Professional Feed Pellet Machine Manufacturer, CE Certificated

- We are Leading Pellet Machine Manufacturer

- 15+ years factory with CE ISO9001 certificate

- 1000+ happy customers worldwide

- shipped to over 60+ countries

- pellet machine made with enhanced top level steel

- easier to start your pellet production plant

- 24*7 Hours online service

Privacy Policy: Security and Privacy Guaranteed 100%

advantages of our Feed Pellet machine

Our feed pellet machine is perfect for large, medium, and small companies looking to expand and improve process animal feed pellets. Whether you’re an aquaculture plant or a grain factory, or a livestock farm, this pellet feed mill will work wonders for you.

Farmers and livestock feed companies have used it all over the world. It doesn’t require your raw materials to be dried, as even powdered ingredients can produce cylindrical particles. It will save you time and energy, making it easier for you to make more feed (and more money) in your business.

Driven by a powerful motor, it can press feed pellets and press wood sawdust pellets as long as the moisture content of the raw materials is around 12 to 20%. There are multiple die diameters you can choose from, allowing you to process materials one granule at a time – but quickly and more efficiently to keep your production line right on track.

Here are some of the main features of our feed pellet machine:

1. Multiple power ratings available: You can buy this machine with multiple power ratings ranging from 3 KW in the smallest model up to 15 KW or more. This makes it highly efficient for factories and businesses of any kind. Power options vary depending on your needs, including electric, diesel, gasoline, or PTO. You can tailor these options to make your machine easier to move, power, and more efficient to run.

2. Easy to operate: This feed pellet machine has a high output with low consumption and low noise. Not only is it quiet to operate, but it’s easy to operate, too. It’s easy to train new operators to use the machine and only takes one person to run.

3. Requires minimal maintenance: Maintenance is essential for any feed pellet machine, but with this product, you’ll find that it has parts and components that make it easy to take care of. It has a high-pressure filtration system and independent lubrication systems, so you won’t constantly stop lubricating the machine.

4. Versatile in its applications: You can use this feed pellet machine to process feed pellets for just about any type of species. It can work with things like rice husks, peanut shells, sunflower husks, wood parts, and much more, making it one of the most versatile products you can buy. It works with high density and low density materials, low moisture content, and high moisture content alike.

5. Multiple apertures available: Several different apertures are available to suit the needs of different types of animals and their required feeds. Not all feed can be processed through the same flat die, so this machine makes it easy to change them out.

The pressure roller and grinding disc are made of chromium-manganese steel, which is more durable after high-temperature quenching treatment. The newly upgraded grinding cavity is 10-20 times the wear resistance of ordinary materials.

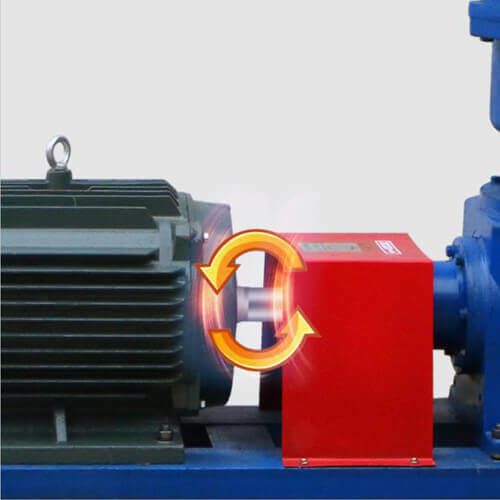

Electric coupling, direct docking, simple operation, and convenient installation. The coupling is stable and durable, made of stainless steel, after high-temperature quenching treatment, more durable than ordinary materials. The newly upgraded coupling drive, compared with the old belt drive, has less transmission ratio loss and is more durable and wear-resistant

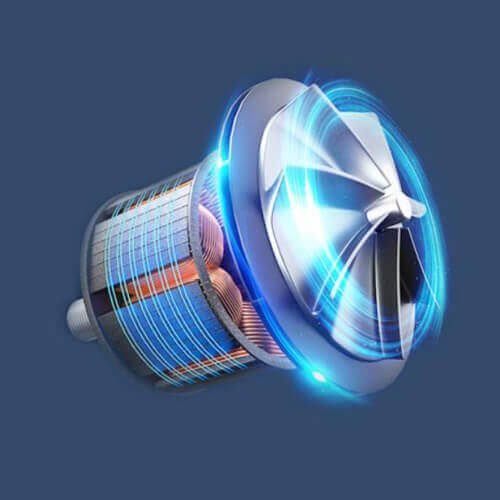

100% copper wire motor, long service life, large horsepower, saving power. All copper coil, heat sink, long service life, silent bearing, stable operation, and low noise. Power off at high temperature to avoid malfunction caused by high temperature

Larger feed inlet design makes feeding more convenient and work efficiency higher Widened discharge port design, design with baffles on both sides to avoid feed spilling, widened and enlarged discharge port, discharge faster and smoother.

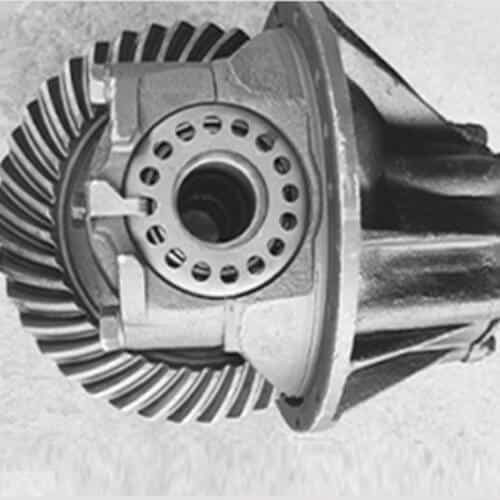

It adopts the automobile rear axle differential assembly design, which has a good gear combination, reduces the load on the main engine, and has good stability.

Easy to refuel, simple to use, GL-5 heavy-duty gear oil must be filled before use.

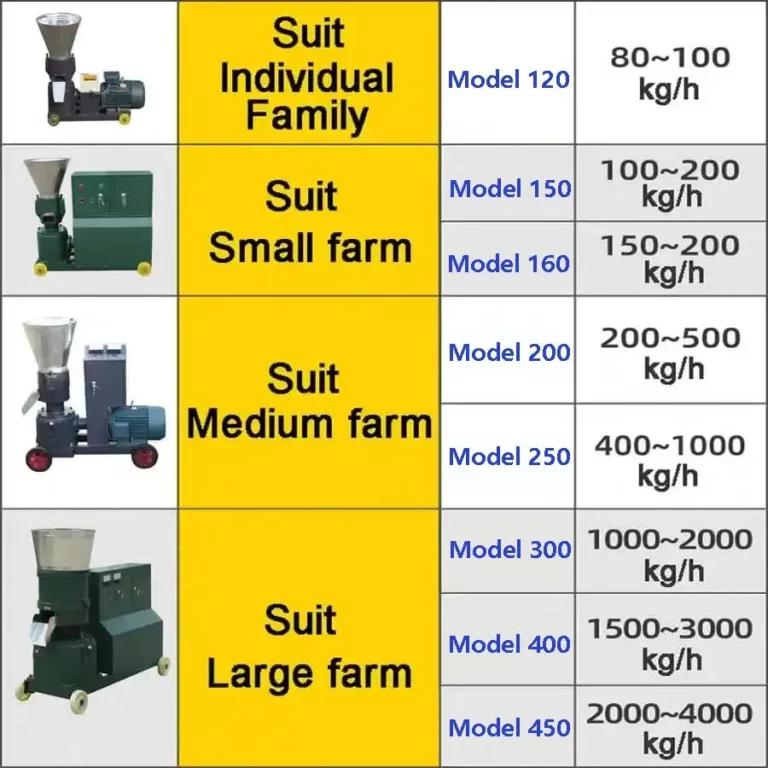

Feed Pellet Machine Model Suggestion

Based on different customers making scale, we have various models for feed pellets making, either you want for home pellet making or large scale farm pellets manufacturing, we can offer you customized solution.Capacity from 100kgs/h to 20t/h animal feed pellets making.

| Model | Capacity | Pinch Roller | Power | Voltage(V) | Weight | Dimension |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg/h | Double roller | 2.2kw | 220V/380V | 95kgs | 68*42*53cm |

| TFC150 | 150-200kg/h | Double rollers | 7.5kw | 220V/380V | 100kgs | 72*45*65cm |

| TCF200 | 300-400kg/h | Double rollers | 11kw | 380V | 180kgs | 126*53*92cm |

| TCF250 | 600-800kg/h | Double rollers | 15kw | 380V | 320kgs | 131*54*93cm |

| TCF300 | 800-1000kg/h | Double rollers | 22kw | 380V | 400kgs | 146*59*110cm |

| TCF350 | 1000-1200kg/h | Double rollers | 30kw | 380V | 580kgs | 186*70*128cm |

| TCF400 | 2000kg/h | Double rollers | 37kw | 380V | 680kgs | 206*76*137cm |

| TCF450 | 2000-2500kg/h | Double rollers | 45kw | 380V | 780kgs | 218*79*140cm |

about us

TCPEL a professional pellet machine manfuacturer in China since the year 2004 .Our factory integrate research and development, production, sales and service, we have modern equipment for manufacturing and excellent technical research and development team.

Factory Size : 40000㎡

Working Staff: 200+

Annual Export Value: $15Million

We have experienced and skilled after-sales service team. Based on detailed customers requirements, we can always offer satisfying solutions for pellet production projects.

Quality and service is our soul for company development, we will try our best to support customers on pellet making, to achieve win-win cooperation.

Why 1000+ Customers Choose us?

Our Engineers

We employ highly skilled, professional engineers devoted to researching and improving all our products. Our senior engineers are well-qualified with advanced degrees. Our experienced and skillful R&D engineers can help solve your problems regarding the machines or production and assist with after-sales service.

Strict Quality Control

Quality is important to us. We are IS0 9001, CE, and SGS certified. All components used in our machines pass our strict quality inspection. We carry out a trial run for each machine and wearing testing before shipment.

Competitive Price

Manage your budget in a smart way and minimize your manufacturing costs. We offer competitive prices for all our machines. Contact our sales team for support for custom solutions.

Professional Sales Team

We have a highly qualified international sales team that will reply to you within 24 hours regarding any pre-sales questions you may have. After sales, we offer 24/7 email and phone communications, and can arrange onsite support.

Full Technical Support

Full 24/7 support both before and after your purchase. We offer free testing to develop the manufacturing process at your business and are dedicated to find the best solution for your specific needs. If you are interested in partnering with us to sell our machines, we are happy to consult with you.

Ordering and Payment

Ordering with us is fast and convenient. Our professional sales team replies quickly to inquiries and strives to solve your problems, both pre-sales and after-sales. We securely accept all forms of payment including T/T transfer, LC at sight, PayPal, and Western Union.

Feed Pellet Machine- The Beginner's Guide

Feed Pellet Machine is a well designed and manufactured pellet mill that is ideal for producing feed pellets from a variety of raw materials. It is easy to operate and can be used in both small and large scale operations. This machine can be used to make feed pellets from various agricultural by-products such as corn cobs, rice straws, barley straws, sunflower heads, peanut shells as well as from other raw materials like cotton linters, bagasse etc. Are you new to the world of poultry feed pellet machines? Have you heard a lot of information thrown at you and are now just feeling overwhelmed? This beginner's guide will provide you with everything you need to know in order to get started with feed pellet machine. Whether you are a beginner or seasoned expert, our guide on feed pellet machine will provide insight for both beginners and the more advanced user.

What is a Feed Pellet Machine?

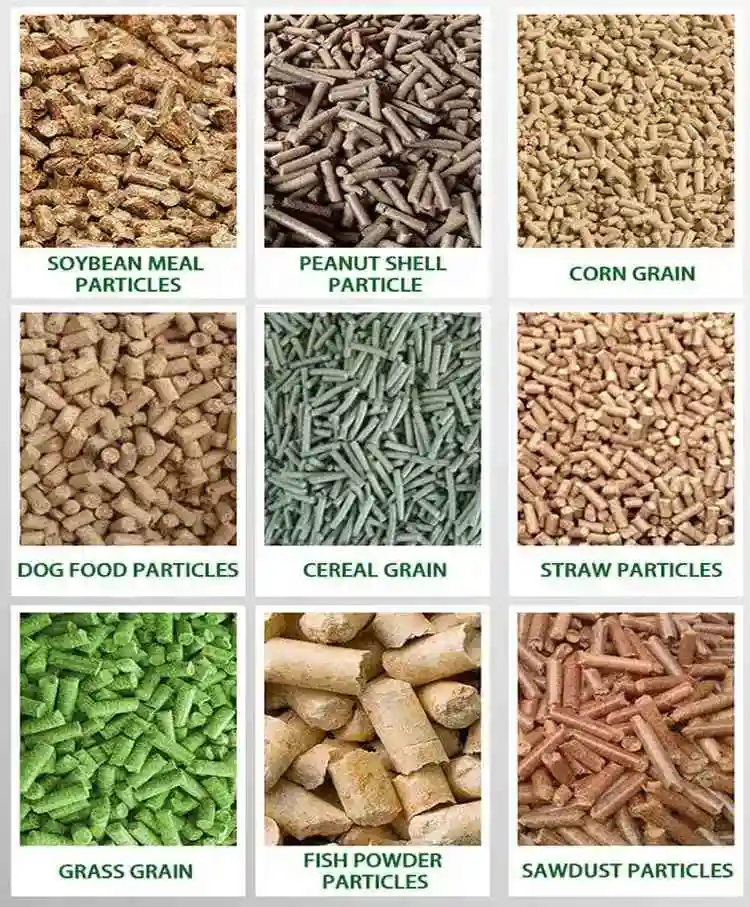

Feed pellet machine also known as animal feed pellet machines, feed pellet mill, it’s a machine used to process materials like soybean meal, corn, rice husks, grass, straw etc into feed pellets which can be used as food for livestock.

Feed pellet machines are the most commonly used equipment for making small animal feed pellets. Feed pellet making machine can make various kinds of pellets by adjusting the materials and recipes. Feed pellet machine is widely used in the poultry, cattle, pig, horse and other animal husbandry industries.

What Does a Feed Pellet Machine Do?

A feed pellet machine is a device that turns ingredients into small pellets, making it easier for animals to eat.

The process of making pellets from raw materials is known as pelleting. The resulting product is often referred to as feed pellets. Feed pellets are sometimes referred to as dry feeds or animal feeds.

Feed pellet machines can be used for a wide variety of raw materials, including grain, corn and soybeans. A feed pellet machine can also be used to produce other types of pet food or livestock feed.

These machines work by first taking in the raw material and then pulverizing it with a hammer mill. The hammer mill will break down the material into smaller particles until they are small enough to fit through a grinder mill. This grinder mill will then further grind the material into even finer particles before passing them through a classifier which will separate out any impurities or foreign objects that might have made their way into the mix during processing. After this last step has been completed, the finished product will be ready for packaging and shipping off to distributors who will sell it on retail shelves around the world!

How Does a Feed Pellet Machine Work?

A feed pellet machine works in a relatively straightforward way.

First, you will crush the materials with the machine. You can feed all kinds of material into a feed pellet machine, including corn, wheat, grass, bran, and so on. When you insert the raw material, it needs to be crushed to make sure all grains are made into a canister, powder-like form.

Then, the pellet machine mixes all of the ingredients. The mixing device combines the powders in different portions, forming a mixture known as mash. In some cases, the process stops – many companies buy mash to feed to animals (like young baby chicks) because it is easier for them to digest.

If you have a small pellet machine or a homemade feed pellet machine, this might be where you choose to stop when making certain types of food. That way, you can tailor your product better to the specific animal you are trying to feed.

However, if you run a business specializing in producing livestock feed pellets for sale, you will need to keep going. You will need to make the pellets by pressing the feed mesh into compact, dried forms. There are all types and sizes of feed pellet machines you can choose from, each of which varies in terms of speed, processing capacity, and efficiency.

How Much Does a Feed Pellet Machine Cost?

If you are searching for a feed pellet machine for sale, know that the average feed pellet machine price can vary widely. You can find a cheap option with an animal feed pellet machine price of around $1000 to $2000. Still, in some cases, you may even be able to find less expensive options (typically those designed for homeowners with hobby farms who want to feed their animals less expensively) for around $500 or less.

There are also large-scale feed pellet machines that are more expensive – several thousand dollars or more. Similarly, there are pellet machines for other types of products (like wood pellets) that are more or less expensive depending on their function.

The typical biomass pellet machine price, for example, will cost around $2000 to $6000.

How Many Types of Feed Pellet Machine?

Although there are many different sub-varieties of feed pellet machines you can choose from, most can be broken down into two distinct categories – ring-die and flat-die.

Though both types of feed pellet machines should help you get the job done with relative ease, it is important to note that flat die pellet mills tend to be cheaper in terms of the purchase price. That said, ring die pellet mills are more energy-efficient, so they may save you more money over time since they conserve energy.

Both types of pellet machines can be found in varying sizes depending on your specific needs. Most are powered with steam, though this, too, can vary, and some even have built-in grinders and mixers, depending on your needs.

Within those two larger overarching categories, there are both large-scale feed pellet mills and small-scale pellet mills. Most small-scale mills use a flat die since they’re just grinding up dried powder into pellets – they aren’t grinding and mixing. Large-scale feed pellet machines use ring dies and can be assembled like complete production lines, processing large amounts of animal feed.

As you might expect, these can also grind and mix and operate at a much higher capacity.

How to Choose the Best Feed Pellet Machine for Pellet Production?

Although you can use any old type of pellet machine to make animal feed pellets, it’s recommended that you choose an animal feed pellet machine specifically. Each piece of machinery plays a particular role, and this role is important. Here are a few things to consider as you start shopping.

Flat Die vs. Ring Die

This is one of the most important considerations you will need to make when shopping for a feed pellet machine. Most people use ring die pellet machines when the content of powdery material, like powdered grass, is less than 40%.

That’s because the surface of the granules is more glossy and because the curing rate of ring die pellet machines is higher than flat dies.

Plus, ring die pellet machines offer a higher sealing performance. There’s not usually a lot of large dust particles when you are making feed, so there won’t be as much friction or as much damage. Ring die pellet machines are also ideal for pre-processing for premixed feed.

Raw Material and Animal Type

Again, for processing more concentrated types of feed, both ring die and flat die pellet mills will work. If you’re processing grass-feed or mixed feed, ring die is best.

Consider the animal type, too. You’ll want a thicker pressing die for animal feed to feed chickens and pigs, but you can use a thinner die for animals like sheep and cattle. This has to do with the diets of each respective animal.

Power

Check the power rating for your feed pellet machine. This will determine the efficiency and output of the machine along with its production capacity.

How Do You Make Animal Feed Pellets?

Making animal feed pellets is quite simple. Before you get started, make sure you read the information included in the instruction manual for your machine quite carefully. You need to make sure you are adhering to all recommended safety guidelines before you start working. Otherwise, you run the risk of injuring yourself.

To begin making pellets, you need to gather your raw materials. Most animal feed pellets are made from peas, corn, wheat, barley, oats, alfalfa, kelp, cultured yeast, fish meal, crab meal, salt, aragonite, and more. The exact ingredients you use will vary depending on which species of animal you are trying to target.

Shop wisely for these products – often, you can get them at low prices during or immediately after the harvest season, even if you have to have them shipped to you. Make sure the ingredient you choose matches the recommended nutritional formula for the given species. Chickens, for example, need around 7% lysine, 16.5 to 19% crude protein, 2% methionine, 3% crude fat, 3.5% calcium (this can vary), and 5% crude fiber.

Make sure your ingredients are balanced before you begin.

Then, the steps will vary depending on what kind of feed pellet machine you are using.

Start by making your premix. The premix will include all the ingredients that are already powdery, like fish meal, flaxseed, and salt. Measure these out and combine them. You can store them for later use or use all of the premixes at once when you make your pellets. It’s up to you.

The quality of your ingredients will play a big role in the quality of your pellets. More often than not, people use raw materials like rice, animal meal, fish meal, soybean, and corn for their pellets. Depending on the audience you are marketing your livestock pellets too, you may find ways to use organically- or ethically sourced ingredients, too. You may be able to command a higher price when you sell feed pellets like this.

It is important to note that you should use as little fat as possible when making your pellets. If the raw material has large percentages of fat in it, it can damage the quality of the feed pellet and reduce the longevity of your feed pellet machine.

Next, crush the whole grains. Use a feed grinder or, if you just have a small-scale operation, use a stone. You can then add your crushed material to the premix. Make sure the raw materials are more or less uniformly sized. Use a grinder to crush the material into fine particles. If you don’t, you may find that the feed pellets you produce aren’t of the right size or density.

Use a feed mixer to combine the whole grains with the premix. You can also mix them by hand if that’s easier, depending on the size of your operation.

You can then feed all of the mixed materials into your feed pellet machine. The machine will press them into pellets for you. Let them cool or use a pellet drying machine like a rotary dryer to cool them faster (this will also remove excess moisture).

If you plan on using your feed pellets right away, you don’t have to do too much else. You can simply feed them to your livestock! Otherwise, you will need to store the feed pellets in a covered bin. They should be good for several days to several weeks when stored in a cool, moisture-free environment.

Before making your feed pellets, ensure that your machine is in good working order. IT should be lubricated and maintained so that all rollers, dies, mixers, blades, and hammers are in the best possible condition. One important factor to consider before you start working is the amount of steam that exists before you put the raw material in the machine. The steam and moisture level needs to be properly optimized to make the pelletizing process successful.

How to Make a Feed Pellet Machine?

You can make your feed pellet machine, though it’s far easier just to buy a professional machine for many professionals, as it can be installed and serviced a bit easier.

To build your feed pellet machine, you’ll need to consider how it will be operated, what capacity it will be, and what your raw material will be. Most feed pellet machines can be operated by electric motors, gasoline engines, diesel engines, or PTO.

Remember that different materials need different types of raw materials. Pellet machines of different capacities have different powers, so their energy consumption varies. If you’re just interested in a pellet machine for home use, then a small capacity machine is fine. However, if you’re planning on using the pellet machine even on a semi-regular basis, you should choose professional, store-bought, and large-capacity types.

To give you an idea of how to make a feed pellet machine that meets your needs, here are some common technical parameters of a flat die animal feed pellet machine.

Power(Kw) | Pellet size(mm) | Die size(mm) | Output(Kg/h) | Diamension(mm) | Weight(Kg) |

3 | φ2.5-φ6 | 120 | 80-100 | 600×450×900 | 50 |

7.5 | φ2.5-φ6 | 150 | 100-300 | 750×450×870 | 100 |

11 | φ2.5-φ8 | 200 | 300-500 | 1150×530×750 | 150 |

15 | φ2.5-φ8 | 250 | 400-700 | 1250×600×850 | 200 |

If you don’t have the right materials for building your own homemade feed pellet machine, you should just buy a store-bought model. More information on the best model is below!

Choose a reliable manufacturer for your feed pellet machine rather than making a homemade feed pellet machine. They’ll provide you with quality products through layers of testing and better after-sales service.

How to Make Floating Fish Feed Pellets?

You can use a dry-type fish feed extruder or a fish feed pellet mill to produce aquatic feed pellets for fish along with shrimp, crab, and other animals. These will have an excellent shape, nutrition, and texture.

To make them float and float for longer periods, all you need to do is make small extrusion degree adjustments when extrude the pellets.

The most common ingredients used in fish food pellet machines include reduced dust, wheat chaff, mustard cake, maize, cotton seeds, bone or fish powder, and innards.

Below is a diagram of how biomass pellet plants like feed pellet machines work to give you a better idea:

How to Use a Feed Pellet Machine for Beginners?

Here are a few more tips to help you use your feed pellet machine successfully.

Pre-Check All Materials for Debris

Make sure all hard objects are removed from raw materials before you feed them into the pellet machine. You would be amazed at what sorts of materials end up in the animal feed, from bits of metal to small pieces of plastic. Even small shards can be detrimental and cause damage to the main shaft, die, or roller.

If you don’t check these places for contaminants first, you may want to consider installing a tubular magnet inside the feed hopper. This should catch bits of metal to prevent them from damaging or contaminating the food.

Grind Materials First

Most flat dies and rollers in pellet machines are processed using high-heat treatment. There are many rags inside the die holes, so you should always grind the material thoroughly.

Pretreat Your Raw Materials

This won’t be necessary for all types of materials, but you may find that you need to treat super wet material before feeding it into the feed pellet machine. It would be around 14% to 20% for the best results. Materials that are too dry won’t take shape well, while those too wet will cause the pellets to be loose and soggy.

Make sure the size of the raw material is less than the size of the hole size on the dies, too. This usually means that raw materials should be 5 mm or less. Otherwise, they can clog the holes and make your pellet production endeavors less efficient.

Finally, know that the adhesive force will determine how quickly you can make pellets with your machine. Some materials, like rice husk, have a very low adhesive force and need to be mixed with sawdust or other types of binders to make pellets. Others have lignin, which melts under high temperatures. Do your research before you start making pellets to end up with the best possible results!

Check the Thickness and Length of our Pellets

The thickness of your feed pellets will be determined by the hole size on your die, with the length determined by our slicer. Therefore, it’s much easier to change the length size later on than it is the thickness.

You will find the slicer beneath the flat die, but in a ring die pellet machine, it will be installed outside the ring die. However, you can adjust both types to get the ideal size. It’s better to be too short than too long if you’re making animal feed pellets for our use – however if you plan on selling and transporting them, be a little long.

Once your pellets come out of the machine, they’ll be hot and steamy. You can dry and cool them by laying them out in an open area with good air circulation, or you can use a cooler machine. Cooling them quickly can make it easier for you to get them loaded into a truck for quick, convenient transport.

Don’t Shut Down Right Away.

Once you are done making pellets, resist the urge to just close up shop and walk away. Instead, there are a few steps you should take to keep your machine running as smoothly as possible.

For example, you should add some mixed oil and feed materials to the pellet machine. Let it run for a couple of minutes. This will allow the die holes to fill with oil mixture – that way, you can start making pellets immediately the next time. It maintains the mold while also saving time.

You can loosen the adjusting screw and clean out the leftover materials as soon as this is done.

How to Maintain a Feed Pellet Machine?

In addition to the tips listed above, one of the best ways to make animal feed pellets is to regularly maintain your feed pellet machine.

First, know that the temperature inside the pelletizing chamber can get extremely hot. Also, the roller undergoes intense pressure. It’s easy for them to overheat, and this can cause parts to malfunction over time. There’s no dust protector in most pellet machines, so you will need to clean the bearings and lubricate them with oil once every few hours or so.

After about eight hours of working time, the main shaft will need to be oiled. Not only that, but you should schedule a cleaning for your gearbox every six months. If you have a high level of heat in your gearbox, for whatever reason, try to increase the gear clearance for easier maintenance – and try to use better-quality gear oil.

How to Choose Pellets Die Diameter For Your Animal Feeds Manufacturing

For animal feed pellets making, choosing the correct pellets die diameter is on top priority, this will affect the animal feeding efficiency and nurtition, which will affect your ROI. Based on different animals, including fish feeds, rabbit, chicken, ducks, chicken, dogs, pigs, cows, horses, camels etc, please check our suggestions for feed pellets die.

Which Kinds Of Pellets For Making ?

Our animal feed pellet machine can process various materials for different animals feed pellet making, we can also design simple and complete feed pellet production line based on customers requirements.

This simple feed pellet production line include one stainless steel mixer, one stainless steel screw conveyor, and one feed pellet machine, simple line can achieve whole feed pellet production ,capacity from 100kgs/h to 4000kgs/h. We can also customize bigger capacity based on your needs.

TCPEL Feed Pellet Machine Introduction