Pellet Production Profit Analysis: Is it a Profitable Business?

Today, numerous companies are making wood pellets for profit. It is fair to say that pellet making has become a profitable investment. Nowadays, people use wood pellets for power generation, home heating, and boilers’ fuel.

Looking to start a wood pellet company? This post will give you a detailed pellet production profit analysis. But first, let’s look at the growing demand for wood pellets.

The Global Demand for Wood Pellets

Are pellet mills profitable? A lot of novices entering into this industry want to know this. It is crucial to understand that the wood pellet industry has been continuously growing, thanks to the ever-increasing demand for sustainable energy sources.

According to an article published in Globe News Wire, the global wood pellet industry would reach USD 23 billion-plus by 2028.

Wood pellets are a fantastic source of sustainable energy since they are made from wood waste. People are utilizing them as fuel. In Europe, wood pellets have been massively used for power generation. In several western countries, people also use them for heating.

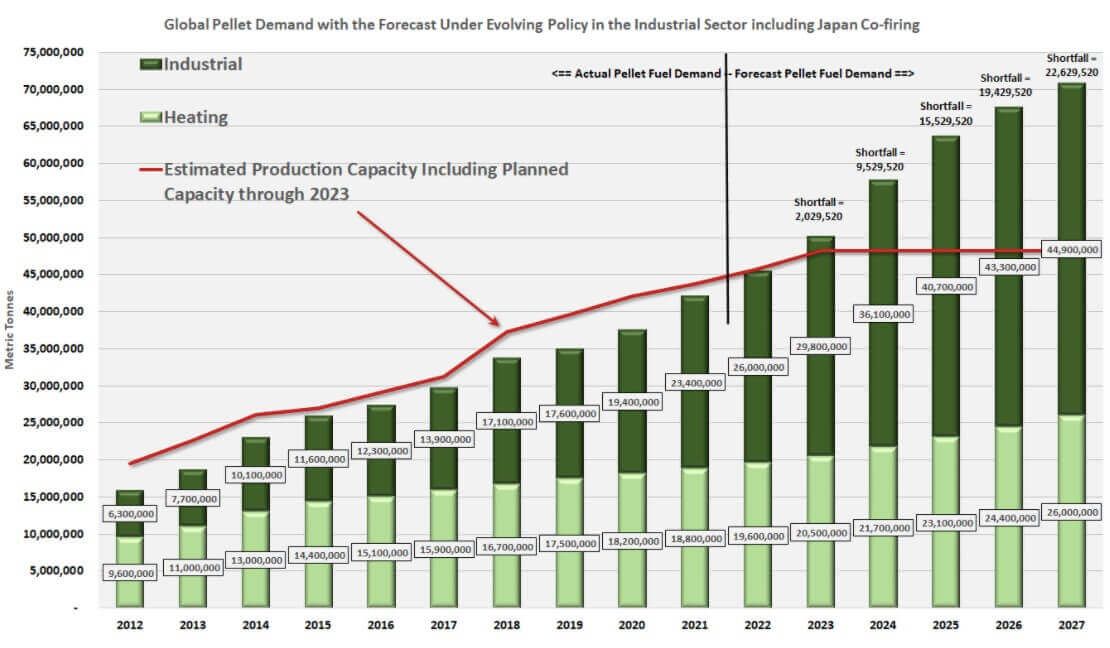

As per the report of Future Metrics, the worldwide demand for heating pellets in western countries would reach up to 26 million metric tons by 2027. If you have a solid wood pellet business plan, you can take advantage of this demand and earn handsomely.

Let us look at what industries are utilizing wood pellets and what for.

Use of Wood Pellets in Different Industries

Before you do pellet production profit analysis, you must learn the uses of wood pellets. It will give you an idea of the profit you can gain from this business.

Home Heating

Wood pellets are a suitable option for home heating as they are efficient, clean. Unlike gas and oil-fired furnaces and boilers, wood pellets are environmentally-friendly.

In Sweden and the United Kingdom, pellets are very popular. People use them as fuel for pellet heating furnaces and stoves. With the help of boilers, pipes, and heating radiators, pellets can generate heat in a home.

Fuel for Industrial Boiler

People also use wood pellets as a substitute for natural gas and coal in industrial boilers. Unlike traditional fuels, they do not pollute the environment excessively. Since wood pellets are low in nitrogen and sulfur, they are carbon-neutral. There are a few significant distinctions between wood pellets and cool pellets.

Power Generation

Wood pellets have superior heat value. As a result, you may utilize them as a fuel for gasification and the generation of thermal energy. As the cost of biomass pellets is lower than other fuels, people are using wood pellets for both commercial and residential purposes.

Pellet Production Profit Analysis

Before you start a wood pellet business, you must do a pellet production profit analysis. It will show you whether or not manufacturing wood pellets for profit is a viable option.

In the above sections, you learned about the expansion of the wood pellet market globally and the growing demand for pellets. Now let’s study its profitability.

There are several things you will be paying for when making wood pellets for profit. Let us calculate the approximate cost of the following goods for making 1 ton of biomass pellets in the Chinese market.

This pellet production profit analysis is for Tcpel Pellet Machine (TCZL560). It produces 1.4t/h and consumes 90 kW of power.

Raw Material (76.9)

Raw materials like sawdust, straw forest residues, wood chips are primary requirements for making wood pellets. You will need to spend about USD 76.9 on raw materials.

The straw and wood cost is USD 30.8-92.3/Mt.

Consuming: USD 61.5/mt

Wood Pellet Machine Capacity: 1.4mt/h, needing 1.75t/H sawdust.

Therefore to make 1-ton pellets, the raw material cost would be:

1.75*61.5/1.4=USD 76.9

Energy Consumption Cost (USD 6.75)

You will need to set aside some money for the power usage bill. The approximate cost for 1-ton pellets production cost would be USD 6.75.

The cost for 1kwh energy is USD 0.15.

The machine’s power consumption is 90kwX0.7=63kwh

For making 1Mt pellets, the approx power consumption cost is: 0.15*63/1.4=USD 6.75

Labor Cost (USD 2.1)

You also require labor to run the production line and take care of the process. Let us say one person’s salary per day is USD 23.1 and the total working hours in a day are 8.

So you can estimate like this: 23.1/8/1.4= USD 2.1.

Roughly it will cost you $2.1 for 1ton biomass pellets.

Spare Parts Cost (USD 0.7)

Another cost you have to add is spare parts costs. The ring die is a major part of a pellet machine that requires replacement after a certain time. A standard ring die lasts for 800 to 1000 hours.

The one die cost is USD 892.3

Consuming its lifetime: 900h.

The total die pellet making capacity is 900*1.4=1260Mt.

To make 1-ton pellets the total spare part cost would be USD 892.3/1260 = USD 0.7.

Maintenance Costs (USD 1)

Like every machine, a pellet-making machine also requires maintenance, from time to time.

If we give you a rough estimate, it would cost you

USD 0.8-1.2/Mt

Consuming: USD 1/Mt

Factory Cost (USD 0.7)

You can expect to spend USD 7.8 per day on factory costs. Every hour, you will have to pay USD 1. Therefore, to make 1MT biomass pellets, the estimated factory cost would be

USD1/1.4= USD 0.7.

Equipment Depreciation & Other Costs (USD 1)

It would cost you USD 10.8 per day. If you divide by 8 hours per day, you would get 10.8/8h= USD 1.35/h. USD 1.35/1.4=USD 1.

Total Cost

If you add all the above costs, you will be paying USD 89.15 for 1-ton biomass pellets. If you sell them at USD 120, the total profit per 1Mt will be USD 30.85. Now multiply this profit to 8hs.

30.85×1.4= USD 345.50.

So your one-day net profit is USD 345.52. If you run your factory for 250 days a year, your annual net profit will be 345.52×250= USD 86380.

For your convenience, we have created the table below.

1-Ton Biomass Pellets Production Cost Analysis

Pellet Making Machine Model: TCZL560; Pellets Capacity: 1.4t/h

Item | Unit Cost (USD Per Ton Pellets ) | Remark For China Local Market |

Raw Material | USD76.9 | The straw ,wood cost :USD 30.8-92.3 / Mt Consuming :USD61.5/Mt; wood pellets capacity :1.4Mt/h, needing 1.75t/H Sawdust; Making 1Mt Pellets Raw Material Cost: 1.75*61.5/1.4=USD76.9 |

Power Consumption Cost | USD6.75 | 1kwh cost :USD0.15 Power consumption :90kw*0.7=63kwh Making 1Mt Pellets Raw Material Cost :0.15*63/1.4=USD6.75 |

Labor Cost | USD2.1 | One person salary /day :USD23.1 Working Hours:8h/day Making 1Mt Pellets Labor Cost: USD23.1/8/1.4=USD2.1 |

Spare Parts Cost | USD0.7 | Standard Ring die lifetime :800-1000h ; One Die Cost: USD892.3 ; Consuming its lifetime: 900 h Total the die pellets capacity: 900*1.4=1260 Mt Making 1Mt Pellets Spare Parts Cost: USD892.3/1260=USD0.7 |

Maintenance costs | USD1 | Making pellets Maintenance costs: USD 0.8-1.2/Mt Consuming :USD1/Mt |

Factory Cost | USD0.7 | USD7.8/Day; Cost per hour: USD1 Making 1Mt Pellets Factory Cost: USD1/1.4=USD0.7 |

Equipment depreciation and other costs | USD1 | USD10.8/Day—-10.8/8h=USD 1.35/h Making 1Mt pellets Cost: USD1.35/1.4=USD1 |

Total Cost | USD89.15 | All the costs above |

Pellets Selling Price | USD120 | 1Mt pellets Price |

1Mt pellets Profit | USD30.85 | Pellets Selling Price -Total Cost |

One Day Profits /8hs | USD345.52 | USD30.85*8*1.4=USD345.52 |

One Year Profits /250days | USD86380 | USD345.52*250 Days=USD86380 |

Final Words

So it is a quick pellet production profit analysis using the Tcpel TCZL560 pellet making machine. Now you can learn that the wood pellet business is exceptionally profitable. If you want to buy an international-standard pellet machine or a complete pellet production line, contact TCPEL.

Talk to An Expert

SHARE THIS POST

Talk to An Expert