Professional wood hammer mills - manufacturer in China

- Higher capacity and less wear parts costs

- Wide range of application suitability

- Stable running performance and easy operation

Wood Hammer Mill - The Beginner's Guide

Are you looking for a hammer mill to crush wood materials of even small sizes? Then, a wood hammer mill is a machine you should choose. This tool will make wood to be finer than ever before. Sometimes you can fail to get the right hammer mill. But don’t worry. Here you’ll know all about getting the best wood hammer mill. Let’s start by learning what a wood hammer mill is.

What is a Wood Hammer Mill?

A wood hammer mill is a machine that helps crush and grind wood materials. The wood items can be like corn straw, branches, or herbs.

This machine uses a high level of tech. The blades have quality carbon, steel, and alloy material.

What Does a Wood Hammer Mill do?

A hammer mill for wood grinds wood materials less than 50 mm wide. After the process, your materials can have a fineness of 3 to 5 mm.

So, you’ll get the best pellets using this machine. Also, this hammer mill for wood will help you make many biomass briquettes. Well, it’s because of the parts inside this hammer mill wood.

Cost of a Wood Hammer Mill

If you want a wood hammer mill for sale, know that this machine isn’t costly. Yes, you’ll get this machine with excellent specs at a low cost.

Remember, the prices will depend on the model you choose to buy. Also, it will vary with the power and capacity of the materials you are going to crush. They range from as low as $400 to as high as $9,300.

Also, as you buy a wood hammer mill, look at the guaranty of the machine. When choosing the best one, sometimes the prices shouldn’t be the rule to determine the costs of the device.

You’ll only get the diesel and electric wood hammer mill. The one that uses more kilowatts will cost you more. But you’ll have an easy time as you crush your wood materials and biomass.

How Fast Does a Wood Hammer Mill Spin?

The speed at which a wood hammer mill machine will spin depends on the model you have. Well, expect the bigger ones to crush the wood faster than the small wood hammer mill.

Each wood hammer mill has knives or hammers. These knives rotate at speed starting from 2500 RPMs to even more than 60 000 RPMs. Remember, these knives or hammers move at high speed to make the materials very small and faster.

With these speeds, they can move clockwise or anticlockwise. It will depend on the motor’s size. Also, the electric wood hammer mill makes the pellets faster than the diesel ones.

Wood Hammer Mill’s Working Principle

It won’t matter the type or function of the wood hammer mill; they all work in the same way. But, it’s only the size and purpose of the wood hammer mill that can differ.

Remember, it’s simple with how the machine works. So, read on to see the hammer mill principle. You’ll know how it works even before you buy it.

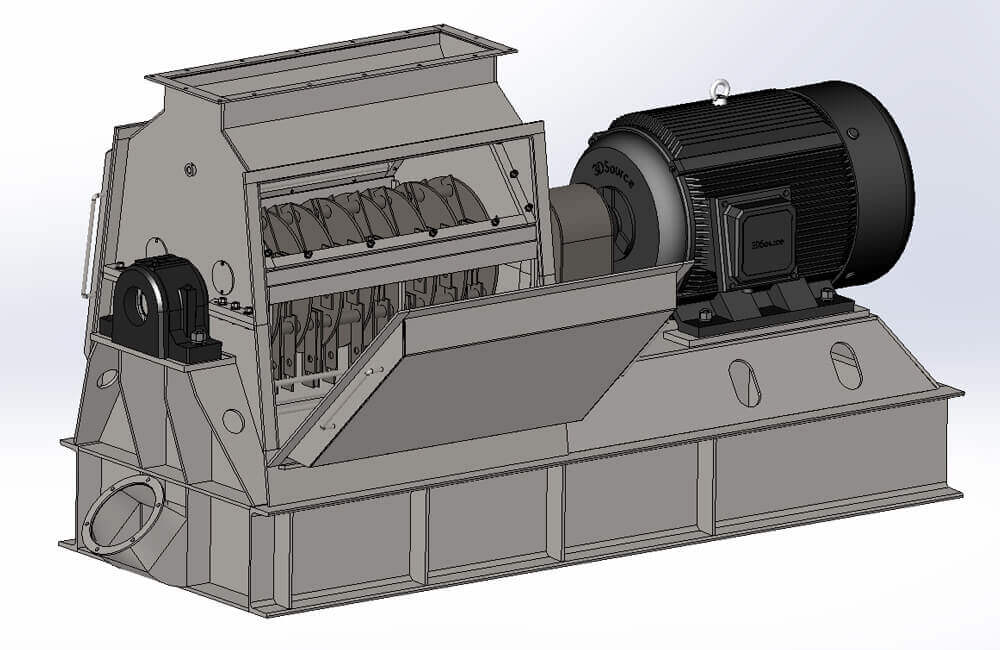

Design of the Hammer Mill for Wood

Here, we’ll look at the parts that make this machine work. It doesn’t matter if it’s electric or uses diesel. Every wood hammer mill has five main features.

Remember, the size of each part won’t be the same on every wood hammer mill. But each piece plays a vital role in the machine.

The parts include the feeding plate, crushing area, delivery device, screens, and rotor. So, below is the info on the function of each piece.

- Feeding Plate

Every hammer has a feeding area. It’s where you place the wood or biomass materials you want to crush.

How the feeding plate will work depends on the design. Some can use gravity to take in the materials. Others use the meter or electric power.

Most firms use electric wood hammer mills. So, the feeding plates have a meter to allow the materials to be uniform even as you crush them.

When you buy a small wood hammer machine, the feeding plate will use gravity to take in the materials. Don’t expect the wood materials to enter uniformly.

- Crushing Room

After coming from the feeding plate, the wood cravings will go to the crushing part. Here, you’ll get hammers or crushing knives.

They move very fast. It’s from this movement that the machine crushes the wood into pellets.

These knives and hammers are on the horizontal shafts. As they crush, they can either move clockwise or anticlockwise.

The blades have high-quality steel. It makes them last for a long time and be free of wear. Also, the air blower works as a cooler.

The screens will determine the size of the particles that come from the crushing room. Remember, most wood hammer mills have many screens meshes.

All screens are in a given order. This arrangement helps in giving you fine pellets.

- Delivery

This part receives the pellets or wood shavings after you crush them. At this point, you can make your wood cravings or pellets even finer.

Also, here will depend on the type of wood hammer mill you use. The electric ones will deliver better than the hammer mill for wood that uses a diesel engine.

- Control Zone

This part of the wood hammer mill allows you to control how the machine works. It’s where you can power it on and off. Also, it’s from here that you’ll handle the speed at which the feeding plate takes in the materials.

- Rotor

This part rotates as a shaft together with a motor. It’s the part that holds the blades or hammer.

Some wood hammer mills have belts. These belts help reduce cases of a shock to the crushing tools.

How the Wood Hammer Mill Works?

The diagram of how every wood hammer mill works varies with the size and purpose. But here are basic things similar to every hammer mill for wood.

- You’ll first place the wood material through the feeding part. Remember, these materials should be in the correct sizes. Also, they should have the right looks that match what the machine can crush.

- After going through the feeding chamber, they’ll head to the crushing area. It’s here that the major work begins.

- Once again, the speed at which these materials move is by the help of gravity or electric power.

- At a very high speed, the blades or hammers will hit the wood items many times. This act will help reduce them into tiny particles within a short time.

- The speed at which the machine crushes these materials depends on the diameter of the materials. Also, if it’s an electric wood hammer mill, expect things to be a bit fast.

- Then, the materials will go through the screens. It’s where they become finer. The pellets or particles that aren’t fine go through the nets again.

Picking the Best Wood Hammer Mill for Pellet Making

If you want the best wood hammer mill to make pellets, it shouldn’t worry you. The process is easy. You’ll only have to look at the following things.

- Hammer Mill’s Capacity Calculation

Make sure your machine can crush wood and make pellets. Every wood chipper hammer mill has instructions on them. One of the things is the rated capacity under normal conditions.

Buy a wood hammer mill with a higher production level than the number of pellets you want to make. Things will still run well even if your machine gets to wear, which makes the process stop.

But sometimes, it can be hard to understand the miller capacity. Know that the larger the mill, the high its ability it will have. But here’s a table to help you calculate the capacity.

|

Wood Hammer Mill’s Capacity(ton/h) |

Power in Kilowatts |

Weight in Kgs |

Size (mm) |

|

1 to 3 |

22 |

860 |

1310 by 800 by 1070 |

|

2 to 4 |

37 |

1350 |

1380 by 800 by 1010 |

|

3 to 6 |

55 |

1520 |

1900 by 800 by 1100 |

|

5 to 8 |

90 |

1830 |

2100 by 1700 by 1500 |

|

3 to 10 |

160 |

2300 |

2100 by 1000 by 1100 |

- Materials to Use

The materials you will process on your hammermill can also affect what you’ll pick on as your machine. Well, since wood is a rigid material, buy a wood hammer mill with a non-sieve grinder.

If you are going to mix the wood with small particles, use a special non-sieve grinder. You’ll make the best pellets.

- The Power of the Machine

The power that a wood shavings hammer mill or a woodcutter hammer mill uses is vital. Remember, this power level will depend on the type of material you’ll use to make the pellets.

Look at the size of the screens. It will show you the power of the machine you want to pick.

- Discharge Means of the Wood Hammer Mill

If a machine can put away the raw materials well, go for it. Most of the excellent wood hammer mills use the self-weight way. You’ll have an easy time as you make the pellets.

How Beginners can Use a Wood Hammer Mill?

Yes, if it’s your first time using this machine, it will be a bit hard for you. But don’t worry. . Here’s how to use it.

- Every part should be working well. It will help reduce any damage to the mill.

- Have your PPE After that, start the machine using the control section. Remember, it’s also where you control the feeder and motor.

- As the machine starts to run, place the wood material in the feeder. It’s after you feed the materials into the feeder that the hammers will grind them. Inside the drum, the hammers can swing fast as the rotor spins.

- After the crushing, the materials will go into the screens. It’s where they’ll get finer.

- The screens will remove the fine ones. You’ll now collect the materials as you move on to the next step of making pellets.

Maintaining a Wood Hammer Mill

Like any other machine, if you maintain a wood hammer mill, expect it to function well and for a long time. If you don’t keep it well, there are high chances that the machine will lose its value fast.

The good thing is that hammer mills aren’t that prone to damage. You only have to care for it well. So, here is how you should maintain your wood powder hammer mill.

- Lubricate the Hammer Mill Wood

Ensure you lubricate the machine well. Use the lubricator that the firm directs you to use. Also, it’s the firm that will tell you when to do it.

You’ll need to apply the grease on ball bearings as you adjust them. Some wood hammer mills can auto-lubricate. But it would help if you never missed maintaining the machine.

- Double Check every Part

Always double-check to see if the machine works well. Do it before you start using it and as you grease it.

- Look at the Airflow

Checking for the airflow is key for hammer mill for wood powder. Make sure you do it regularly. If there isn’t enough airflow, the machine’s speed will have a problem.

Buying a Cheap Wood Hammer Mill

You’ve now known all that involves a wood hammer mill. You should also know that buying the wood hammer mill you can afford is key.

Yes, finding an affordable one isn’t easy. You might get a cheap one, but it won’t give you the best output. So, keep reading and how you can buy it at the right cost.

- Can it handle the Raw Material Moisture Levels?

Ensure that what you are buying can handle the raw moisture levels of all materials. If it can’t, it will become hard for it to crush some items.

Remember, the moisture content rises with how dense the material is in the crushing area. But if the machine can handle high moisture levels, then it’s suitable for a pick.

- Crushing Chamber’s Diameter

A machine with a wide crushing chamber’s diameter makes it productive. It means that the device can handle any number of raw materials. It’s where you can determine the value for money of that machine.

- Speed

Here, ensure you look at the spindle speed. It should have a high limit value. So, it will mean that the machine has a high production power.

- Ease of Maintenance

The wood hammer mill price is vital when looking for an affordable wood hammer mill. But ensure it gives you an easy time to maintain it. You might buy a cheap one, but it will cost you many dollars to keep the parts well.

Conclusion

A wood hammer mill crushes wood materials into powder before they become pellets. It would help if you knew how both electric and diesel wood hammer mills work.

So, pick the best and affordable wood hammer mill. If you are new to using this mill, follow every step of how to use it.

Tcpel Wood Hammer Mill Introduction

Whether you’re processing biomass, like soybeans and weeds, corn stalks, wood shavings, or inorganic matter like PVC foam board, rubber, or other materials, the Tcpel wood hammer mill is the versatile machine that can help take your production to the next level.

As you probably already know, most pellet mills require raw materials to be powdered form with a diameter of no more than five millimeters. These raw materials don’t come like the sin of nature! Therefore, crushing them down is essential.

If you’re looking for a smooth-operating, high-capacity machine, you’ll find all of that (and more!) in the Tcpel wood hammer mill machine. It can be used in operations of all kinds, including in wood pellet mills, feed production lines, organic fertilizer factories, and more.

Tcpel Wood Hammer Mill Features

Are you still shopping for the best wood hammer mill? Consider the Tcpel hammer mill’s many features as you do so.

1. Versatile: This diverse and versatile machine can handle biomass materials of all types and sizes, including crop stalks, wood chips, tree branches, coconut shells, and more. It will grind all of them down into a powder equal to or less than three to five millimeters. That’s the perfect size for making pellets and even briquettes! It can even handle a non-organic matter like rubber, foam board, PVC, and more. It can be used to process agricultural or forestry waste, in Chinese herbal medicine, in chemical factories, and much more.

2. Easy to Maintain: This hammer mill has numerous features that make it easy to maintain. It has a revolutionary cold water cooling structure. This helps resist damage to spare parts inside the machine that are often caused by friction. It also has a unique two-motor operation drive, allowing for higher capacity and smoother operation without worrying about wear and tear.

3. High Precision Machines: The high-precision components of the Tcpel hammer mill mean that this machine will last longer and have a higher performance than its competitors. It has CNC-engineered systems that help the machine stay durable. Every part is manufactured in this way, from the screener to the hammers and spare parts.

4. Environmentally Friendly: This machine comes with all sorts of features that make it safer for the environment. For example, it has a certified and qualified motor with a thick copper coil for more stability and a smoother process. As a biomass hammer crusher, it can work with an air fan and cyclone so that crushed powder will come out of the bottom and be easier to collect. That’s less debris going into the air and making a mess of your work environment.

5. Thicker Knives: Made out of H13 steel, the knives on this hammer mill have special abrasion-resistant treatment technology. It’s harder and resists wear, meaning it can cut wood and have a longer time before it needs to be serviced. The materials are made with tungsten carbide spot welding and are thicker, too, allowing for a better overall working time and performance.

6. Fast Cutting Rate: Last but not least, the material has blades that cut and process material much faster than others. It uses high-speed airflow and reversed and rotational blade cutting direction to allow the machine to be crushed at a normal double rate.

Tcpel Wood Hammer Mill Parameters

| Model | Capacity(T/H) | Power(kw) | Weight (Kg) | Dimension (mm) | Hammer qty(piece) | Note |

|---|---|---|---|---|---|---|

| GXP65X27 | 1-2 | 22 | 860 | 1310×800×1070 | 24 | Φ4, can be adjust |

| GXP65X55 | 2-4 | 37 | 1350 | 1380×800×1010 | 48 | Φ4, can be adjust |

| GXP65×75 | 3-6 | 55 | 1520 | 1900×800×1100 | 72 | Φ4, can be adjust |

| GXP65*100 | 5-8 | 90 | 1830 | 2100×1700×1500 | 72 | Φ4, can be adjust |

| GXP130*55 | 8-10 | 160 | 2300 | 2100×1000×1100 | 160 | Φ4, can be adjust |