Vertical Pellet Mill VS Horizontal Ring Die Pellet Mill, how to choose?

With the new round of energy crisis, and new Nord Stream 1 and Nord Stream 2 gas leak occurs, many people looking for new energy to go through cold winters. Biomass pellets is a very ideal alternative for heating. That’s why we get many orders about pellet machines from Europe customers recently, especially in August and September 2022.

While choosing pellet machines, there are two choices for biomass pellet machine: vertical pellet mill and horizontal ring die pellet mill. Some new beginners’ don’t know how to choose, hereby we write this article to explain the difference between them and help you go through about the decision. Keep on reading.

Difference between Vertical Pellet Mill and Horizontal Ring Die Pellet Mill

1. Feeding Method

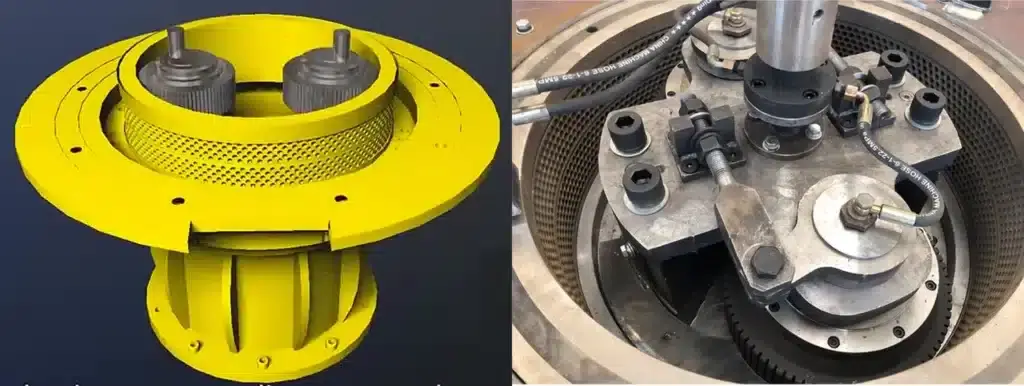

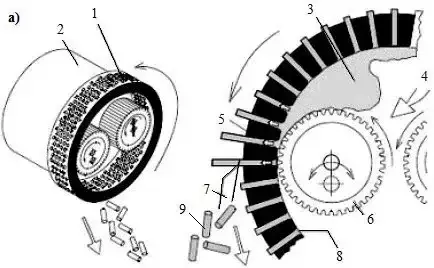

Vertical pellet mill ring die is flat laying, opening on top, the sawdust will feed directly into the pelleting making room by gravity.

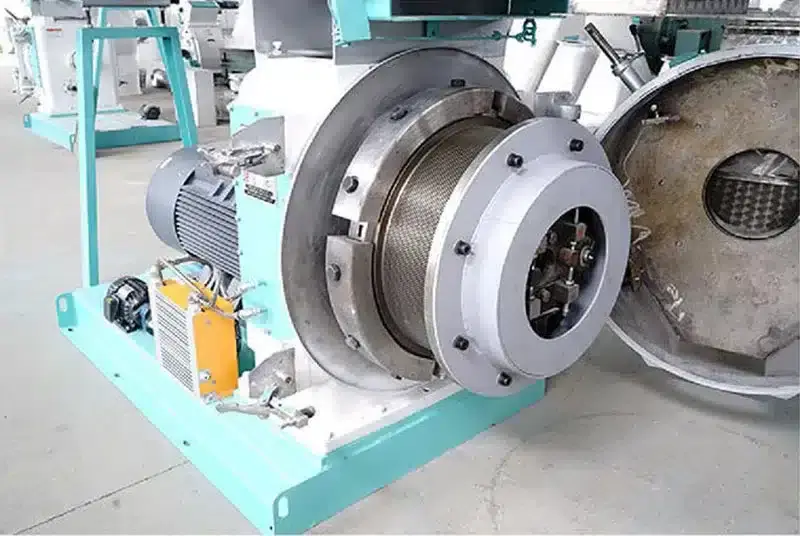

For horizontal ring die pellet mill, the ring die is put upright, the sawdust feed from side, then enter into the pelleting making room.

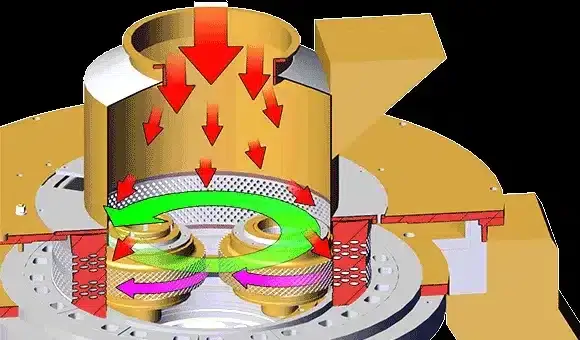

2. Pellet Making Method

Vertical pellet mill the ring die is fixed, and the roller rotate in high speed. The shaped pellets will pushed out directly from the holes, so there is no second hit between pellets, the pellets length are more uniform and less sawdust. Higher successful rate for pellet making.

Horizontal ring die pellet machine the ring die rotate, but the roller fixed. The pellets will be mixed inside and easy to broken between them. So the final pellets quality can not control.

3. Machine Structure

Vertical ring die pellet machine feeding hole is open, which is easy to for heat dissipation. Also vertical pellet mill standard with the dust collector and cooling system, which can easure the pellet making in constant temperature. This machine is also equipped automatic lubricating system, saving labor and lowered the manufacturing cost, the bearing also durable and not easy to break.

The horizontal ring die pellet machine is sealed working environment. The sawdust will get hotter during manufacturing. With the hot working, the bearing will be easily broken, which will increase the production cost and lower the capacity. Most horizontal ring die pellet mill don’t have automatic lubricating system, which need manual lubricating. For the horizontal ring die pellet machine, there are cooling system, but it’s equipped by one side, which is not easy to suck out the steam and dust thoroughly.

4. Operation Method

Vertical pellet mill the ring die is placed axially vertically, with wrought iron and large steel bearing seats to reduce any stress on its bearings. The main shaft is short to reduce pressure. Obviously, the machine is not easy to be damaged, which prolongs the working time.

The ring die of the horizontal ring die pellet machine is placed horizontally on one side of the machine and lifted by a large shaft. Such a large and heavy steel mold is on one side of the machine, and the pressure and torque it is subjected to is very high. When the machine is running, it is easy to be damaged due to torque.

The rotating speed of the horizontal ring die pellet machine is more than 200rpm, while the rotating speed of the vertical ring die is 75rpm. It is like the torque of a car, when the speed is fast, the torque is small, and when the speed is slow, the torque is large. The woods in South and Southeast Asia are hardwoods and require high-torque equipment.

The horizontal ring die pellet mill adopts a six-stage motor, and the vertical ring die pellet mill adopts a four-stage motor. In the case of the same power, the efficiency of a six-stage motor is lower than that of a four-stage motor. At the same time, the replacement and maintenance cost of the six-stage motor is much higher than that of the four-stage motor.

5. Machine Stability:

The material of the vertical ring die pellet mill is fed by the rotating knife at the bottom of the pressing roller. It produces no material offset and reduces vibration. For equipment, a complete set of rotating components are precisely balanced. The vertical ring die pellet mill is rotated by the pressing wheel, which will not cause the material to be overweight or vibrate. In addition, the complete set of rotating parts of the vertical ring die granulator has undergone precise dynamic balance, plus its own weight.

The ring die of the horizontal ring die pellet machine is placed horizontally on one side of the machine. When the material is conveyed unevenly, the material will accumulate into the mold below under the action of gravity. The first few rows will be discharged, and the latter few rows will sometimes not discharge the material. It creates vibrations that damage the bearings. Since the mold of the horizontal ring die pellet machine is placed horizontally on the side of the machine, when the feeding is uneven, the material will accumulate under the mold under the action of gravity, which will cause vibration and damage the bearing.

Conclusion

Above are the differences of vertical pellet mill and horizontal ring die pellet mill, choosing the right pellet mills are quite important for pellet making business. Study more and do some research will help you avoid unnecessary loss.

Talk to An Expert

SHARE THIS POST

Talk to An Expert