World Top Poultry Feed Pellet Machine Manufacturer, ISO9001 Certificated

- Higher capacity and less wear parts costs

- Wide range of application suitability

- Stable running performance and easy operation

Poultry Feed Pellet Machine - The Beginner's Guide

Choosing the right Poultry Feed Pellet Machine is not always an easy task due to the number of factors you need to put into consideration. We understand how difficult this can be, which is why we have compiled for you all the information you need to make an informed decision when buying a poultry feed pellet machine.

What Is A Poultry Feed Pellet Machine?

A poultry feed pellet machine is a type of machine that is used to compress raw materials into pellets that are used for feeding chicken, ducks, geese, and doves. You can use a poultry pellet machine to make feed pellets for your own farm, or to sell to other poultry farmers.

What Is A Poultry Feed Pellet Machine Used For?

A poultry feed pellet machine is used to convert powdered raw materials like corn, soybean meal, rice husks, wheat, cottonseed husks, flour, and other food products into small-size pellets that are easier for poultry to consume.

Using a poultry feed machine offers several advantages. First, it reduces poultry feed waste and creates less mess during feeding. Second, pelletized poultry feed is easier to store and transport.

Mixing and converting poultry feed into pellets also allows you to ensure that your chickens are getting all the right nutrients they need for healthy growth.

How Does A Poultry Feed Pellet Machine Work?

The working principles of a poultry pellet feed machine is pretty simple. Once you feed your powdered raw material into the poultry feed pellet machine, the machine will first mix the different ingredients together to form a powdery mixture referred to as mash. This step is useful when you’re making pellets from different raw materials.

The mash is then transferred to the pelletizing chamber, which contains a die with several holes, as well as two or more roller gears. Some poultry feed pelleting machines have a flat die and roller gears that rotate above the die, while others have a ring die which rotates around fixed roller gears.

In the pelletizing chamber, the poultry mash is spread on the die. For flat die poultry feed pellet machines, the roller is used to spread the mash across the die, while ring die poultry feed pellet machines rely on centrifugal force to spread the mash on the inner surface of the ring die.

The roller gears then compress the mash against the die and push it through the die holes to form compact, dry poultry feed pellets. A blade is placed outside the pelletizing chamber to slice the pellets into uniform sizes.

How Much Does A Poultry Feed Pellet Machine Cost?

The cost of a poultry feed pellet machine will vary depending on the capacity of the poultry feed pellet machine, as well as the type of machine.

If you want a small poultry feed pellet machine for feeding a small number of poultry on your own farm, you can get one for as little as $500.

If you’re looking for high capacity poultry feed pellet machines for producing poultry feed pellets for commercial purposes, you’ll have to spend more. Large scale poultry feed pellet machines usually fall in the $2,000 to $6,000 price range.

How Many Types Of Poultry Feed Pellet Machines Are There?

Poultry feed pellet machines can be grouped into two types – flat die poultry feed pellet machines and ring die poultry feed pellet machines.

Flat die poultry feed pellet machines are usually smaller and are best suited for small scale operations. Due to their small size and low production capacity, flat die poultry pellet machines are quite affordable.

Ring die poultry feed pellet machines, on the other hand, are more expensive and are best suited for large-scale operations. They also have more efficient energy consumption compared to flat die poultry feed pellet machines.

How To Choose The Best Poultry Feed Pellet Machine For Pellet Production?

Different people have different needs when buying a poultry pellet machine, so you have to make sure you’re buying the right poultry pellet machine for your specific needs. Some of the things you should look at when choosing a poultry feed pellet machine include…

Die Type

The first consideration when buying a poultry pellet machine is whether to go for a flat die or a ring die poultry pellet machine. If you’re looking for a poultry pellet machine for your own home use, you should go for flat die poultry feed pellet machines, which are usually smaller and cheaper.

For those who want to produce poultry pellets commercially, you’ll be better off with a ring-die poultry feed pellet machine. These are usually larger and have higher capacity that can support commercial production.

Production Capacity

Are you producing poultry feed pellets for use in your own farm or for commercial purposes? If you want to sell poultry feed pellets, you’ll need a large-scale machine that can produce over 1 ton of poultry feed pellets per hour. Most large scale poultry feed pellet machines use a ring die.

If you’re buying a poultry pellet machine for your own domestic use, go for a small scale flat die poultry pellet machine.

Reliability And Ease Of Service

Always buy poultry feed pellet machines from trusted poultry feed pellet machine manufacturers who are known for their reliability, such as Tcpel. You should also check whether service parts for the poultry pellet machine you’re buying are readily available.

Energy Consumption

A poultry feed pellet machine with high energy consumption can significantly increase your operation costs, leading to low margins for those producing poultry feed pellets commercially.

It’s therefore important to check the power rating of a poultry feed pellet machine against its production capacity to make sure you’re buying an energy-efficient machine.

How To Use A Poultry Feed Pellet Machine For Beginners?

Using a poultry feed pellet machine is pretty easy, even for complete beginners. Here’s what to do before you start operating a poultry pellet machine:

- Go through the user’s manual before you start using the machine to prevent you from damaging the machine and protect you from causing injury to yourself.

- Make sure that the moving parts of the machine are well lubricated before switching on the machine.

- Gather your raw material and check that there are no hard substances contained in the raw material. Things to watch out for include stones, pieces of metal, plastics, and so on. These can cause damage to your poultry pellet machine, and can also cause health issues for your poultry.

- Check the moisture content of your raw material. If the raw material is too wet, reduce the moisture content by putting the raw material out in the sun to dry, or using a pellet cooler machine.

- Crush your raw material into small particles. Ideally, you should grind your raw material into particles that are less than 5mm. The point here is to make sure that the raw material is smaller than the diameter of the die holes on your poultry feed pellet machine. If you don’t do this, you risk blocking the die holes.

- Turn on your poultry feed pellet machine, pour your raw material into the feeding hopper, and wait for the machine to produce ready poultry feed pellets through the discharger.

- Spread out the poultry feed pellets in an open, well ventilated area to allow them to cool down and dry, and then pack them into bags for transportation or storage. You can also feed them to your chicken, ducks, and geese after the pellets have cooled.

- Finally, mix some raw material with oil, feed them into the poultry feed pellet machine and allow it to run for a few more minutes. This will help maintain the die molds and allow you to start making pellets faster the next time you are using the machine.

How To Maintain A poultry Feed Pellet Machine?

Proper maintenance of your poultry feed pellet machine is mandatory if you want it to serve you for a long time. Here are some things you can do to extend the lifespan of your poultry feed pellet machine:

- Before you start operating the machine, go through the user’s manual.

- Always check for any debris in the pelletizing chamber before switching on the machine.

- Since the poultry feed pellet machine doesn’t come with a dust protector, you’ll need to regularly clean the machine to avoid dust build up, which can affect the machine’s efficiency, as well as the quality of your poultry feed pellets.

- When using the poultry pellet machine for extended periods of time, always oil the main shaft after every eight hours of operation.

- There’s a lot of heat generated when a poultry feed pellet machine is running. To prevent excessive heat buildup within the motor, which can damage the machine, always use the poultry pellet machine in a well-ventilated area.

- Keep the transmission on your poultry pellet machine well lubricated at all times to keep it operating smoothly and prevent excessive wear.

- Clean the gearbox on your poultry pellet machine after every six months.

- When using your poultry pellet machine in winter months, allow the machine to run for a couple of minutes before adding your raw material. This will give it enough time to get to the right temperature before you start producing your poultry pellets.

TCPEL Poultry Feed Pellet Machine Introduction

Whether you are a poultry farmer looking for a better, more efficient way of feeding your birds, or a commercial animal feed producer looking for a powerful pellet machine for producing poultry feed pellets, the Ttcpel poultry feed pellet machine is one of the best options available.

Designed to the highest quality standards by our team of talented engineers, the Tcpel poultry feed pellet machine is highly durable and is the top recommendation for poultry feed pellet production by experts across the world.

- Multiple die diameters: The Tcpel poultry feed pellet machine comes with multiple die sizes, including 2.5mm, 3mm, 4mm, 6mm, and 7mm. This allows you to produce different sized pellets for different types of poultry, including chicken, pigeons, ducks, and geese.

- Multiple power ratings: Choose between different power ratings based on your needs. We have small models with as low as 3 KW, to big models with a power rating of up to 15 KW.

- Highly versatile: The Tcpel poultry feed pellet machine works with multiple types of raw material, regardless of the density of the raw material, provided the raw material has a moisture content of 12% – 20%. You can use this machine to pelletize peanut shells, rice husks, flour, cottonseed husks, wheat, sunflower husks, soybean meal, corn, and other poultry food products.

- Minimal maintenance required: This machine comes with wear-resistant parts that don’t need a high level of maintenance.

- Multiple output capacities: Choose between different output capacities depending on your needs. We have small models capable of producing 60-100 kilograms of pellets per hour, to larger models that can produce as much as 1 ton of pellets per hour.

Poultry Feed Pellet Machine Parameters

| Model | Capacity | Pinch Roller | Power | Voltage(V) | Weight | Dimension |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg/h | Double roller | 2.2kw | 220V/380V | 95kgs | 68*42*53cm |

| TFC150 | 150-200kg/h | Double rollers | 7.5kw | 220V/380V | 100kgs | 72*45*65cm |

| TCF200 | 300-400kg/h | Double rollers | 11kw | 380V | 180kgs | 126*53*92cm |

| TCF250 | 600-800kg/h | Double rollers | 15kw | 380V | 320kgs | 131*54*93cm |

| TCF300 | 800-1000kg/h | Double rollers | 22kw | 380V | 400kgs | 146*59*110cm |

| TCF350 | 1000-1200kg/h | Double rollers | 30kw | 380V | 580kgs | 186*70*128cm |

| TCF400 | 2000kg/h | Double rollers | 37kw | 380V | 680kgs | 206*76*137cm |

| TCF450 | 2000-2500kg/h | Double rollers | 45kw | 380V | 780kgs | 218*79*140cm |

TCPEL Poultry Feed Pellet Machine Advantages

Chromium-manganese steel parts: The grinding disc and the pressure roller on the Tcpel poultry feed pellet machine are made from temperature treated chromium-manganese steel. This makes these parts up to 20 times more durable compared to the materials used by our competitors.

Easy to refuel, simple to use, GL-5 heavy-duty gear oil must be filled before use.

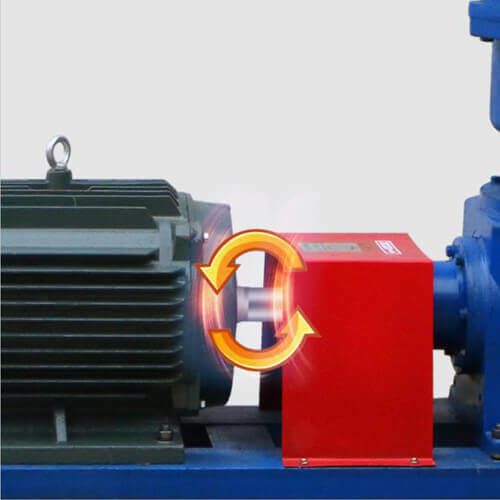

Electric coupling: Unlike older pellet machines, which use a belt drive, the Tcpel poultry feed pellet machine uses an electric coupling drive, which is more efficient, with minimal transmission ratio loss. The coupling drive is made from high-temperature treated stainless steel for exceptional durability and wear-resistance.

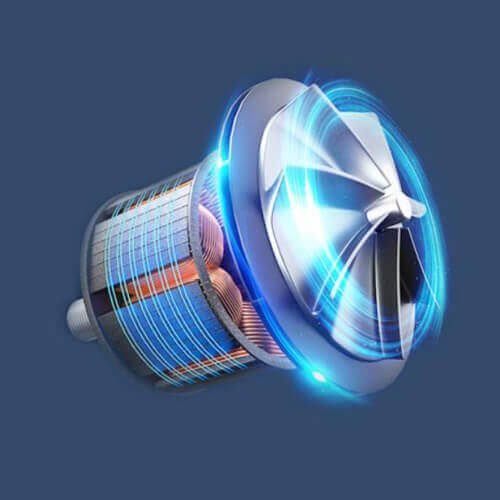

Copper wire motor: The motor on this machine uses 100% copper wire, resulting in extended lifespan, low noise operation, and better power output.

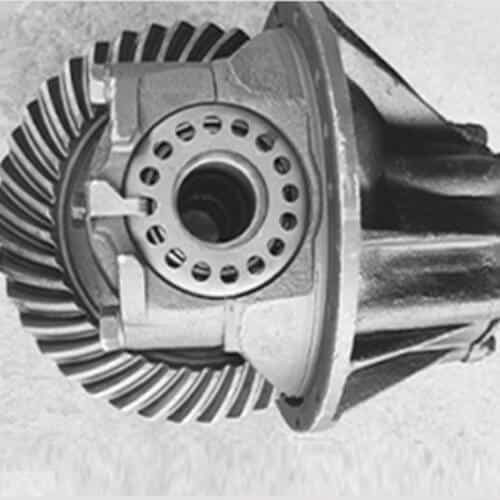

Unique differential assembly design: The differential assembly on this machine uses the same design used on the rear axle differential on vehicles. This provides better gear ratios, leading to better stability and improved performance.

Wider discharge port: The Tcpel poultry pellet feed is fitted with a wider discharge port, which allows for faster operation. The discharge port is also fitted with baffles to minimize pellet spillage.

Adopt nylon sliding casters, wear-resistant and durable