Professional Small Pellet Machine Manufacturer, ISO9001 Certificated

- Higher capacity and less wear parts costs

- Wide range of application suitability

- Stable running performance and easy operation

Small Pellet Machine - The Beginner's Guide

Small pellet machines come in a variety of shapes and sizes, and sometimes, choosing the right one for your needs can sometimes get confusing. If you want to learn more about small pellet machines so you can make the right decision, you’re in the right place. This beginner’s guide will teach you all you need to know about small pellet machines.

What Is A Small Pellet Machine?

A small pellet machine is a low capacity and affordable machine used to make pellets from powdered raw material.

Due to their relatively low output capacity, small pellet machines are most suitable for use in homes, small offices, and small-scale farms. Small pellet machines can also be used for small scale pellet production for commercial purposes.

Small pellet machines are designed with portability in mind. Some even come with wheels to make it easier for you to move them around. Their relatively low output capacity also means that small pellet machines are cheap to run, since they don’t have huge power requirements.

What Is A Small Pellet Machine Used For?

Small pellet machines have a variety of uses. You can use a small feed pellet machine to create animal feed pellets from raw materials like grasses, straws, rice husks, agricultural stalks, flour, and other agricultural waste. Feed pellets are easier for livestock and poultry to consume and lead to less feed wastage. You can also use a small pellet machine to create litter pellets for your livestock and pets.

Small pellet machines can also be used to convert agricultural and wood processing wastes like sawdust, peanut shells, leaves, wood, tree barks, and straw into pelletized biomass fuel.

How Does A Small Pellet Machine Work?

To understand how a small pellet machine works, we need to first look at the key parts that make up the machine. A small pellet machine consists of three key parts – a feeding hopper, a pelletizing chamber, and a motor.

The feeding hopper is the section through which you feed your raw material into the small pellet machine. The feeding hopper directs the raw material into the pelletizing chamber.

Inside the pelletizing chamber is a flat or ring die with multiple perforations, as well as two or more roller gears.

When you switch on the small pellet machine, the motor creates power and through the transmission, rotates the die or the roller gears. This rotation compresses the raw material against the die and pushes it through the perforations on the die to form pellets. A blade chops the pellets to the appropriate length as they exit the die.

How Much Does A Small Pellet Machine Cost?

Small pellet machines are relatively affordable. A lot of small pellet machines for sale will usually fall in the $200 to $1,500 range.

There are several factors that affect the small pellet machine price. For instance, small feed machine pellet price will differ from the price of a small biomass fuel pellet machine.

The cost of a small pellet machine will also be influenced by the kind of technology used to compress the raw material into pellets. Generally, ring die small pellet machines are a bit more expensive compared to flat die small pellet machines.

Finally, the cost will also vary depending on the production capacity. The price of a small pellet machine with an output capacity of 60 kilograms per hour will vary from the price of a machine that can produce 150 kilograms per hour.

How Many Types Of Small Pellet Machines Are There?

Small pellet machines are classified depending on their mechanical working principles. This results in two types of small pellet machines – flat die small pellet machines and ring die small pellet machines.

Flat die small pellet machines are the most common. Inside the pelletizing chamber of a flat die small pellet machine is a round flat die with multiple holes. Above the flat die are two or more roller gears that are used to spread the raw material across the die and compress the raw material into the die holes.

Ring dies are mostly used in higher capacity pellet machines, but you’ll still find small pellet machines that use a ring die. Inside the pelletizing chamber of a ring die pellet machine is a perforated ring die, which rotates around two or more roller gears. The raw material is spread across the inner surface of the ring die using centrifugal force.

How To Choose The Best Small Pellet Machines For Pellet Production?

Different small pellet machines are designed for different uses, so it’s important to make sure that the machine you’re buying is well suited for your needs. Here are some considerations to keep in mind when choosing the best small pellet machine:

Ring Or Flat Die?

Ring die small pellet machines are more efficient when it comes to power consumption, and they tend to provide better sealing performance. On the downside, they are usually more expensive compared to flat die small pellet machines.

Type Of Raw Material

Small pellet machines that are designed to pelletize livestock and poultry feeds are different from those designed to pelletize wood, sawdust, barks, and other wood waste products. Therefore, you need to think about your intended use before choosing a small pellet machine.

If you’re buying a small pellet machine to process animal feeds, most small feed pellet manufacturers also recommend choosing a machine depending on animal type. For instance, chicken feed pellets will require a different die size from cattle feed pellets. Therefore, when evaluating a small feed pellet machine for sale, remember to check the die size.

Energy Consumption

One of the reasons you’re buying a small pellet machine is because you want to keep costs low. When choosing a small pellet machine, therefore, you should go for one with minimal energy consumption to keep your electricity or fuel costs low.

Production Capacity

Even when buying a small pellet machine, it’s still important to think about the output capacity of the machine. For instance, if you’re buying a small pellet machine to process feed for a small chicken farm, even a capacity of 50 kilograms per hour might be enough.

However, if you’re buying a small pellet machine for small scale commercial purposes, you’ll want to go for a small pellet machine with higher output capacity, say about 100 to 200 kilograms per hour.

How To Use A Small Pellet Machine For Beginners?

Using a small pellet machine is very easy, even for first timers. Some small pellet machine manufacturers like Tcpel will even provide training on how to use the machine after your purchase.

Here are the steps you need to follow:

- Read the instructions from the small pellet machine manufacturer before operating the machine. Doing this ensures both your safety, as well as that of the small pellet machine.

- Check to confirm that the gearbox, the transmission, and other moving parts have proper lubrication. For small pellet machines with an automatic self-lubricating system, such as the Tcpel small pellet machine, you can skip this step.

- Collect your raw material and inspect it to confirm that there are no foreign particles in the raw material, such as pieces of metal, stone, glass, or plastic, which can cause excessive wear to your small pellet machine. Such foreign particles can also be dangerous to your livestock if you’re producing animal feed pellets.

- If your raw material is not already in powder form, use a hammer mill to crush and grind the raw materials into small particles that can fit through the die holes of your small pellet machine to avoid blocking the holes and damaging your small pellet machine.

- Ensure that your raw material is not excessively wet, since this will affect the quality of your pellets. In case of excessive moisture content, dry your raw material in a pellet cooler or under the sun before you start pelletizing.

- Power on the small pellet machine, allow it to run for a few minutes, and then add your raw material. The machine will process the raw materials into pellets and discharge the ready pellets through the discharging port.

- Give the pellets some time to cool down and lose some of their moisture content before packing them for transportation or storage. If you store or transport them before cooling down, they might crumble since they’ll not have hardened sufficiently.

- Switch off your small pellet machine and clean it thoroughly.

How To Maintain A Small Pellet Machine?

Small pellet machines are as durable as any other pellet machine, but if you want your small pellet machine to have a long lifespan, you have to maintain it properly. Here are some things you can do to give your small pellet machine a long lifespan:

- Don’t use your small pellet machine before you are familiar with its operational procedures. You can learn this from the small pellet machine manufacturer’s manual.

- Always remember to check for debris and impurities in your raw material before adding it to the small pellet machine. Such impurities will accelerate the machine’s rate of wear.

- To avoid damaging the roller gears and dies, always clean the pelletizing chamber to remove any debris before you start operating the machine.

- The heat generated when operating the small pellet machine can cause excessive wear to the motor and other parts of the machine. To prevent this, always use your small pellet machine in an area with enough ventilation that allows efficient heat dissipation.

- Inspect the moving parts of your small pellet machine after every one month to check for damage or excessive wear. If you notice any damage, have the damage repaired before using the machine.

- Always keep the moving parts of your small pellet machine well lubricated with the correct oil specified in the owner’s manual. These include the main shaft, the rollers, as well as the gear box.

- If your small pellet machine is powered by an electric motor, keep the motor protected from rodents, water, and moisture.

Tcpel Small Pellet Machine Introduction

Are you looking for an affordable but reliable small pellet machine that will allow you to make your own biomass fuel pellets and animal feed pellets right at home?

If you answered yes, we recommend the Tcpel small pellet machine, which is one of the most reliable options available in the market today.

The Tcpel small pellet machine is made using advanced materials and technology that guarantee you strength, durability, and outstanding performance.

Whether you’re looking to convert the agricultural wastes from your small farm into fuel and animal feed pellets, or looking to start a small scale pellet production business, the Tcpel small pellet machine is the best solution for your needs.

Small Pellet Machine Parameters

| Model | Capacity | Pinch Roller | Power | Voltage(V) | Weight | Dimension |

|---|---|---|---|---|---|---|

| TCF120 | 80-100kg/h | Double roller | 2.2kw | 220V/380V | 95kgs | 68*42*53cm |

| TFC150 | 150-200kg/h | Double rollers | 7.5kw | 220V/380V | 100kgs | 72*45*65cm |

| TCF200 | 300-400kg/h | Double rollers | 11kw | 380V | 180kgs | 126*53*92cm |

| TCF250 | 600-800kg/h | Double rollers | 15kw | 380V | 320kgs | 131*54*93cm |

| TCF300 | 800-1000kg/h | Double rollers | 22kw | 380V | 400kgs | 146*59*110cm |

| TCF350 | 1000-1200kg/h | Double rollers | 30kw | 380V | 580kgs | 186*70*128cm |

| TCF400 | 2000kg/h | Double rollers | 37kw | 380V | 680kgs | 206*76*137cm |

| TCF450 | 2000-2500kg/h | Double rollers | 45kw | 380V | 780kgs | 218*79*140cm |

Taichang Small Pellet Machine Advantages

High temperature treated parts: The grinding parts of a small pellet machine operate under intense heat and pressure. To ensure long term durability even under such intense heat and pressure, the Taichang small pellet machine uses a grinding disc and pressure roller made using high temperature treated chromium-manganese steel, which is up to 20 times stronger than the regular materials used on other small pellet machines.

Multiple die hole diameters: To allow you to make different sized pellets, the Taichang small pellet machine offers dies with multiple hole diameters. This way, you can choose different die hole sizes depending on the kind of pellets you are producing. The Taichang small pellet machine also has a design that simplifies the process of switching between different dies.

Highly versatile: Whether you want to produce animal feed pellets, livestock pen litter pellets, or biomass fuel pellets, the Taichang small pellet machine is designed to handle it all. You can use this machine to pelletize a wide range of raw materials, including wood, tree branches, wheat, rice husks, peanut shells, and many other types of raw materials.

Low power consumption: The Taichang small pellet machine is designed to operate with as little power consumption as possible, with our smallest models having a power rating of just 3 KW.

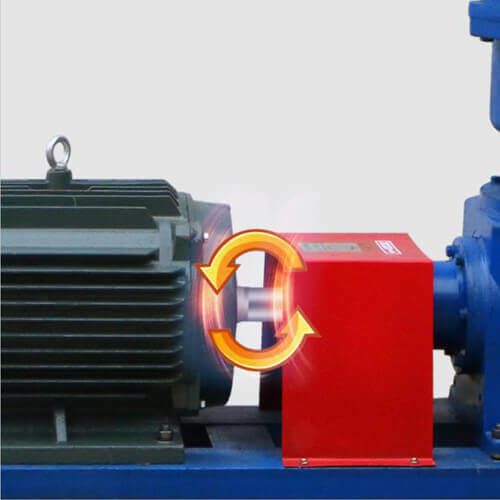

Electric coupling: The Taichang small pellet machine uses an electric coupling drive instead of a belt drive. This reduces transmission ratio loss, leading to better performance, and an extended lifespan.

Copper wire motor: The Taichang small pellet machine uses a 100% copper wire motor, which is highly energy efficient and provides more power while minimizing noise during operation. In addition, the 100% copper wire motor is more durable.

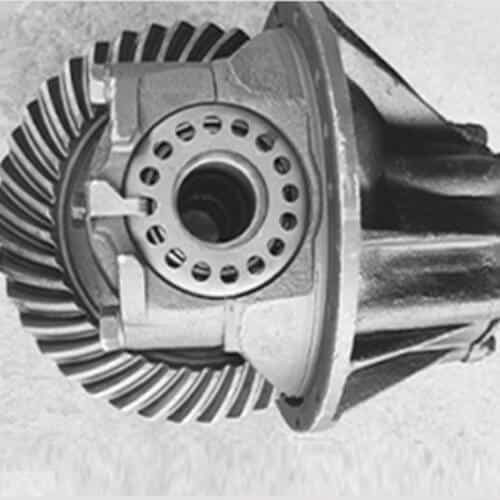

Innovative differential assembly: This machine replicates the differential assembly design used in automobile rear axles for better gear combination, resulting in improved stability, and better power output.

Easy to maintain: This machine is made using highly durable, easy to maintain parts that are meant to ensure minimal downtime.

Nylon sliding casters: For improved portability, our small pellet machine comes with highly durable, wear-resistant nylon sliding casters.