Disc Chippers: The Ultimate Guide

In this extensive article, we have gathered all the important questions you may have about disc chippers. As a result, you will get highly researched answers to the most frequently asked questions.

This guide will be of great utility and equally benefit both beginners and professionals. So, let’s dive in!

Table of Content

- What is a Disc Chipper?

- What Does a Disc Chipper Do?

- How Much Does a Disc Chipper Cost?

- How Does a Disc Chipper Work?

- What Is the Difference Between a Drum Chipper and a Disc Chipper?

- How To Choose the Best Disc Chipper for Pellet Production?

- How To Buy an Affordable Disc Chipper?

- How To Use a Disc Chipper for Beginners?

- How to Maintain a Disc Chipper?

- Conclusion

What is a Disc Chipper?

Disc chipper, also called disc wood chipper, it’s one kind of wood chipper designed to process wood into wood chips. Suitable for chipping logs(after peeling), small-diameter logs and branches(diameter less than 200mm) etc into high quality industrial wood chips with uniform length, flat incision and uniform thickness. It’s named disc chipper because its cutting knives mounted on discs.

It is a special equipment for preparing high-quality wood chips, widely used by paper making plant, particleboard factories, fiberboard factories and wood chip production bases.

Wood chippers can be divided into two categories according to their mechanical structure: disc chippers with cutting knives mounted on discs and drum chippers with cutting knives mounted on cylindrical drums.

What Does a Disc Chipper Do?

A disc chipper cuts and chops large blocks of wood into smaller wood chips and pellets. Plenty of items can be churned through the disc chipper.

The list of items is extensive but can include branches, twigs, leaves, organic debris, and cardboard and paper. A large industrial-grade disc chipper is also capable of churning large tires into debris.

How Much Does a Disc Chipper Cost?

The ultimate cost of the disc chipper is entirely dependent on the type of disc chipper. The other determining factors include the volume and the function based on your requirements.

The complete assembly of a disc chipper is priced between US $300 to $400000. The price tag is naturally higher for a disc wood chipper with better specifications and dealing with a large volume of raw material.

Since even the simplest of disc chipper comes with a hefty price tag, it is wise to go for a rental disc wood chipper initially. This will give you a fair idea of the utility of the machine. Eventually, it will help you reach a decisive conclusion.

How Does a Disc Chipper Work?

All the different types of wood chippers have varying work principles.

Components in a Wood Chipper

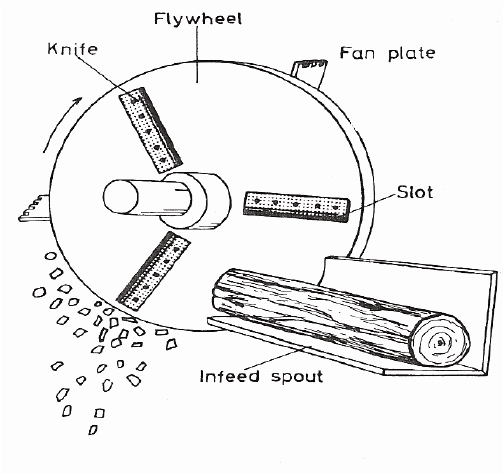

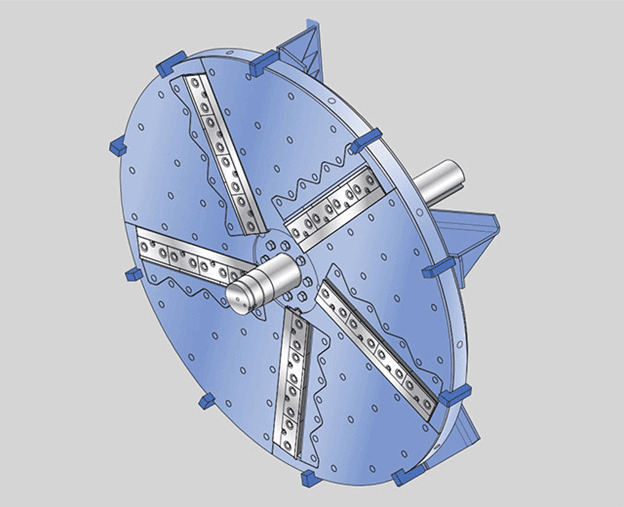

- The disc wood chipper comprises a flywheel with mounted blades in slots.

- The anvil is present right below the disc, and the upper and lower casings encapsulate the disc.

- The wood chipper cutting disc serves as a hub for the cutting knives.

- The wooden chipper disc resembles a flywheel.

- The hydraulic-powered wheels serve to draw the raw material closer to the disk.

Raw Material in a Disc Chipper

The raw material is inserted in the disc chipper through the feeding port. The motor-powered disk contacts the wood raw material at a perpendicular angle and turns it into wooden chips.

Usually, a chute is present which serves as an outlet for the wooden chips. The outlet port or the discharge port works on the principle of airflow for the chips’ withdrawal from the disc chipper.

The perpendicular positioning of the rotating disk is attributed as the cause of cutting the precision of blades. The feedstock is not directly processed into wooden chips. Instead, the large feedstock or raw material is first processed to large form and then broken down into wood chips.

Working Capacity of a Disc Chipper

The working capacity of a disc chipper is highly dependent on the type and size of the disc chipper.

What Is the Difference Between a Drum Chipper and a Disc Chipper?

The debate of disc chipper vs. drum chipper is quite a popular one. We have compared both in detail below.

| Comparison | Disc Chipper | Drum Chipper |

| Structure | cutting knives mounted on discs. | cutting knives mounted on cylindrical drums. |

| Price range | $3000-$20000 | $12000-$48000 |

| Final Wood Chips | smaller size, uniform, length within3cm, thickness within 5mm | bigger size, length 3-5cm, thickness 5mm |

| Working Principle | cut directly with disc knife, the wood chips more uniform | first press with roller, and then cut with flying knife, there will be crack on the wood chips, not uniform |

| Capacity | usually small, max 8t/h | max capacity 30t/h |

| Application | industries which need high quality wood chips | Industries which need big quantity wood chips |

The key to settling this debate lies in understanding the differences between the disc chipper and the drum chipper.

What is Drum Chipper?

The drum chipper gets its name from the large central drum in the machine. The drum pulls the raw material into the machine.

It is a large machine and is usually used for industrial grade. The drum wood chipper is capable of churning large volumes of raw material. The blades or knives are attached in a horizontal direction.

What is Disk Chipper?

The disc chipper, on the other hand, comprises the flywheel-like disc with mounted blades. Instead of the drum, it includes of disc chipper cutting disc.

Unlike the drum chipper, the blades are attached in a perpendicular direction in the disc chipper. The disc chipper is available in various sizes ranging from smaller home-based variants to large commercial grade variants.

Disc Chipper vs. Drum Chipper — Comparison

Research proves that the disc chipper has higher energy efficiency in comparison to the drum chipper. It also uses 19 percent less fuel per unit product as compared to a drum chipper.

However, the drum variant is large and has a more complicated design. Along with that, the drum chipper also produces better chip output when compared to the disk-type chipper.

The research proves that a drum chipper is eight percent more productive than a disc chipper. Furthermore, a comparison of the types of chips drawn from each type of machine was also drawn. The wooden chips produced by the drum chipper are finer and uniform than those of the disc variant.

Safety Comparison

From a safety point of view, a drum chipper is a large machine. It has a strong pull force to increase production efficiency. Thus, there is a high probability of accident occurrence. In comparison, the wood chipper disc is a relatively safer option.

The ultimate choice between the two types of chippers is dependent on usage and preference.

For a lower volume of raw material or home-based usage, a disc-type chipper is more suited.

On the other hand, a large volume of feedstock and commercial usage is more appropriately handled by drum-type chippers. Thus, it relatively settles the much-heated debate.

How To Choose the Best Disc Chipper for Pellet Production?

Choosing the best disc chipper requires research and analysis. We have listed out several important factors to consider before buying the best machine.

The best disc chipper for pellet production depends upon a variety of factors. Some of the factors include the type of disc chipper, the volume of wood to be used, and the designated budget.

It is subjective and depends on your needs and project complexity. The best disc chipper for pellet production is the one that fits your set of requirements.

Type of wood chipper

This depends on the type of project you want a wood chipper for. For example, if you want a drum chipper for your small forest or backyard, then a forestry drum wood chipper is the best option.

You can also buy a mobile drum chipper for your ease.

If you want to chip wood on an industrial scale, then you need an industrial drum-style wood chipper. Such disc chippers can chip up to 150 diameters of wood!

The volume of wood to be chipped

A disc chipper can be used for pellet production on both a small and a large commercial scale.

However, in most cases, the disc chipper is used to generate raw material for pellet production. First, the large logs, barks, and twigs of wood are inserted into a disc chipper. The large-sized raw material is then converted into smaller-sized wooden chips by the wood disc chipper.

If you have a large volume of wood to be chipped, your requirement includes a heavy-duty wood chipper. In addition, you need an industrial scale drum disc chipper that can carry out the job easily.

If you require pellet making, then you need a different disc chipper. In this case, the finished products of the disc chipper are used as raw materials for pellet production.

The biomass pellet production line makes use of these wooden chips. The chips are then churned into wooden pellets by the pellet-making machinery.

For small projects, a mobile drum chipper is the best option. It will be easy on the budget and perform the small jobs perfectly.

Your budget

In the end, you need to consider the budget for your machines. A big budget can buy you heavy-duty machinery that can perform bigger tasks.

Moreover, you need to consider the electricity bills and horsepower requirements of the machines to select the best option.

How To Buy an Affordable Disc Chipper?

Wood disc chipper can be quite hefty on your pocket. The term affordable does not only refer to the initial price tag of the item. In the long run, an affordable disc chipper is worthwhile. This essentially means that the running and maintenance costs must be as minimum as possible.

Plenty of businesses owners, particularly beginners, tend to confuse affordability with the initial cost. Unfortunately, a simple miscalculation on their part proves to be problematic in the long run.

The maintenance and running costs aside, the energy and production efficiency also contribute to the affordability as a whole.

A disc chipper that has a lower price tag might have lower energy efficiency and production capacity. This defeats the whole purpose of purchasing an affordable product.

Similarly, a disc chipper with a high initial cost may prove to be affordable if it has higher energy efficiency and high production capacity.

The lower running and maintenance cost also contribute a great deal to the overall yield of the product. Thus, it renders the products more cost-effective.

Thus, an adequate cost-benefit analysis ought to be done before purchasing a disc-type wood chipper.

Are you in quest of an affordable disc wood chipper for sale? Our custom pricing packages are curated to significantly lower handling and manufacturing costs for our clients. Contact our support team today to get a quote on the most affordable disc-type wood chipper in the market.

Efficient pre-sales and post-sales services further supplement the affordability of our products. Furthermore, the product and parts warranty also aids in making our disc-type wood chipper cost-effective.

How To Use a Disc Chipper for Beginners?

Whether you use an industrial-grade disc chipper or a home usage disc chipper, an absolute beginner need to learn a great deal.

The operational aspect of a disc chipper requires a thorough understanding. Furthermore, accidents with wood chippers are fairly common. If you’re a beginner, keep reading.

Disc wood chipper placement

It would be best if you placed a disc wood chipper appropriately. A flat-lying well supported disc chipper without rocking and tipping movement performs the job in a better manner. In addition, most disc chippers come with parking brakes which help achieve a steady position for the machine.

You must learn how to position the raw material, i.e., the wood on the roller belt. It is wise to insert the blunt end of the wood before the sharp end.

Avoid the heating up of the machine.

A beginner might not be aware, but the incidence of machine heating up is quite frequent. To avoid this, use a lubricating agent like green limbs with dried branches and logs.

This significantly reduces the machine heating incidences. Thus, a beginner will be able to operate the machine without any hiccups in the process.

Adjust the direction of flying chips

The disc wood chipper wheel produces small wooden chips so; the finished products fly out of the chute. Therefore, a beginner needs to adjust the direction and distance for the chips.

It is also important for the operator to position in a manner to avoid any accident occurrence.

First, Personal ProtectionBoth types of disc chippers are accident-prone, but the incidence of mishaps is higher in industrial-grade ones. Therefore, as a beginner, you should thoroughly read the operator and the safety manual before proceeding with the operation.

Personal protection always comes first. Thus, beginners should always ensure that they have adequate personal protective equipment while operating a disc-type wood chipper.

Personal protection includes wearing tight-fitting clothes with thick gloves. Eye and ear protection are also vital. Properly donned personal protection minimizes the hazard for the operator. Furthermore, the machine also requires frequent safety checks from the concerned authorities.

All in all, proper know-how of how to use the disc chipper ensures the full yield of the product.

How to Maintain a Disc Chipper?

Maintenance is the key to the longevity of equipment, particularly machinery.

A well-maintained disc chipper ensures full yield. A poorly maintained disc chipper results in poor function.

A disc chipper needs to be cleaned after use. This step will ensure adequate removal of debris from the machine. In addition, a pressure wash can be used to clear the disc chipper from debris that may clog it and hinder its function.

Prolonged and repeated usage of blades reduces their efficacy and efficiency in the long term. Thus, it is important to sharpen the blunt blades for better productivity periodically. It is advised to get the blades professionally sharpened. In other cases, you may also sharpen the blades on your own, although it is risk-prone.

It is also important to get the machine professionally inspected periodically. For example, the air filter and parts of the disc wood chipper ought to be regularly checked. The use of high-quality genuine spare parts is also essential for maintenance.

A well-maintained disc chipper produces better quality chips. Thus, a deteriorating chip quality may be an indication that your wood chipper requires maintenance.

Conclusion

This article sums up our comprehensive guide on disc chippers. We hope that this article has thoroughly given you an insight into the working of disc chippers and adequately answered all your questions. As an experienced disc chippers manufactuere in China, we are ready to offer support for you anytime.

Also Read:

Talk to An Expert

SHARE THIS POST

Talk to An Expert