Product

We offer complete pellet making machines. Including Wood Chipper, Hammer Mill, Rotary Dryer, Pellet Machine, Pellet Cooler and Pellets Packing Machines. Beside that, we also offer disc chipper, log debarker machine wood shavings machine etc. Here we list our products based on different sections for making pellets.

Crushing Section

Crushing section is used to process your raw materials into smaller size from big size. The input raw material can be waste wood branche, log, palm shell, bamboo, waste pallet ,cotton stalk, corn stalk etc. The final output size of raw material is 3-10cm. For crushing section, our main machines are drum chipper, brush chipper ,disc chipper.

Drum Chipper is used to process big size wood related materials into wood chips. The capacity from 3-30t/h based on customer requirement. The wood chips size is 3-5cm.

Brush Chipper is portable wood chipper, it’s designed to process garden waste into wood chips. The engine can be optional with electric and diesel engine.

Disc Chipper is used to process small logs into uniform wood chips.

Hammer Mill Section

Hammer Mill section is used to process wood chips size materials into sawdust. Because for making wood pellets, you need to prepare all your materials into sawdust size. The input size of the hammer mill is 3-10cm, the output sawdust size is 3-5mm. The main machines we offer for this section is hammer mill machine.

Hammer Mill is used to process wood chips size material into sawdust. The capacity from 1-20t/h based on customer requirement.

Drying Section

Drying section is used to dry the sawdust material. Remove the sawdust moisture, and keep their moisture in 10-15%, this is best for making pellets. For this section, the machine we can offer is rotary dryer machine.

A rotary dryer machine is a type of industrial equipment used to remove moisture from materials through the process of evaporation. It consists of a rotating drum or cylinder that is heated either internally or externally. Wet materials, such as wet grains, minerals, chemicals, or biomass, are fed into the rotary dryer, and as the drum rotates, hot air or other heating elements are introduced to heat the material. Based on different structure, we can offer single pass rotary dryer, triple pass rotary dryer.

Pellet Mill Section

A pellet mill section is a specialized area or component within a pellet manufacturing facility or process that is dedicated to the production of pellets. Pellets are small, cylindrical or spherical compressed units typically made from various materials such as wood, biomass, agricultural residues, or even plastics. These pellets are commonly used as fuel, animal feed, or in various industrial applications. For this section, the machines we can offer is wood pellet machine and feed pellet machine.

A flat die pellet machine, also known as a flat die pellet mill, is a type of pelletizing equipment used to create small, cylindrical pellets from various materials, such as wood, biomass, agricultural residues, and more. It is called a “flat die” machine because it features a flat, horizontal die and stationary rollers or blades.

A vertical ring die pellet machine, also known as a vertical ring die pellet mill, is a type of pelletizing equipment used for producing wood pellets, biomass pellets, and other types of pellets. The vertical ring die pellet machine is designed with a vertically oriented ring die. We have 3 main models, capacity 1t/h pellet machine, 2t/h pellet machine and 3t/h pellet machine.

A feed pellet machine, also known as an animal feed pellet machine or feed pellet mill, is a piece of equipment used to produce pellets from various raw materials for animal consumption. These pellets are designed to provide balanced and nutritious feed for livestock, poultry, pets, and other animals.

Pellet Cooler

Pellet Cooler is a machine which adopting counterflow cooling structure to cool down the pellet. For the pellet cooler design, the pellets will drop from the top, while the cooling air flow from the bottom of the machine, this structure can help to remove the high temperature and high humidity from the pellets, to finish the full cooling process. So the pellet cooler also called counterflow pellet cooler.

The pellet cooler is used to cooler down the temperature of wood pellets.

After the wood pellet cooler machine, the temperature of the cooled pellets is not higher than the outside temperature +5℃, and the rate of moisture reduction is not less than 3.8%, which plays a good role in producing high-quality pellets, extending the storage time of pellets, and improving economic benefits.

Pellet Packing Machine

Pellet Packing Machine is used to pack the biomass pellets into small bags. It solves the problems of packaging some special chemical raw materials, has a wide range of applications and is simple to operate. Widely used in light industry, chemical industry, metallurgy, building materials, ports, mining, food, grain and other industries.

This packing machine can pack wood pellets into small bags, 15-50kgs/bag based on your needs, the packing speed is 200-300bags/hour.

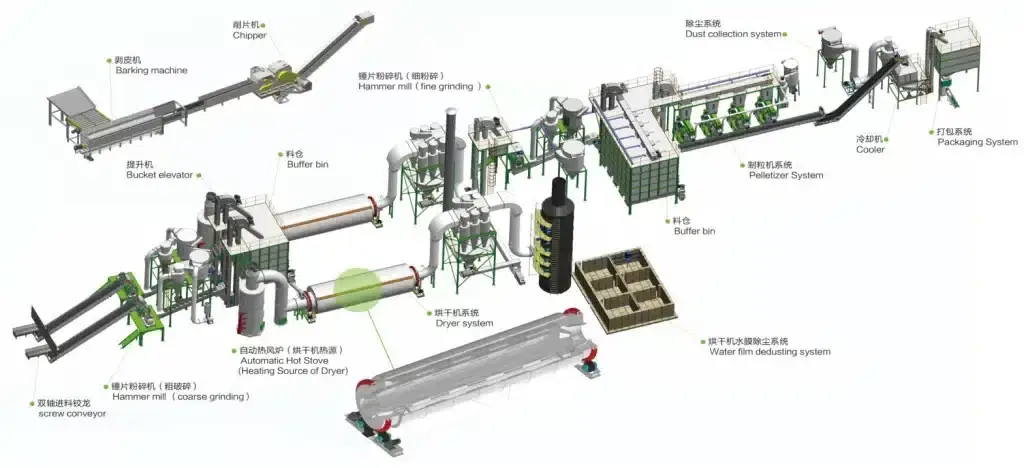

Pellet Line

A pellet line, often referred to as a pellet production line or pellet manufacturing line, is a complete system or assembly of equipment and machinery designed for the continuous or semi-continuous production of pellets from raw materials. These raw materials can include wood, biomass, feedstock for animals, and other materials that can be compressed and shaped into small, cylindrical pellets. Pellet lines are used in various industries for different applications, including biomass energy, animal feed, and more.

We offer complete pellet making solution based on various requirement. From the first crushing section to the final packing section. We can always offer satisfying solution to customers. Capacity from 100kgs/h to maximum 50t/h.

Other Machines We Supply

A wood shaving machine, also known as a wood shaver or wood shaving mill, is a piece of equipment designed to convert wooden logs, wood blocks, or wood waste into thin, curled shavings or flakes. These shavings are commonly used for various purposes, including animal bedding, poultry farming, and as raw material for the production of wood pellets, particleboard, and other wood-based products.