Top Alfalfa Pellet Machine Manufacturer, ISO9001 Certificated

- Higher capacity and less wear parts costs

- Wide range of application suitability

- Stable running performance and easy operation

Alfalfa Pellet Machine - The Beginner's Guide

If you’re thinking of investing in an alfalfa pellet machine for processing alfalfa into livestock feed pellets, biomass fuel pellets, and fertilizer pellets, this guide will provide you with all the information you need to know to help you choose the best alfalfa pellet machine for your needs.

What Is An Alfalfa Pellet Machine?

An alfalfa pellet machine is a type of press mill that is used to convert alfalfa into pellets. Alfalfa pellet machines are suitable for both domestic use in small scale farms, as well as for commercial production of alfalfa pellet feed in a factory.

What Is An Alfalfa Pellet Machine Used For?

The major use of an alfalfa pellet machine is to create alfalfa pellet feed for livestock. Pelletizing alfalfa makes it easier to store and transport, and reduces wastage when feeding your livestock. Alfalfa pellet feed is suitable for cows, sheep, goats, ostriches, rabbits, pigs, and other livestock.

An alfalfa pellet machine can also be used to create biomass fuel pellets for use in a pellet stove. If you intend to use alfalfa as a fuel, you’ll need to dry the alfalfa fully, since wet alfalfa will not burn.

Finally, you can also use an alfalfa pellet machine to create pelletized fertilizer for your farm.

How Does An Alfalfa Pellet Machine Work?

An alfalfa pellet machine relies on high pressure to convert alfalfa material into pellets. When you pour your alfalfa material into the feeding hopper, the material is directed into the pelletizing chamber.

In the pelletizing chamber, the alfalfa material is spread across a perforated die, either by roller gears or using centrifugal force, depending on the type of alfalfa pellet machine.

Rotating roller gears then force the alfalfa material through the perforations on the die, resulting in compact cylindrical pellets. As the pellets exit the die, a blade placed outside the die chops them to the desired length.

How Much Does An Alfalfa Pellet Machine Cost?

You’ll find alfalfa pellet machines for sale for as little as $500, or as much as $10,000.

One factor that determines the price of an alfalfa pellet machine is the size of the machine.

Large alfalfa pellet machines capable of producing more than a ton of alfalfa pellets per hour will usually fall in the $4,000 to $10,000 range. Smaller alfalfa pellet machines, on the other hand, will cost between $500 to $4,000.

Other factors that might affect the cost of an alfalfa pellet machine include whether the machine uses a ring die or a flat die, and whether the machine is electric,fuel or PTO powered.

How To Choose The Best Alfalfa Pellet Machine For Pellet Production?

When searching for an alfalfa pellet machine to buy, here are some factors that will help you choose the right machine for your needs:

Production Capacity

How much alfalfa pellets are you looking to produce? If you only want to produce small amounts of alfalfa pellets for a few livestock, a small capacity alfalfa pellet machine will do. If you want to produce alfalfa pellets commercially, you’ll need to buy a higher capacity alfalfa pellet machine.

Type Of Livestock

Different alfalfa pellet machines have different die sizes depending on the animal you’re producing pellets for.

For instance, an alfalfa pellet machine for producing pellet feed for cows and sheep will have large die holes, while a machine for producing alfalfa pellet feed for fish and chicken will have finer holes.

The Alfalfa Pellet Machine Manufacturer

Buying an alfalfa pellet machine is a significant investment, so you need to make sure that you’re buying the machine from a reliable manufacturer.

Take your time researching the manufacturer, and confirm that you’re buying from a manufacturer who is known for reliability, and one who provides good after-sales service, such as training and machine servicing.

Power Type

Alfalfa pellet machines can be powered by electricity, diesel, gasoline, and or the PTO gear on a tractor. You’ll therefore need to choose an alfalfa pellet machine that is most suitable for you based on your particular situation.

For instance, you should not buy a PTO powered alfalfa pellet machine if you don’t have a tractor. Similarly, a diesel alfalfa pellet machine will have lower operation costs compared to a gasoline powered alfalfa pellet machine.

Ease Of Operation

When buying an alfalfa pellet machine, you should go for one that doesn’t require lots of training before you can start operating it, and one that can be easily operated by one person.

How To Buy An Affordable Alfalfa Pellet Machine?

Alfalfa pellet machines cost thousands of dollars, and therefore, when buying one, you’ll want to make sure you’re getting the most affordable deal. So, how do you do this?

The best strategy for getting an affordable alfalfa pellet machine is to buy your alfalfa pellet machine directly from a manufacturer in China. Most alfalfa pellet machine manufacturers are based in China, and due to economies of scale, they are able to manufacture the machines at lower prices.

Actually, a lot of US-based alfalfa pellet machine brands buy their machines from China, and then brand them as their own and pass them off as US-produced machines.

When you buy from such brands, you’re in effect purchasing from a middleman who has already added their own markup to the cost of the alfalfa pellet machine, so you are very unlikely to get a good deal on the machine.

It’s good to note, however, that not all Chinese manufacturers make high quality alfalfa pellet machines. Therefore, do your research and ensure you’re buying from a reputable manufacturer, such as TCPEL.

Another thing to put into consideration if you want to buy an alfalfa pellet machine at an affordable price is to look at how available replacement parts are.

If the parts are not readily available, you’ll always spend more whenever you need to replace some worn out parts. In addition, you’ll also incur the cost of downtime while you’re searching for parts.

How To Use An Alfalfa Pellet Machine For Beginners?

After buying your alfalfa pellet machine, here are the steps you’ll need to follow when using the machine for the first time.

The first step is to get the alfalfa pellet machine ready. For a small alfalfa pellet machine, just follow the instructions in the user’s manual to set up the machine. For larger, commercial alfalfa pellet machines, most manufacturers will do the on-site installation for you.

With the machine ready, the next step is to dry your alfalfa material. Alfalfa usually contains a lot of water content. If you pelletize the alfalfa before drying, you’ll produce low quality alfalfa pellets that easily break down. To get high quality pellets, dry the alfalfa to a moisture content of about 15%.

For small scale production, you can simply dry your alfalfa material out in the sun. For large scale production, you’ll need access to a drier.

Once your alfalfa material is sufficiently dry, the next step is to grind the alfalfa to fine particles. If you pelletize alfalfa in its natural form, you’ll not get high quality pellets.

Before grinding your alfalfa material, it’s recommended that you check for any foreign particles that could damage your machine, such as stones and pieces of metal and plastic.

After grinding, you can now go ahead and put the ground alfalfa into the alfalfa pellet machine through the feeding hopper. The machine will then compress the alfalfa material through the die holes and discharge the formed pellets through the discharge port.

The alfalfa pellet machine operates under a lot of pressure and heat, and therefore, the alfalfa pellets will be very hot when they come out of the alfalfa pellet machine. If you touch them immediately with your bare hands, you could get burnt, so give the pellets some time to cool down. Allowing them to cool before packing will also improve the quality of the pellets.

Finally, you can now feed the alfalfa pellets to your livestock, or package them in bags and either store them or transport them to your customers.

How To Maintain An Alfalfa Pellet Machine?

Taking good care of your alfalfa pellet machine is important if you want the machine to have a long service life. Here are some things you can do to keep your machine running smoothly for a long time:

- Make yourself conversant with the operational procedures of your alfalfa pellet machine by carefully reading the user’s manual that came with the machine.

- Always confirm that there’s no foreign material in the pelletizing chamber before you start operating your alfalfa pellet machine. Foreign material like pieces of metal and small stones can cause damage to the die and roller gears.

- When using your alfalfa pellet machine during winter, give it some time to preheat before adding alfalfa material into the machine. This will improve its performance and at the same time prevent excessive wear.

- The alfalfa pellet machine produces a lot of heat during operation. To prevent this heat from causing excessive wear to the motor, always operate your alfalfa pellet machine in a place with good air circulation.

- Always confirm that there’s enough lubrication on the moving parts before you start operating your alfalfa pellet machine. Proper lubrication improves the performance of the alfalfa pellet machine and at the same time extends the lifetime of the moving parts.

- Regularly inspect your alfalfa pellet machine to check for worn out or damaged parts. If any part looks worn out or damaged, have the parts replaced before you continue operating the machine. If you notice any issues while the alfalfa pellet machine is in operation, shut it down immediately.

TCPEL Alfalfa Pellet Machine Introduction

If you’re searching for a reliable machine for processing alfalfa into pellets, you’ll not find a better machine than the TCPEL alfalfa pellet machine.

The TCPEL alfalfa pellet machine is made using high quality, wear resistant materials that guarantee you durability and long term reliability, while the powerful motor provides exceptional performance.

Whether you are a farmer looking for a better way of processing your animal feeds, or a livestock feed company looking for a more efficient way of commercially producing alfalfa pellet feed, the TCPEL alfalfa pellet machine is the perfect machine for you.

- Easy to maintain: With its highly durable and wear-resistant parts, the TCPEL alfalfa pellet machine is very easy to maintain and guarantees you maximum uptime. The design on this machine also makes servicing very easy whenever you need to replace worn out parts.

- Multiple output capacities: Whether you’re looking for a small model suitable for domestic use, or a larger model that is suitable for a pellet feed plant, you’ll find the right machine for your needs. Our alfalfa pellet machines have output capacities ranging from 60kg per hour to as much as 1,100 kg per hour.

- Multiple die hole sizes: With the TCPEL alfalfa pellet machine, you can choose between different die hole sizes depending on your needs. Options include 7mm, 6mm, 4mm, 3mm, and 2.5mm. For instance, you can use the 7mm die to make alfalfa pellet feeds for cows and sheep, and a different die with 2.5mm holes to make alfalfa pellet feeds for fish and chicken.

Alfalfa Pellet Machine Parameters

| Model | Capacity | Pinch Roller | Power | Voltage(V) | Weight | Dimension |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg/h | Double roller | 2.2kw | 220V/380V | 95kgs | 68*42*53cm |

| TFC150 | 150-200kg/h | Double rollers | 7.5kw | 220V/380V | 100kgs | 72*45*65cm |

| TCF200 | 300-400kg/h | Double rollers | 11kw | 380V | 180kgs | 126*53*92cm |

| TCF250 | 600-800kg/h | Double rollers | 15kw | 380V | 320kgs | 131*54*93cm |

| TCF300 | 800-1000kg/h | Double rollers | 22kw | 380V | 400kgs | 146*59*110cm |

| TCF350 | 1000-1200kg/h | Double rollers | 30kw | 380V | 580kgs | 186*70*128cm |

| TCF400 | 2000kg/h | Double rollers | 37kw | 380V | 680kgs | 206*76*137cm |

| TCF450 | 2000-2500kg/h | Double rollers | 45kw | 380V | 780kgs | 218*79*140cm |

TCPEL Alfalfa Pellet Machine Advantages

Highly durable parts: The parts in the pelletizing chamber are made of chromium-manganese steel, which is highly durable. These parts are also given high-temperature quenching treatment to make them even more wear-resistant.

Easy to refuel: simple to use, GL-5 heavy-duty gear oil must be filled before use.

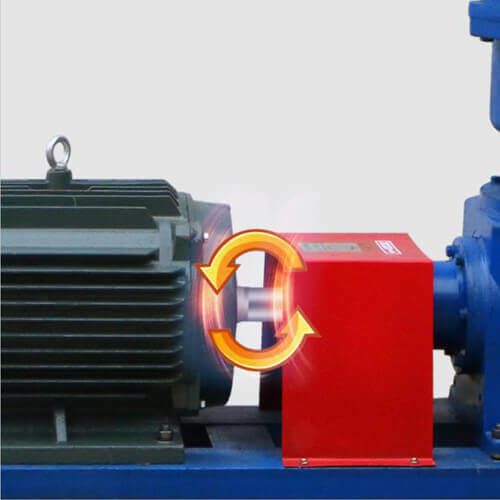

Electric coupling: This machine uses a direct docking electric coupling drive that is easier to install compared to a belt drive. The electric coupling drive is also more efficient and provides better performance due to decreased transmission ratio loss. The coupling drive is high-temperature treated for maximum durability.

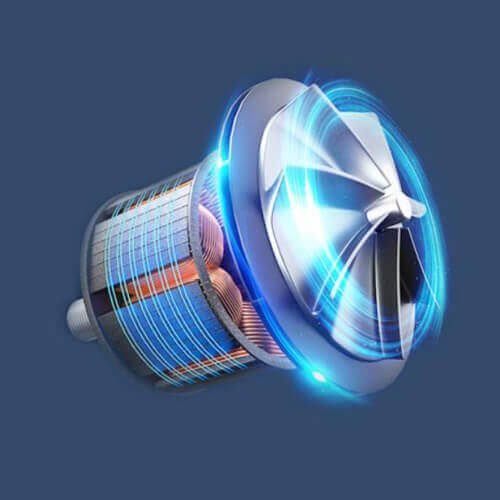

Copper wire motor: The 100% copper wire motor on the TCPEL alfalfa pellet machine provides longer service life, more power with lower energy consumption, and low noise operation.

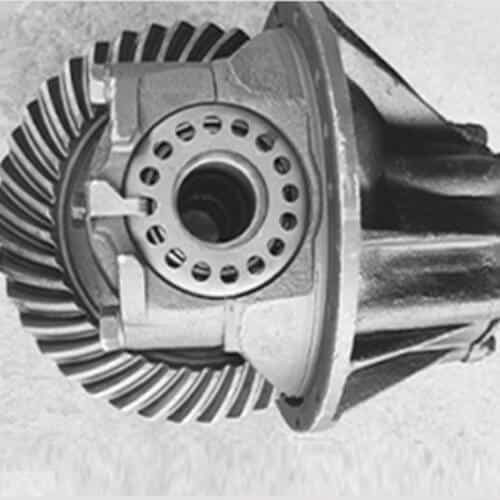

It adopts the automobile rear axle differential assembly design, which has a good gear combination, reduces the load on the main engine, and has good stability.

Wider discharge port: The discharge port on the TCPEL alfalfa pellet machine is wider to allow for smoother and more efficient pellet discharge, while the baffles on the sides of the discharge port minimize pellet spillage.

Nylon sliding casters: Smaller models of the TCPEL alfalfa pellet machine are fitted with wear-resistant nylon sliding casters for better portability.