Wood Pellets: The Ultimate Guide

Over the past few years, the use of wood pellets (in both commercial and domestic sectors) has noticeably increased.

They are the perfect environmentally-friendly substitute for fossil fuels. The reason is that raw materials for wood pellets are sourced sustainably from forests. Compared to conventional heating options, wood pellet fuel produces ten times less carbon.

Wood pellets are versatile. Individuals have been using them to heat their homes and offices.

Also, they make excellent fuel for industrial boilers. Since they have good heat value, people use them as fuel in gasification and thermal power production.

In addition to this, they work well for patio heaters and pizza ovens. The ash of the pellets can also be reused as potash for plants. People also use pellets as bedding for animals as they absorb moisture and are less dusty.

This post provides complete info about wood pellets, their making, uses, and growing demand. If you want to start a pellet making business and are wondering if it is profitable, read this guide till the end.

Let us get started without any further ado.

What are Wood Pellets?

Wood pellets are even-sized cylindrical pieces made of fine-grounded sawdust, bark, wood chips, or wood waste. Depending on the die holes of a pellet-making machine, their size could be 10-20mm long.

Generally, sawdust, bark, and harvesting residuals of the forest are used for wood pellet making.

Based on the raw material you choose, the color of wood pellets might vary from warm reddish brown to pale blonde to dark walnut.

If wood pellets have a moisture content between 5 to 10%, they can offer a heating value of 16,500,000 BTU per ton.

How Are Wood Pellets Made?

Making wood pellets involves several steps, such as preparing raw materials, making pellets, cooling, and packing them.

A fine powder of wood products is used for making wood pellets. The powder is put in the opening chamber of a pellet-making machine. As the machine works, it passes raw material through its die-holes at high temperatures.

The compression and high temperature melt the powder and bind its particle into a pellet shape. After cooling, the pellets become solid.

Wood Pellets Uses in Different Industries

According to a report, the global wood pellets market could reach a valuation of USD 9.21 billion by the end of 2022. Market CAGR from 2022 to 2032 would be 11%.

Let us find out what are the primary industries that use wood pellets.

Home Heating

Primarily, people use wood pellets as fuel for their heating stoves and furnaces.

Since wood pellets are clean and affordable, people prefer them over gas and electric heaters.

Wood pellets produce less ash in comparison to wood chips. Furthermore, they are easy to store and transport.

About 1,000,000 houses use wood pellets exclusively for home heating in the United States. While in Europe, wood pellets have emerged as a promising alternative to gas and coal.

According to studies, home and commercial heating account for 60.5% of total wood pellet use in Europe.

In 2018, the European Union adopted the REDII Renewable Energy Directive to focus on renewable energy sources.

Power Generation

Pellet fuel has become one of the fastest-growing energy carriers that have been used in different industries. And thermal and gasification power generation industries are no exception.

Several thermal power generation and gasification power generation firms worldwide have been using wood pellets as fuel.

In the cogeneration sector, wood pellets are burned to generate both heat and power.

In the gasification industry, pellets are processed in a hot oxygen-starved area. It produces a gas containing hydrogen and carbon monoxide. The gas helps the turbine to produce electricity.

As Fuel for Industrial Boiler

Since wood pellets produce less pollution than conventional fuels without compromising on the heating value, people use them in industrial boilers. They serve as perfect alternatives to coal and natural gas.

The latest wood pellet boilers are more than 90% efficient. They are better than most traditional fossil fuel systems, which are between 70 and 80% efficient.

Are Wood Pellets Better Than Wood?

Many individuals wonder whether wood pellets are better than wood.

Wood pellets are made of wood products. However, they are different in terms of their heating value and moisture level.

Wood pellets are composed of finely ground hardwood, while wood chips are hardwood pieces.

The raw material of pellets is dried and then crushed with a wood hammer mill. Subsequently, it is compressed between the die and roller under high temperature and pressure.

In comparison to wood or wood chips, pellets have several benefits.

Advantages of Wood Pellets

Multiple Uses

Wood pellets are versatile. People use them as fuel for pellet grills, charcoal grills, or pellet heaters. On the contrary, wood chips can only be used in electric smokers or kamado grills.

Additionally, unlike wood chips or pieces, pellets can be utilized as animal bedding.

Slow Burning

Wood pellets burn gradually; therefore, produce continuous heat for a long time. On the other hand, wood pieces burn quickly.

Heating Value

For heating, one ton of wood pellets equals…

- 120 gallons of heating oil

- 170 gallons of propane

- 16,000 ft of natural gas

- 4,775 kilowatt hours (kWh) electricity

Wood pellets have high heating and combustion value. Usually, the moisture content of wood pellets is between 5% and 10%.

On the other hand, the moisture content of wood is about 20%. Remember, the more moisture content the less heating value you get. Wet woods produce creosote while burning.

Wood pellets have about 75 to 85% carbon and only 3 to 6% ash content.

Smoke

Burning wood pieces produce too much smoke, which might be a health concern in the long run.

However, wood pellets do not make that much smoke. They do not cause any problems to the respiratory system and eyes. Biomass pellets do not produce P205 or SO2

Better Fire Control

Wood pellets offer better fire control. Individuals do not need to worry about bursts of fire. When used for cooking, it cooks food slowly but evenly.

Shortage of Wood Pellets Due to The Russia-Ukraine War

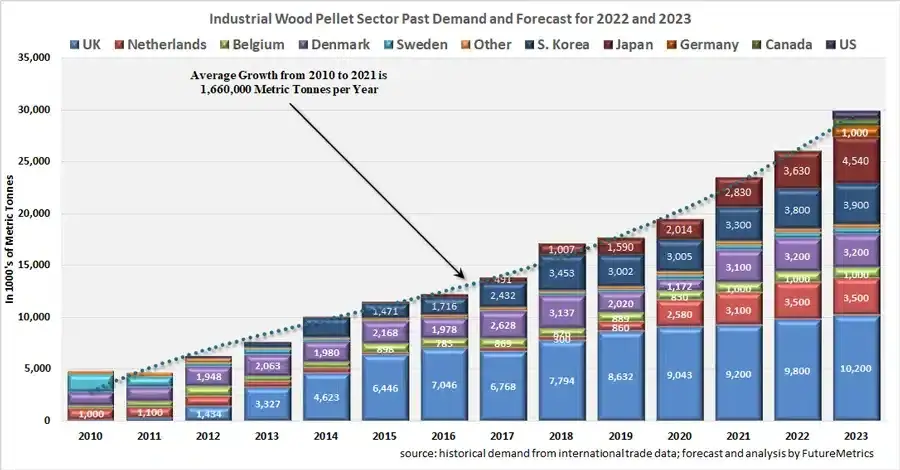

Since the last decade, the demand for wood pellets has been increasing steadily. But due to the war between Russia and Ukraine, it has boomed dramatically.

There are multiple reasons behind it. One is, the war is driving up the cost of gasoline, coal, and oil worldwide. The Russia-Ukraine war has led to huge turbulence in the global energy market. Therefore, a discernible shift could be observed in energy prices.

According to the International Energy Agency, fuel cost contributes to about a 90% increase in the average price for electricity generation globally.

Consequently, wood pellets have been viewed as a substitute energy source for fuel. Unfortunately, a sudden rise in the demand for pellets has caused the shortage.

The global wood pellet market is dealing with the supply issue. Even before Russia invaded Ukraine, the demand and supply of the global wood pellet market were not subpar.

But now, the entire world is experiencing a scarcity of wood pellets.

In response to the economic sanctions on Russia, the country has cut down the gas flow to the EU by 80%, causing a significant shortfall in energy.

As a result, the demand for alternative energy sources, including wood pellets, has increased.

No country has a self-sufficient market to supply wood pellets. Between 12 and 15% of the world’s wood pellet supply originates from Belarus and Russia.

Three nations, Ukraine, Belarus, and Russia, produce 25% of the global timber and forest products. However, the war halted the transport of timber to Europe. It is another cause for the deficit of pellets.

According to Jaano Haidla, the CEO of the largest pellet manufacturing firm in Europe, “due to the Russia-Ukraine war, Baltic States are experiencing a 2 million cubic meter biomass shortage“.

How Wood Pellet Producers Have a Great Opportunity Due to the Global Energy Crisis

The Russia-Ukraine war is indeed a big worry from the energy point of view. But it is an opportunity for people who want to start a wood pellet business.

According to an article published in Forbes, several wood pellet businesses have emerged in the United States. Some of them have begun generating pellets up to 10 million tons annually.

According to the Wall Street Journal, the wood pellet market is growing rapidly. Power plants in Western Europe that run on pellets instead of coal buy pellets from North America.

However, premium US wood pellets are not affordable for all Europeans. If you start pellet making business in Europe, you can fill this gap and make huge profits.

You can take advantage of the growing requirement for wood pellets across Europe and the world.

If you do an in-depth pellet production profit analysis, you will find that it can turn into a profitable investment. And during this energy crisis, success is almost assured.

European countries are the largest market for wood pellets. In 2021, Ukraine, Belarus, and Russia together supplied about 3 million tonnes of wood pellets.

However, due to the ongoing war between Russia and Ukraine, the supply is no longer obtainable.

EPC, or European Pellet Council, has suspended all EnPlus-certified pellet manufacturers and traders in Russia and Belarus. However, the need for these pellets is exceptionally high.

While European nations have increased their imports from Canada and the United States, it is not adequate for the people of Europe.

So if you sell EnPlus A1 wood pellets especially, you can make good profits.

If your budget does not allow you to start a pellet-making business, you can become the seller of EnPlus A1 pellets.

Let us get to know more about EnPlus A1 pellets and find out why they are better.

What are EnPlus A1 Wood Pellets?

EnPlus A1 wood pellets are high-quality pellets that meet the qualities set by the EnPlus A1. It is a quality assurance scheme that applies to wood pellet manufacturers and distributors.

These manufacturers and distributors go through several quality checks. Every year their plants get audits from a third party.

EnPlus A1 certification assures quality for the entire wood pellet supply chain. From a production company to a delivery firm, everyone is accountable for transparency.

EnPlus A1 is an independent certification scheme working dedicatedly for wood pellets. As a result, people prefer EnPlus A1 wood pellets.

Specification of EnPlus A1 Wood Pellets

EnPlus A1 wood pellets that comply with European standards have the following specifications.

- Diameter: 6-8mm

- Length: 10-40mm

- Moisture: less than 10%

- Ash: less than 0. 7%

- Net calorific value: 17

- Sulfur, S: less than 0.03%

- Chlorine, CL: less than 0.02%

- Nitrogen, N: less than 0.3%

- Dust: less than 3%

- Ash deformation temp More than 1100-degree Celsius

Advantages of EnPlus A1 Wood Pellets

Quality Assurance

When you buy EnPlus A1 wood pellets, you rest assured about the quality. As mentioned above, an individual party keeps an eye on manufacturers and distributors. These wood pellets do not contain any additives.

High Calorific Value

EnPlus A1 wood pellets have a high calorific value of 17. It makes them ideal to use for home heating. Calorific value refers to the energy content.

Low Ash Content

EnPlus A1 wood pellets produce comparatively low ash. Usually, it is less than 0.7%. They do not make cakes or slag when burned.

Environmentally-Friendly

EnPlus A1 pellets are made of wood waste. Therefore, they are environmentally friendly in comparison to conventional energy sources. Their raw materials are sourced from forests taking a holistic approach.

Low Humidity

The moisture content of EnPlus A1 wood pellets is always less than or up to 10. As a result, they are excellent at transferring.

If you want to sell EnPlus A1 wood pellets in your country, get in touch with TCPEL. We will supply EnPlus A1 wood pellets from China to your place at an affordable price.

If you want to start your own pellet-making business, you can do that too. Let us find out how to do that.

How to Start a Wood Pellet Business?

You need a complete pellet production workshop and a steady supply of biomass materials to start a wood pellet business. Besides this, you have to consider the transportation cost, labor cost, and electric power consumption.

Below are steps to start a wood pellet business commercially.

Arrangement for Raw Material

Sawdust and compressed wood waste are used to make wood pellets. You must have continuous access to these raw materials. For the same, you can contact the local farm owner or timber supplier.

If there is a forest nearby, you can gather bamboo, branches, and bark from there. Apart from this, you can buy wood shaving and chips from a wood processing plant.

How much sawdust you need to produce a ton of pellet depends on three factors: The purity of sawdust, its moisture content, and the type of pellet mill you use.

You must have raw materials for at least 15 days.

Building Workshop

You will need a spacious workshop to store raw materials and install wood pellet manufacturing equipment.

The warehouse must have stable ceilings and walls that protect pellets and raw materials from rain, fire, and wind.

Confirm the space depending on your production needs and the plant design.

Always set up your workshop at a prime location. It ensures the smooth supply of raw materials and wood pellets.

Also, calculate the price for electricity, water, and rent according to the local policy.

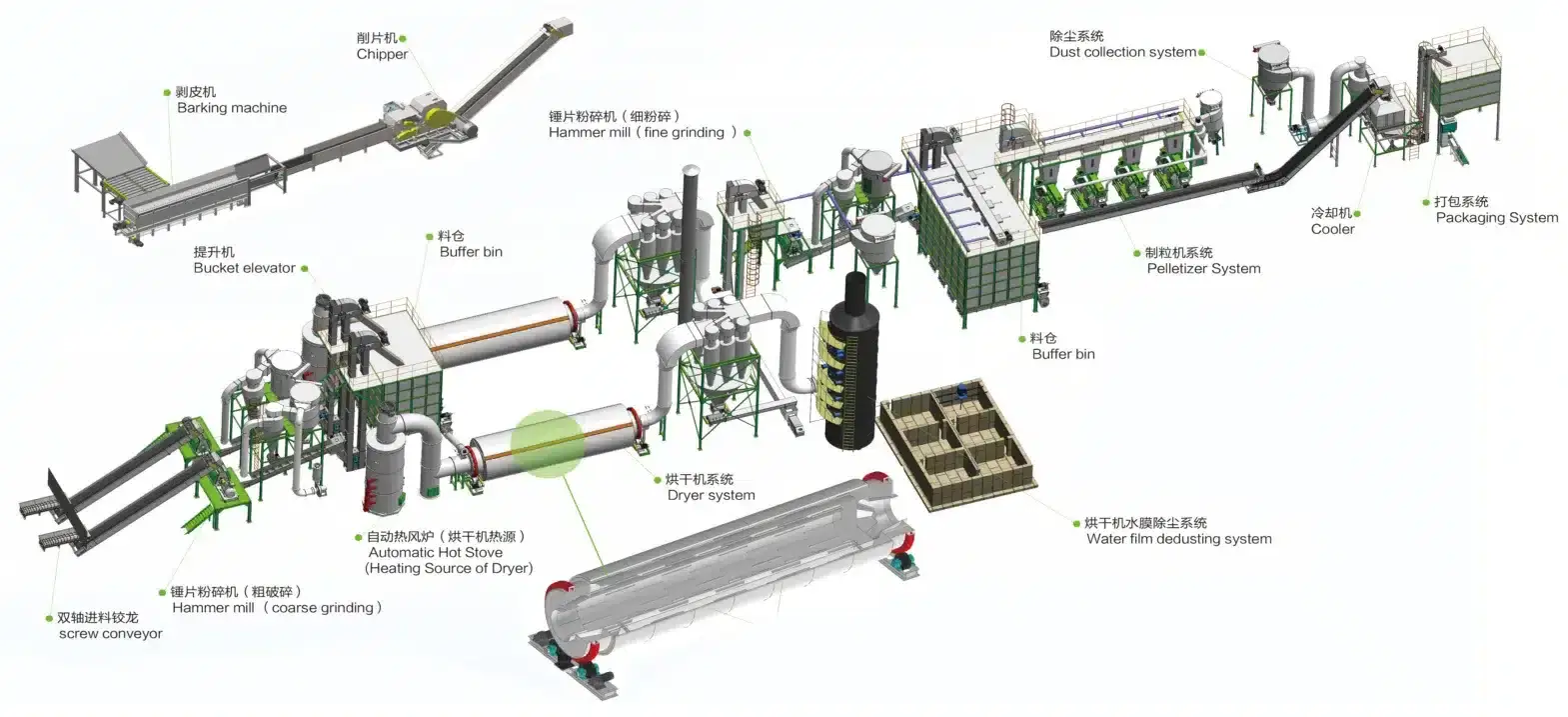

Equipment for Pellet Manufacturing

You need to buy every machine needed to produce wood pellets commercially. These include:

Crushing Equipment

You will require crushing equipment to crush raw materials into small sizes. Depending on your requirement, you can buy a disc chipper, hammer mill, drum chipper, and wood pulverizer.

If you make wood pellets out of sawdust or wood powder, you do not require them.

Raw materials that are under the size of 30mm can be crushed with a hammer mill. It will reduce them to 3mm.

If you are using a large wood log larger than 30mm, you will need to crush it with the help of a drum or disc chippers.

Conveyer

It takes your crushed raw material to the next equipment. In short, it functions as the connection part between various processing equipment. A screw conveyor transmits wood pellets from one place to another.

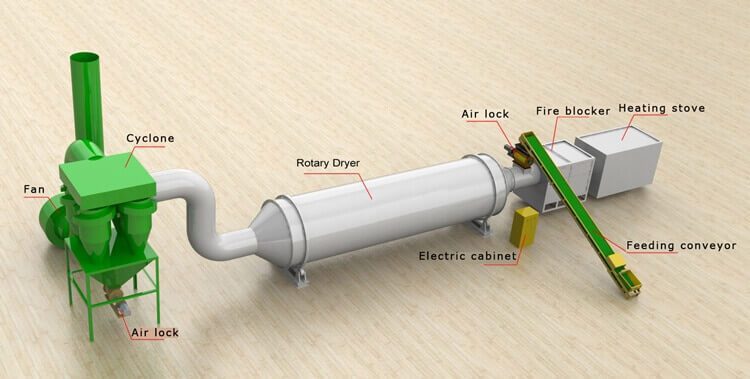

Drying Equipment

The raw material requires a certain percentage of moisture to make quality pellets.

A drying machine helps you manage the moisture content of your raw material.

To dry raw material in bulk, you can use a drum dryer. It is an automatic dryer with high efficiency. For a small batch of raw material, an airflow dryer is suitable. It is smaller in size and affordable.

Wood Pellet Machine

It is the most crucial machine in the pellet-making process. So choose it wisely.

It turns the biomass raw material into wood pellets. Two types of pellet mills are available in the market: Flat die pellet mill and Ring die pellet mill.

A flat die pellet machine is a compact-size machine designed for limited pellet production. Generally, it produces pellets under 500 kg per hour.

On the contrary, a Ring die pellet machine is used for large-scale production. Let us quickly learn the difference between a Ring die Pellet Machine and Flat Die Pellet Machine.

Capacity: Ring Die pellet machine can produce more than 1-ton pellets per hour. On the contrary, the capacity of a flat die pellet machine is up to 500 kg.

Raw Material: Ring Die pellet mill can process both soft and hard raw materials, including peanut shells, stalks, grass, and sawdust. A flat die pellet mill is suitable for soft biomass material, such as straw, grass, and sawdust.

Price: The cost of a ring die pellet mill is typically thousands of dollars higher than a flat die mill.

Learn how to make high-quality pellets with a pellet-making machine.

Pellet Cooler

Another important piece of equipment you need to invest in is a pellet cooler. Wood pellets are very hot when they come out of the mill. To retain their shape they need cooling. With the help of this cooler, the temperature of the cooler goes down to room temperature.

Packaging Machine

If you are making pellets in big numbers, you will need an automatic pellet packaging machine.

An advanced pellet packaging machine can weigh, pack, transmit and sew pellet packages. It is advisable to use air-tight and waterproof bags.

At TCPEL, we have all the equipment required to set up a complete pellet production company. If you need assistance with setting up the mill, we would love to help you out.

Is it Worth it to invest in a Wood Pellet Making Business?

Several people have this question in their minds – is it worth it to start a wood pellet-making business now?

According to us, 2022-2023 is the best time to start a pellet-making business. Gaining a profit takes time for every firm. But your chances of success are higher if you get started right away.

Read our post – How to start a wood pellet business Successfully 2022 for the best tips.

Due to the Russia-Ukraine war, the demand for wood pellets has increased spectacularly. The war has cut off the supply of pellets from Ukraine, Russia, and Belarus.

Since the EU has banned the import of wood pellets from Russia, oil and gas prices have set a record. In entire Europe, the demand for pellets is outpacing.

Most households are now dependent on wood pellets for home heating. Apart from this, power plants also need pellets as fuel.

Research indicates that in 2022, demand for wood pellets in the EU will rise to a new high. Europe collectively needs about 25.8 million metric tons of wood pellets this year.

This business may bring in a sizable profit if you can offer a consistent supply of wood pellets. If you want a complete analysis, we recommend reading our post: Pellets Making Profit Analysis 2022. It will help you estimate your earnings and how much you spend on each thing.

All-in-all, it is the right time to start pellet making business and capitalize on the opportunity.

Talk to An Expert

SHARE THIS POST

Talk to An Expert