Drum Chipper: A Comprehensive Buying Guide

This is a comprehensive buying guide on drum chippers. In this buying guide, you will find everything you need to know about drum chippers. Just briefly, below are what we will be discussing:

Table of Content

- What is a Drum Chipper ?

- How Does a Drum Chipper Work?

- Types of Wood Chippers

- Electric Wood Chipper VS Gas-powered Wood Chipper

- Difference Between Chipper, Shredder, and Mulcher

- Should I Buy Or Rent A Drum Chipper?

- Features to Look for in a Drum Chipper

- Tips To Effectively Make Good Use Of Your Drum Chipper

- Frequently Asked Questions

- The drum chipper we recommend

- Advantages Of The TCPEL Drum Chipper

What is a Drum Chipper ?

Drum chipper, also called drum wood chipper, it is one kind of machine used to process small diameter wood, wood residues (twigs, branches) etc into wood chips(length 3-5cm, thickness within 5mm). It is called drum chipper because its cutting knives are mounted on cylindrical drums.

The base of the drum wood chipper is welded with high-cavity steel plates, which is the support base of the whole machine; two flying knives are installed on the knife roller, and the flying knives are fixed on the knife roller with the specially manufactured flying knife bolts through the pressure block. According to the different thicknesses of the raw materials to be cut, the upper feeding roller assembly can float up and down within a certain range with the help of the hydraulic system; the qualified wood chips fall through the mesh screen holes from the bottom row, the large wood chips will be in the machine to cut again.

The final produces wood chipper can be used as artificial boards such as particleboard, fiberboard, compressed board, etc. It’s widely used in the paper industry for pulp processing, biological power plants, wood chip factories and other industries and manufacturers.

How Does a Drum Chipper Work?

A drum chipper’s action is anything but magical. The machine is a collection of several parts working in tandem.

In a drum chipper, a steel drum guides the feedstock towards the blades. The rotating blades are linked to a gearbox, making it possible to control the cutting speed.

Due to the heavy-duty nature of the drum chipper, the machine often uses a gas-powered engine. The power from the motor drives the rotating blades through a system of pulleys and belts.

With the drum chipper, you decide how quickly the feedstock is cut using the gearbox controls.

Once cut, wood chips are ejected through a chute on the drum chipper. Of course, you’ll need to ensure the chute faces the right direction.

Some drum chippers have multiple feed rollers connected by a conveyor belt to the pulley system. You can adjust the feed rollers’ speed with the hydraulic system playing a part in such machines.

The blades in a drum chipper are often made from steel and chromium to withstand the feedstock’s toughness. Depending on the machine, the blade configuration can either be supported on individual shafts or hosted on a single platform.

The difference in blade configuration can affect the speed and efficiency of the machine. While shaft supported blades are quicker and more efficient, the other form of blade configuration isn’t that fast, but the result is a more consistent outcome.

Types of Wood Chippers

1. Drum Chipper

Its unusual name is due to the metallic drum at the core of the machine. When a feedstock is loaded, the drum pulls the item into the machine, where the waiting knives chip it. The structure of the drum chipper has been confirmed to offer increased productivity compared to other variants. This machine can handle bigger feedstock than the other types. You can feed logs of wood, branches, and others into the machine. Aside from having a better output, the drum chipper delivers smaller wood chips. The underbelly of the drum chipper is its safety. Due to the drum’s pull on anything (besides the feedstock), accidents are likely. Fortunately, there are a handful of models with gimmicks to minimize the risks.2. Disk Chipper

Shaped like a flywheel, this chipper depends on revolving disks and housing blades to cut the feedstock. Unlike the drum chipper, this machine uses hydraulic wheels to get to the moving disks. The tree chipper is loaded through its hopper. The rotating disk in this machine is positioned perpendicular to the feedstock. This explains the cutting precision of the attached blades. In the disk chipper, the feedstock is sliced in large forms before it is broken into chips. The capacity of a disk chipper is dependent on the size of the machine. With bigger units, you can expect the chipper to handle more extensive feedstock.3. Screw Chipper

This chipper type gets its name from the conical screw blades used in chipping wood. Here, the conical screw blades rotate at a specific speed, cutting whatever is set before them. Like the disk chipper, a flywheel makes an appearance, but it supports the screw blades, not just shape the machine. Depending on the model of the screw chipper, a conveyor setup feeds the blades with the feedstock. Unlike the disk and drum type, the screw chipper cuts at the feedstock at a uniform speed. This is evident from the homogeneity of the chips expelled. The screw chipper is ideal for chipping branches and small wood logs. Don’t attempt feeding the machine with a large tree trunk or similar; it will affect the device’s performance.4. High Torque Roller

This type of chipper should be a favorite for anyone looking to go green. High Torque Rollers are typically driven by electric power, which explains the near-noiseless operation of the machine. But sanity – the absence of noise – does come at a steep price: lower cutting speed than the other types. The high torque roller is often packed with innovative features like anti-jam that prevent the feedstock from clogging the machine.Also, it is suited for households in need of a chipper for occasional use. It’s relatively cheaper than the rest

Electric Wood Chipper VS Gas-powered Wood Chipper

While gas-powered drum wood chippers are bulky and mostly immobile, the electric types are lightweight and compact.

Difference Between Chipper, Shredder, and Mulcher

All three outdoor equipment are united in their purpose: to help get rid of wood waste in the most advantageous of ways. Yet, knowing the difference between these machines can make it easier to pick the right tool for your situation.

A chipper works on more enormous wood wastes, like tree branches, trunks, and similar items. Introducing smaller things like leaves tend to clog the machine. And you might have to spend a pretty penny to resolve the impasse.

The shredder is limited to small wood waste. You can only shred small tree branches due to the mechanism of this machine.

A mulcher only works on leaves, plant matter, and vegetation. The machine can’t handle wood waste or branches.

Another difference between the chipper and the shredder is the cutting segment. The average chipper depends on rotating sharp blades to chop wood.

In a shredder, the blades are intentionally blunt, making it possible to break down smaller plant matter.

You can also tell a chipper and tree shredder apart based on the number of hoppers the machines have. While a chipper has a single hopper, the shredder comes with two.

Should I Buy Or Rent A Drum Chipper?

This is a popular question, and considering the purchase cost of this machine (thousands of dollars), you don’t want to jump on a drum chipper for sale that ends up gathering dust on your property half the time.

Before you decide whether to buy a drum chipper, you should clearly understand your needs. If you have to use the machine once in a blue moon, then owning one might not be advisable.

Like any other machine, the drum chipper has parts that are susceptible to wear and tear. Owning the equipment means you have to deal with replacing or repairing these components on a recurrent basis. If you’re not open to carrying out this maintenance routine on your own, then get ready to pay a dealer to do the job.

One of the giant wood chippers is the drum type. That means you have to consider the available space on your property before deciding to own or rent one.

If you’re planning to get that small wood chipper that has been put up for sale, you must make provisions for a storage setup.

If you live in an area where it snows heavily during the winter season, you will need to get the machine ready for the long spell of inactivity. Those looking to rent the drum chipper need not go through this process.

Yet renting a drum chipper isn’t entirely flawless. Most outfits that rent these machines only let out big units. That means you have to deal with the additional costs of hiring a tow truck to bring the chipper to your property.

There’s also the time factor to remember. Renting a chipper is often done by the hour. To avoid getting a hefty bill afterward, you might have to get the job done in record time.

Regardless of the challenges of owning a drum chipper, it’s an economical approach if there are multiple trees on your property you intend to make maximum use of the wood waste.

Features to Look for in a Drum Chipper

Every drum chipper might have the basics – blade, hopper, and chute – but the machine’s capability goes beyond these.

When getting a drum chipper, there are specific attributes you should look out for in the machine. Below are some of these features:

1. Powerful engine

The chipping ability of a drum chipper is down to its engine capacity. If you intend to crush tree trunks and massive wood wastes in a few minutes, then opting for chippers with powerful engines is crucial.

The engine drives the blades, so if the former isn’t strong enough, this will affect the revolutions per minute (rpm) of the blades.

Gas-powered units are often ideal as they have engines rugged enough for the task. Of course, you still need to check the machine’s rating – the greater its horsepower(HP), the more powerful the engine is.

2. Quality parts

When picking the right drum chipper, you should only settle for a machine that has quality components.

An excellent place to start is the frame of the drum chipper. Your ideal choice of a drum chipper should have a metal frame, as this keeps the machine intact.

3. Automatic belt tensioning setup

If you’re interested in a drum chipper that uses a pulley and belt arrangement, ensure the machine is equipped with automatic belt tensioning. This will save you the strain of doing this manually – and safeguard the device against belt failure.

4. Safety gimmicks

Using a drum chipper lacking in safety features is like sitting on a keg of gunpowder – things will spiral out of control no matter how you handle the machine.

When picking such a machine, ensure the equipment has safety fittings, such as an automatic shutdown system, easily accessible turn off button, and others. Industrial wood chipper manufacturers often include such features in their machines.

Having a drum chipper that shuts down when there are underlying issues prevents further damage to the machine. Some have an easily accessible power button, making it easy to shut down the engine if things appear to be going wrong.

5. Quick start

To avoid the woes of spending hours in starting a drum chipper, you can opt for those with a quick start button.

However, you might not find such on gas-powered models since they come with a pull-cord instead. Here, you just have to ensure the engine responds promptly when you use the pull cord.

6. Capacity

Drum chippers, despite their significant size, differ in their ability to handle the large wood waste. Some can accommodate wood waste of not more than 4 inches in dimension; others can tackle 20 inches of wood without issues.

Your preferred drum chipper should have the capacity to handle whatsoever you throw at it. If you’re getting the machine to crush tree trunks and large branches, scrutinize the power of the drum chipper that interests you.

7. Silent operation

The average drum chipper is loud and boisterous, so it might not be the right choice for use on properties in a crowded neighborhood.

Fortunately, the decibel rating isn’t the same on all drum chippers. Some don’t emit loud, unpleasant noise, making them a great fit. Other drum chippers are equipped with mufflers to reduce the noise generated by the machine.

While electric chippers are generally noiseless, they lack the power of the gas-powered type.

Tips To Effectively Make Good Use Of Your Drum Chipper

Being a whole tree chipper, this machine can be a handful, sometimes. To ensure it’s smooth sailing when using the drum chipper, we have compiled some valuable tips. Check them out below:

i) Use appropriate clothing

When using the drum chipper, loose clothing that can get entangled by the machine should be avoided. Tight-fitting clothing – that is less likely to get drawn into the drum chipper – is advisable. Also, leave out any clothing accessory that can be pulled into the machine.

Considering the nature of the drum chipper, you should always have on your safety goggles, gloves, earmuffs, work boots, and others.

ii) Introduce the feedstock slowly

On starting the wood chipper, don’t be in haste to breeze through the feedstock. Initially, load the machine with a small amount of the feedstock before proceeding to add more. Afterward, stay within the limit of the chipper. This way, the likelihood of unpleasant events happening is reduced.

iii) Don’t ignore the manual

The common practice among many is to discard the manual and proceed to use the machine. This should not be the case. Instead, read and digest the content of the wood chipper manual.

This booklet is often packed with valuable information regarding the machine, from technical specifications to the how-to section.

iv) Start with the lowest speed settings

Avoid starting the drum chipper at the highest speed settings. This might spell doom for the machine if one of its components is flawed or damaged.

The best way around this is always to start the drum chipper at its lowest speed. This allows you to identify any faulty component before it escalates to something worse.

v) Be aware of your surrounding

Since the drum chipper releases the chips to the exterior, you must always beware of your environment.

Those chips – no matter how superior the discharge chute might be – can hit someone within the vicinity of the machine.

This reinforces the need always to stay conscious of happenings in your surroundings to avoid causing damage to anyone.

If you observe the drum chipper is unsafe to operate at any time, you should turn it off.

vi) Assess the drum chipper’s state

Never start the machine without confirming its condition. And should you uncover any damaged bolts or loose screws, fix the problem before starting the drum chipper.

vii) Keep your distance

Remember, the drum chipper is as dangerous to you as it’s to the feedstock. Keep your distance while operating the machine to avoid accidents from happening.

viii) Watch what you feed the drum chipper

Scrutinize the feedstock before it gets fed into the machine. Items like rocks and stones should be removed to avoid damaging the gears.

Frequently Asked Questions

I) Is there any difference between the drum chipper and its disk counterpart?

Yes, there are several differences. The drum chipper has a more complicated design compared to the disk type. The outcome is better fuel efficiency in the latter.

A drum chipper outshines the disk variant in its chip output despite the similar feedstock used in both machines. This is attributed to the uniform distribution of energy across the blades in the drum chipper.

II) How does a drum wood chipper work?

A massive steel drum is propelled into circular motion in a drum chipper through a motor, often powered by a gas engine. The position of the drum is such that it draws the feedstock towards moving blades.

Once the knives have chipped the feedstock, the chips are moved to the chute, exiting the machine.

III) What does a wood chipper do to a person?

A track chipper is a dangerous tool if handled poorly. The machine can leave far-reaching consequences on an operator; frankly, death is highly likely through excess bleeding from injuries sustained.

IV) Can a wood chipper kill you?

Yes, a wood chipper can kill a person. On loading the machine with the feedstock, there’s a small chance of the operator getting drawn into the spinning blades. This is so real that no less than 12 persons have died due to accidents involving a US wood chipper.

V) What size wood chipper do I need?

This will depend on the nature of wood waste you intend to feed the wood chipper. A compact chipper fit for residential properties should do just fine for chipping branches not more than 2.5” in diameter. For larger branches and tree trunks, you’ll need a commercial-grade wood chipper.

VI) What is a disc chipper?

The disk chipper uses disc-shaped blades to crush wood waste. The simplicity of its design isn’t available on other types.

Unlike the drum type, this one regurgitates partly chipped wood, so the blades can go to work chipping them to perfection.

VII) What can I do with chipper wood chips?

The wood chips can be used as mulch for the plants in your garden. This wood waste does an excellent job of keeping the flower bed cool as evaporation is halted significantly.

Due to the high organic matter content of wood chips, they provide nutrients to the plants.

VIII) Do electric wood chippers work?

Of course, they work. The electric wood chippers are great at handling the small branches and leaves. Don’t attempt to use this type of chipper for heavy-duty work as they’ll disappoint you.

IX) How fast is a wood chipper?

The speed of the chipper blades falls between 1000 to 2000 rpm. Of course, this will depend on the capacity of the machine. Once the feedstock has been chipped, the chips exit the device through the chute.

X) What are wood chips used for?

Besides being used as compost or mulch in gardens, wood chips can serve as quality biomass fuel. The wood waste can also be converted into wood pulp – the raw material of the paper industry.

The drum chipper we recommend

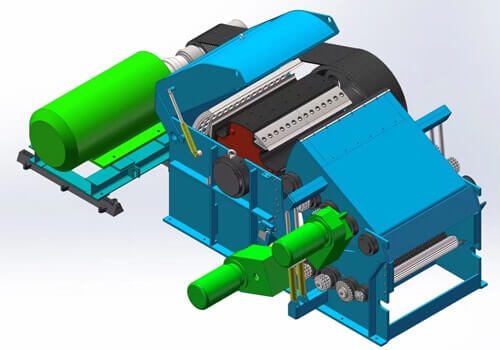

This TCPEL drum chipper has all the attributes of a well-built machine. Its carbon steel frame says a lot about the durability of the equipment.

Depending on the model you opt for, the Tcpel machine can handle feedstock of variable dimensions (230mm to 680mm).

Its feed roller meets these differences in size through the input of the drum chipper’s highly intuitive hydraulic system. Fewer machines are equipped with such innovative technology.

The feed roller’s alloy frame (steel and manganese) gives it increased strength to withstand chipping rigors. No worries about the feed roller becoming redundant after a few tasks.

With this drum chipper, there’s less risk of the feedstock damaging the machine. Its feeding chain conveyor does a great job of ensuring the branches, tree trunks, and others get to the blades in an orderly manner.

This TCPEL machine can handle different sizes of feedstock thanks to its knife roller often loaded with multiple blades. You can choose your preferred blade with the click of a button.

Every chipping action is down to the nature of the blade used, so it’s great to see this chipper is fitted with an H13-based blade. The material is renowned for being resistant to wear and tear.

Compared to its peers, it might be a long time before you have to switch the blades in this Tcpel drum chipper.

Unlike other drum chippers, it’s easier to change and service the chipper blade on the our model. The blades stay sharp for days before they have to be sharpened – and this could be longer if occasionally used.

Considering the many exciting features of this machine, it stands well above the competition. You can expect to do a lot of chipping in the shortest possible time.

Still surprised? Check out this drum chipper through this link.

Advantages Of The TCPEL Drum Chipper

- It’s built to last.

- Uses a unique knife roller

- It’s mechanical and intuitive – few machines have such a pleasant combination.

- Easy to maintain – say goodbye to spending long hours on the maintenance of the drum chipper.

- Equipped with the highest quality blade

Also Read:

Brush Wood Chipper Buying Guide

Talk to An Expert

SHARE THIS POST

Talk to An Expert