Hammer mills for sale - manufacturer & supplier in China

- Higher capacity and less wear parts costs

- Wide range of application suitability

- Stable running performance and easy operation

Hammer Mill - The Beginner's Guide

Whether you're interested in a biomass hammer mill, a hammer mill for wood pellets, a small hammer mill, a grain hammer mill, or even a mini hammer mill, you'll find that there are all kinds of products out there for you to choose from. So how do you find the best one? Understanding exactly how a works is the best way to recognize how a hammer mill machine can help your business.

So do hammer mills work – and what should you look for when shopping for a hammer mill crusher?

Here’s what you need to know.

What is a Hammer Mill Machine?

A hammer mills is a machine, or a mill, whose sole purpose is to crush or shred significant bits of material into smaller pieces. As the name implies, its core working part is a little hammer! The basic hammer mill principle is that repeated blows of tiny hammers help process material like wood or fibrous plant parts into smaller pieces.

Hammer mills can be used in many industries, including in sawmills, where shavings and scrap wood can be turned into wood pellets or mulch, for milling grain, making fruit juice or fluff pulp defiberizing, in producing ethanol plants, shredding paper, shredded garden, and yard waste, crushing rocks, and even in waste management and shredding scrap automobiles.

Hammer mills are incredibly diverse, effective machines that are necessary for all kinds of industries. We’ll take a deep dive into how these machines work next!

Hammer Mills Working Principle (Diagram, Design)

Whether it’s a wood hammer mill or a livestock feed hammer mill grinder, all hammer mills work in the same primary way. Most hammer mill parts (hammer mill screen, hammer mill hammers, hammer mill blades, and so on) are similar between machines – it is the size and application of these hammer mill parts that will vary.

Here’s the basic hammer mill principle to help you understand the question – how do small hammer mills work?

It’s not as complicated as it might seem. A hammer machine usually has five core parts, each of which will vary in their complexity. The number of elements in the hammer mill can also vary – this depends on the complexity of the machine’s design.

Each part is important, however, in the overall hammer mill working principle and hammer mill design.

Basic Hammer Mill Design

The first component to be aware of in a small hammer mill is the feeding mechanism. This is how particles enter the crushing chamber. Depending on how the hammer mill is designed, it can use gravity or a feeding system that is metered.

Metered systems are most common in industries where the uniformity of materials needs to be consistent. Gravity feed systems rely solely on the gravitational force, so the material may not enter in as uniform of a fashion (or exit in a uniform way either).

A hammer mill will also have a control box that allows the operator to power on or off the machine. It may also allow him to control the motor speed for the feeding system. Some of the more advanced hammer mills also come with display panels, so you can keep an eye on all of the machine’s various processes.

Next, the most important part of a hammer mill – the hammers or crushing knives. These individual knives or hammers rotate very fast – usually at speeds of anywhere from 2,500 to more than 60,000 RPMs!

These knives or hammers tend to be mounted on horizontal shafts. They can rotate clockwise or counterclockwise depending on the rotor rotation direction.

The rotor is a rotating shaft that is coupled with an electric motor. The crushing tools themselves can be attached to the engine or belt-driven, depending on the design of your machine.

These belts are meant to cushion the system from shock.

Finally, the hammer mill also has a set of screens. The size of the particles that you get after processing materials through your hammer mill will depend largely on the screen variations.

Hammer mills can have more than a dozen different screen meshes, all of which are usually arranged in a particular order within the crushing chamber. They offer predictions of up to 200!

How Hammer Mills Work

Again, exactly how a hammer mill works will vary depending on the industry. Here are the basics.

First, the operator will introduce material through the hopper. These materials need to have been cut to the right size and have the right physical properties given the type and design of the machine. Once they’re inserted into the hopper, they will be moved into the crushing chamber (again, this can be done by gravity or by a metered system).

Once the materials are in the crushing chamber, the hammers or knives will hit the material numerous times. These move at an extremely high rate of speed to reduce materials to the right size as quickly as possible.

Only materials whose diameter matches that of the screen size will pass through – if they don’t, the hammer will hit them again and again until they are the right size and can then pass through.

The materials within the hammer mill chamber are, in this sense, basically reduced down to size by a repeated combination of impact with the knives, hammers, and inside of the milling chamber’s wall. The collision between particles can also help reduce them down to size in a timely process.

This is a basic mechanical process that’s relatively easy to understand. The operator should avoid opening the door to the crushing chamber when the machine operates, or it can lead to pretty dangerous outcomes.

After the material has been processed in the chamber, it will go out of the milling chamber through the perforated screens. These are also sometimes referred to as bar gates. The smaller particles will pass through while the coarser material remains in the section to be “reprocessed.”

The material can then be packed into capsules vai capsule filling machines (something often done in the pharmaceutical industry) or moved along to the next stage in the process (if you’re working with a wood pellet production line, for example).

Numerous factors determine theft uniting and output of the hammer mill, including the configuration of the knives or hammers, the screen size, and the shaft speed. For a more refined finish particle size, operators should consider using a smaller screen size and additional crushing knives or hammers (or larger ones). A faster rotor speed can help, too.

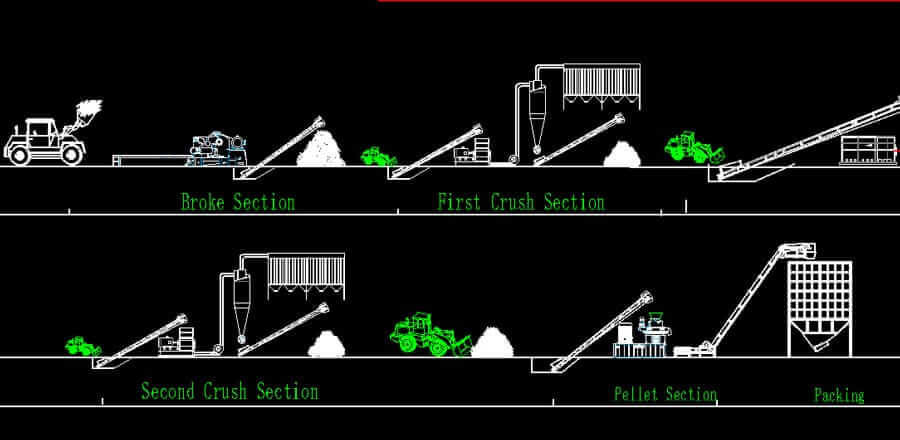

Still looking for clarification? Here’s a helpful hammer mill diagram that shows the basic steps and components of such a machine as part of a larger biomass pellet plant. Again, hammer mills will vary depending on the type of machine, but this should give you a basic overview.

How Much Does a Hammer Mill Cost?

Buying a hammer mill for sale is an intelligent choice for your business. However, the average hammer mill price will vary widely depending on variables like the size of the machine, your intended output, the type of raw material you plan on processing, and other features.

Newer, commercial-scale machines will, of course, cost more than a mini-version designed for home use. A commercial machine can cost up to $26,000 or more, while a cheap, farm-use mini hammer mill designed for homesteaders can cost less than $100.

Don’t settle for a cut-rate machine based on price alone. Do some comparison shopping to make sure the hammer mill you buy is a good value for the money – regardless of how much you decide you want to spend.

How Many Types of Hammer Mills?

There are a few main types of hammer mills out there. You may also hear them referred to as a small hammer mill crusher or hammer mill grinder.

They can loosely be categorized as “up running” and “down running” mills. An up-running mill will use perforated screens to process complex or soft materials. It might also use grate bars instead of the screens. The type and size of material that needs to be reduced will largely determine how the rotor is built. This can be adjusted based on wear and tear.

A down-running hammer mill grinder is designed specifically for fibrous materials. It has a higher concentration of shearing action.

Even further than that, you can categorize hammer mills as reversible or nonreversible. The grinding abilities and working format of both machines are similar, but the construction is somewhat different.

For example, a small grain hammermill is a small machine that can be operated on a household current, while a larger hammer mill used to work in automobile factories may require a diesel or electric motor.

There are even screenless hammer mills that use airflow instead of a screen to separate large particles from smaller ones. These newer technologies are meant to be more reliable – and also more efficient and less expensive to run – than traditional hammermills.

There are dozens – if not hundreds – of different types of hammer mills out there. Finding the right one for your business will depend largely on your end goal and intended use. However, all hammer mills, whether a feed hammer mill or a wood hammer mill, are more or less the same in how they are built and how they operate.

What Does a Hammer Mill Do?

A hammer mill is a high-precision machine that can grind up both solid and hard granules into uniform pieces to be processed in other machinery later on. The ideal hammer mill will offer consistent levels of grinding, noiseless operation, and minimal heat build-up.

Hammer mills can be customized to meet your unique needs and the types of products you are hoping to produce. For example, some are designed for use in the pharmaceutical industry, while others can shred, pulverize, or crush food ingredients like corn and sorghum for livestock feed productions.

What are Hammer Mill Advantages and Disadvantages?

Hammer mills are considered the oldest and most effective type of grinding mill. While there are other types of grinding mills, you can use, hammer mills are, by and large, considered the most advantageous.

Hammer mills offer several advantages. They offer numerous size distributions and can sort out particles of different sizes. They can produce your specific scope of particles without having to add a closed-circuit crushing system. They have high reduction ratios and capacities and reasonable energy requirements – they won’t suck your system dry!

They can grind many types of materials, including brittle ones and those that are tougher. Hammer mills don’t take up much space, are easy to maintain, and operate.

However, they can be disadvantageous because they aren’t as well suited for abrasive, sticky, or plasticky components. The heat generation is so intense that it can damage materials that have a low melting rate. Hammer mills occasionally choke up and become clogged, too, especially if the feed rate is not adequately controlled.

Foreign materials like metals or stone can find their way into the machine and damage or clog the screen, too, meaning there’s an additional level of care that needs to be taken to ensure that these machines work effectively.

How to Choose the Best Hammer Mill for Pellet Production?

There are a few variables you will want to consider when shopping for a hammer mill for pellet production. First, make sure it’s meant specifically to process materials that will be used for pellet production.

While you can use most hammer mills for this purpose, some are designed for other applications (like automobile crushing) and, therefore, will not be appropriate.

Hammer Mill Capacity Calculation

The capacity of your machine is one of the most important variables. The instructions and nameplate on your device should tell you the rated capacity under standard conditions.

Choose one that has a higher production capacity than your demand – that way, in case you suffer from wear on your machine that causes production to take a dip, and you can still keep things up and running.

If you’re having trouble figuring out the capacity of your hammer mill, know that it usually corresponds to its power weight and dimensions. The larger the hammer mill, in general, the higher the capacity it will have.

Here’s a simple chart to break those calculations down for you:

Capacity(T/H) | Power(kw) | Weight (Kg) | Dimension (mm) |

1-3 | 22 | 860 | 1310×800×1070 |

2-4 | 37 | 1350 | 1380×800×1010 |

3-6 | 55 | 1520 | 1900×800×1100 |

5-8 | 90 | 1830 | 2100×1700×1500 |

3-10 | 160 | 2300 | 2100×1000×1100 |

Material Type

What kind of raw material do you plan on processing with your hammer mill? If you want to crush grain feed into pellets for the livestock, you should choose one with a feed hopper on the top. For bran or wheat ingredients, choose a disc mill. For hard materials, choose a non-sieve grinder, and for a mixed feed with small and adjustable particle sizes, select one with a special non-sieve grinder.

Power

The power of your hammer mill will vary depending on the type of material you are processing. For instance, sorghum needs about one times more power than corn. The different sizes of screen mesh can also impact the load.

You’ll also need to consider power consumption in addition to output. In some parts of the world, the government has regulations in place regarding the energy efficiency of certain machines. Take this into consideration when you’re shopping.

Discharge Mechanism

How are raw materials discharged from the machine? Usually, this occurs in negative pressure suction mechanical transport, or self-weight mechanism, with self-weight being the most common.

How to Operate a Hammer Mill for Beginners?

Are you new to the world of hammer mills? Fortunately, operating a hammer mill is relatively straightforward to do.

First, you’ll make sure all parts are maintained and in good working order. Put on your PPE (goggles, gloves, etc.). Power on the machine with the on/off switch in the control box. You can also control different features here, like the motor speed or feeding system.

You will then feed your material into the hammer mill. A steel drum with a vertical or horizontal rotating shaft or drum will have hammers mounted on it. The hammers can swing with a rotor spinning at high speed inside the drum, too. When you feed material into the feed hopper, it will be impacted by these hammers before being shredded and expelled.

It is expelled through screens of a specific size. You can then collect the material and move on to the next step in the pellet production process.

How to Maintain a Hammer Mill?

Maintenance is a critical element of keeping your hammer mill productive and functioning well long into the future.

Without maintaining a hammer mill, injury or degradation of the machine are both highly probable. That’s one reason why insurance companies are sometimes hesitant to insure businesses with hammer mills on site!

The elite, however, is that hammer mills in and of themselves are not dangerous in the slightest. It is only when a hammer mill is not properly maintained that the operator and business owner will run into trouble.

There are various considerations to make when maintaining your hammer mill. For one, you need to make sure it is properly lubricated. The manufacturer will have the best recommendation for the ideal type of lubrication for your machine. They’ll also tell you when it will need to be greased and when bearings need to be lubricated and adjusted.

Of course, these schedules can vary a bit – but you should never ignore essential maintenance. Auto lubrication is a feature on some hammer mills, but it’s still important to double-check to ensure these features are working effectively.

You should also check the airflow into the machine regularly. If there’s not enough airflow, the speed of the machine will be affected, and materials can get stuck in the screens and beaters of the device, too.

How to Buy an Affordable Hammer Mill?

Finding an affordable hammer mill can be tough. You don’t want to get a cut-rate machine that’s not going to do the job effectively – yet how do you know if you’re spending too much (or too little) on your machine?

There are a few ways you can make sure you are getting a good value.

For one, make sure the machine has the ability to work with a raw material of all moisture contents. The moisture content can increase the viscosity of raw materials, reducing their fluidity and lowering your overall production efficiency and output speed.

You should also look for how productive your machine will be. Look for a machine with a reasonable crushing chamber diameter. The size of the crushing chamber should be able to adapt to your various raw materials, and the size of the mesh sieve or your hammer mill isn’t a great value for your money.

When considering the affordability of your machine, it’s important to consider not just the sticker price when you buy it but also how easy the hammer mill will be to maintain and operate. If you have to invest thousands of dollars in routine maintenance and costly training programs for your operators, it’s not going to be a great overall value for your money.

So while you might spend less money when you initially buy the machine, you’re wasting it later on.

Finally, consider the spindle speed. The higher the spindle speed, the more productive your machine will be. Once it reaches the limited value, your efficiency will drop – making your machine not as great of a value for your money.

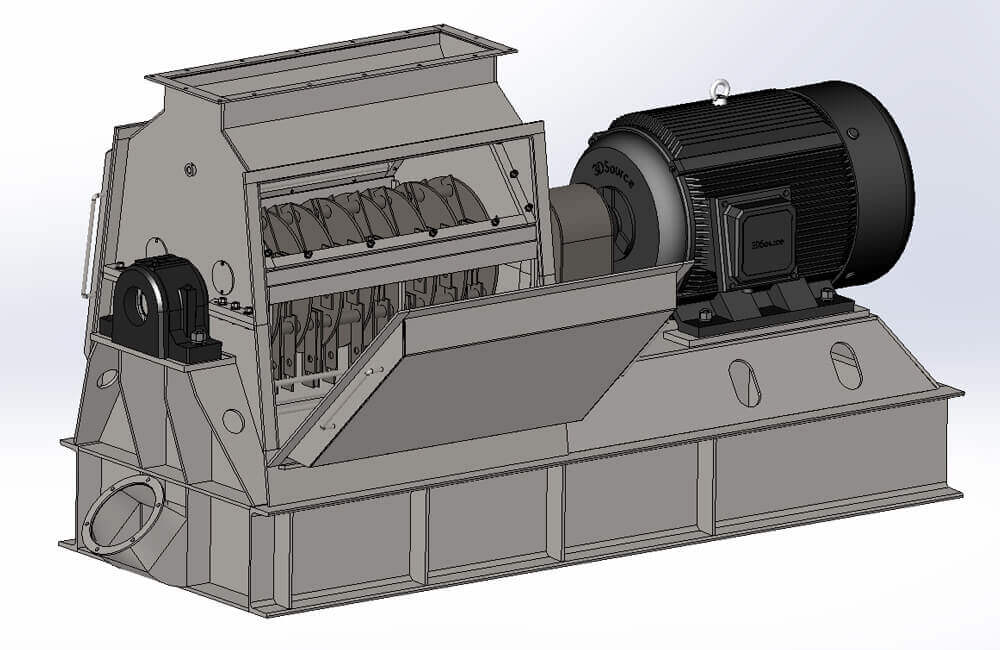

TCPEL Hammer Mill Machine Introduction

Whether you’re processing biomass, like soybeans and weeds, corn stalks, wood shavings, or inorganic matter like PVC foam board, rubber, or other materials, the TCPEL hammer mill is the versatile machine that can help take your production to the next level.

As you probably already know, most pellet mills require raw materials to be powdered form with a diameter of no more than five millimeters. These raw materials don’t come like the sin of nature! Therefore, crushing them down is essential.

If you’re looking for a smooth-operating, high-capacity machine, you’ll find all of that (and more!) in the TCPEL hammer mill machine. It can be used in operations of all kinds, including in wood pellet mills, feed production lines, organic fertilizer factories, and more.

TCPEL Hammer Mills Features

Are you still shopping for the best hammer mill? Consider the TCPEL hammer mill’s many features as you do so.

1. Versatile: This diverse and versatile machine can handle biomass materials of all types and sizes, including crop stalks, wood chips, tree branches, coconut shells, and more. It will grind all of them down into a powder equal to or less than three to five millimeters. That’s the perfect size for making pellets and even briquettes! It can even handle a non-organic matter like rubber, foam board, PVC, and more. It can be used to process agricultural or forestry waste, in Chinese herbal medicine, in chemical factories, and much more.

2. Easy to Maintain: This hammer mill has numerous features that make it easy to maintain. It has a revolutionary cold water cooling structure. This helps resist damage to spare parts inside the machine that are often caused by friction. It also has a unique two-motor operation drive, allowing for higher capacity and smoother operation without worrying about wear and tear.

3. High Precision Machines: The high-precision components of the TCPEL hammer mill mean that this machine will last longer and have a higher performance than its competitors. It has CNC-engineered systems that help the machine stay durable. Every part is manufactured in this way, from the screener to the hammers and spare parts.

4. Environmentally Friendly: This machine comes with all sorts of features that make it safer for the environment. For example, it has a certified and qualified motor with a thick copper coil for more stability and a smoother process. As a biomass hammer crusher, it can work with an air fan and cyclone so that crushed powder will come out of the bottom and be easier to collect. That’s less debris going into the air and making a mess of your work environment.

5. Thicker Knives: Made out of H13 steel, the knives on this hammer mill have special abrasion-resistant treatment technology. It’s harder and resists wear, meaning it can cut wood and have a longer time before it needs to be serviced. The materials are made with tungsten carbide spot welding and are thicker, too, allowing for a better overall working time and performance.

6. Fast Cutting Rate: Last but not least, the material has blades that cut and process material much faster than others. It uses high-speed airflow and reversed and rotational blade cutting direction to allow the machine to be crushed at a normal double rate.

TCPEL Hammer Mill Machine Parameters

| Model | Capacity(T/H) | Power(kw) | Weight (Kg) | Dimension (mm) | Hammer qty(piece) | Note |

|---|---|---|---|---|---|---|

| GXP65X27 | 1-2 | 22 | 860 | 1310×800×1070 | 24 | Φ4, can be adjust |

| GXP65X55 | 2-4 | 37 | 1350 | 1380×800×1010 | 48 | Φ4, can be adjust |

| GXP65×75 | 3-6 | 55 | 1520 | 1900×800×1100 | 72 | Φ4, can be adjust |

| GXP65*100 | 5-8 | 90 | 1830 | 2100×1700×1500 | 72 | Φ4, can be adjust |

| GXP130*55 | 8-10 | 160 | 2300 | 2100×1000×1100 | 160 | Φ4, can be adjust |