Pellet Cooler

Pellet Cooler Introduction

A pellet cooler is a machine used in various industries, primarily in the field of biomass and feed pellet production. Its main purpose is to reduce the temperature of newly formed pellets, which are typically hot and soft when they come out of the pellet mill or pelletizing machine. Cooling the pellets is essential to enhance their durability, prevent moisture absorption, and make them suitable for storage and transportation.

After the pellet mill cooler, the temperature of the cooled pellets is not higher than the outside temperature +5℃, and the rate of moisture reduction is not less than 3.8%, which plays a good role in producing high-quality pellets, extending the storage time of pellets, and improving economic benefits.

Pellet Cooler Design

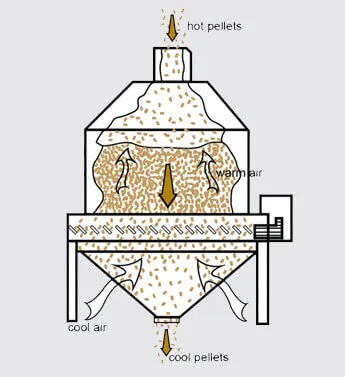

For the pellet cooler design, the pellets will drop from the top, while the cooling air flow from the bottom of the machine, this structure can help to remove the high temperature and high humidity from the pellets, to finish the full cooling process. So the pellet cooler also called counterflow pellet cooler.

Pellet Cooler Machine Specification

The pellet cooler whole system include the cooler, air lock, vibrator, fan, cyclone, and dust collector. The pellet cooler machine is also equipped with vibration device, it can also sort out the fine pellets from mixed sawdust, which can ensure you can get high quality pellets after cooling.

It can be applied to the cooling of various materials such as pellets, lumps, flakes, granules, and the like, particularly material similar to pellet in size. If you want to get a large amount of pellets with better quality, a pellet mill cooler is an essential equipment for the whole pellet making process. If you are looking for a pellet cooler for sale, TCPEL can also offer customized solution for you. Our pellet mill cooler capacity can be customized from 500kgs/h to 10t/h.

Model | Power (kw) | Output(T/H) | Capacity(CBM) | Power of Fan(kw) |

SKLN1.2 | 1.1+1.5 | 0.5-0.8 | 1.2 | 5.5 |

SKLN1.5 | 1.5+0.25 | 1-2 | 1.5 | 7.5 |

SKLN2.5 | 2.2+0.55 | 2-3 | 2.5 | 11 |

SKLN4 | 3+0.7 | 3-4 | 4 | 18.5 |

SKLN6 | 4+0.7 | 6-10 | 6 | 22 |

Pellet Cooler Machine From TCPEL

Pellet Cooler FAQs

What is a Pellet Cooler?

A pellet cooler is a crucial piece of equipment in pellet production. It's designed to lower the temperature of hot pellets, making them suitable for storage and transport. These coolers play a vital role in maintaining pellet quality, including biomass pellets and animal feed pellets.

How Does a Pellet Cooler Work?

Pellet coolers use ambient air to reduce the temperature of hot pellets. They typically consist of a perforated conveyor belt that carries the pellets through a chamber while cool air is blown over them. This process effectively reduces the pellet temperature.

After Pellet Cooler, What is the Pellet Temperature and Moisture?

Before entering the pellet cooler, the pellet temperature is about 70-85°, after the pellet cooler, the pellet temperature can be controled in 25-35°. The rate of moisture reduction is not less than 3.8%.

Why is Pellet Cooling Necessary?

Pellet cooling is essential because it prevents pellets from undergoing further thermal stress, which can lead to cracks and fines formation. Proper cooling ensures the pellets maintain their integrity and quality.

What Industries Use Pellet Coolers?

Pellet coolers are widely used in industries such as animal feed production, biomass pellet production, and wood pellet manufacturing. They are essential for any industry that produces pellets as part of their production process.

How Do I Maintain a Wood Pellet Cooler?

Maintaining a pellet cooler involves regular cleaning, checking for wear and tear, and ensuring proper lubrication of moving parts. Routine maintenance is crucial to keep your cooler running efficiently.