Best Fish Feed Pellet Machine Manufacturer in China with 14+ Years Experience

- Higher capacity and less wear parts costs

- Wide range of application suitability

- Stable running performance and easy operation

Fish Feed Pellet Machine - The Beginner's Guide

A fish feed pellet machine, also known as a pellet mill or extruder, might be the piece of equipment you need to take your business to the next level. A feed pellet machine may assist in the transformation of items like soybean meal, corn, or rice husks, among other materials, into smaller pellets. These will be given to animals and eventually help save money and time.

As the leading fish feed pellet machine manufacturer, we’ve included all the information you need about this important piece of equipment, and you’ll find everything you need in this guide.

What is a Fish Feed Pellet Machine?

A feed mill that uses a feed mill to press crushed material such as straw soybean meal, corn, straw, grass, and even rice husk into feed pellets is called a pellet machine. It’s commonly utilized in commercial aquaculture farms, livestock farms, poultry operations, and major, medium, and small food processing facilities.

What are Fish Feed Pellet Machines Used For?

In plain words, a fish feed pellet machine is a tool used to transform materials into smaller pieces. They can be fed to animals that either can’t eat big chunks of food or that would be unhealthy to consume due to their size.

How Does a Fish Feed Pellet Machine Work?

Now that we have covered what a fish feed pellet machine is and what it’s used for let’s dive deeper into the subject and explain how it works.

The compression roller spins as a result of the frictional force between the main axis and flat-die. The starch is fermented at a high temperature between the die and the roller, and the protein concentrates.

It then comes out as tiny pieces of fish food (called “pellets”) from the die’s holes. Of course, the size and shape of these pellets are set by the machine per default. However, you may also adjust the angle of cutting by changing it to suit your needs.

Blend 5 or 10 kilograms of mashed grain with an edible oil containing 5% to 10% fat. If the mash feed clogs, we should break it up to keep the feed-in powder form.

Before you turn on the mill, put the feed into it to get started. Then, until the food can be extruded without difficulty, adjust the press roller bolt.

Before adding dry powder into the machine, we recommend you test the machine and the results with the oily mash feed 3 to 5 times to verify if this is the outcome you need.

Last but certainly not least, pellets come out of the mill very hot and should therefore be placed in a ventilated area to cool down before placing them in their packaging.

How Much Does a Fish Feed Pellet Machine Cost?

A fish feed pellet machine is one of the important pieces of equipment in the industry. It can produce large amounts of premium pellets for fish feeding.

Of course, there are a few factors to think about when checking any fish pellet machine price. Other than the fish feed pellet machine manufacturer in question, the type of mill and its quality play a big role.

For those pellet machines with low production capacity or more home-style ones, the price will be between $300 to $3000.

On the other hand, If you want larger output, you should expect to pay more. The average high output pellet machine’s cost ranges from US$5000 to US$7500, but it can get to tens of thousands of dollars for the priciest ones.

How Many Types of Fish Feed Pellet Machines are There?

There are currently two types of fish feed pellet machines on the market:

- Dry Type Fish Feed Extruder

- Wet Type Fish Feed Extruder

Of course, these are the two different types, but you will find endless models available. They can be categorized into big-scale and little-scale versions. The ring dies pellet machine and the flat die pellet machine is two of the most prevalent pellet mills.

In addition, it’s important to highlight the fact that a fish feed pellet machine isn’t the only piece of equipment you need. These are the important machines you will need in your production line:

- Screw Elevator

- Feed Crusher

- Mesh Belt Dryer

- Feed Peller Cooler

- Oil Spraying Machine

How to Choose the Best Wood Pellet Machines for Pellet Production?

You will need to think about many elements when selecting your pellet machine for fish feed. Let’s list them one by one.

Quality and Duration

First and foremost, you’ll want a stable and durable machine. It’s crucial to choose a sturdy one with a potent die.

Make sure your pellet machine’s die meets all technical criteria and has a high-quality surface finish. To ensure uniform wood pellets, make sure the inner holes are equally distributed and symmetrical. Choose a die that doesn’t contain blind or joint holes.

If you bought a set of pellet-making equipment and spent much of your time maintaining it, your overall production process will slow down and eventually make you waste time and money.

Energy Consumption and Output

When purchasing a pellet mill, consider both its energy use and output. For example, if the output of the pellet mill is extremely high, but the power consumption is significant, profits will be lower. So before buying a machine, you should understand more about per kilowatt-hour of electricity production.

On top of that, pellet machines can produce 50-800 kg/h, but bigger equipment can reach up to 2,000 kg/h or more. Most manufacturers advise selecting a ring die pellet mill with a custom-made die to remain safe if you require a greater output.

The Price

It would be best if you always chose the most suitable equipment for both your budget and your needs. Sure, as discussed previously, a fish feed pellet machine can be extremely pricey, but you should plan to increase your revenue using a bigger one.

Some sellers may advise you to purchase a lot of supplementary equipment that is perhaps unnecessary and adds to the overall price and being accounted for on the plan. As a result, when selecting a floating fish pellet machine for sale, keep an eye on price rather than features.

Maintenance

Maintenance is an often underestimated element when choosing the machine, and most customers frequently neglect these expenses. Every so often, a normal machine would need to be maintained, and the longer it can stay without maintenance, the higher your profits.

After-sales service

Last but not least, the after-sales service is an important thing to observe. Choose a firm with a good corporate culture that has a strong after-sales staff. It’s critical to have prompt, efficient after-sales service that won’t increase the price for you in any way.

Here at TCPEL, we proudly tick all the boxes above, ensuring that you get the best machine for all the steps in the process. Lastly, our after-sales team makes sure that you remain satisfied after purchase which is a factor that makes us stand out from the other organizations on the market.

How to Make Fish Feed Pellets?

A few steps in the process and other pieces of equipment are involved apart from the fish feed pellet machine.

First of all, the grinding step. The size of the particles is determined in the crushing process by a variety of elements. For instance, the rotor speed, the number, and size of hammer blades, the screen size, the hammer strikes.

A screen with mesh holes must be used to keep objects from passing through the discharge hole of a hammer mill. To control particle size reduction, a screen with diverse-sized holes may be utilized.

The speed of the hammer mill has the most influence on the finished particle size. The hammers whirl around rapidly, striking the material with tremendous impact, breaking it down.

Secondly, the mixing part is just as important as grinding. When grinding ingredients, they then should be mixed them homogenously.

During the mixing part, it’s instrumental in remembering two points: every formulation has its mixing time. If you mix the materials for too long, they will start to decompose. Apart from that, incorporate some ingredients like additives as well to fill the mixer.

After that comes the extruding of the pellets. The process is essentially the extrusion part that can create pellets. The sizes range from less than a millimeter to several centimeters, suitable for different species of fish. After that, fatty acids like fish oil are added.

The pellets need then to be dried. The wet or humid pellets will need to be dried to get to a moisture percentage of 10% or even less whenever possible. In the ideal world, you should do this part of the process at lower temperatures – less than 60 ºC. And with sufficient airflow to dry the pellets as fast as possible. This is to ensure that heat-sensitive nutrients like vitamins are not ruined.

At last, the packing part is the easiest yet not the least important. When the pellets are dry, they must be stored in containers or bags to remain safe from insects, rats and keep moisture away. Plastic bags should be avoided since feeds can sweat, and they can encourage the growth of mold.

How to Use a Feed Pellet Machine?

In terms of operation, each pellet machine is different. However, there are a few basic guidelines that apply to all of them.

To start, adjust the clearance between the pressure roller and the flat die according to how tightly packed the pellets are.

Also, the raw material should be smaller than the pellet size. To make the substance smaller, you may need to use a wood chipper or a hammer mill (or sometimes both). The water ratio of the raw ingredients should also be 12% (or possibly less) before starting.

After that, feed the ingredients through your pellet machine. It will come out at a fast speed, so keep clear. The materials fed into the machine will be shaped into pellets by the die’s hole and then pushed out.

Finally, follow the manufacturer’s instructions when assembling your newly purchased pellet machine. If you’re not comfortable doing it yourself or find it complex, TCPEL provides onsite installation services.

How Does the Maintenance of a Fish Feed Pellet Machine Work?

Every fish feed pellet machine requires regular maintenance. The main goal of routine maintenance is to ensure that all equipment necessary for product manufacture is always operating at full efficiency.

To keep your pellet machine in good working order, you must take certain measures to preserve it. Make sure the pieces of the transmission are lubricated regularly. These should be lubricated to increase their longevity. Change the gearbox’s oil every month and conduct a comprehensive examination of the parts every month. This might include everything from bearings to gears, as well as rollers and dies.

If you detect anything incorrect at any time, you must correct it immediately. Also, make sure all of the components are secure and not loose. Remove and clean the roller after each use.

If the machine is not cleaned, metal or other foreign substances may accumulate inside, causing it to break down eventually. To avoid damage to the equipment, clean up the raw materials. Always inspect extruded goods for quality and replacement of worn components.

How are Fish Feed Pellet Machines Made?

The hopper, in which the feed meal is fed into the machine, and the pelleting chamber are two of the most vital components of a fish feed pellet machine. The shaft is driven by a pulley and belt system powered by an electric motor.

Adequate material selection has to be made to achieve the following goals: easy maintenance, reduce noise, produce machinery at a low cost, improve and lessen dimensions, enhance machine aesthetics, increase mechanical strength and resistance to wear, corrosion, and acid medium.

Mild steel, stainless steel, cast iron, and chemical paint are used to construct machines.

TCPEL Fish Feed Pellet Machine Introduction

This flat die pellet machine is perfect for large, medium, and small companies looking to expand and improve how they process animal feed pellets. Whether you’re an aquaculture plant or a grain factory, or a livestock farm, this pellet feed mill will work wonders for you.

Farmers and livestock feed companies have used it all over the world. It doesn’t require your raw materials to be dried, as even powdered ingredients can produce cylindrical particles. It will save you time and energy, making it easier for you to make more feed (and more money) in your business.

Driven by a powerful motor, it can press feed pellets and press wood sawdust pellets as long as the moisture content of the raw materials is around 12 to 20%. There are multiple die diameters you can choose from, allowing you to process materials one granule at a time – but quickly and more efficiently to keep your production line right on track.

Here are some of the main features of this product:

1. Multiple power ratings available: You can buy this machine with multiple power ratings ranging from 3 KW in the smallest model up to 15 KW or more. This makes it highly efficient for factories and businesses of any kind. Power options vary depending on your needs, including electric, diesel, gasoline, or PTO. You can tailor these options to make your machine easier to move, power, and more efficient to run.

2. Easy to operate: This feed pellet machine has a high output with low consumption and low noise. Not only is it quiet to operate, but it’s easy to operate, too. It’s easy to train new operators to use the machine and only takes one person to run.

3. Requires minimal maintenance: Maintenance is essential for any feed pellet machine, but with this product, you’ll find that it has parts and components that make it easy to take care of. It has a high-pressure filtration system and independent lubrication systems, so you won’t constantly stop lubricating the machine.

4. Versatile in its applications: You can use this feed pellet machine to process feed pellets for just about any type of species. It can work with things like rice husks, peanut shells, sunflower husks, wood parts, and much more, making it one of the most versatile products you can buy. It works with high density and low density materials, low moisture content, and high moisture content alike.

5. Multiple apertures available: Several different apertures are available to suit the needs of different types of animals and their required feeds. Not all feed can be processed through the same flat die, so this machine makes it easy to change them out.

Fish Feed Pellet Machine Parameters

| Model | Capacity | Pinch Roller | Power | Voltage(V) | Weight | Dimension |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg/h | Double roller | 2.2kw | 220V/380V | 95kgs | 68*42*53cm |

| TFC150 | 150-200kg/h | Double rollers | 7.5kw | 220V/380V | 100kgs | 72*45*65cm |

| TCF200 | 300-400kg/h | Double rollers | 11kw | 380V | 180kgs | 126*53*92cm |

| TCF250 | 600-800kg/h | Double rollers | 15kw | 380V | 320kgs | 131*54*93cm |

| TCF300 | 800-1000kg/h | Double rollers | 22kw | 380V | 400kgs | 146*59*110cm |

| TCF350 | 1000-1200kg/h | Double rollers | 30kw | 380V | 580kgs | 186*70*128cm |

| TCF400 | 2000kg/h | Double rollers | 37kw | 380V | 680kgs | 206*76*137cm |

| TCF450 | 2000-2500kg/h | Double rollers | 45kw | 380V | 780kgs | 218*79*140cm |

TCPEL Fish Feed Pellet Machine Advantages

The pressure roller and grinding disc are made of chromium-manganese steel, which is more durable after high-temperature quenching treatment. The newly upgraded grinding cavity is 10-20 times the wear resistance of ordinary materials.

Easy to refuel, simple to use, GL-5 heavy-duty gear oil must be filled before use.

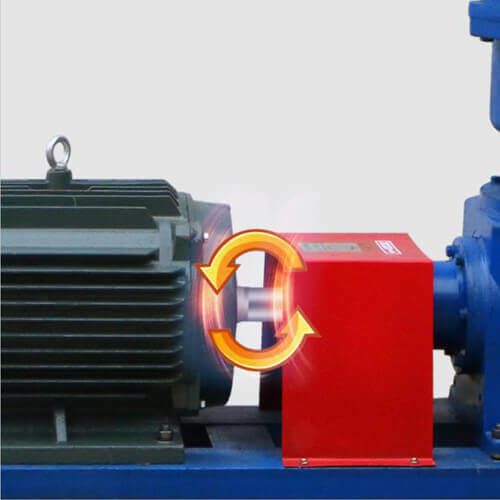

Electric coupling, direct docking, simple operation, and convenient installation. The coupling is stable and durable, made of stainless steel, after high-temperature quenching treatment, more durable than ordinary materials. The newly upgraded coupling drive, compared with the old belt drive, has less transmission ratio loss and is more durable and wear-resistant

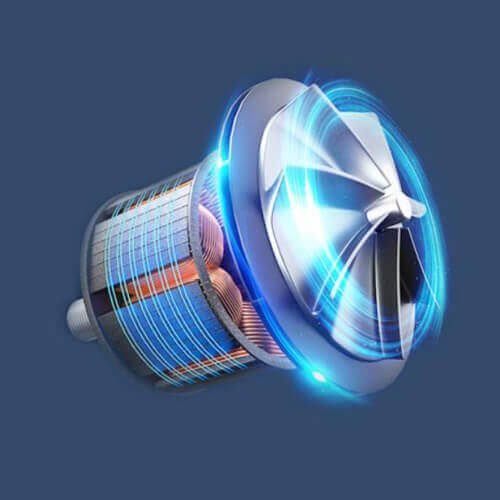

100% copper wire motor, long service life, large horsepower, saving power. All copper coil, heat sink, long service life, silent bearing, stable operation, and low noise. Power off at high temperature to avoid malfunction caused by high temperature

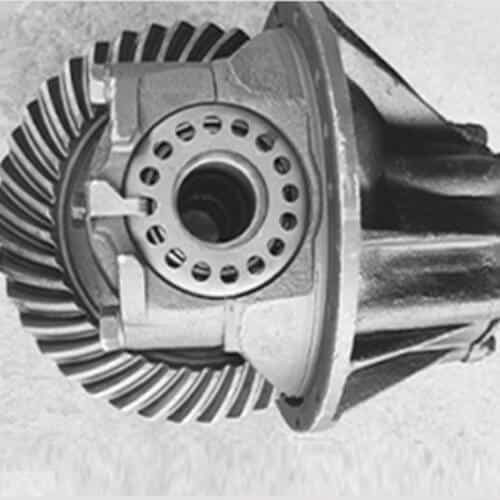

It adopts the automobile rear axle differential assembly design, which has a good gear combination, reduces the load on the main engine, and has good stability.

Larger feed inlet design makes feeding more convenient and work efficiency higher Widened discharge port design, design with baffles on both sides to avoid feed spilling, widened and enlarged discharge port, discharge faster and smoother.

Adopt nylon sliding casters, wear-resistant and durable