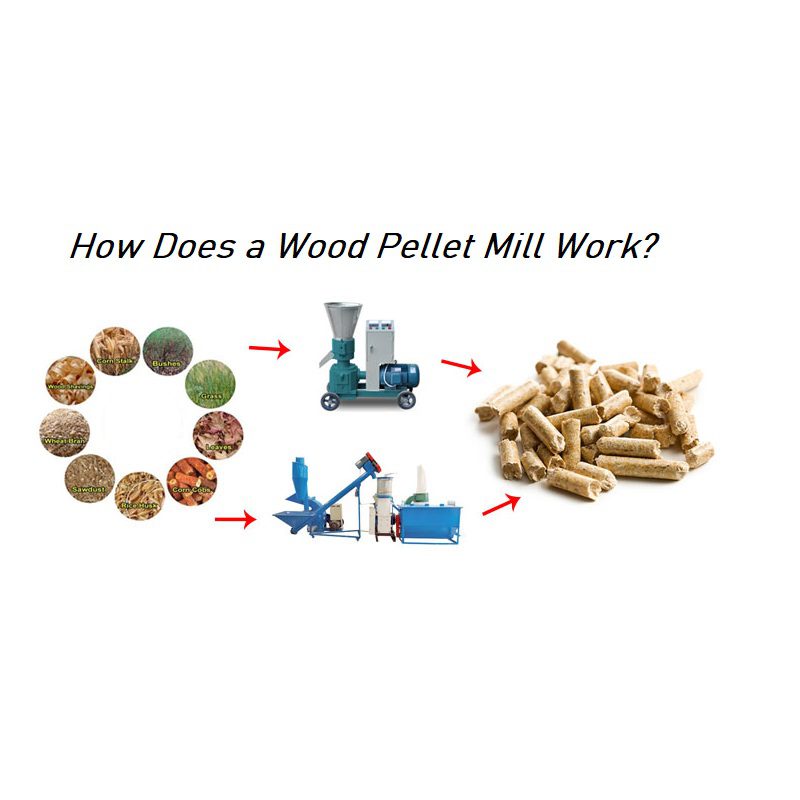

How Does a Wood Pellet Mill Work?

A wood pellet machine is an efficient and cleaner alternative to standard fossil fuels. However, while this eco-friendly process is gaining popularity, many are unsure how a pellet mill works. So, how does this machine work?

This article contains all you need to know about wood pellet machines, from what they are to how they make pellets. Read on to find out more.

What Is a Wood Pellet Mill?

A wood pellet mill, sometimes referred to as a pellet press, is a type of mill that turns wood chips, sawdust, and other powdered raw materials (biomass) into pellets.

The way pellet mills work is the complete opposite of how grinding mills do. Wood pellet machines work by fusing smaller materials to form a single large mass, which is then cut into pellets. However, grinding mills take larger masses and break them down into smaller bits.

While convenient and effective, a wood pellet mill does not run automatically. Therefore, it requires a pellet mill operator, whose job is to make sure that the machine makes the right pellet size and that the pellet is of the highest quality.

Types of Pellet Mills

Although several types of pellet mills exist, there are two main kinds, which are flat die and ring die pellet mills. Here is detailed information about these types of mills.

Flat Die Pellet Mills

Flat die pellet mills are pretty straightforward. Their components include four wheels, an upper cabinet, an engine base, a feed hopper, an electric motor, a gearbox, and others.

One reason why people enjoy using a flat die pellet mill is its adaptability. Thanks to this characteristic, its electric motor can be replaced with a diesel engine to make it a diesel pellet machine. Alternatively, its motor can be switched out for a PTO connector or gasoline engine.

The flat die of this mill has numerous holes; the diameters of these extrusion holes can range from 2.5 mm to 10 mm.

Flat die pellet machines typically come in two types; the die-turned and roller-turned types. The die-turned is portable and has a lower cost, while the roller-turned is bigger and lasts longer. Regardless, both types produce high-quality pellets.

Overall, flat die pellet mills work best for small-scale wood pellets production. This is because they are smaller and more affordable than ring die pellet mills. However, the flat dies require regular replacement because they wear quickly.

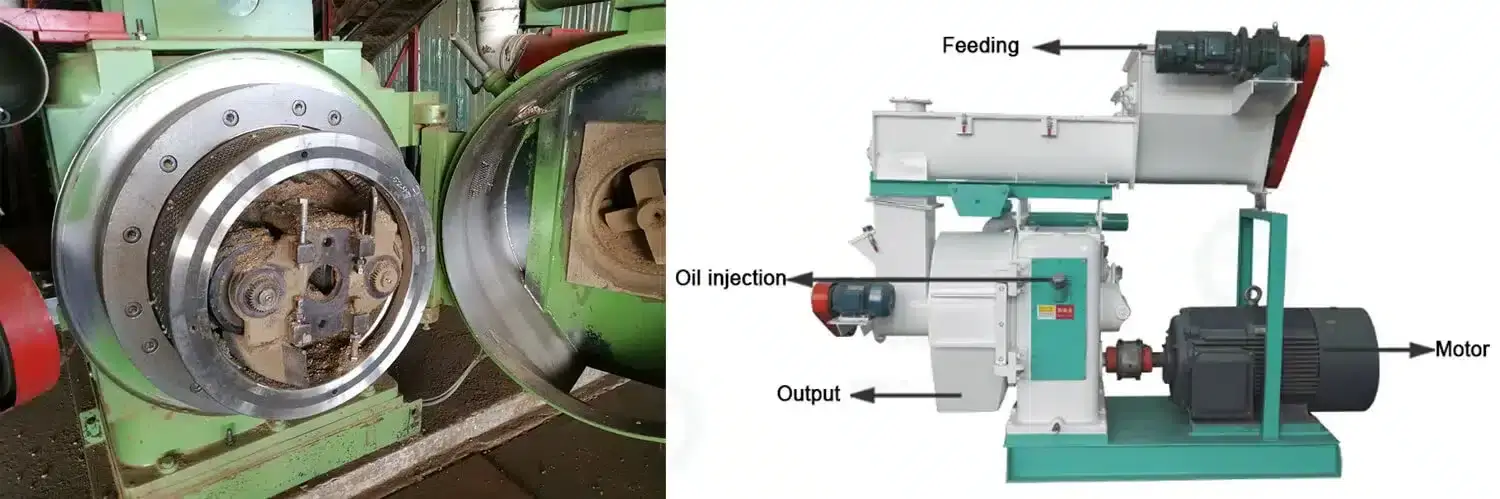

Ring Die Pellet Mills

The ring die pellet machine is made up of a screw feed, electric motor, ring die, conditioner, gearbox, roller, pedestal, ring die, and discharge ports.

There are two types of ring die pellet mills based on the placement of the ring die. These types include vertical and horizontal ring die pellet machines.

On a horizontal ring die machine, the ring die is vertically placed. Thus, when biomass drops from the conditioner, it is force-fed horizontally into the ring die.

Conversely, the vertical ring die machine has the ring die placed horizontally. Hence, the feed hopper is directly above the ring die, meaning biomass falls straight into it.

With a vertical ring die pellet mill, both the ring die and roller rotate, which means the biomass will be distributed evenly.

However, only the ring die rotates with the horizontal die pellet machine. So, the raw materials will be distributed by the screw feeder.

Ring die pellet mills have a high capacity, so they are optimal for large-scale production, with production reaching anywhere from 800 kg to 20 tons per hour. For a better idea of how much production that is, a flat die pellet mill only has a capacity of 100 kg to 1 ton per hour.

Furthermore, the power consumption rate per unit is lower for ring die pellet mills thanks to the higher production.

Keep in mind that ring die pellet machines take more effort for clearance adjustment and typically cost more than flat die pellet mills. In addition, they are heavier and take up more space.

Pellet Mill: How Does It Work

Now that you understand what a wood pellet mill is and the different types, it’s time to learn about the pelletizing process and how pellet mills work.

Pre-Processing of Raw Materials

Before the raw materials can go through the pellet mill, they need to be refined to have a better particle consistency. This means chipping, grounding, or shredding the materials.

In addition, to get the best result from the pelleting process, the material has to have the optimal moisture level, which should be about 15%.

Moisture can be reduced by oven-drying the particles or blowing them with hot air.

Feeding the Raw Material into the Mill Hopper

After getting the proper consistency for the biomass, it is taken to the mill hopper for processing. The mill hopper contains the raw materials and controls the rate at which it enters the mill.

Without the hopper to properly control the flow of the raw materials, the quality of the pellet might be drastically reduced.

Compressing and Forming the Pellets

This is the final stage where the pellet is created. The roller compresses the raw material against the heated die, and the raw materials are squeezed through the holes in the die.

Due to the pressure conditions and high-temperature level (extrusion process), the biomass particles will merge to become a congealed mass (pellet).

Afterward, a blade swiftly slices the mass into a suitable length as it leaves the die. It is important to note that some raw materials merge better than others. For instance, sawdust works exceptionally well for pelleting.

Conclusion

If you are looking to invest in wood pellet mills, then it is vital that you understand how they work. Fortunately, the pelleting process is pretty simple.

The wood pellet mill turns powdered raw materials into pellets using dies and rollers. As the biomass is force-fed through the heated die, it comes out fused as a large mass. This large mass is then cut into an appropriate size using fast-moving blades to make pellets.

So, if you want to take your business to the level using wood pellet mills, then reach out to us today and discover how we can help you achieve your goals using only the best equipment.

Talk to An Expert

SHARE THIS POST

Talk to An Expert