Professional Grass Pellet Machine Manufacturer, ISO9001 Certificated

- Higher capacity and less wear parts costs

- Wide range of application suitability

- Stable running performance and easy operation

Grass Pellet Machine - The Beginner's Guide

As a leading pellet machine manufacturer in China, we always hear this question, can I make grass pellets? Yes, you can. And we have the best solution for you, our advanced grass pellet machine. It is not mandatory to use a special pellet machine for grass pellets. You can use a feed pellet machine to produce grass pellets. Whether small or large pellet mills, both can produce grass pellets. Feed pellet machines are also named animal feed pellet mills, or just pellet mills. You can choose one for your grass pellet production. But, before you plan to buy one, you should consider some factors.

We receive many questions on grass feed pellet machines from around the world. That’s why we prepared this beginner’s guide to help you acquire knowledge on this machine and buy one that suits your needs.

What is a Grass Pellet Machine?

The grass pellet machine is nothing but a feed pellet machine that can make pellets from grasses. The grass is an excellent ingredient to make pellets.

A grass pellet machine can process chopped grasses into pellets, just like wood. You can make not only regular pellets but also biofuel pellets using a grass pellet machine.

You can make pellets from grasses at a low cost compared to wood. If you are in the agriculture industry, large-scale production of grass pellets can save you lots of money.

What Is a Grass Pellet Machine Used For?

As the name suggests, grass pellet machines are used for making pellets from grass. You must know grass is the staple food of herbivores like sheep, goats, horses, rabbits, etc. So, you can feed them by preparing grass pellets from a grass pellet machine.

The grass is not easy to transport or store in its normal state. But you can easily store grass pellets. Grass pellets don’t have much dust, and animals can easily digest them. In addition, it’s easier to transport grass in the pellet form.

There is another vital use of grass pellets. You can use them as fuel if you can control the moisture accurately. Grass pellets should produce more ashes than wood pellets, but comparing the cost is much cheaper than wood pellets.

How Does A Grass Pellet Machine Work?

Grass pellet machines are of two types – Ring Die pellet machine and Flat Die pellet machine. You can also categorize them as large production and small production.

If you want a green grass pellet machine for large production, a ring die pellet machine will be ideal for you. They are made for industrial-grade production. On the other hand, a flat die pellet press machine is ideal for small production and in-house applications.

Before processing the grass using a grass pellet machine, you have to crush the raw materials first. To complete this process the hammer mill is an ideal machine. The next step is to clean the crushed grass. You should adjust the moisture also. Then you can use the grass pellet press machine to create grass pellets.

First, in a flat die machine, you feed the machine with crushed grasses and start the motor. Here the motor holds the central shaft which holds the press roller. It rotates about the main shaft and creates the pellets.

Then the rotating press pushes the grasses into the holes for molding. From there, pellets get out in a cylindrical shape.

The working process of a ring dies grass pellet machine is similar, with some exceptions.

How Much does a Grass Pellet Machine Cost?

You can not get the answer in a single line. There are many factors that affect the grass pellet press machine cost. So, before buying one, you should consider those factors and the purpose of your use.

- The first factor that affects the price of the grass pellet machine is the type. As we mentioned earlier, there are two types of machines – for small production and large production.

- The next one is the power usage options. Grass pelleting press machines can run on diesel electricity, PTO, and gasoline. Grass pellet press machine cost will also depend on the fuel/energy type you will use.

- Then comes the manufacturing technique. Not all machines are made with the same industry standards. As a leading grass pellet press machine manufacturer we follow all the standards to produce an efficient, durable, and long-lasting grass pellet press machine.

So, you can understand it’s not possible to tell you the price of a grass pellet press machine unless a grass pellet press machine manufacturer knows your requirement. When you see a grass pellet machine for sale you should see whether it meets your requirements or not.

Grass pellet press machines for small production (for home use) can cost USD 500 or less. But if you are looking for a standard grass pellet press machine, you should spend between USD 1000 – 2000. Then comes industrial grade machines, and they can cost between USD 2000 – 6000.

How Many Types of Grass Pellet Machines?

You can categorize green grass pellet machines into two types – Large scale and small-scale production.

Large scale grass pellet press machine is typically used to produce animal feed pellets for large firms. You can also produce wood pellets and fuel pellets with a large-scale grass pellet machine.

Large-scale grass pellet machines are used for commercial purposes, and they have some unique features such as a long life span and work for a long time without any interval. Moreover, the fuel consumption of a large-scale grass pellet press machine is much less than small-scale machines.

On the other hand, a small-scale green grass pellet machine is ideal for in-house use. They are cheap and portable.

If we consider the working principle, you can divide them into two categories, hydraulic press and screw press. The basic working principle is more or less the same for both.

Considering the production capacity, you can divide them into two categories, flat die grass pellet machine and ring dies grass pellet press machine.

Ring die is ideal for large-scale production, and flat is good for small-scale production. As a result, the price of a ring dies grass pellet press machine is much higher than a ring dies grass pellet press machine.

In TCPEL we have premium quality ring die and flat die grass pellet machine for sale.

How to Choose the Best Grass Pellet Machine For Pellet Production?

Choosing the right grass pellet press machine is not that easy. You have to consider some factors before choosing one for yourself. Here are some tips from us you should consider before selecting a high-quality grass pellet press machine:

The Exterior

The finishing of the machine will give you a fair idea about the grass pellet mill. It should have uniform spray paint and no paint leakage. You will see glossiness and fastness on the clad layer. The stainless steel parts should have smooth finishing.

The Die

Die has some specific technical standards, and you should ensure the die meets those standards. The surface finish should be good without any manufacturing error. Dies are processed using heat treatment. Therefore, it is easy to determine the standard of the die just looking at the appearance.

The inner holes of the die should be symmetrical and uniform. Holes must be smooth without any rags. Do not buy if there are any joints or blind holes.

Rotation of the Die

You can check the rotation of the die by running a test run or by your hand. If it shakes while rotating or gets friction from other components, you should avoid that machine.

Fastening Assembly

Next thing is to check the drive engine and the fastening of the main body. If you are buying a large-scale (ring die) grass pellet machine, check the roller support also. And in flat die inspect the die lock nut assembly and the pellet cutter.

Check the movements of the compression chamber’s door. And check the connection between the chamber and the feed-stranding cage.

Grass pellet Quality

You should also check the quality of the grass pellet by running a live test. The pellet should contain a smooth surface without any cracks. They should come out in a uniform shape, and breaking them with your bare hands should not be easy.

Test Run

We always encourage our clients to have a test run before buying the machine. Check the electric motor’s rotating direction switching off and on several times. If you are satisfied and find no problem, only then purchase the machine.

After confirming the idle is normal, you can add some powder feed to the feed stranding cage. Keep the pellet machine commissioning under medium load, and observe the current reading of the spindle motor.

Safety inspection

When you are buying any type of machine, you should take safety very seriously. Ring pellet machines contain a safety lineage to prevent the machine from getting outside particles. You should check that it’s working perfectly.

How to Use a Grass Pellet Machine For Beginners?

Any type of device needs some pre-knowledge to operate. Especially when you are dealing with manufacturing machines kike grass pellet machines, you should know how to deal with them. Otherwise, you can hurt the machine yourself and damage the raw materials.

As a responsible grass pellet machine manufacturer, we provide free training sessions, supports and all of our machines have the necessary documentation. Here we are sharing some tips for beginners.

Lubricate the Machine

Lubrication plays a very vital role for the smooth, efficient operation of a grass pellet machine. Lubrication not only helps the machine work efficiently but also ensures extended lifespan. So, lubricate the roller, shaft, and gearbox before you start the machine.

Check the Roller and Flat Die

You should check nothing is blocking the roller and flat die’s operational way. Any blockage can result in severe damage.

Adjustment

You should adjust the clearance between the roller and the die. This process will help to increase the lifespan of the machine.

Connecting Parts

Grass pellet machines come with cap bolts at the end of each roller. It would help if you tightened them at the highest level. Remember, if they fall off, that can damage the roller. Make sure other connecting parts are tight enough to run the operation.

Rotating Direction

Rotating direction and the indicative sign is a vital factor for the machine. Sometimes beginners miss the trick and do not check it. Check whether the rotating diffraction is consistent or not. If not, adjust the drive engine.

Safety

A silly safety error can cause severe damage to the machine or to the operator. So, be very careful about the safety precautions. If there is any power leakage that can stop the machine from working. Also, any voltage load problem, presence of unwanted items can affect the machine’s operations.

So, use a voltage stabilizer if needed and place the machine where no unwanted things can enter.

We highly recommend engaging an expert person to run the machine. Any good grass pellet machine manufacturer should provide training when you buy the machine. If you face any issue, you should immediately contact their customer service department.

How to Maintain a Grass Pellet Machine?

Maintenance is very important to expand the longevity of your grass pellet machine. Here are some tips from us:

- You should lubricate your machine properly, maintaining the guideline provided by the grass pellet machine manufacturer. Remember, different parts demand different lubricants. Read the manual carefully to know more about it.

- Change the gearbox lubricating oil regularly. This process is very important to expand your machine’s life span.

- Inspect the parts of the grass pellet machine at least once a month. Your inspection should include the gear, die, roller, bearing. If any part has any issue, instantly change the part. Always remember, a part will affect other parts

- Trying to receive more production than recommended from your grass pellet machine. Overloading is a terrible idea. This will affect the machine in the long and short run.

- Clean your machine after every use. Cleaning is a very important maintenance process. Proper cleaning will increase the machine’s efficiency, reduce fuel consumption, and at last, it will expand the lifespan.

- If you are not using your green grass pellet machine for a while, place them in a safe area. There should be no water around it, and you should cover the machine well so that no unwanted things can enter.

In TCPEL, we also have dedicated customer care to help our customers. Our clients can ask us if they face any issues or want to know about the maintenance process. We also provide an on-hand demonstration in our training sessions.

TCPEL Grass Pellet Machine Introduction

Tcpel is a leading grass pellet machine manufacturer in China with clients in over 50 countries around the world. We have been in the industry for over a decade. We are an ISO9001, CE, and SGS certified company, and all of our machines are tested according to the industry standard.

In TCPEL, we have a dedicated research and development team. Our team is relentlessly developing our products and introducing new technologies to make pellet machines more efficient, durable, and long-lasting.

We have one of the finest factories in China. Also, we have a dedicated quality testing team. Therefore, we can guarantee that every grass pellet machine from our factory is 100% efficient.

We offer a free setup service with every machine. We also offer a free training session to all of our customers. Besides, we have 12 regional offices in the world and offer onsite training from those local branches.

Customer satisfaction is one of our utmost priorities. To provide our customers with the best after-sales service, we have a dedicated after-sales team. Our customer service department is open 24/7/365. They never sleep so that you can sleep well.

You can send us a message from our website, send us emails or call us to know more.

Grass Pellet Machine Parameters

| Model | Capacity | Pinch Roller | Power | Voltage(V) | Weight | Dimension |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg/h | Double roller | 2.2kw | 220V/380V | 95kgs | 68*42*53cm |

| TFC150 | 150-200kg/h | Double rollers | 7.5kw | 220V/380V | 100kgs | 72*45*65cm |

| TCF200 | 300-400kg/h | Double rollers | 11kw | 380V | 180kgs | 126*53*92cm |

| TCF250 | 600-800kg/h | Double rollers | 15kw | 380V | 320kgs | 131*54*93cm |

| TCF300 | 800-1000kg/h | Double rollers | 22kw | 380V | 400kgs | 146*59*110cm |

| TCF350 | 1000-1200kg/h | Double rollers | 30kw | 380V | 580kgs | 186*70*128cm |

| TCF400 | 2000kg/h | Double rollers | 37kw | 380V | 680kgs | 206*76*137cm |

| TCF450 | 2000-2500kg/h | Double rollers | 45kw | 380V | 780kgs | 218*79*140cm |

TCPEL Grass Pellet Machine Advantages

Chromium-manganese steel-made pressure roller and grinding disc offer more durability. You can use our grass pellet machine at a tremendous temperature. 10-20 times more wear-resistant.

User-friendly interface and easy to refuel. We suggest using GL-5 heavy-duty gear oil before operation.

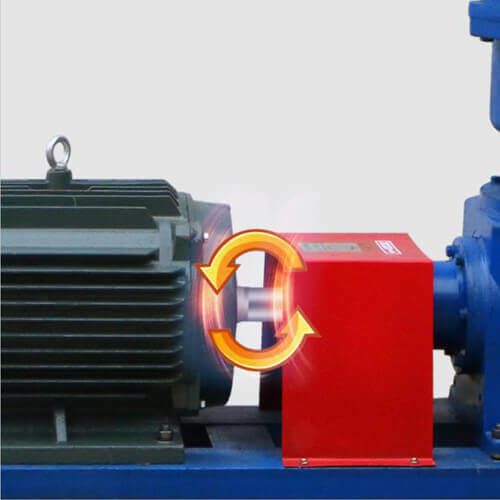

Effortless installation, direct docking, simple operation, and electric coupling.We used premium quality stainless steel for the coupling which is more durable than average materials. The upgraded coupling drive reduced the transmission ratio loss of the previous old belt drive and made it more wear-resistant.

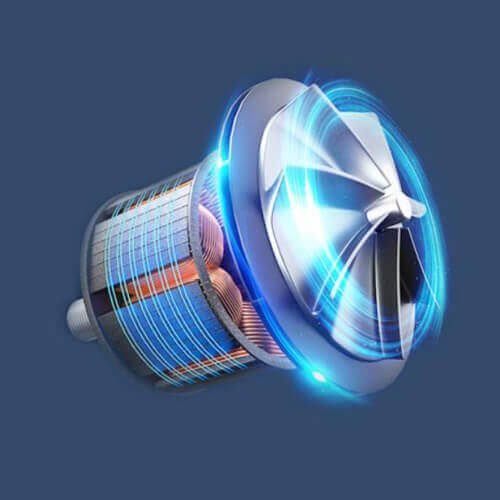

100% copper wire motor and larger horsepower ensure an extended lifespan. The copper coil and the heat sink ensure stable and efficient operation and a longer life span without noise. The auto power-off feature ensures there will be no malefaction in high temperatures.

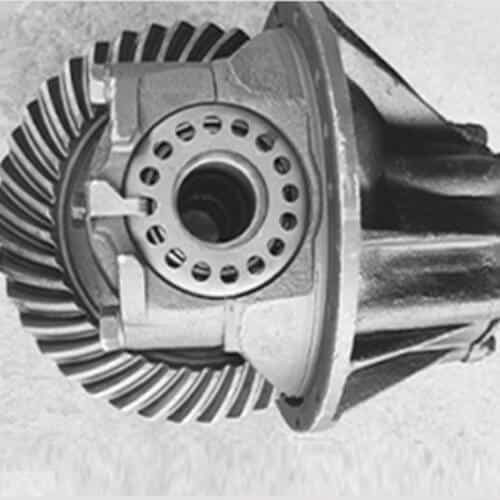

Our newly adopted automobile rear axle differential assembly design reduces the loading time of the engine. This design also has an advanced gear combination and provides more stability.

It comes with an expanded feed inlet design. This advanced design offers convenient feeding. The higher widened discharge port design ensures improved work efficiency. Baffles on both sides stop grass from spilling. Discharge is smoother and faster with a widened discharge port.

Durable, wear-resistant, and adopts nylon sliding casters.