1t/h Biomass Pellet Machine For Sale

5.0 based on 52 ratings and reviews

Brand :

TCPEL

Model :

TCZL560

Catagory :

Vertical Ring Die Biomass Pellet Machine

Capacity :

1-1.5t/h

Price Range :

$15000-$19800 based on configuration

Payment Term :

T/T/Visa/Mastercard/American Express/Discover cards

Delivery Time :

15days after get deposit payment

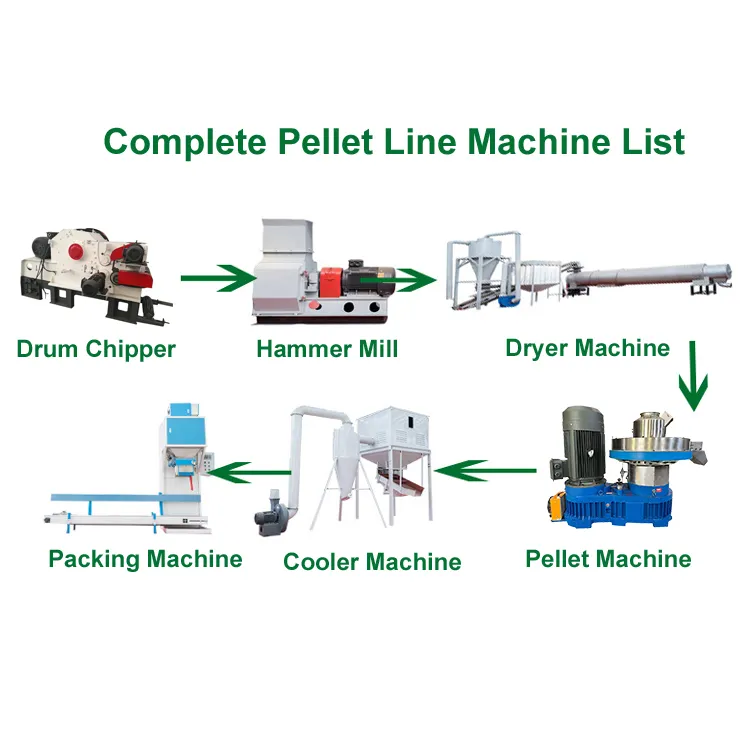

Biomass Pellet Machine Introduction

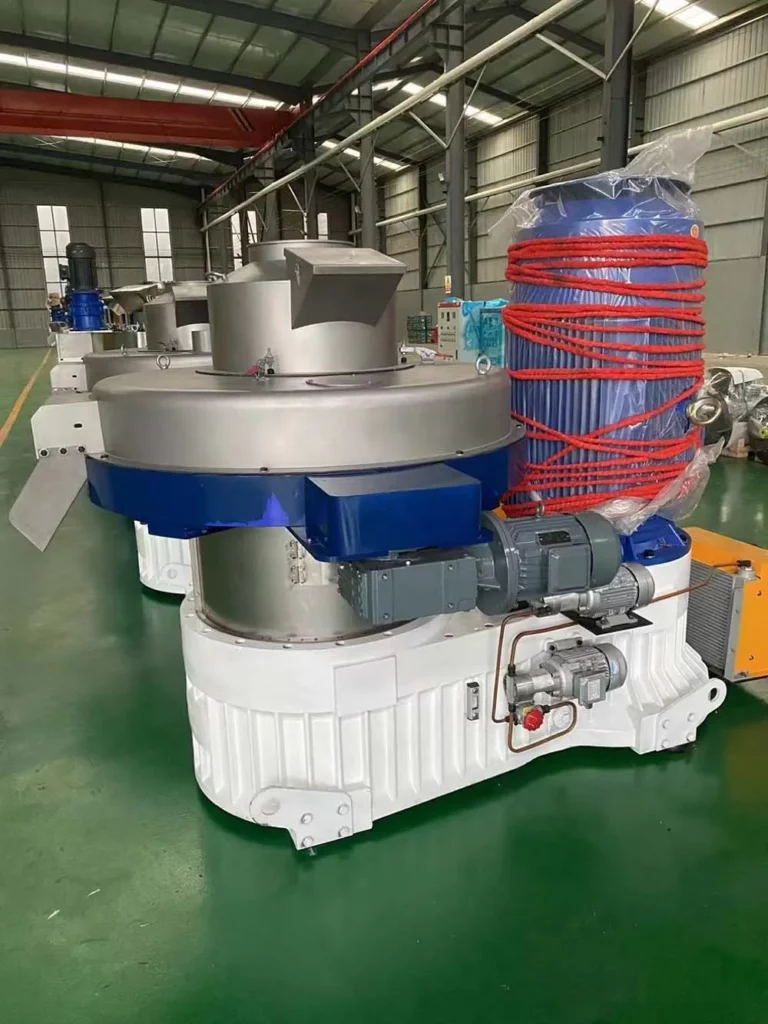

TCZL560 is our first generation biomass pellet machine, with 90kw motor, this machine can achieve 1-1.5t/h capacity. It’s widely used for processing biomass waste and agricultural leftovers into pellets.

TCZL560 Biomass Pellet Mill Features

Heavy duty structure ensure durable and long-lasting, 24 hours of work time without stop and less maintenance.

Suitable for various materials, including wood, sawdust, rice husk, EFB, palm shell, olive waste, fruit straw beech etc. and more.

Enhanced stainless steel dies have a service life of 1000 to 1500 hours, less power to achieve higher capacity.

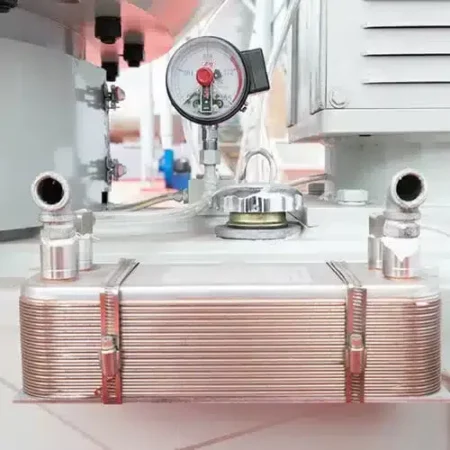

Built-in cooling system and fan blower to help cool down the pelletizing area, ensure continuous high quality output.

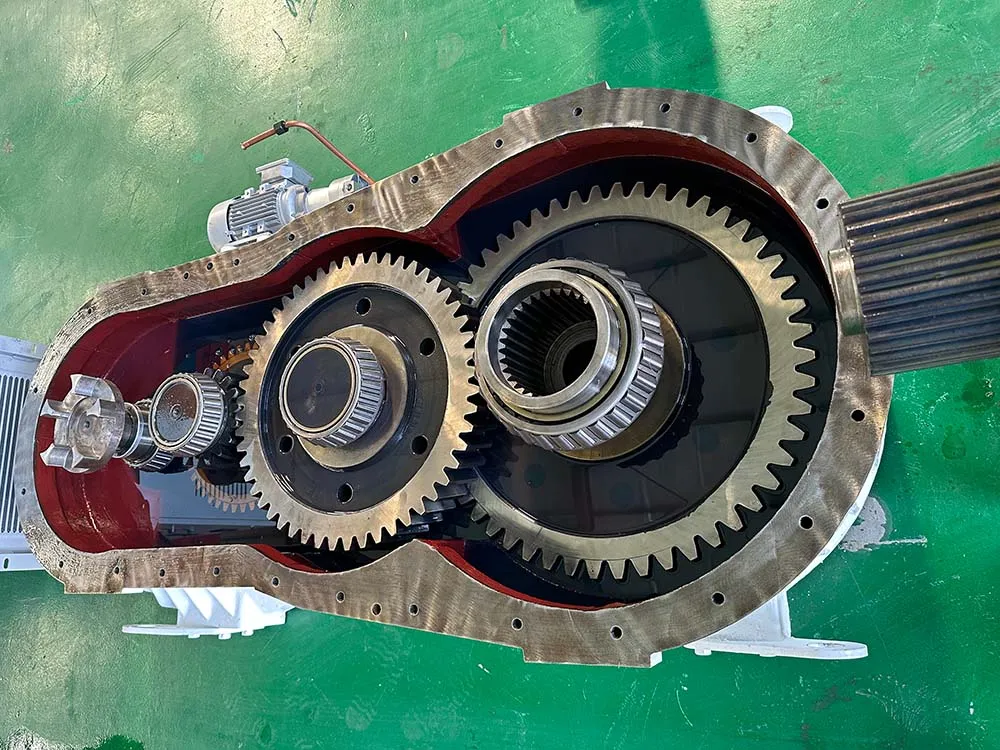

The main shaft inside our pellet machine is also wear-resistant, which can ensure produces wood pellets with a smooth, consistent surface.

The vertical laying dies feed directly with a broad range of applications and excellent heat dissipation. It offers improved efficiency with reduced cost.

Biomass Pellet Making Machine Parameters

| Model | TCZL700 |

| Type | Biomass pellet machine |

| Output | 2-2.5t/h |

| Main Motor | 160kw |

| Lubrication pump Motor | 0.55kw |

| Pellet collecting Motor | 1.5kw |

| Independent cooling Motor | 1.1kw |

| Material of Ring Die | Stainless steel 4Cr13 |

| Roller Shell | 55# steel |

| Inlet&Feeding Cover | SS304 |

| Pellet Diameter | 6mm,8mm,10mm, 12mm |

| Pellet Length | Can be customized made |

| Pellet Density | 1.0-1.4g/cm3 |

Pellet Making Machine Detailed Pictures

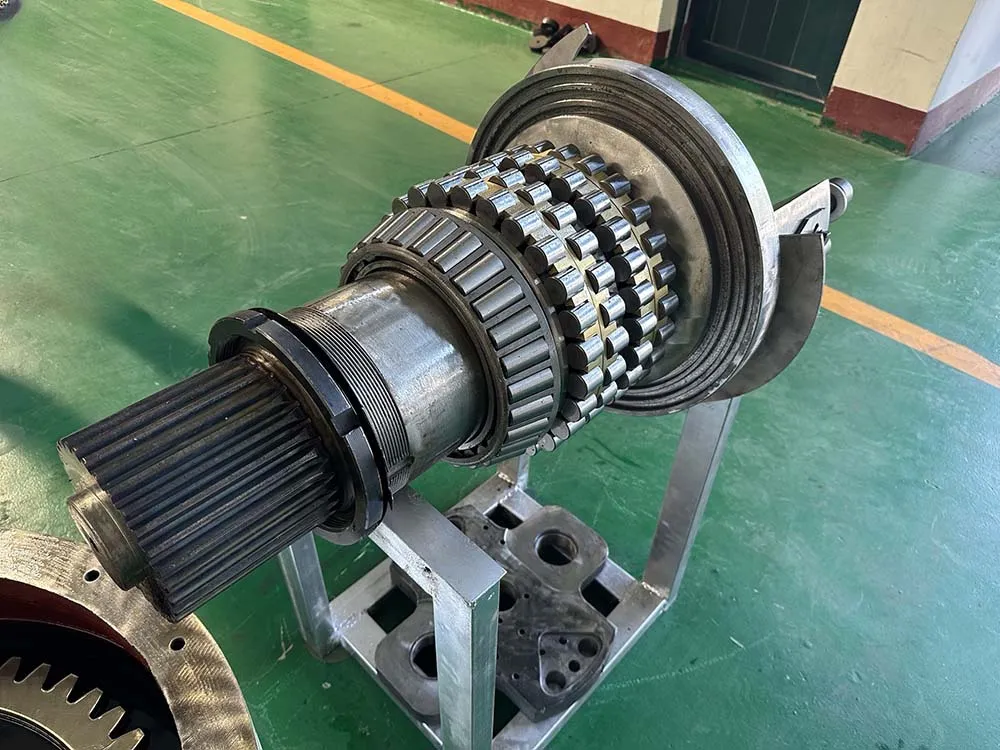

Pellet Making Machines Spare Parts

Biomass Pellet Machine - The Beginner's Guide

If you’re in search of a certified Biomass Pellet machine from a trustworthy source – you’re at the right place. In this guide, we’ll talk about the working principle, cost, maintenance, and tips on choosing the best biomass pellet machine for your specific need.

What is a Biomass Pellet Machine?

Simply stated, biomass pellet machines are used to make small pellets of the powdery raw materials. The pellets produced by a biomass pellet machine have a widespread utility as fuel for cooking, heating, and several industrial processes.

This device compresses organic and renewable biomass from powdered form to pellets of variable shapes and sizes. Primarily, the biomass pellet machine is used in the production of biofuel.

What is Biomass Pellet Machine Used for?

A biomass pellet machine has several uses. Some of these include:

- convert organic and renewable powder into pellets

- turn low-density organic material into high density, solid energy-carrying pellets

- increase the utility of otherwise useless organic matter and biomass

- recycle the organic and inorganic waste materials

- produce clean and green fuel for residential and commercial uses

- reduce the burden on the depleting reservoirs of non-renewable energy sources

- competitive advantage in terms of power and running cost

How Does a Biomass Pellet Machine Work?

The biomass pellet machines work on the principle of compression and integration.

Pre-Production

The first step is the collection of raw material. The raw material used in pellet production is usually wood, sawdust, bamboo, pine, alfalfa, straw, wheat bran, cotton and corn stalk, rice husk, and several other types of organic and biomass material. The operator must ensure that the raw material is fine powder before adding it to the feeder.

Production Stage

The powdered biomass is placed in the feeder of the biomass pellet machine, which regulates the flow of material into the pellet mill. A variable speed screw feeder thoroughly controls the process of feeding. The feeder plays a crucial role in regulating the material flow in the inlet opening, ensuring optimal operation.

The raw material then enters the conditioning chamber of the biomass pellet machine, where steam softens and lubricates the raw material. The process in the conditioning chamber is regulated for optimal pellet quality.

After this, the conditioned raw material moves further into the die cavity. The processed and prepared feed is pressed through the die by the activity of the rollers present in the pellet mill. The material exists from this die in the form of long rolls and contacts stationary knives. The knives or blades turn the finished product into pellets of similar size and shape. The pellets then exit the pellet mill.

Post Production

In most cases, these pellets are moist as they exit the pellet and ought to be cooled prior to collection.

How Much Does a Biomass Pellet Machine Cost?

The biomass pellet machine price varies a great deal. The pellet biomass machine cost depends on the purpose, scale, and type of machine in question.

The biomass pellet machine for manufacturing homemade pellets and domestic usage costs much less than the industrial and commercial biomass pellet machinery. The price range for a biomass pellet machine begins as low as $300 and may go as high a several million dollars.

Individual budget and purpose of purchase of biomass pellet machine greatly influence the cost of biomass pellet machinery.

How Many Types of Biomass Pellet Machines?

The biomass pellet machines are of several types based on different features. But, primarily, the types are divided based on the scale of manufacture.

There are biomass pellet machines meant for large-scale and small-scale usage. These are further classified on the die used.

Flat die pellet machine

The flat die pellet machines are smaller in size and meant for small-scale usage. The raw material is introduced from the top slot in this type of pellet machine. The flat die pellet machine has a roller mounted on a relatively flat disk with perforation. The material is forced through these perforations to form pellets.

Ring die pellet machine.

The ring dies pellet machines are more extensive and meant for large-scale commercial and industrial usage. In this case, raw material is fed into the interior compartment. A ring with inner rollers that push the raw materials through the perforations is used to obtain pellets.

How to Choose the Best Biomass Pellet Machine for Pellet Production?

The best biomass pellet machine is the one that adequately meets your tailored requirements. We have researched five most important points to remember while buying a biomass pellet machine:

Purpose

The purpose of manufacture is the primary factor that influences. If you are looking for biomass pellet production for domestic or home-based usage, it is best to invest in a small-scale biomass pellet mill. However, larger units are more suited for production on a commercial and industrial scale.

Flat or Ring Die Pellet Machine

The flat die pellet machines are more cost-effective as compared to the ring die pellet machine. The flat die pellet machine is perfect for small-scale manufacture where high efficiency is not critical. The ring dies pellet machines are highly efficient, produce a better yield, and have a higher running cost. Thus they are more suitable for industrial usage.

Pellet Quality

The pellet quality is a crucial determinant while choosing the machinery for pellet production purposes. The pellet quality is paramount in the case of commercial and industrial pellet manufacture. A trial on various machinery prior to purchase is the key to evaluating pellet quality.

Energy Consumption

Pellets are produced with the critical purpose of conserving energy. Thus, a pellet production machine that is not energy efficient demolishes the entire sense. Therefore, it is crucial to purchase energy-efficient machinery from reliable manufacturers such as TCPEL.

Overall

Despite the numerous guides and directions, ultimately, the best biomass pellet machine is the one that checks all your requirements. The term best is subjective to user requirements and experiences.

How to Use a Biomass Pellet Machine for Beginners?

A biomass pellet machine operation can be pretty overwhelming for a beginner. Adequate knowledge of the functioning and operation of a biomass pellet machine is essential for the ease of beginners. Thus, here are a few instructions on the usage of biomass pellet machines for the novices:

- Thoroughly read the user manual for it gives a fair idea of the operational aspects of the pellet machine

- Preempt the incidence of accidents and risk. The key is to train you to minimize the incidence; however, managing such incidents is more critical.

- Firstly, assemble the part. As a beginner, the manual would be of great help in guiding the assembly. However, some commercial and industrial grade machinery require you o seek professional help for assembly. The assembly of the machinery is easier for individuals who have prior experience of dealing with machinery.

- After assembly comes the trial run, the trial run is vital before you jump into the full-scale running of such complex machinery. A trial run gives a fair idea of whether the assembly was adequately performed.

- Lubrication is also an essential element that most beginners tend to skip. The post assembly lubrication is exceptionally vital for smooth functioning and running operations of the machinery.

- Beginners often tend to struggle with raw material loading as they have no prior experience. The user manual most definitely mentions the size and quantity of raw material to be used. The raw material ought to be in fine powdered form for optimal pellet yield. As a beginner, it is your job to pre-grind the raw material that seems larger than the appropriate size.

- Avoid overloading the feeder. Overloading errors are pretty common and recurrent, especially by beginners.

- It is necessary to check temperature and water content before beginning the operation.

How to Maintain a Biomass Pellet Machine?

Proper maintenance of a biomass pellet machine is crucial for adequate functioning and longevity. If properly maintained, a biomass pellet machine serves as a lifetime investment. Good maintenance also significantly reduces the running cost due to less investment in repairs and fixing.

Following are the recommendations for optimal maintenance of biomass pellet machinery:

- The instruction manual of the biomass pellet machine tends to come with an instruction manual with proper instructions pertaining to maintenance. It is vital to it a thorough read.

- A scheduled periodic check of all the components of the biomass pellet machine is a vital element of maintenance. The rollers, gear, die, and bearings all require an inspection from time to time.

- Friction increases the wear and tear of machinery. Adequate lubrication of each element of the biomass pellet machine is exceptionally crucial. The transmission parts, in particular, have to be oiled and lubricated at fixed intervals.

- Cleaning the biomass pellet machine from all residues after the operation is also vital for long-term maintenance. The roller, in particular, has to be removed, pressure washed and dried as a part of the maintenance regimen.

- The gearbox oil has to be checked and replenished before each operation.

- All spare parts require periodic assessment. The malfunctioning and worn spare parts have to be removed and replaced with high-quality original spare parts.

- Scheduling a bi-annual maintenance check with the biomass pellet machine manufacturer is also a good idea.

Tips When Buying a Biomass Pellet Machine

In order to serve you better, please try to provide the below information:

1) What is the material to make wood pellets? Better if you can share us some pictures

2) Hardness of your material?

3) Moisture content?

4) Maximum diameter of the material to be processed?

5)The capacity per hour you want to get for the pellet production.

Then we will recommend suitable model based on your actual needs.