Professional Manure Pellet Machine Manufacturer, ISO9001 Certificated

- Higher capacity and less wear parts costs

- Wide range of application suitability

- Stable running performance and easy operation

Manure Pellet Machine - The Beginner's Guide

Investing in a manure pellet machine can help you make organic fertilizer for your fields. Additionally, you can use it to make feed pellets for your cattle. People who wish to start a fertilizer or animal feed pellets business can also purchase this machine. Let us get complete information about the manure pellet machine, its functionality, price, and more.

What is a Manure Pellet Machine?

A manure pellet machine is a type of mill that can turn organic manure into pellets. The source of this organic matter could be animal droppings or grass manure.

The mill processes the powdery material and creates a homogeneous mass.

Manure pellet machines come in a variety of sizes and types. You can even choose a poultry manure pellet machine or a chicken manure pellet machine for sale.

What is a Manure Pellet Machine Used For?

Depending on its type, an operator can use a manure pellet machine for several applications. Modern manure pellet-making mills, for example, can be used to make both animal feed and organic fertilizer.

The manure pellet mill turns powdery organic manure into fertilizer pellets. Organic manure pellets improve the fertility of the soil and maintain its carbon-nitrogen ratio.

You can establish an organic fertilizer business by purchasing a manure pellet mill. Commercial manure pellet mills are used by organic manure fertilizer production companies.

Aside from that, it’s a clever technique to dispose of animal excrement.

How Does a Manure Pellet Machine Work?

A manure pellet machine consists of several components. You will find a feeding hopper, roller, die, motor, and more. These components work together to transform powdered manure into pellets.

First, you put crushed material into the feeder. After that, the machine mixes the crushed material. And at last, the crushed material is converted into pellets of equal size.

As soon as you put the shattered organic matter into the hopper, it falls on the die. After that roller and die, process material and pellets come out of the discharger.

How Much Does a Manure Pellet Machine Cost?

Several factors influence the cost of a manure pellet machine. The type and size of the machine decide how much you will pay for it.

In addition to this, features, origin of the machine, cost of shipping are other crucial factors.

Generally, the price of a manure pellet machine starts at $1000. A commercial and feature-rich mill, on the other hand, may cost more. You won’t mind spending extra because current pellet machines are employed for several purposes.

Isn’t buying a machine that allows you to create manure and animal feed pellets a good idea? You can ask us to send a price quote for a such machine.

How to Choose the Best Manure Pellet Machine for Pellet Production?

There are several types of manure pellet machines available on the market. They serve varied purposes and have

distinct production capacities. You must determine which mill will meet your requirements. Apart from this, keep following things in your mind when selecting a manure pellet machine.

Output Capability

A home use manure pellet machine is sufficient if you wish to manufacture organic fertilizer for your backyard garden or a small area.

TCPEL gasoline-powered manure pellet machines can produce 60 to 100 kg manure pellets per hour. If you have a production line of animal feed or manure pellets, choose the machine that produces around 1000 kg pellets per hour.

Kind of Pellets You Want to Produce

Make sure the machines you choose can process manure matter and animal feed you want to use for making pellets.

Die Type

A manure pellet machine comes with different die types. If the amount of powdery material in your raw material is less than 40%, choose a ring die mill. Moreover, the ring die pellet machine provides better performance. On the contrary, a flat die mill is suitable for home use.

Also, you have to consider the aperture size of the die. If you wish to make large-sized pellets, choose a die with holes of at least 7mm in diameter.

Power Source and Rating

Manure pellet machines come in a variety of power ratings. It will determine your machine’s efficiency and output. Furthermore, some mills run on electricity, while others run on gasoline or diesel. As a result, you must examine these elements based on your requirements.

Select a Trustworthy Manufacturer

Last but not least, you should collaborate with a reliable and certified manufacturer. It will ensure that the manure pellet machine is of high quality.

How to Get an Affordable Manure Pellet Machine?

Choose Appropriate Manure Pellet Mill

If you want to avoid overspending, you should not invest in things that you don’t need. If you search for a manure pellet machine on the internet, you will find numberless options. However, not all of them will be appropriate for you.

What is the point of investing in a commercial manure pellet machine if you only need a small number of pellets? Always invest in a pellet mill according to your needs only.

Look for a Chinese Manufacturer

You will find that Chinese manure pellet machines are more affordable than European pellet mills. So you can look for a reputable Chinese company that deals in manure pelleting machines.

It is no longer surprising that Chinese businesses sell high-quality goods at affordable prices. They can do that because raw materials are readily available around China. Moreover, shipping and labor costs are low in the country.

Compare Prices

On the internet, you may locate a lot of companies that sell chicken manure pellet machines. Do not choose someone at random. Compare costs and make a decision based on the information you have gathered.

Avoid interacting with middlemen because they will add their fee to the total amount of the mill.

Ask Discount for Bulk Orders

If you need commercial manure pelleting machines in a large number, ask your manufacturer for a discount. Most businesses will gladly offer discounts on large orders.

How to Use a Manure Pellet Machine as a First-Time User?

It is simple to operate a manure pellet machine. Most people can run it without having any special training. If you are a first-time user, you can start with the instructions below.

Check the Quality of Raw Material

Whether you are making animal feed or organic fertilizer, use only appropriate raw materials. Make sure it does not have pebbles and plastic pieces. Remember, such material can damage the roller, die, and shaft of your machine.

You may also consider installing a tubular magnet inside the feed hopper to catch metal debris.

Crush the Raw Material

Before you put material into the feeding hopper, crush it properly. Otherwise, you may face issues like die blockage.

Ensure the Right Moisture in the Matter

Make sure the raw material has adequate moisture. The moisture content should be between 14 to 20%. A material that is too dry will not take shape, whereas a material that is too moist will result in mushy or loose pellets.

Lubrication of the Machine

Lubricate roller, die, and other components that rub against each other. Also, do not compromise on the quality of the lubricants. It is best to follow your manufacturer’s instructions in this regard.

Choose the Right Die Type

As we mentioned above, dies of pellet machines are available with different hole sizes. Also, you have to choose between flat and ring die. Commercial companies should often choose pellet machines with ring die as they have better output capability.

Preheat the Mill

Before you feed raw material, preheat the mill. Let the temperature inside the machine reach around 50-degree celsius. Mix some oil into the raw matter, and then put it in the machine.

Let your Pellets Cool

Keep your manure pellets in the open air so that they can cool down and maintain their shape. You may also use a cooler machine if you wish to load and supply pellets instantly.

How Do You Keep a Manure Pellet Machine in Good Working Order?

If you want to keep your manure pelleting machine in good working order for a long time, you must do routine maintenance. Below are the steps for the same.

- Clean your manure pellet machine frequently. Ensure feeder, discharger, die, gearbox, bearings, and roller are clean before using the mill.

- Make sure the die’s holes are clear of any obstructions. Otherwise, it will affect the shape of your pellets. You may also use die cleaner if required. Apart from cleaning, lubricate these parts appropriately

- Do not forget that shaft, die, and bearings require frequent lubrication. Also, check the gearbox from time to time. Use a good quality gear oil for it.

- Examine your machine. If you observe any signs of wear and tear, replace that part right away before things get worse.

- For proper maintenance, follow the manufacturer’s instructions. Contact your manufacturer if you require any assistance.

At TCPEL, we offer complete installation, maintenance, and operating support for manure pellet machines.

Tcpel Manure Pellet Machine Introduction

Tcpel is a certified manure pellet machine manufacturer in China, serving the industry since 2004. We are professional pellet machine makers, producing a wide range of biomass and feed-making machines.

We supply our manure pellet mills to more than 60 countries. Our manure pellet machine has passed various quality certifications. Therefore, you can be confident about its performance.

Tcpel is a well-appreciated company, having thousands of customers across the world. Several leading animal feed and manure pellet production companies are our regular customers.

We have received several quality certifications such as ISO 9001 2000 Certification, CE Certification, and SGS Certification.

Manure Pellet Machine Parameters

| Model | Capacity | Pinch Roller | Power | Voltage(V) | Weight | Dimension |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg/h | Double roller | 2.2kw | 220V/380V | 95kgs | 68*42*53cm |

| TFC150 | 150-200kg/h | Double rollers | 7.5kw | 220V/380V | 100kgs | 72*45*65cm |

| TCF200 | 300-400kg/h | Double rollers | 11kw | 380V | 180kgs | 126*53*92cm |

| TCF250 | 600-800kg/h | Double rollers | 15kw | 380V | 320kgs | 131*54*93cm |

| TCF300 | 800-1000kg/h | Double rollers | 22kw | 380V | 400kgs | 146*59*110cm |

| TCF350 | 1000-1200kg/h | Double rollers | 30kw | 380V | 580kgs | 186*70*128cm |

| TCF400 | 2000kg/h | Double rollers | 37kw | 380V | 680kgs | 206*76*137cm |

| TCF450 | 2000-2500kg/h | Double rollers | 45kw | 380V | 780kgs | 218*79*140cm |

Tcpel Manure Pellet Machine Advantages

- TCPEL manure pellet machine is an ideal investment for individuals and companies that produce quality feed and fertilizer pellets.

- Our pellet machine has a high-quality metal body, polished with premium paint. Therefore, our manure pelting machine does not catch rust.

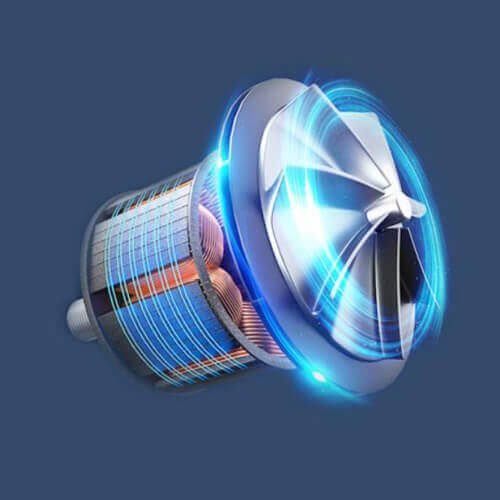

- You will find branded accessories in our pellet mill, whether it’s a heat sink, bearing, die, roller, or copper coil.

- TCPEL manure pellet machine can be used for multiple applications. Its powerful motor enables you to process feed pellets, fertilizer pellets, and sawdust pellets. However, the moisture content in raw material should be around 12 to 20%.

- Additionally, you can use our machine for making chicken manure pellets and poultry manure pellets.

- At TCPEL, we have manure pellet machines that run on different energy sources. For instance, you can buy pellet mills that run on diesel, gasoline, and electric power.

- Similarly, we have manure pellet machines with different power capacities. You can choose them according to the number of pellets you want to produce. For instance, a manure pellet machine of four horsepower lets you produce 60 to 100 kg pellets per hour. On the other hand, a fifty-five horsepower machine can make 600 to 800 kg pellets per hour. So you can choose the machine type based on your requirements.

- TCPEL manure pellet machine is user-friendly. You do not need training for days to learn how to operate it. Just read our user-manual guide, and run it.

- Unlike conventional machines, our chicken manure pellet machine for sale consumes low power but provides high output.

- Our manure pellet mill does not make too much noise. It means your production factory will not be that noisy even if you operate multiple mills.

We have used chromium-manganese steel in making grinding discs and pressure rollers in our machine. Our die and roller are 20 times more wear-resistant than a regular die and roller.

TCPEL Manure Pellet Machine accepts dies of different thicknesses. You can buy dies with holes ranging from 2.5 mm up to 7mm die. Different die types are suitable for various applications. For example, a 4mm die lets you make chicken pellets, whereas a 7mm die is appropriate for making feeds for camels, sheep, and adult cattle.

Easy to refuel, simple to use, GL-5 heavy-duty gear oil must be filled before use.

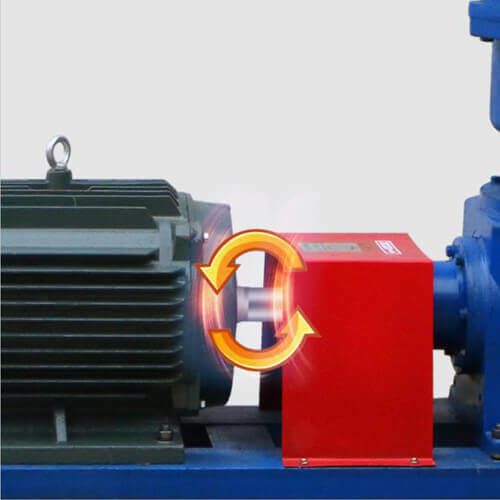

TCPEL manure pellet machine features stainless steel and durable electric coupling. Therefore, it prevents the loss of electric transmission.

We have used a high-quality copper motor in the machine that ensures superior performance. Besides this, you get long-lasting rollers and die.

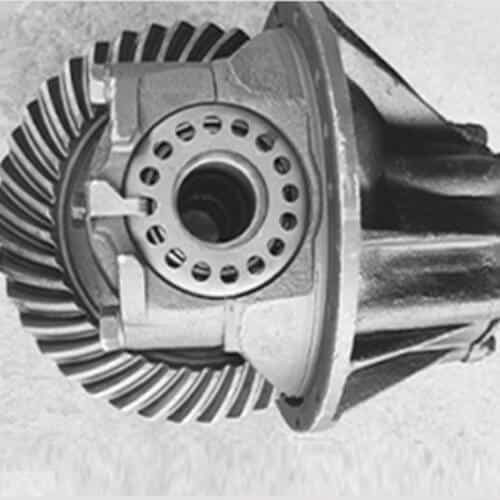

It adopts the automobile rear axle differential assembly design, which has a good gear combination, reduces the load on the main engine, and has good stability.

Larger feed inlet design makes feeding more convenient and work efficiency higher Widened discharge port design, design with baffles on both sides to avoid feed spilling, widened and enlarged discharge port, discharge faster and smoother.

Our manure pellet mill is easy to move. It comes with nylon tires that let you take the machine from one place to another without making much effort.