300-500kgs/h Flat Die Pellet Machine

5.0 based on 28 ratings and reviews

Brand :

TCPEL

Model :

TCZL400

Catagory :

Flat Die Pellet Machine

Capacity :

300-500kgs/h

Price Range :

$6800-16000 based on configuration

Payment Term :

T/T/Visa/Mastercard/American Express/Discover cards

Delivery Time :

10-15days after get deposit payment

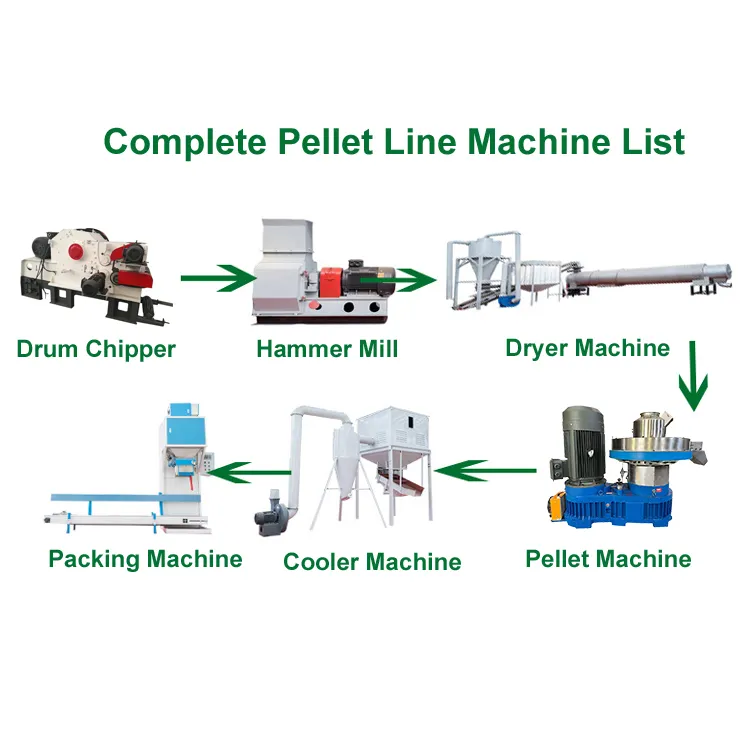

Flat Die Pellet Machine Introduction

This flat die pellet machine is our first generation pellet machine series. The structure is flat die. Capacity from 300kgs/hour to 1500kgs/h.

TCZL400 Pellet Machine Application

This machine is developed for making animal feed pellet making, later this machine is upgraded with high power, now this machine can also used for making wood pellets. It can process various materials like rice husk, corn stalk, rice straw, peanut shell, sawdust etc. It’s quite suitable for small capacity pellet making for home use.

Flat Die Pellet Machine Parameters

| Model | Power(kw) | Capacity for Wood pellets(kgs/h) | Weight of the machine(kgs) | Dimension of the machine (mm) |

| TCZL250 | 15 | 100-200 | 400 | 1120x440x1060 |

| TCZL300 | 22 | 200-400 | 800 | 1280x560x1220 |

| TCZL400 | 37 | 300-500 | 900 | 1350x550x1320 |

| TCZL450 | 55 | 600-800 | 1500 | 1620x690x1600 |

| TCZL550 | 55 | 800-1000 | 1600 | 1700x690x1600 |

Flat Die Pellet Mill Advantages

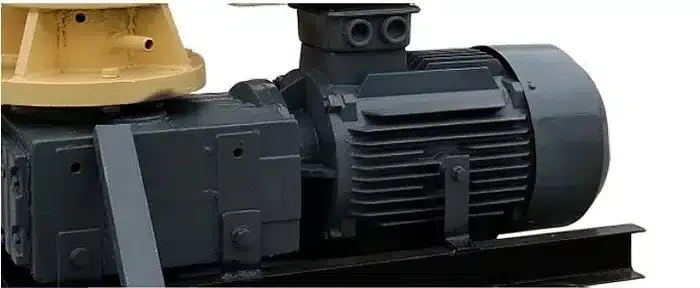

Central spindle quenching and tempering installation, to ensure the stable operation of the flat die pellet machine.

Our flat die pellet machine standard with lubricating oil pump, which can automatically lubricating the main shaft.

Flat die pellet machine equipped with 100% pure copper wire motor, ensure enough power supply to achieve high quality pellets forming.

The reducer made of high strength material, which can ensure durable and longer lifetime for heavy duty work.

Flat Die Pellet Machine Spare Parts

Flat Die Pellet Machine Detailed Pictures

FAQ

Flat die pellet machine is kind of machine used for making pellets. It’s named because of the flat die structure.

Flat die wood pellet machine can be used for making wood pellets, it can also used for processing animal feed pellets.

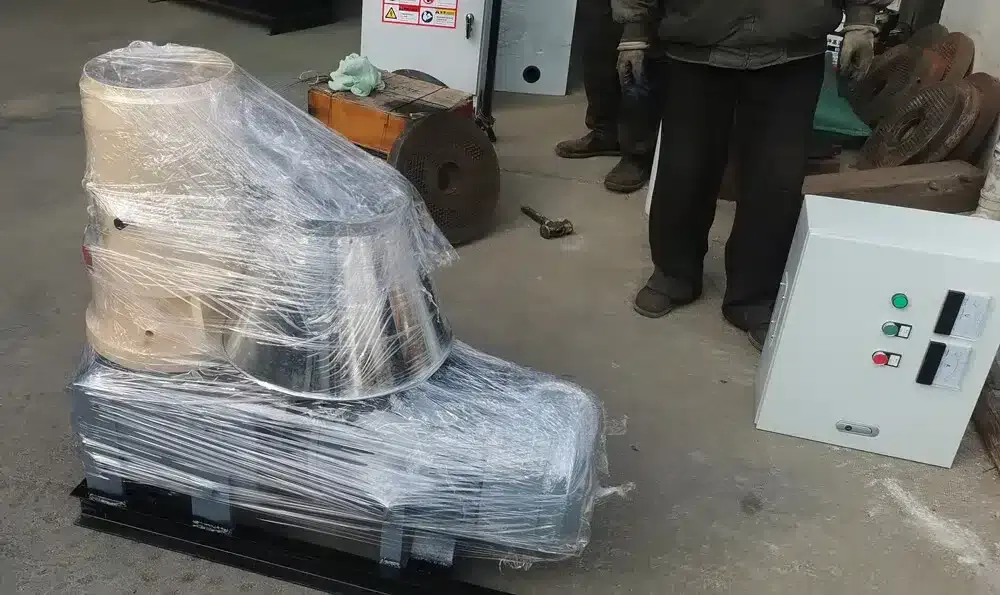

Our standard complete flat die pellet machine quote include screw conveyor, main pellet machine, control panel, oil pump and assemble tool box.

Please check the flat die pellet mill structure below :

The wear parts of our flat die pellet mill for sale is the flat die and roller shell. The lifetime of the flat die and rollers are 600-800hours.

Please check the difference of the flat die vs ring die pellet mill in our post: https://www.tcpel.com/ring-die-pellet-machine-or-flat-die-pellet-machine/

We can finish manufacturing of our flat die wood pellet machine in 10days after get payment. For big orders, please contact with our sales person.

Our payment term is 30%T/T deposit after confirm the order, 70%T/T balance before shipment.