Professional Wood Pellet Machines Manufacturer and Supplier in China

- Automatic lubricating system ensure longer work time without stopping

- More than 90% parts are self made, quality controlled by ourselves

- Lower power consumption and higher efficiency

Wood Pellet Machines - The Beginner's Guide

Are you thinking of purchasing a wood pellet machine, either for your home use or for commercial use, but don’t know where to start? If you answered yes, this beginner's guide will tell you everything you need to know about wood pellet machines.

What Are Wood Pellet Machines?

Wood pellet machines, also referred to as pellet mills, are a type of press machine that are used to compact fine particles of a material into condensed pellets.

Examples of materials that can be compressed into pellets using wood pellet machinery include wood, sawdust, leaves, straw, peanut shells, grass, and so on.

What Are Wood Pellet Machines Used For?

Wood pellet machines are mainly used to create high density, low moisture wood pellets that can be used as fuel in a pellet stove.

Wood pellet machines can also be used to compress animal feeds into pellets that are easier for livestock to consume, or to produce bedding pellets for livestock stalls.

How Does A Wood Pellet Machine Work?

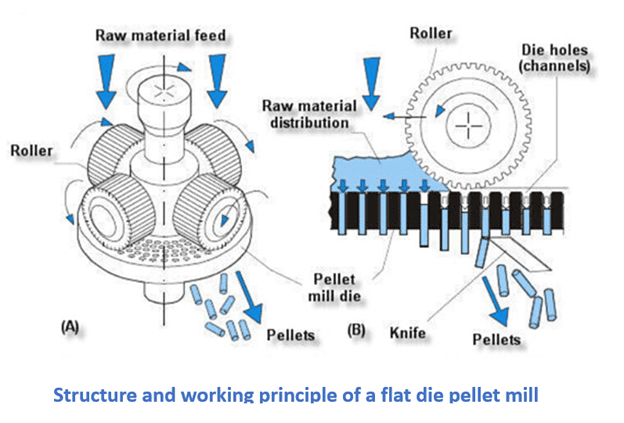

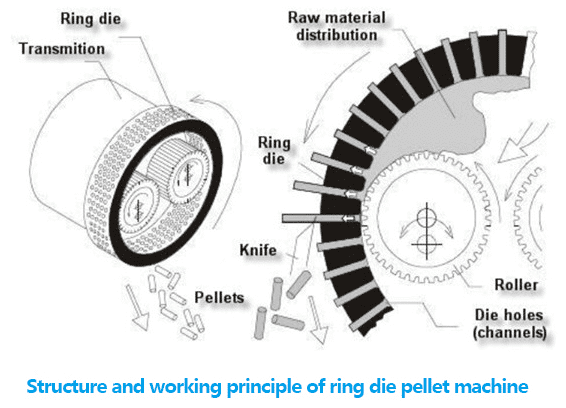

Wood pellet machines work by using roller gears to push raw material through the holes of a die. However, the process varies slightly depending on the type of wood pellet machine.

For flat die wood pellet machines, when the raw material is fed into the machine, it falls onto a perforated flat die, where a roller spreads it across the die.

The roller then compresses and forces the raw material through the holes in the die, forming compact pellets. A blade below the die cuts the pellets to the desired length.

Ring die pellet machines, on the other hand, consist of two roller gears inside a perforated ring die. After feeding the raw material into the machine, it first goes into the conditioner, where it is mixed with butter or vapor to increase adhesiveness.

The conditioned material is then transferred to the pelletizing area, where it is distributed onto the inner side of the ring die using centrifugal force. The two roller gears then force out the material through the holes in the ring die. The pellets are cut into the desired length by a blade sitting outside the die.

How Much Does A Wood Pellet Machine Cost?

The price of a wood pellet machine will vary depending on the type of wood pellet machine you’re looking for. Small wood pellet machines will cost you just a couple dollars, typically in the $200 to $1,000 range.

For large wood pellet machines and commercial wood pellet machines, the prices will obviously be much higher. The wood pellet machine price for larger units meant for commercial use will often fall in the $1,000 to $10,000 range. Sometimes, you’ll find commercial wood pellet machines for sale going for tens of thousands of dollars.

Wood pellet machine cost will also depend on the intended use of the machine. For instance, the price of a wood pellet machine used to produce livestock feed pellets will vary from the price of a biomass wood pellet machine that’s used to produce fuel pellets.

How Many Types Of Wood Pellet Machines Are There?

Wood pellet machines can be categorized into flat die and ring die wood pellet machines, based on their mechanical working principles. Flat die wood pellet machines compress raw material against a flat, perforated die, while ring die wood pellet machines compress the raw material against a perforated ring die that rotates around the roller gears.

Wood pellet machines can also be categorized into small scale and large scale, based on their capacity. Small scale wood pellet machines only produce a few kilograms of pellets per hour. Large scale wood pellet machines, also known as industrial wood pellet machines, can produce 7-10 tons of pellets per hour.

How To Choose The Best Wood Pellet Machines For Pellet Production?

Wood pellet machines can be expensive, and therefore, you want to make sure you’re getting the right wood pellet machine for your needs. Some of the things you need to look at when choosing a wood pellet machine include:

Type Of Raw Material

Different wood pellet machines are suited for different types of raw materials. For instance, a wood pellet machine that is meant for compacting sawdust might not be the best option if you’re interested in making pellets from straw.

Before choosing a wood pellet machine, ensure that the machine will be compatible with the kind of raw material you want to make pellets from.

Capacity

What is your expected pellet production capacity? If you’re only producing pellets for your household needs, office, or a small farm, you’ll be better off going with a small-scale wood pellet machine.

If you’re producing pellets commercially, on the other hand, you’ll need a higher capacity wood pellet machine. In this case, you should go for a large scale ring die wood pellet machine.

Energy Consumption

Wood pellet machines are powered by electricity, gasoline, or diesel. The more energy a wood pellet machine uses, the more expensive it will be for you to run, leading to reduced profits.

To avoid this, always go for an energy-efficient that gives you high production capacity with minimal energy consumption.

Ease Of Operation

Ideally, you should go for a pellet machine that can be easily operated by one person. Pellet machines that are difficult to use, or those that require more than one operator mean you’ll have to spend more money training operators and paying them to operate the machine.

Reliability

Do your research and ensure that you’re going for a pellet machine brand that is known for its reliability, one that doesn’t keep breaking down.

In addition to reliability, you should make sure that the wood pellet machine you’re going for is easy to service, and has readily available spare parts. The point here is to go for a wood pellet machine that minimizes downtime as much as possible.

Do A Test Run

We recommend buying your wood pellet machine from a manufacturer that will allow you to do a test run before purchasing the machine. This way, you’ll be certain that the pellet machine you’re paying for is the best one for your needs.

How To Buy An Affordable Wood Pellet Machine?

Wood pellet machines can be expensive, and therefore, when you’re ready to buy a wood pellet machine, you’ll want to go for the most affordable wood pellet machine for your needs. So, how do you do this?

One of the best ways to get affordable pellet machines is to buy your wood pellet machine in China.

Most wood pellet machines are manufactured in China. Even some US brands claiming to manufacture their wood pellet machines in the USA source the machines from Chinese manufacturers, and then brand them as “made in US” wood pellet machines.

Rather than buying from these American suppliers who add hefty mark ups to their prices, you’ll get a better deal buying directly from Chinese manufacturers. Note, however, that Chinese does not automatically mean high quality. Therefore, even if you’re buying your wood pellet machine from China, do your research to ensure you’re buying from a reliable, certified manufacturer.

The next thing to keep in mind if you want to buy an affordable wood pellet machine is to look at the availability of parts and how easy it is to service the machine.

If you go for a machine that is difficult to service and whose parts are hard to find, you’ll spend more in case your machine breaks down. Over time, such expenses can significantly push up the cost of your wood pellet machine.

Finally, consider the ease of operation of the wood pellet machine you’re interested in buying. Machines that are difficult to operate mean you’ll spend extra money training people how to operate the wood pellet machine.

How To Use A Wood Pellet Machine For Beginners?

While the actual operation procedure will vary depending on your wood pellet machine, there are some general steps that are followed when using a wood pellet machine.

The very first step is to assemble your wood pellet machine according to the manufacturer’s instructions. Some manufacturers, such as Tcpel, will even do the onsite installation for you.

Once the wood pellet machine has been assembled, make sure the gearbox and all other moving components are well lubricated, and that the clearance between the die and the pressure roller is well adjusted.

Note, however, that there are some wood pellet machine models that do not require lubrication, so you’ll need to check the manufacturer’s instructions before doing this.

Now that your wood pellet machine is ready, the next step is to prepare your raw material. As a general rule, the raw material should be crushed into particles that are smaller than the size of the die holes.

If your raw materials are larger than the pellet size, you can use a hammer mill or wood chipper to crush the raw material into a smaller size.

It’s also good to note that the raw material should have a moisture content of 12% or less. If your raw material has higher moisture content, you can remove the extra moisture using a pellet cooler, or by drying the raw material in the sun.

With your raw material ready, switch on the wood pellet machine and feed the raw material into the hopper. The machine will compact the raw material and push out formed pellets.

Due to the pressure from the wood pellet machine, the pellets will be hot and wet when they come out of the machine. Using a pellet cooler will help you reduce the moisture content of the pellets and cool them down, making them harder and easier to store or transport.

Finally, you can now weigh and pack the pellets ready for sale or transportation. If you’re producing pellets on a large scale, you’ll need a pellet packing machine to automatically weigh and pack the pellets into plastic bags.

How To Maintain A Wood Pellet Machine?

If you want your wood pellet machine to serve you for a long time, you’ll need to take good care of it. Below are some tips on how to properly maintain your wood pellet machine:

- Make sure you’ve read the manufacturer’s instructions before using your wood pellet machine for the first time.

- Every time you’re done using the wood pellet machine, take out the roller, clean it thoroughly but carefully, and then put it back into the machine.

- Place your wood pellet machine in a place with good ventilation. This will allow heat from the motor to be dissipated quickly, thus prolonging the life of your machine.

- Before you start the machine, check whether any debris was left in the pelletizing area. Such debris can increase starting resistance, so clear this debris before starting the machine.

- Regularly add oil to the transmission to keep it properly lubricated and reduce the rate of wear.

- Regularly inspect the belt and ensure that it is tight enough. If it looks slack, tighten it before using the machine.

- Inspect all parts of the wood pellet machine every month, and if anything looks faulty, have it repaired or replaced.

- If you notice any kind of malfunction while using the wood pellet machine, switch it off immediately for inspection and maintenance.

- If you’re going to spend some time without using your wood pellet machine, clean it, apply an anti rust oil on the surface of the machine, and then cover it using a tarpaulin to keep away dust.

How To Make A Wood Pellet Machine?

While most wood pellet machines are designed for use in a wood pellet machine factory, there is a growing market for home wood pellet machines that are designed for homeowners who want to convert their organic waste into wood pellets that can be used as fuel.

Homemade wood pellet machines are small-scale pellet machines that are designed for use inside homes and residences that don’t have high pellet output requirements.

These home wood pellet machines are usually reasonably priced compared to industrial wood pellet machines. They are also typically smaller and occupy minimal floor space, which makes it possible for you to store them inside your basement or garage when not in use.

Many homemade wood pellet machines also come with wheels, which allows you to move them outside whenever you need to make pellets.

To use a home wood pellet machine to make your own homemade wood pellets, the first thing you need to do is to gather your raw material, such as logs, sawdust, wood chips, tree branches and so on. Next, chop down the raw material into small pieces, and then use a hammer mill to break the raw material down into even smaller pieces.

Next, put the raw material in the sun for about 24 hours to reduce the moisture content, and once it’s sufficiently dry, run the raw material through a sieve to get rid of any stone or metal contaminants.

Finally, run the raw material through your home wood pellet machine to create pellets, and then pack and store your homemade wood pellets ready for use.

Tcpel Wood Pellet Machines Introduction

If you’re looking for a high quality wood pellet machine for your wood pellet business, or even for home use, you’ll never go wrong with the Tcpel wood pellet machine.

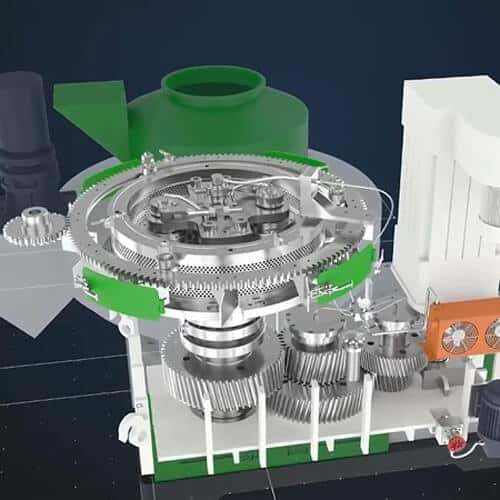

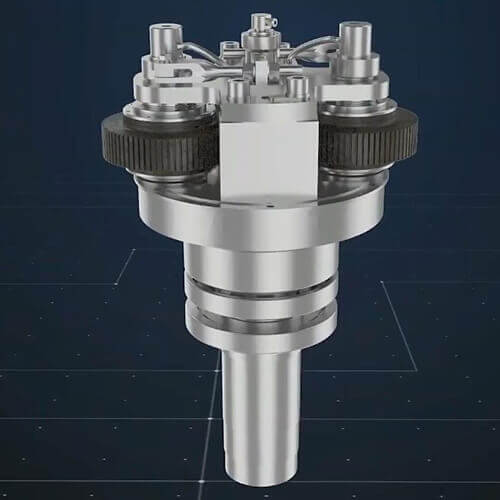

Our wood pellet machines are designed to the highest quality standards, and are made using German alloy steel, which guarantees strength and reliability. What’s more, we make more than 90% of the parts on the Tcpel wood pellet machine ourselves, so you’re guaranteed of the best quality.

Whether you are looking for a wood pellet machine to produce wood pellets for use in a pellet stove, feed pellets for feeding livestock, fertilizer pellets, or bedding pellets for use in livestock pens, the Tcpel wood pellet machine is your best bet.

When you purchase the Tcpel wood pellet machine, we also offer free installation, training, and around-the-clock customer service.

Tcpel Wood Pellet Machines Features

Tcpel is a professional company that specializes in the production, research, and development of wood pellet production machinery. We’ve been around for more than a decade and employ a team of talented engineers and designers. We are ISO 9001, CE, and SGS certified, meaning our products are manufactured under the strictest quality control standards

Based in China, we offer quality machines – guaranteed. Our products are manufactured under these strictest quality control standards. We offer complete installation service for a turn-key experience. We’ll even help train your operators so that they fully understand how to use the new pellet machine onsite.

And after your product has been installed, we’ll provide you with quick, reliable, and responsive after-sale service. From 24/7 email to phone communication or even onsite visits, we’ll be here to help you out.

Durability: The Tcpelwood pellet machine is a heavy duty machine that is built using wear-resistant alloy steel designed to handle long hours of operation while providing peak performance. You can keep the Tcpel wood pellet machine running for 24 hours non-stop.

Versatility: The Tcpel wood pellet machine is highly versatile, and will handle whatever raw materials you throw at it. Whether you’re looking to produce pellets from tree branches, rice husks, sunflower peanut shells, or even tree stems, this machine will not disappoint you.

Vertical ring die: Unlike other pellet machines, the Tcpel wood pellet machine comes with a vertical ring die. This die design greatly improves heat dissipation, leading to improved performance and an extended lifespan. The vertical die design also makes repairs and maintenance easier.

Wear resistant main shaft: Our machines are designed with a compact, wear-resistant main shaft that will go thousands of hours without the need for repair or replacement.

Stainless steel dies: The dies on this machine are made out of stainless steel, guaranteeing you up to 1500 hours of service life. This results in significant cost savings, since you don’t have to keep replacing the dies.

In-built cooling system: The Tcpel wood pellet machine has a fan and an in-built cooling system that keeps the machine within optimal temperatures during operation, thus increasing performance while at the same time extending the life of internal parts.

Multiple output capacities: There are different Tcpel wood pellet machine models with different output capacities, from 1 ton per hour to as much as 8 tons per hour.

High-strength transmission: This machine is also equipped with a heavy duty transmission box with wear-resistant bearings to extend the lifespan of the machine.

Tcpel Wood Pellet Machines Parameter

| Model | Power(kw) | Pellet Size(mm) | Capacity(t/h) | Size(cm) |

|---|---|---|---|---|

| TCZL560 | 90 | 6-12 | 1-1.5 | 263x130x230 |

| TCZL650 | 160 | 6-12 | 1.5-2.5 | 290x130x240 |

| TCZL850 | 220 | 6-12 | 2.5-3 | 330x140x310 |

| TCZL315 | 315 | 6-12 | 3-4.5 | 380x168x340 |

| TCZL315-450 | 315-340 | 6-12 | 4.5-6 | 410x185x380 |

| TCZL550-660 | 550-660 | 6-12 | 6-10 | 430x198x395 |

Tips When Buying a Wood Pellet Machine

In order to serve you better, please try to provide the below information:

1) What is the material to make wood pellets? Better if you can share us some pictures

2) Hardness of your material?

3) Moisture content?

4) Maximum diameter of the material to be processed?

5)The capacity per hour you want to get for the pellet production.

Then we will recommend suitable model based on your actual needs.