8 Principles When Choosing Raw Materials For Pellet Production

Pellet production is an important stage in the wood processing industry. Wood pellets are used as fuel for residential and commercial heating systems. It’s important to choose the right raw materials for pellet production since they are used to create a product that can be burned in homes and businesses. There are many different types of raw materials commonly used in pellet production, and it’s very important to know what they are. This article will show you 8 essential principles when choosing the right materials for pellet production, which will help you save cost and avoid unnecessary loss. Keep on reading ~

Avoid Using Materials from Chemically-treated Lumber

Chemically-treated lumber is heavily treated with fungicides, insecticides and herbicides before being used for any purpose. Their chemicals can be transferred into the newly created pellets and can also contaminate the environment if pellet mills are not equipped with adequate pollution control systems.

Choose Materials That Are Easy To Acquire

The first thing that you should consider when choosing a raw material for pellet production is the availability of it. If the raw material is not easily available, it will cause some unnecessary problems for your production later on. It’s very important for you to choose a proper source of supply so that you don’t need to worry about its availability in future production.

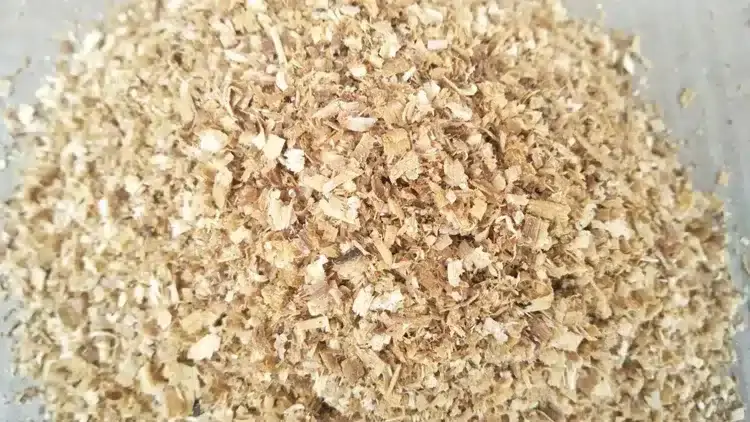

Choose Materials With Small Size

When choosing right materials for pellet production, it is important to choose with small size first. The smaller size is easier to be crushed and pressed into pellets. If the size of raw materials is too big, they need to be crushed first. And if you choose large size material, then the cost will be high because it requires more process steps and equipment investment, which increases the cost of your project.

Choose Materials With Compact Structure

To keep the density of pellets high and make them compact, it is necessary to choose the powder with a high degree of compaction; otherwise, it will not only affect its own performance but also affect its physical properties such as mechanical strength and thermal conductivity when used as fuel.

For example, if you want to produce high-quality pellets from sawdust, you should choose sawdust with compact structure instead of big ones with less density. This will help you achieve higher compression ratio and increase efficiency during pelletization process.

Choose Materials With High Calorific Value

Pellets produced from low-quality raw materials will burn slowly and produce a lot of smoke during combustion, which can lead to leakage into your home and damage your heating system.

The best raw materials for pellet production have high calorific value. The calorific value is the amount of energy that is released when something burns. For example, if we burn wood it releases heat and light energy (called thermal energy). This process is called combustion and it happens when oxygen combines with carbon in the wood to produce carbon dioxide gas and water vapor. This energy is called thermal energy because it produces heat. It also produces light energy because burning things will make them glow red hot like a fire does when it burns something up completely in its flames. In fact, this process is so efficient at producing heat that it’s often used by humans as fuel for heating their homes during winter months so they don’t freeze.

Choose Materials Free From Heavy Metals, Dioxins and Other Harmful Substances

The raw materials must be clean, meaning there are no foreign substances that could potentially contaminate the product and make it dangerous for use. They also need to be free from damaging substances like heavy metals, dioxins and other harmful chemicals. It’s vital to ensure that your production materials are safe, so you can avoid any issues with your end product.

Choose Materials Moisture Content Less Than 20%

The moisture content of raw materials is one of the major factors affecting pellet production. If it has more than 20% water, then it’s going to take more energy to dry it out before pelletizing it, which increases your costs and reduces your profits. The higher the moisture content, the more difficult it is to process and store.

In order to avoid this phenomenon, it is necessary to pay attention to the moisture content of raw materials before they enter into the process. The moisture content of raw materials should be less than 20%.

Choose Materials With Low Ash Content

The ash content is also an important factor choosing raw materials for pellet production. The ash content is the residue left after burning a material. It consists of mineral and organic components, such as carbonates, silicates, phosphates and metals. The ash content in pellets is often used to define their quality.

The higher the ash content, the less efficient the pellet boiler will be at producing energy from biomass. This means that it will take longer to heat up your hot water and there are more emissions being released into the atmosphere. If you want to get the most out of your biomass boiler, then it’s best to choose a wood pellet with a low ash content.

Conclusion

So after going through this article, if you ever get a chance, keep these points in mind. Choose the right materials for pellet production and you will reap the benefits for many years to come.

Talk to An Expert

SHARE THIS POST

Talk to An Expert