Pellet Line: Everything You Need To Know

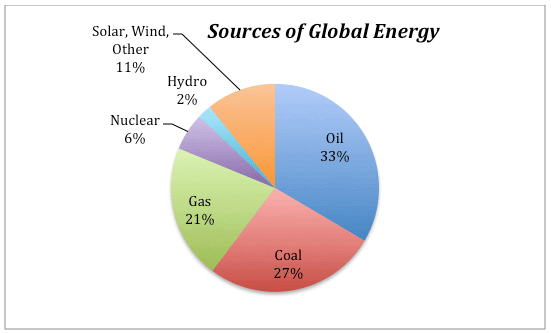

Across the world, individuals, corporations, and governments are reviewing their energy sources and moving towards more sustainable and environmentally responsible options. As long as human beings need heat for cooking and comfort, this quest will continue. However, the earth’s resources are not infinite. Oil, gas, and fossil fuels require enormous effort, money, and time to access. They are also highly polluting and hazardous to health and safety.

One of the answers to this problem is biomass pellets. They are relatively easy to mass-produce, use cheaply available raw materials that are renewable, easy to store and transport, and the residue after burning can be used as fertilizer.

The quest for clean sources of energy is an ongoing one. In many parts of the world, biomass is used extensively for heating and cooking. Many homeowners and businesses have set up small and large pellet lines to produce biomass or wood pellets.

What Is Biomass?

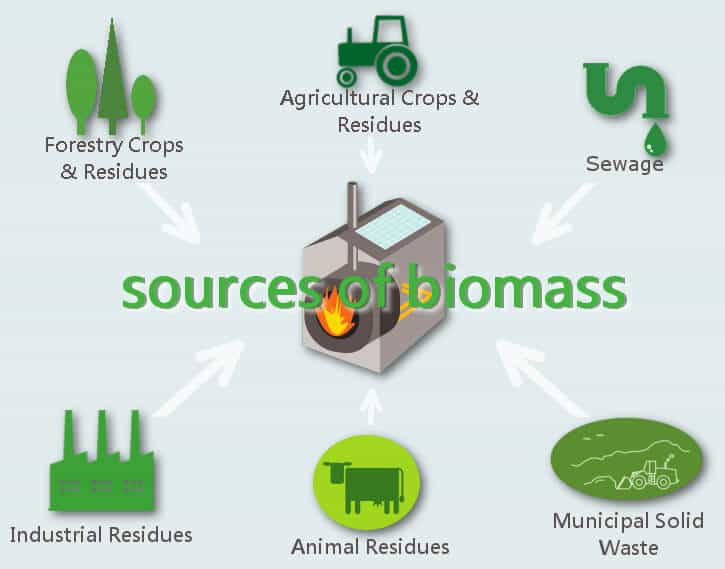

The term refers to any recently dead or living organisms, including plants and animals, and these byproducts. It also includes residues of crops or other biological materials. Plants are living entities that take in carbon dioxide and release it when used for energy. This makes them and other biomass fuels almost completely carbon-neutral forms of energy. Hence they have a lesser impact on climate change and global warming.

Though they have been around almost since the dawn of human history, there is still a lot of misinformation and mystery surrounding biomass fuels. They are not new inventions or a modern form of energy. Animal dung, dry wood, leaves and plants, and timber were used and extensively utilized for energy, heating, and cooking.

Later, humans slowly began switching to other forms of fuel such as ethanol, whale oil, fish oil, and vegetable oils as industries grew around lighting and heating. Pine sap from which turpentine was manufactured was another energy source for lighting. Steam energy was generated with the use of some of these resources. Coal, crude oil, and fossil fuels got a boost with the arrival of petroleum and the invention of the diesel engine.

Green energy movements have come full circle to the advocacy of biomass. Governments worldwide have realized that it is the need of the hour.

Biomass Pellets and Production

Biomass pellets are made from agricultural waste, stalks, straw, husks, coconut shells, sugarcane bagasse, forestry residue, paper/sawmill waste, recycled cotton waste, paper, cardboard, and packaging materials.

The production process incorporates a Biomass pellet production line done by a pellet maker machine. It follows a series of procedures to create equal-sized and shaped, standard weight pellets that can be stored and transported easily.

- Screening, Cleaning, and Sorting: Raw material is thoroughly screened, and metal/stone/sand/debris is removed.

- Drying: The process requires a certain level of moisture, and the raw materials are brought to the desired level of dryness.

- Crushing: The raw materials are crushed into powder form.

- Pellet making: The pellet machine may be of the flat or ring die mold type, based on whether it produces smaller or larger capacity. The crushed raw material passes through the die at high heat and pressure. As it extrudes, it is cut to the desired size.

- Cooling: Pellets must be thoroughly dried and cooled before being packed, stored, and transported.

Pellet Line

Since the production involves several stages, they can be easily and more efficiently combined in a pellet line. A wood pellet production line is a one-time investment that saves you time, money, and effort. It helps to reduce manual labor through automation and can replace the work of 2-3 persons. Higher levels of automation ensure better profits.

Another advantage of a pellet line is that you get consistently good products. Pellet production lines usually consume low energy and are simple to operate and control.

A good quality wood pellet line can handle a range of raw materials without the need for any additives or extra inputs.

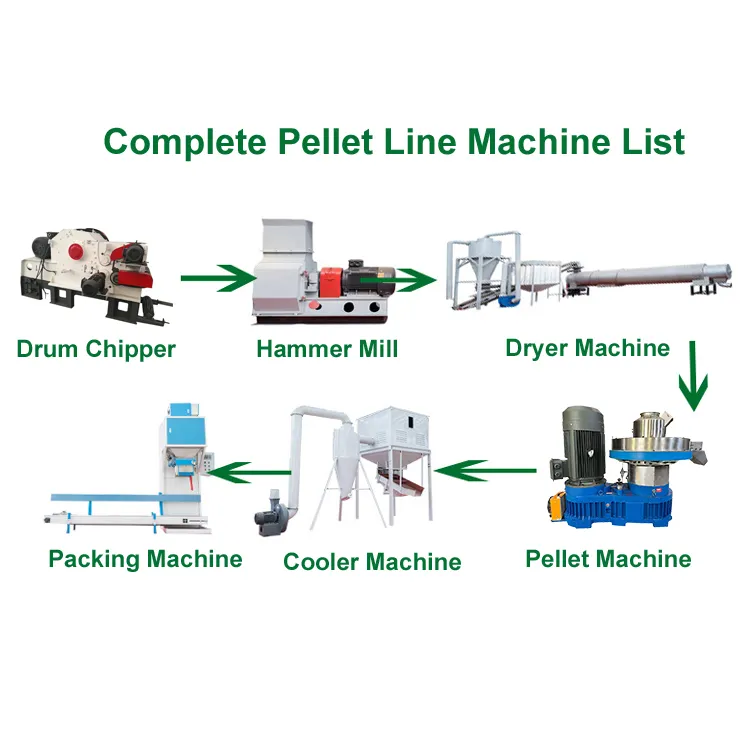

A small pellet line can produce around 200-800 kgs of pellets per hour. This is ideal for smaller or household requirements. This pellet line combines crushing, conveying, drying, pelletizing, and pellet cooling. Different types of equipment are used in a series, and they include hammer mill/crusher, conveyor, dryer, small capacity pellet mill, cooler, and if required, a packaging machine. These machines are fueled by electricity or diesel.

When choosing a pellet line for sale, customers can select all or some of these pieces of equipment based on their individual preferences and budget.

Larger pellet plants are suitable for bigger capacity production by midsized or large-scale farmers who can use raw material from local agricultural waste. These pellet lines can produce up to 1400 kg pellets per hour. However, they require a larger floor area and use more power. They create a lot of noise and need at least one person to be fully employed on the production line.

These plants are arranged to form a pellet line through different production parts. They have electronic control panels for line operation. Pellets are produced by the use of:

- Raw material input conveyor

- Separator and sorter

- Crusher

- Transport to the silo for dust filtration

- Conveyor to die press

- Dust extraction fans

- Extruder and cutter

- Cooling conveyor

- Packaging bag holder

- Sealer

Tips For Choosing The Right Pellet Line

Homeowners and small-capacity pellet producers can upgrade to more commercial operations by creating a sturdy and efficient production architecture.

It’s important to keep some points in mind before you select and purchase a pellet machine and other equipment to form a pellet line.

- Study the process thoroughly and gain first-hand experience before you start your own line

- Analyze the market or household needs

- Firm upon your budget and costs involved

- Understand your source of raw materials and ensure a steady supply

- Evaluate the available space, power source, and convenience of access

- Select the machines according to your present and projected capacity

- Ensure that you purchase products that guarantee after-sales service

- The equipment must be easy to install and simple to operate.

- Purchase good quality equipment that doesn’t vibrate or gets easily damaged. It should be stable and safe for use.

- A multi-use mill can be used for other types of pellet production such as wood pellets, biomass, or feed pellets, as well

Talk to An Expert

SHARE THIS POST

Talk to An Expert