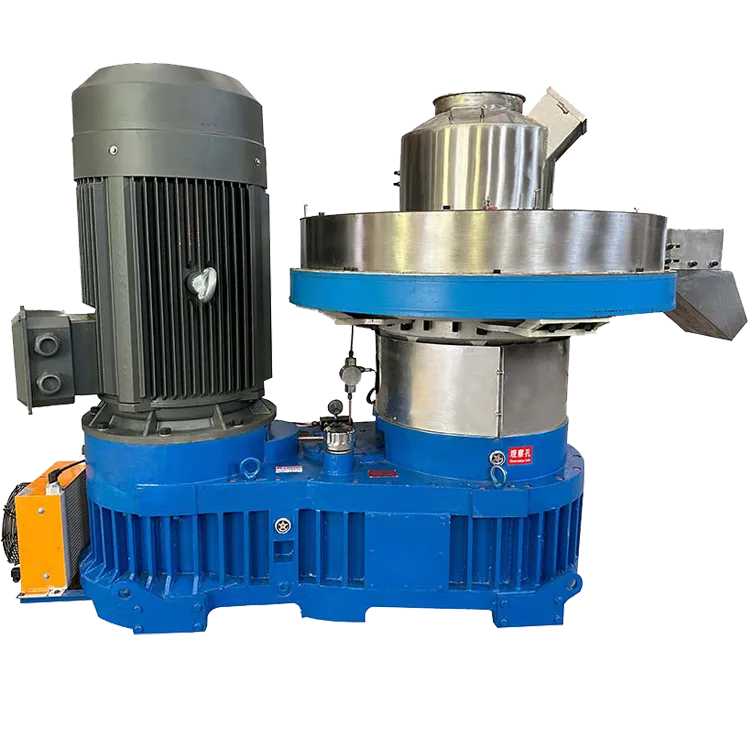

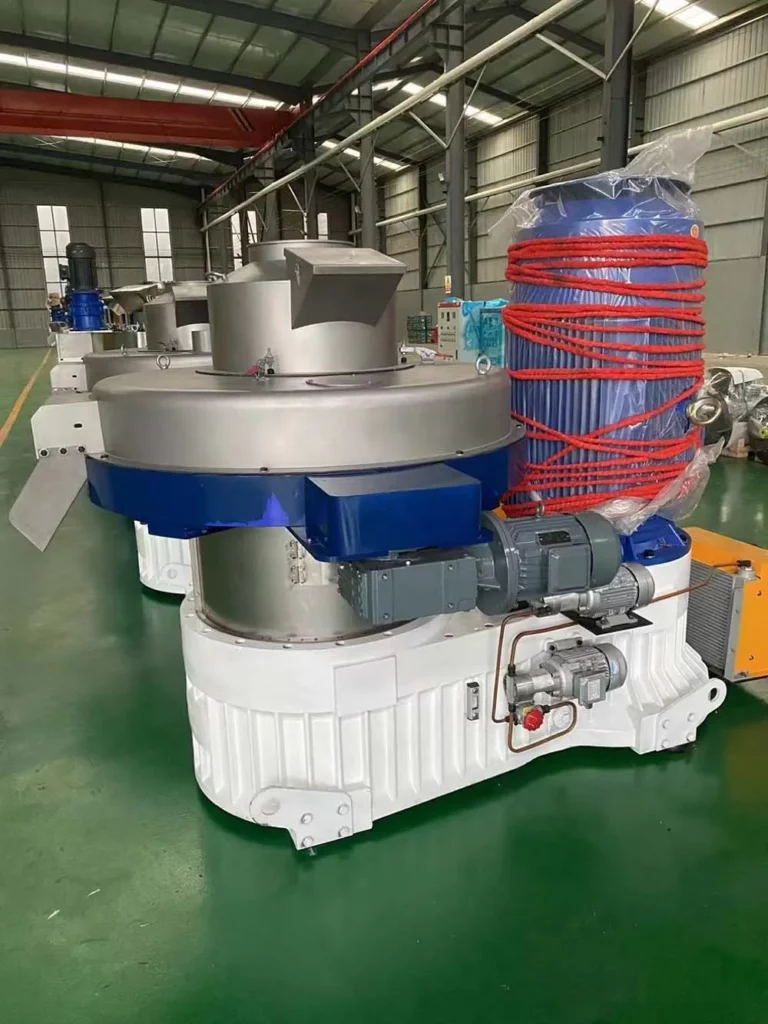

2t/h Pellet Making Machines for Sale

5.0 based on 52 ratings and reviews

Brand :

TCPEL

Model :

TCZL700

Catagory :

Vertical Ring Die Pellet Making Machine

Capacity :

2-2.5t/h

Price Range :

$30000-$35000 based on configuration

Payment Term :

T/T/Visa/Mastercard/American Express/Discover cards

Delivery Time :

15days after get deposit payment

Pellet Making Machine Introduction

With 160kw main motor, our pellet making machine TCZL700 can reach capacity 2-2.5t/h ,which can be widely used for making biomass pellets for pellet plant, power plant in large scale.

Pellet Making Machines Features

Heavy duty structure ensure durable and long-lasting, 24 hours of work time without stop and less maintenance.

Suitable for various materials, including wood, sawdust, rice husk, EFB, palm shell, olive waste, fruit straw beech etc. and more.

Enhanced stainless steel dies have a service life of 1000 to 1500 hours, less power to achieve higher capacity.

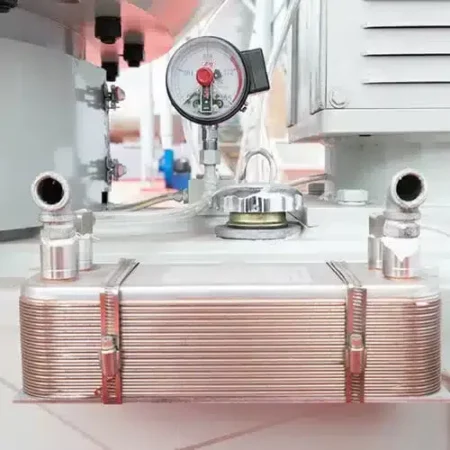

Built-in cooling system and fan blower to help cool down the pelletizing area, ensure continuous high quality output.

The main shaft inside our pellet machine is also wear-resistant, which can ensure produces wood pellets with a smooth, consistent surface.

The vertical laying dies feed directly with a broad range of applications and excellent heat dissipation. It offers improved efficiency with reduced cost.

Pellet Making Machine Parameters

| Model | TCZL700 |

| Type | wood pellet making machine |

| Output | 2-2.5t/h |

| Main Motor | 160kw |

| Lubrication pump Motor | 0.55kw |

| Pellet collecting Motor | 1.5kw |

| Independent cooling Motor | 1.1kw |

| Material of Ring Die | Stainless steel 4Cr13 |

| Roller Shell | 55# steel |

| Inlet&Feeding Cover | SS304 |

| Pellet Diameter | 6mm,8mm,10mm, 12mm |

| Pellet Length | Can be customized made |

| Pellet Density | 1.0-1.4g/cm3 |

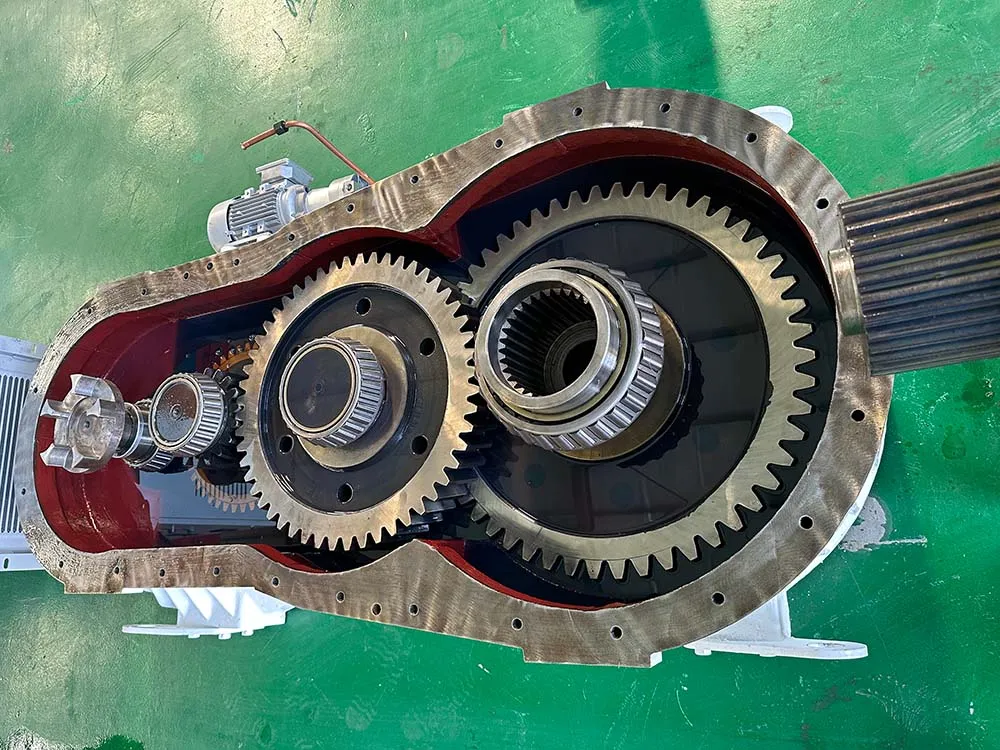

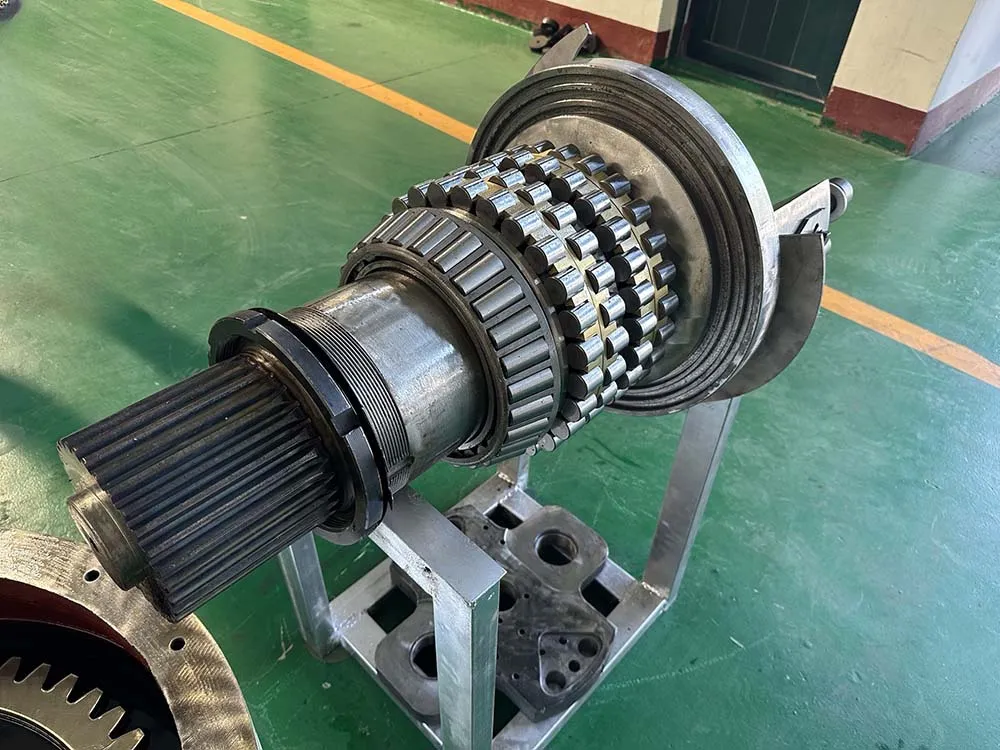

Pellet Making Machine Detailed Pictures

Pellet Making Machines Spare Parts

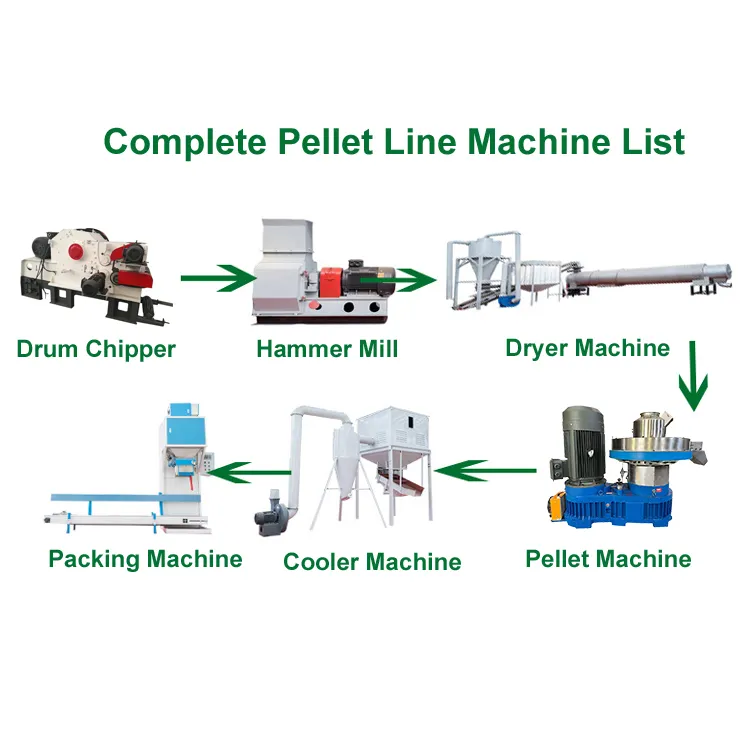

Pellet Making Machines - The Beginner's Guide

Are you buying pellet making machines for the first time? Do your homework well before investing. After all, a small mistake can affect the grade of your pellets and your revenue. Here is an in-depth beginner's guide to assist you in making the best decision.

What are Pellet Making Machines?

As the name suggests, pellet making machines help you make pellets from crushed or powdered material. They combine crushed raw material into a uniform mass. Depending on the machine type, the raw material could be wood, rice husk, etc.

Pellet making machines come in a variety of sizes and types, including feed pellet making machines, fertilizer pellet making machines, chicken pellet making machines, and so on.

You have to choose the machine depending on your requirements and applications. Also, you have to use raw materials accordingly.

Remember, you can not use a wood pellet machine for making chicken pellets and vice versa.

What Are the Different Applications of Pellet Making Machines?

You can use pellet making machines for industrial as well as domestic purposes, based on their size. As mentioned above, they make pellets from powdery material.

Industrial pellet making machines produce pellets on a large scale. A small pellet making machine, on the other hand, is suitable for use at home.

You must understand that different pellet making machines have different roles. Some pellet making machines for sale make feed pellets while others make biomass pellets. So choose them as per your needs.

You can use biomass pellets for a wide range of applications such as cooking & residential heating in pellet boilers and stoves, animal beddings, fuel for electric power plants, and so on.

People use feed pellets as food for livestock such as cattle, rabbits, alpacas, deer, etc.

How Do Pellet Making Machines Work?

The working principle of pellet making machines varies (though slightly) as per their types. For example, a fertilizer pellet making machine works differently from a biomass pellet making machine.

Aside from that, the size of a machine affects its functionality.

A portable pellet making machine will not work as an industrial machine.

In general, there are two types of biomass pellet making machines: Ring Die Pellet Machines and Flat Die Pellet Machines.

In a flat die pellet machine, the raw material enters into the pressing chamber with the help of its weight. After that, the material is pushed into the holes on the flat die by the rotating press.

The Ring Die Pellet Machine follows a straightforward working principle. It spreads raw material over the inner surface of a revolving die to compress it into the ring die holes and form pellets.

Ring die pellet machine can make up to 20ton pellets per hour, while a flat die machine has a maximum output of 2000KG. However, the flat die machine is pocket-friendly and has low wear-tear.

The good news is that pellet making machines exist that combine the best of both worlds. For example, the Tcpel pellet machine combines the benefits of both the Ring die and Flat die machines.

How Much Do Pellet Making Machines Cost?

If you search on the internet, you will find that the price for a pellet making machine starts at USD 300. The pellet making machine cost can go up to USD 10,000. It all depends on the kind of machine you choose.

There are tons of factors that influence the price of the machine, such as the machine’s type, size, origin, feature, shipping cost, and so on.

It is advisable not to go with any random listing for pellet making machines for sale on the internet. Some manufacturers sell machines at very low prices due to poor product quality.

Do your research before choosing the product. Learn about the manufacturer, their product quality, after-sales service, and market reputation. After all, these things matter a lot when you buy pellet making machines in bulk for industrial use.

How Many Types of Pellet making Machines are There?

There are several types of pellet making machines available in the market. You can divide them into two categories based on their size and production capacity & application.

Let us get to know about these two types in detail.

Production Capacity

Small-scale and large-scale pellet machines are there when it comes to size. Large-scale machines are professional machines that give high output and are suitable for commercial production.

Generally, a Ring Die pellet machine is used for large-scale production. Flat die machines are suitable for small-scale production. These are low-cost mills that you can use at home.

Applications

There are different pellet machines for diverse operations. For instance, fuel pellet making machines are different from feed making machines.

How to Choose the Best Pellet Making Machine for Pellet Production?

Buying a pellet making machine could be tricky for anyone. First, determine your needs. If you want to produce pellets in a large quantity, choose an industrial biomass pellet making machine. Otherwise, a mini pellet making machine will suffice.

After choosing the machine type, pay attention to the following things.

Machine Exterior

Make sure the manufacturer has used high-grade metal for the machine. The exterior metal parts should be galvanized, painted, and polished uniformly.

Analyze The Die

The die is a crucial part of a pellet making machine. It can determine the overall performance of your production line. So you need to check this part cautiously.

Ensure it does not have any manufacturing defects and meet all the required technical standard. Pay attention to the surface of the die. It must have fine finishing on each side.

Check the inner holes of the die carefully. Make sure they have a uniform distribution. If you notice blind or joint holes, tell your manufacturer about them in advance.

Analyze the Die Rotation

Sometimes, while rotating the machine, the die shakes inside and causes friction with other parts. It can affect your production quality. Give a test run to observe these flaws. You can spin the die by hand to check it.

Check the Assembling of Different Parts

Double-check that all of the components are in perfect working order. Also, check the fasteners of the drive engine and main body.

When purchasing a flat die pellet machine, pay special attention to the pellet cutter and die lock nut.

Quality of Pellets

If everything is right with the machine, you will get quality pellets. When doing a test run, check the quality of pellets. Be sure they do not have cracks and rough surfaces.

How to Buy an Affordable Pellet Making Machine?

We do not recommend you to go for an extremely cheap pellet making machine. There is a good chance that it does not meet standard quality requirements.

However, it is also true that you should not go beyond your budget.

So what is the solution? Below are a few tips to help you get an affordable pellet making machine.

Search Online & Compare Prices

One of the ideal ways to get an affordable pellet making machine is, search the keyword “Pellet making machines for sale” on the internet. You will get several results.

Make a list of potential manufacturers and ask them to send a price quote for your requirements. Most manufacturing companies will not deny sending you quotations. Compare them and finalize the one selling a high-quality pellet making machine at a better price.

Choose a Chinese Manufacturer

Chinese manufacturers are known to provide international-standard pellet making machines at affordable prices. You will not find any difference in the quality of a European pellet machine and Chinese machinery. However, the cost of the Chinese pellet making machine is comparatively low.

It is because China is the largest manufacturing hub in the world. It takes about 28.7% of global manufacturing output. They have affordable labor, an abundance of raw materials, and a competitive shipping market.

Consider Your Requirements

As we mentioned in the above section, there are several types when it comes to pellet making machines. You must consider the application for which you want to use the pellet machine. There are large, medium, and small-scale pellet making machines available in the market.

After-Sale Service

Choose the manufacturer who provides all the possible after-sales service for the pellet making machine. What is the benefit of buying a cheap machine and not getting necessary post-sales services such as timely delivery of products, warranty service, user training, and online support?

Remember that some companies sell pellet making machines for a low price and then charge extra for the post-sale services. Make sure you are clear on everything ahead of time.

Negotiate Price for Bulk Orders

You can also try negotiating with your potential manufacturer on the price. If you buy several pellet making machines for your pellet production line together, some companies may offer a discount on bulk orders.

How to Use a Pellet Making Machine for Beginners?

As we said above, the working principle of a pellet making machine somewhat varies depending on its size and type.

If you are a newbie looking to operate the machine, you must read the operation manual and other instructions/warnings from the manufacturer carefully.

Businesses with large-scale biomass pellet production lines must arrange the training for their workers to operate the machine carefully.

Below are the steps to operate a biomass pellet making machine.

Assembling and Installation of the Machine

Follow your manufacturer’s guidelines for the assembling of the machine. You can refer to manuals and drawings the company gives you.

A commercial pellet making machine runs for a long time. Therefore, the machine needs a firm base to hold it. You can affix it into a cemented foundation. Also, you can install the pellet making machine on an iron angle if the floor is not steady.

After the installation, check all parts of the machine. Make sure they are securely fastened. Pay attention to the belt in particular.

Lubricate Machine

Since your machine will run continuously for several hours, high heat pressure may cause the thin lubricating film to break. Make sure your pellet making machine’s moving parts are well lubricated. It will avoid metal-to-metal contact and friction.

Operation of Pellet Making Machine

You need to add the raw material constantly when operating the machine. Otherwise, it may cause blockage. Analyze the quality of your raw material before feeding it into the machine.

Check for rocks, iron, or other contaminations in the material, as these can damage the internal components.

Stop the machine right away if you notice a shaking or strange noise. Do not start it until you troubleshoot the problem.

How to Do the Maintenance of a Pellet Making Machine?

Maintenance is necessary to enhance the lifespan and operation efficiency of your pellet making machine. Remember, by eliminating minor flaws regularly, you prevent big failures in the future.

You must follow the below steps for the regular maintenance of your machine.

Cleaning of Machine

Do cleaning of your pellet making machines regularly. Regular cleaning of parts like die and roller can significantly improve the performance of your pellet maker. You can use gasoline or die to clean up the machine.

Remove all scattered material before using the machine every time. Also, keep electrical components and motor box dust-free to avoid short circuits.

Lubricate Spare Parts Applicable Lubricants

Lubricate the rollers and die with lithium-based lubricants twice a day. For parts in the gearbox, you can use hyperbolic gear oil. Lubrication of the gearbox once in six months is okay.

As die comes in contact with moisture from biomass material, you must fill it with oil to prevent corrosion.

Day-to-day Inspection and Maintenance

Inspect all the screw parts of your machine frequently. If you notice anyone is slipping out, tighten it.

Check out wearing parts such as die, roller, and bearings on routine. Replace them if required.

Remove the Blockage Out of Die

In regular use, dies get blocked quickly with raw material. Clean this blockage with oil soaking. If required, you can drill out the material with a drill. Do not forget that the obstruction in the die can spoil the shape of your pellets.

Preheat the Machine

Preheat the machine before you put raw material into it. The process will slow down the cooling of raw material when processing the pellets. Make sure the temperature of the machine has reached up to 50-degree Celsius.

Tips When Buying a Pellet Making Machine

In order to serve you better, please try to provide the below information:

1) What is the material to make wood pellets? Better if you can share us some pictures

2) Hardness of your material?

3) Moisture content?

4) Maximum diameter of the material to be processed?

5)The capacity per hour you want to get for the pellet production.

Then we will recommend suitable model based on your actual needs.