tản nhiệt, tuổi thọ cao, ổ trục không ồn, hoạt động ổn định và ít tiếng ồn. Tắt nguồn ở nhiệt độ cao để tránh sự cố do nhiệt độ cao

Thiết kế cửa nạp liệu lớn hơn giúp cho việc nạp liệu thuận tiện hơn và hiệu quả công việc cao hơn Thiết kế cửa xả mở rộng, thiết kế có vách ngăn ở cả hai bên để tránh thức ăn tràn ra ngoài, cửa xả được mở rộng và mở rộng, xả nhanh hơn và mượt mà hơn.

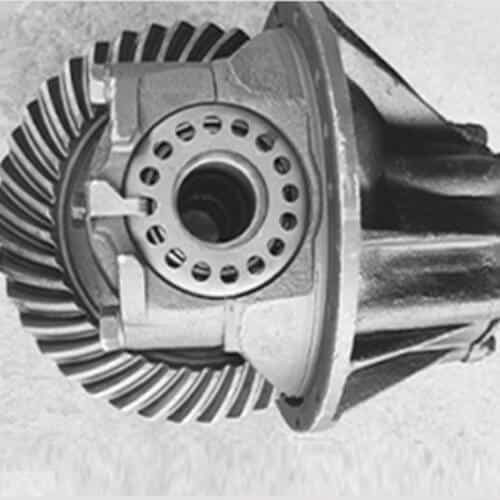

Nó áp dụng thiết kế lắp ráp vi sai trục sau ô tô, có sự kết hợp bánh răng tốt, giảm tải cho động cơ chính và có độ ổn định tốt.

Dễ tiếp nhiên liệu, sử dụng đơn giản, dầu hộp số hạng nặng GL-5 phải được đổ đầy trước khi sử dụng.

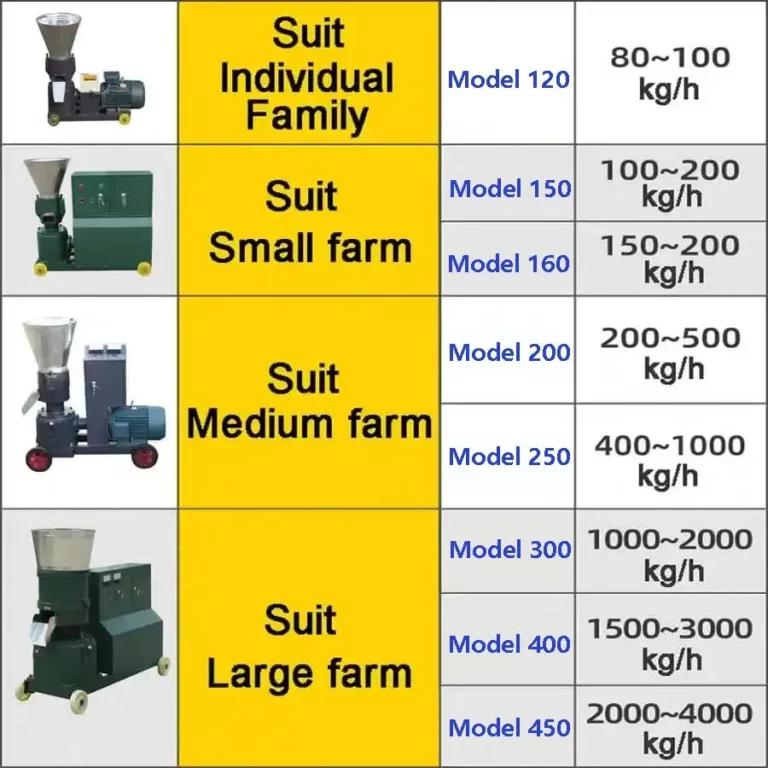

Đề xuất mô hình máy viên thức ăn chăn nuôi

Dựa trên quy mô sản xuất thức ăn viên của các khách hàng khác nhau, chúng tôi có nhiều mô hình khác nhau để sản xuất thức ăn viên, bạn muốn sản xuất thức ăn viên tại nhà hoặc sản xuất thức ăn viên trang trại quy mô lớn, chúng tôi có thể cung cấp cho bạn giải pháp tùy chỉnh. Công suất từ 100kgs/h đến 20t/h thức ăn chăn nuôi viên .

| Mô hình | Sức chứa | Pinch roller | Power | Điện áp (V) | Trọng lượng máy | kích thước |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg / h | con lăn đôi | 2.2kw | 220V / 380V | 95kgs | 68 42 * * 53cm |

| TFC150 | 150-200kg / h | Con lăn đôi | 7.5kw | 220V / 380V | 100kgs | 72 45 * * 65cm |

| TCF200 | 300-400kg / h | Con lăn đôi | 11kw | 380V | 180kgs | 126 53 * * 92cm |

| TCF250 | 600-800kg / h | Con lăn đôi | 15kw | 380V | 320kgs | 131 54 * * 93cm |

| TCF300 | 800-1000kg / h | Con lăn đôi | 22kw | 380V | 400kgs | 146 59 * * 110cm |

| TCF350 | 1000-1200kg / h | Con lăn đôi | 30kw | 380V | 580kgs | 186 70 * * 128cm |

| TCF400 | 2000kg / h | Con lăn đôi | 37kw | 380V | 680kgs | 206 76 * * 137cm |

| TCF450 | 2000-2500kg / h | Con lăn đôi | 45kw | 380V | 780kgs | 218 79 * * 140cm |

về chúng tôi

TCPEL là nhà sản xuất máy ép viên chuyên nghiệp tại Trung Quốc kể từ năm 2004. Nhà máy của chúng tôi tích hợp nghiên cứu và phát triển, sản xuất, bán hàng và dịch vụ, chúng tôi có thiết bị hiện đại để sản xuất và đội ngũ nghiên cứu và phát triển kỹ thuật xuất sắc.

Kích thước nhà máy: 40000㎡

Nhân viên làm việc: 200+

Giá trị xuất khẩu hàng năm: 15 triệu USD

Chúng tôi có đội ngũ dịch vụ sau bán hàng có kinh nghiệm và tay nghề cao. Dựa trên các yêu cầu chi tiết của khách hàng, chúng tôi luôn có thể cung cấp các giải pháp thỏa mãn cho các dự án sản xuất viên.

Chất lượng và dịch vụ là linh hồn của chúng tôi để phát triển công ty, chúng tôi sẽ cố gắng hết sức để hỗ trợ khách hàng trong việc sản xuất viên nén, để đạt được sự hợp tác đôi bên cùng có lợi.

Tại sao hơn 1000 khách hàng chọn chúng tôi?

kỹ sư của chúng tôi

Chúng tôi tuyển dụng các kỹ sư chuyên nghiệp, tay nghề cao cống hiến cho việc nghiên cứu và cải tiến tất cả các sản phẩm của mình. Các kỹ sư cao cấp của chúng tôi có trình độ cao với bằng cấp cao. Các kỹ sư R&D giàu kinh nghiệm và khéo léo của chúng tôi có thể giúp giải quyết các vấn đề của bạn liên quan đến máy móc hoặc sản xuất và hỗ trợ dịch vụ sau bán hàng.

Kiểm soát chất lượng nghiêm ngặt

Chất lượng là quan trọng đối với chúng tôi. Chúng tôi được chứng nhận IS0 9001, CE và SGS. Tất cả các thành phần được sử dụng trong máy của chúng tôi đều vượt qua kiểm tra chất lượng nghiêm ngặt của chúng tôi. Chúng tôi tiến hành chạy thử cho từng máy và thử nghiệm trước khi giao hàng.

Giá cả cạnh tranh

Quản lý ngân sách của bạn một cách thông minh và giảm thiểu chi phí sản xuất của bạn. Chúng tôi cung cấp giá cả cạnh tranh cho tất cả các máy của chúng tôi. Liên hệ với nhóm bán hàng của chúng tôi để được hỗ trợ cho các giải pháp tùy chỉnh.

Đội ngũ bán hàng chuyên nghiệp

Chúng tôi có một nhóm bán hàng quốc tế có trình độ cao sẽ trả lời bạn trong vòng 24 giờ về bất kỳ câu hỏi nào trước khi bán hàng mà bạn có thể có. Sau khi bán hàng, chúng tôi cung cấp liên lạc qua email và điện thoại 24/7 và có thể sắp xếp hỗ trợ tại chỗ.

Hỗ trợ kỹ thuật đầy đủ

Hỗ trợ đầy đủ 24/7 cả trước và sau khi bạn mua hàng. Chúng tôi cung cấp thử nghiệm miễn phí để phát triển quy trình sản xuất tại doanh nghiệp của bạn và tận tâm tìm ra giải pháp tốt nhất cho các nhu cầu cụ thể của bạn. Nếu bạn quan tâm đến việc hợp tác với chúng tôi để bán máy móc của chúng tôi, chúng tôi rất sẵn lòng tham khảo ý kiến của bạn.

đặt hàng và thanh toán

Đặt hàng với chúng tôi là nhanh chóng và thuận tiện. Đội ngũ bán hàng chuyên nghiệp của chúng tôi nhanh chóng trả lời các câu hỏi và cố gắng giải quyết các vấn đề của bạn, cả trước và sau bán hàng. Chúng tôi chấp nhận một cách an toàn tất cả các hình thức thanh toán bao gồm chuyển khoản T/T, LC trả ngay, PayPal và Western Union.

Feed Pellet Machine- Hướng dẫn cho người mới bắt đầu

Máy thức ăn viên là một nhà máy thức ăn viên được thiết kế và sản xuất tốt, lý tưởng để sản xuất thức ăn viên từ nhiều loại nguyên liệu thô. Nó rất dễ vận hành và có thể được sử dụng trong cả hoạt động quy mô nhỏ và quy mô lớn. Máy này có thể được sử dụng để tạo thức ăn viên dạng viên từ nhiều phụ phẩm nông nghiệp như lõi ngô, rơm rạ, rơm lúa mạch, đầu hoa hướng dương, vỏ đậu phộng cũng như từ các nguyên liệu thô khác như xơ bông, bã mía, v.v. thế giới của máy ép viên thức ăn gia cầm? Bạn đã nghe rất nhiều thông tin ném vào bạn và bây giờ chỉ cảm thấy choáng ngợp? Hướng dẫn dành cho người mới bắt đầu này sẽ cung cấp cho bạn mọi thứ bạn cần biết để bắt đầu với máy tạo viên thức ăn chăn nuôi. Cho dù bạn là người mới bắt đầu hay chuyên gia dày dạn kinh nghiệm, hướng dẫn của chúng tôi về máy tạo viên thức ăn chăn nuôi sẽ cung cấp thông tin chi tiết cho cả người mới bắt đầu và người dùng cao cấp hơn.

Máy tạo viên thức ăn chăn nuôi là gì?

Máy ép viên thức ăn chăn nuôi hay còn gọi là máy ép viên thức ăn gia súc, máy nghiền thức ăn viên, là loại máy dùng để chế biến các loại nguyên liệu như bã đậu nành, ngô, trấu, cỏ, rơm, v.v thành thức ăn viên có thể dùng làm thức ăn cho gia súc.

Máy ép viên thức ăn chăn nuôi là thiết bị được sử dụng phổ biến nhất để tạo viên thức ăn chăn nuôi nhỏ. Máy làm viên thức ăn chăn nuôi có thể tạo ra nhiều loại viên khác nhau bằng cách điều chỉnh nguyên liệu và công thức nấu ăn. Máy ép viên thức ăn chăn nuôi được sử dụng rộng rãi trong chăn nuôi gia cầm, gia súc, lợn, ngựa và các ngành chăn nuôi khác.

Máy tạo viên thức ăn chăn nuôi làm gì?

Máy ép viên thức ăn chăn nuôi là thiết bị biến nguyên liệu thành những viên nhỏ, giúp vật nuôi dễ ăn hơn.

Quá trình tạo viên từ nguyên liệu thô được gọi là ép viên. Sản phẩm thu được thường được gọi là thức ăn viên. Thức ăn viên đôi khi được gọi là thức ăn khô hoặc thức ăn chăn nuôi.

Máy ép viên thức ăn chăn nuôi có thể được sử dụng cho nhiều loại nguyên liệu thô, bao gồm ngũ cốc, ngô và đậu nành. Máy ép viên thức ăn chăn nuôi cũng có thể được sử dụng để sản xuất các loại thức ăn vật nuôi hoặc thức ăn chăn nuôi khác.

Những máy này hoạt động bằng cách đầu tiên lấy nguyên liệu thô và sau đó nghiền thành bột bằng máy nghiền búa. Máy nghiền búa sẽ phá vỡ vật liệu thành các hạt nhỏ hơn cho đến khi chúng đủ nhỏ để vừa với máy nghiền. Sau đó, máy nghiền này sẽ tiếp tục nghiền vật liệu thành các hạt thậm chí còn mịn hơn trước khi đưa chúng qua một bộ phân loại sẽ tách ra bất kỳ tạp chất hoặc vật thể lạ nào có thể xâm nhập vào hỗn hợp trong quá trình xử lý. Sau khi hoàn thành bước cuối cùng này, thành phẩm sẽ sẵn sàng để đóng gói và vận chuyển đến các nhà phân phối, những người sẽ bán nó trên các kệ bán lẻ trên khắp thế giới!

Máy tạo viên thức ăn chăn nuôi hoạt động như thế nào?

Máy ép viên thức ăn chăn nuôi hoạt động theo cách tương đối đơn giản.

Đầu tiên, bạn sẽ nghiền nhỏ nguyên liệu bằng máy. Bạn có thể cho tất cả các loại nguyên liệu vào máy làm thức ăn viên, bao gồm ngô, lúa mì, cỏ, cám, v.v. Khi cho nguyên liệu vào cần nghiền nhỏ để đảm bảo tất cả các loại hạt đều được tạo thành dạng hộp, dạng bột.

Sau đó, máy viên trộn tất cả các thành phần. Thiết bị trộn kết hợp các loại bột theo các phần khác nhau, tạo thành một hỗn hợp được gọi là hỗn hợp nghiền. Trong một số trường hợp, quá trình này dừng lại – nhiều công ty mua thức ăn nghiền để làm thức ăn cho động vật (như gà con) vì chúng dễ tiêu hóa hơn.

Nếu bạn có một máy tạo viên nhỏ hoặc máy tạo viên thức ăn tự chế, đây có thể là nơi bạn chọn dừng khi chế biến một số loại thực phẩm. Bằng cách đó, bạn có thể điều chỉnh sản phẩm của mình phù hợp hơn với loài động vật cụ thể mà bạn đang nuôi.

Tuy nhiên, nếu bạn điều hành một doanh nghiệp chuyên sản xuất thức ăn chăn nuôi dạng viên để bán, bạn sẽ cần phải tiếp tục. Bạn sẽ cần phải tạo các viên nén bằng cách ép lưới thức ăn thành các dạng nhỏ gọn và khô. Có tất cả các loại và kích cỡ của máy ép viên thức ăn mà bạn có thể chọn, mỗi loại khác nhau về tốc độ, công suất xử lý và hiệu quả.

Máy tạo viên thức ăn có giá bao nhiêu?

Nếu bạn đang tìm kiếm một máy ép viên thức ăn chăn nuôi để bán, hãy biết rằng giá máy ép viên thức ăn chăn nuôi trung bình có thể rất khác nhau. Bạn có thể tìm thấy một lựa chọn rẻ tiền với giá máy ép viên thức ăn chăn nuôi khoảng $1000 đến $2000. Tuy nhiên, trong một số trường hợp, bạn thậm chí có thể tìm thấy các lựa chọn ít tốn kém hơn (thường là những lựa chọn được thiết kế cho chủ sở hữu trang trại theo sở thích muốn cho động vật của họ ăn ít tốn kém hơn) với giá khoảng 500 đô la trở xuống.

Ngoài ra còn có các loại máy ép viên thức ăn quy mô lớn đắt hơn – vài nghìn đô la trở lên. Tương tự, có những máy tạo viên cho các loại sản phẩm khác (như viên nén gỗ) đắt hơn hoặc rẻ hơn tùy thuộc vào chức năng của chúng.

Ví dụ, giá máy tạo viên sinh khối điển hình sẽ có giá khoảng 2000 đến 6000 đô la.

Có bao nhiêu loại máy thức ăn viên?

Mặc dù có nhiều loại máy ép viên thức ăn phụ khác nhau mà bạn có thể chọn, nhưng hầu hết có thể được chia thành hai loại riêng biệt – khuôn vòng và khuôn phẳng.

Mặc dù cả hai loại máy ép viên thức ăn chăn nuôi sẽ giúp bạn hoàn thành công việc một cách tương đối dễ dàng, nhưng điều quan trọng cần lưu ý là các loại máy ép viên khuôn phẳng có xu hướng rẻ hơn về giá mua. Điều đó nói rằng, máy nghiền viên khuôn vòng tiết kiệm năng lượng hơn, vì vậy chúng có thể giúp bạn tiết kiệm nhiều tiền hơn theo thời gian vì chúng tiết kiệm năng lượng.

Có thể tìm thấy cả hai loại máy ép viên với các kích cỡ khác nhau tùy thuộc vào nhu cầu cụ thể của bạn. Hầu hết đều được cung cấp năng lượng bằng hơi nước, mặc dù điều này cũng có thể khác nhau và một số thậm chí còn có máy xay và máy trộn tích hợp, tùy thuộc vào nhu cầu của bạn.

Trong hai loại bao trùm lớn hơn đó, có cả nhà máy thức ăn viên quy mô lớn và nhà máy thức ăn viên quy mô nhỏ. Hầu hết các nhà máy quy mô nhỏ sử dụng khuôn phẳng vì họ chỉ nghiền bột khô thành viên – họ không nghiền và trộn. Máy ép viên thức ăn chăn nuôi quy mô lớn sử dụng khuôn dập vòng và có thể lắp ráp như dây chuyền sản xuất hoàn chỉnh, chế biến thức ăn chăn nuôi khối lượng lớn.

Như bạn có thể mong đợi, những thứ này cũng có thể xay, trộn và hoạt động với công suất cao hơn nhiều.

Làm thế nào để chọn máy thức ăn viên tốt nhất để sản xuất viên?

Mặc dù bạn có thể sử dụng bất kỳ loại máy ép viên cũ nào để tạo viên thức ăn chăn nuôi, nhưng bạn nên chọn một loại máy ép viên thức ăn chăn nuôi cụ thể. Mỗi bộ phận của máy móc đóng một vai trò cụ thể và vai trò này rất quan trọng. Dưới đây là một vài điều cần xem xét khi bạn bắt đầu mua sắm.

Flat Die so với Ring Die

Đây là một trong những cân nhắc quan trọng nhất mà bạn cần thực hiện khi mua máy ép viên thức ăn chăn nuôi. Hầu hết mọi người sử dụng máy ép viên dạng vòng khi hàm lượng vật liệu dạng bột, như cỏ dạng bột, nhỏ hơn 40%.

Đó là bởi vì bề mặt của các hạt bóng hơn và bởi vì tốc độ đóng rắn của máy ép viên khuôn vòng cao hơn so với máy ép phẳng.

Thêm vào đó, máy tạo viên khuôn dạng vòng mang lại hiệu suất bịt kín cao hơn. Thường không có nhiều hạt bụi lớn khi bạn làm thức ăn chăn nuôi, vì vậy sẽ không có nhiều ma sát hoặc nhiều hư hỏng. Máy ép viên khuôn dạng vòng cũng là lựa chọn lý tưởng để xử lý sơ bộ thức ăn trộn sẵn.

Nguyên liệu thô và loại động vật

Một lần nữa, để chế biến các loại thức ăn đậm đặc hơn, cả máy nghiền viên khuôn tròn và khuôn phẳng đều sẽ hoạt động. Nếu bạn đang chế biến thức ăn cỏ hoặc thức ăn hỗn hợp, khuôn dập là tốt nhất.

Xem xét các loại động vật, quá. Bạn sẽ muốn có khuôn ép dày hơn cho thức ăn gia súc để cho gà và lợn ăn, nhưng bạn có thể sử dụng khuôn mỏng hơn cho động vật như cừu và gia súc. Điều này liên quan đến chế độ ăn của từng loài động vật tương ứng.

Power

Kiểm tra đánh giá năng lượng cho máy thức ăn viên của bạn. Điều này sẽ xác định hiệu quả và sản lượng của máy cùng với năng lực sản xuất của nó.

Làm thế nào để bạn tạo viên thức ăn chăn nuôi?

Làm thức ăn chăn nuôi dạng viên khá đơn giản. Trước khi bắt đầu, hãy đảm bảo rằng bạn đã đọc kỹ thông tin có trong sách hướng dẫn sử dụng cho máy của mình. Bạn cần đảm bảo rằng bạn đang tuân thủ tất cả các nguyên tắc an toàn được khuyến nghị trước khi bắt đầu làm việc. Nếu không, bạn có nguy cơ bị thương.

Để bắt đầu làm thức ăn viên, bạn cần thu thập nguyên liệu thô. Hầu hết các viên thức ăn chăn nuôi được làm từ đậu Hà Lan, ngô, lúa mì, lúa mạch, yến mạch, cỏ linh lăng, tảo bẹ, men nuôi cấy, bột cá, bột cua, muối, aragonit, v.v. Các thành phần chính xác mà bạn sử dụng sẽ khác nhau tùy thuộc vào loài động vật mà bạn đang cố gắng nhắm mục tiêu.

Hãy mua sắm những sản phẩm này một cách khôn ngoan – thông thường, bạn có thể mua chúng với giá thấp trong hoặc ngay sau mùa thu hoạch, ngay cả khi bạn phải nhờ người vận chuyển đến tận nơi. Hãy chắc chắn rằng thành phần bạn chọn phù hợp với công thức dinh dưỡng được khuyến nghị cho các loài nhất định. Ví dụ, gà cần khoảng 7% lysine, 16.5 đến 19% protein thô, 2% methionine, 3% chất béo thô, 3.5% canxi (điều này có thể thay đổi) và 5% chất xơ thô.

Hãy chắc chắn rằng các thành phần của bạn được cân bằng trước khi bạn bắt đầu.

Sau đó, các bước sẽ khác nhau tùy thuộc vào loại máy ép viên thức ăn mà bạn đang sử dụng.

Bắt đầu bằng cách tạo bản trộn sẵn của bạn. Hỗn hợp trộn sẵn sẽ bao gồm tất cả các thành phần đã ở dạng bột, như bột cá, hạt lanh và muối. Đo lường những điều này và kết hợp chúng. Bạn có thể lưu trữ chúng để sử dụng sau hoặc sử dụng tất cả các hỗn hợp trộn sẵn cùng một lúc khi bạn tạo viên. Tùy bạn đấy.

Chất lượng của các thành phần của bạn sẽ đóng một vai trò lớn trong chất lượng thức ăn viên của bạn. Thông thường, người ta sử dụng các nguyên liệu thô như gạo, bột động vật, bột cá, đậu tương và ngô cho thức ăn viên của họ. Tùy thuộc vào đối tượng mà bạn đang tiếp thị thức ăn viên dành cho gia súc của mình, bạn cũng có thể tìm cách sử dụng các thành phần có nguồn gốc hữu cơ hoặc có đạo đức. Bạn có thể yêu cầu một mức giá cao hơn khi bạn bán thức ăn viên như thế này.

Điều quan trọng cần lưu ý là bạn nên sử dụng càng ít chất béo càng tốt khi làm thức ăn viên. Nếu nguyên liệu thô có tỷ lệ chất béo lớn trong đó, nó có thể làm hỏng chất lượng của viên thức ăn và làm giảm tuổi thọ của máy ép viên thức ăn của bạn.

Tiếp theo, nghiền nát các loại ngũ cốc nguyên hạt. Sử dụng máy nghiền thức ăn chăn nuôi hoặc nếu bạn chỉ hoạt động ở quy mô nhỏ, hãy sử dụng đá. Sau đó, bạn có thể thêm vật liệu nghiền của mình vào hỗn hợp trộn sẵn. Hãy chắc chắn rằng các nguyên liệu thô có kích thước đồng đều hơn hoặc ít hơn. Sử dụng máy xay để nghiền vật liệu thành các hạt mịn. Nếu không, bạn có thể thấy rằng thức ăn viên bạn sản xuất không có kích thước hoặc mật độ phù hợp.

Sử dụng máy trộn thức ăn để trộn ngũ cốc nguyên hạt với hỗn hợp trộn sẵn. Bạn cũng có thể trộn chúng bằng tay nếu điều đó dễ dàng hơn, tùy thuộc vào quy mô hoạt động của bạn.

Sau đó, bạn có thể cho tất cả nguyên liệu hỗn hợp vào máy ép viên thức ăn của mình. Máy sẽ ép chúng thành dạng viên cho bạn. Để chúng nguội hoặc sử dụng máy sấy viên như máy sấy quay để làm nguội chúng nhanh hơn (điều này cũng sẽ loại bỏ độ ẩm dư thừa).

Nếu bạn có kế hoạch sử dụng thức ăn viên của mình ngay lập tức, bạn không cần phải làm quá nhiều việc khác. Bạn chỉ có thể cho chúng ăn gia súc của bạn! Nếu không, bạn sẽ cần bảo quản thức ăn viên trong thùng có nắp đậy. Chúng sẽ tốt trong vài ngày đến vài tuần khi được bảo quản trong môi trường mát mẻ, không có độ ẩm.

Trước khi tạo thức ăn viên, hãy đảm bảo rằng máy của bạn đang hoạt động tốt. NÓ cần được bôi trơn và bảo dưỡng sao cho tất cả các con lăn, khuôn dập, máy trộn, lưỡi dao và búa đều ở trong tình trạng tốt nhất có thể. Một yếu tố quan trọng cần xem xét trước khi bạn bắt đầu làm việc là lượng hơi tồn tại trước khi bạn cho nguyên liệu thô vào máy. Mức hơi nước và độ ẩm cần được tối ưu hóa phù hợp để quá trình tạo viên thành công.

Làm thế nào để tạo ra một máy tạo viên thức ăn chăn nuôi?

Bạn có thể chế tạo máy tạo viên thức ăn viên của mình, mặc dù việc mua một máy chuyên nghiệp đối với nhiều chuyên gia sẽ dễ dàng hơn nhiều vì nó có thể được cài đặt và bảo dưỡng dễ dàng hơn một chút.

Để chế tạo máy tạo viên thức ăn chăn nuôi của mình, bạn cần xem xét cách vận hành máy, công suất của máy và nguyên liệu thô của bạn sẽ là gì. Hầu hết các máy tạo viên thức ăn chăn nuôi có thể được vận hành bằng động cơ điện, động cơ xăng, động cơ diesel hoặc PTO.

Hãy nhớ rằng các vật liệu khác nhau cần các loại nguyên liệu thô khác nhau. Máy ép viên có công suất khác nhau có công suất khác nhau nên mức tiêu thụ năng lượng cũng khác nhau. Nếu bạn chỉ quan tâm đến một chiếc máy ép viên để sử dụng tại nhà thì một chiếc máy công suất nhỏ cũng được. Tuy nhiên, nếu bạn dự định sử dụng máy ép viên thậm chí bán thường xuyên, bạn nên chọn loại chuyên nghiệp, loại mua tại cửa hàng và loại công suất lớn.

Để cung cấp cho bạn ý tưởng về cách chế tạo máy ép viên thức ăn chăn nuôi đáp ứng nhu cầu của bạn, đây là một số thông số kỹ thuật phổ biến của máy ép viên thức ăn chăn nuôi khuôn phẳng.

Công suất (Kw) | Kích thước viên (mm) | Kích thước khuôn (mm) | Đầu ra (Kg/h) | Đường kính (mm) | Trọng lượng (Kg) |

3 | φ2.5-φ6 | 120 | 80-100 | 600 × 450 × 900 | 50 |

7.5 | φ2.5-φ6 | 150 | 100-300 | 750 × 450 × 870 | 100 |

11 | φ2.5-φ8 | 200 | 300-500 | 1150 × 530 × 750 | 150 |

15 | φ2.5-φ8 | 250 | 400-700 | 1250 × 600 × 850 | 200 |

Nếu không có nguyên liệu phù hợp để chế tạo máy tạo viên thức ăn tự chế cho riêng mình, bạn chỉ nên mua kiểu máy mua ở cửa hàng. Thông tin thêm về mô hình tốt nhất là dưới đây!

Chọn một nhà sản xuất đáng tin cậy cho máy ép viên thức ăn chăn nuôi của bạn thay vì tự chế tạo máy ép viên thức ăn chăn nuôi tự chế. Họ sẽ cung cấp cho bạn những sản phẩm chất lượng thông qua nhiều lớp thử nghiệm và dịch vụ hậu mãi tốt hơn.

Làm thế nào để làm thức ăn viên cho cá nổi?

Bạn có thể sử dụng máy đùn thức ăn cho cá dạng khô hoặc máy nghiền thức ăn cho cá để sản xuất thức ăn thủy sản dạng viên cho cá cùng với tôm, cua và các loại động vật khác. Chúng sẽ có hình dạng, dinh dưỡng và kết cấu tuyệt vời.

Để làm cho chúng nổi và nổi trong thời gian dài hơn, tất cả những gì bạn cần làm là thực hiện các điều chỉnh nhỏ về mức độ đùn khi đùn các viên.

Các thành phần phổ biến nhất được sử dụng trong máy tạo viên thức ăn cho cá bao gồm bụi đã giảm, vỏ trấu lúa mì, bánh mù tạt, ngô, hạt bông, xương hoặc bột cá và các bộ phận bên trong.

Dưới đây là sơ đồ về cách thức hoạt động của các nhà máy tạo viên sinh khối như máy tạo viên thức ăn chăn nuôi để giúp bạn hiểu rõ hơn:

Cách sử dụng máy tạo viên thức ăn cho người mới bắt đầu?

Dưới đây là một số mẹo khác để giúp bạn sử dụng máy tạo viên thức ăn thành công.

Kiểm tra trước tất cả các vật liệu để tìm mảnh vụn

Đảm bảo loại bỏ tất cả các vật cứng khỏi nguyên liệu thô trước khi cho chúng vào máy ép viên. Bạn sẽ ngạc nhiên về những loại nguyên liệu có trong thức ăn chăn nuôi, từ những mảnh kim loại cho đến những mảnh nhựa nhỏ. Ngay cả những mảnh vỡ nhỏ cũng có thể gây bất lợi và gây hư hỏng cho trục chính, khuôn hoặc con lăn.

Nếu trước tiên bạn không kiểm tra những nơi này để tìm chất gây ô nhiễm, bạn có thể cân nhắc lắp một nam châm hình ống bên trong phễu cấp liệu. Điều này sẽ bắt các mảnh kim loại để ngăn chúng làm hỏng hoặc nhiễm bẩn thực phẩm.

Nghiền vật liệu đầu tiên

Hầu hết các khuôn phẳng và con lăn trong máy ép viên đều được xử lý bằng phương pháp xử lý nhiệt cao. Có nhiều mảnh vụn bên trong các lỗ khuôn, vì vậy bạn phải luôn mài vật liệu thật kỹ.

Xử lý trước nguyên liệu thô của bạn

Điều này sẽ không cần thiết đối với tất cả các loại nguyên liệu, nhưng bạn có thể thấy rằng mình cần xử lý nguyên liệu siêu ướt trước khi cho nguyên liệu vào máy ép viên thức ăn. Nó sẽ vào khoảng 14% đến 20% cho kết quả tốt nhất. Vật liệu quá khô sẽ không định hình tốt, trong khi vật liệu quá ướt sẽ khiến viên bị lỏng và sũng nước.

Đảm bảo rằng kích thước của nguyên liệu thô cũng nhỏ hơn kích thước của kích thước lỗ trên khuôn. Điều này thường có nghĩa là nguyên liệu thô phải từ 5 mm trở xuống. Nếu không, chúng có thể làm tắc các lỗ và làm cho nỗ lực sản xuất viên của bạn kém hiệu quả hơn.

Cuối cùng, hãy biết rằng lực kết dính sẽ quyết định tốc độ bạn có thể tạo viên bằng máy của mình. Một số nguyên liệu như trấu có lực kết dính rất thấp cần trộn với mùn cưa hoặc các loại chất kết dính khác để tạo viên. Những loại khác có lignin, tan chảy dưới nhiệt độ cao. Thực hiện nghiên cứu của bạn trước khi bạn bắt đầu làm thức ăn viên để đạt được kết quả tốt nhất có thể!

Kiểm tra độ dày và chiều dài của viên nén của chúng tôi

Độ dày của các viên thức ăn của bạn sẽ được xác định bởi kích thước lỗ trên khuôn của bạn, với chiều dài được xác định bởi máy cắt của chúng tôi. Do đó, việc thay đổi kích thước chiều dài sau này dễ dàng hơn nhiều so với độ dày.

Bạn sẽ tìm thấy máy cắt lát bên dưới khuôn phẳng, nhưng trong máy ép viên khuôn vòng, nó sẽ được lắp bên ngoài khuôn vòng. Tuy nhiên, bạn có thể điều chỉnh cả hai loại để có được kích thước lý tưởng. Quá ngắn sẽ tốt hơn là quá dài nếu bạn đang sản xuất thức ăn viên cho động vật để chúng ta sử dụng – tuy nhiên nếu bạn định bán và vận chuyển chúng, hãy dài một chút.

Khi các viên của bạn ra khỏi máy, chúng sẽ nóng và ướt. Bạn có thể làm khô và làm mát chúng bằng cách đặt chúng ở nơi thoáng đãng với không khí lưu thông tốt hoặc bạn có thể sử dụng máy làm mát. Làm nguội chúng nhanh chóng có thể giúp bạn dễ dàng chất chúng lên xe tải để vận chuyển nhanh chóng, thuận tiện.

Đừng Tắt Ngay.

Khi bạn đã hoàn thành việc tạo viên, hãy cưỡng lại ý muốn đóng cửa hàng và bỏ đi. Thay vào đó, bạn nên thực hiện một số bước để giữ cho máy của mình hoạt động trơn tru nhất có thể.

Ví dụ, bạn nên thêm một số hỗn hợp dầu và nguyên liệu thức ăn chăn nuôi vào máy ép viên. Hãy để nó chạy trong một vài phút. Điều này sẽ cho phép các lỗ khuôn chứa đầy hỗn hợp dầu – bằng cách đó, bạn có thể bắt đầu tạo viên ngay lập tức vào lần tiếp theo. Nó duy trì khuôn trong khi cũng tiết kiệm thời gian.

Bạn có thể nới lỏng vít điều chỉnh và làm sạch các vật liệu còn sót lại ngay sau khi hoàn thành.

Làm thế nào để duy trì một máy thức ăn viên?

Ngoài các mẹo được liệt kê ở trên, một trong những cách tốt nhất để tạo viên thức ăn chăn nuôi là thường xuyên bảo trì máy tạo viên thức ăn chăn nuôi của bạn.

Đầu tiên, hãy biết rằng nhiệt độ bên trong buồng tạo viên có thể cực kỳ nóng. Ngoài ra, con lăn trải qua áp lực mạnh mẽ. Chúng rất dễ bị quá nóng và điều này có thể khiến các bộ phận bị hỏng theo thời gian. Không có bộ phận chống bụi trong hầu hết các máy ép viên, vì vậy bạn sẽ cần phải làm sạch vòng bi và bôi trơn chúng bằng dầu cứ sau vài giờ hoặc lâu hơn.

Sau khoảng tám giờ làm việc, trục chính sẽ cần được tra dầu. Không chỉ vậy, bạn nên lên lịch vệ sinh hộp số sáu tháng một lần. Nếu hộp số của bạn có mức nhiệt cao, vì bất kỳ lý do gì, hãy cố gắng tăng khoảng hở bánh răng để bảo trì dễ dàng hơn – và cố gắng sử dụng dầu hộp số chất lượng tốt hơn.

Cách chọn đường kính khuôn viên cho sản xuất thức ăn chăn nuôi của bạn

Đối với việc tạo viên thức ăn chăn nuôi, ưu tiên hàng đầu là chọn đường kính khuôn viên chính xác, điều này sẽ ảnh hưởng đến hiệu quả và dinh dưỡng của thức ăn chăn nuôi, điều này sẽ ảnh hưởng đến ROI của bạn. Dựa trên các loài động vật khác nhau, bao gồm thức ăn cho cá, thỏ, gà, vịt, gà, chó, lợn, bò, ngựa, lạc đà, v.v., vui lòng kiểm tra các đề xuất của chúng tôi về thức ăn viên chết.

Những loại viên nén nào để làm?

Máy ép viên thức ăn chăn nuôi của chúng tôi có thể xử lý các vật liệu khác nhau để sản xuất thức ăn viên cho động vật khác nhau, chúng tôi cũng có thể thiết kế dây chuyền sản xuất thức ăn viên đơn giản và hoàn chỉnh dựa trên yêu cầu của khách hàng.

Dây chuyền sản xuất thức ăn viên đơn giản này bao gồm một máy trộn bằng thép không gỉ, một băng tải trục vít bằng thép không gỉ và một máy ép viên thức ăn, dây chuyền đơn giản có thể đạt được sản lượng thức ăn viên toàn bộ, công suất từ 100kgs/h đến 4000kgs/h. Chúng tôi cũng có thể tùy chỉnh công suất lớn hơn dựa trên nhu cầu của bạn.

Giới thiệu máy ép viên thức ăn TCPEL