Find The Right Pellet Machine: Buy Pellet Machine

With fuel prices spiraling out of control and the earth reeling under the horrendous effects of pollution, more and more people are looking for alternate energy and fuel sources. Oil, gas, and electricity are slowly reaching the end of their useful lives. As humanity faces the bleak prospects of climate change and global warming, it’s time to look beyond these conventional sources of energy.

Today, the world over, governments and individuals are recognizing the need for more modern, environmentally friendly bio-energy and low-carbon resources. Studies show that in 2020, biomass fuels accounted for more than 4000 trillion British thermal units of energy, comprising nearly 5% of total primary US energy consumption. More than 1,000,000 homes in the US today use wood pellets for heating, in free-standing stoves, for cooking, and use in fireplaces, boilers, and furnaces. Larger institutions such as schools and prisons are also turning to this energy source. It is also used in different industries, transportation, commercial, and residential power functions. Many such users prefer to purchase their own pellet machines to manufacture and manage their own supply more efficiently and economically.

What Are Pellets?

Biomass pellets are made from different types of organic waste materials, agricultural products, and by-products, waste products from different industries. The most common material used is wood and lumber waste. Food product waste, energy crops, untreated lumber and agricultural residue are other products that form the basis of biomass pellet production.

They are made by compacting these materials in special pellet making machines through heat and pressure. Certain international standards regulate the quality and size of pellets regarding density, moisture content, structural strength, low ash, and dust content.

Benefits of Pellet Fuel

Pellets are one of the most convenient, efficient, and easy forms of fuel to purchase, transport, store, and use.

- Source of renewable energy: Biomass from plants/trees/agricultural waste is a renewable resource, so this is a sustainable option.

- High heat: Pellets have a high calorific value making them cost-effective.

- Independent price: Since pellet-fuels are not dependent on fluctuating prices determined by governments and oil companies, pellet prices are relatively stable.

- Minimum emission: Pellets are environmentally friendly since they produce minimum smoke and emission

- Easy Storage: Pellets are available in airtight bags, which are easy to store. You can buy the quantity you need, transport it and store it easily.

- Sustainable: The ash from burned wood pellets can be reused as fertilizer in gardens.

Manufacture of Pellets

Wood pellet makers are available based on the type of output and quality of pellets required. In general, the process that is followed by the machine is standardized, no matter what the amount, size, and quality that is produced. Generally, pellet line consist of a hammer mill, separator, conveyor, mill, scraper, dryer, and collection points. If you have a garden or back yard with trees, plants, fallen leaves, twigs, dry grass, weeds, etc, they can be used as raw material.

Household Pellet Machine: A wood pellet machine that produces pellets suitable for a family or household is also called a Flat Die Pellet Mill. It is a pellet mill with slots that uses a flat die.

- You can purchase the pellet powder in ready-made form and introduce it to the top of the die. Or you can collect raw material from your garden, dry and clean it well, removing mud, rocks, and metal pieces, if any.

- Cut or crush larger pieces with a chipper or by hand.

- Start feeding the bits into the machine. If you’re using ready-made sawdust, you can feed this into the machine according to the instructions given on the package.

- As the machine rotates, a roller squeezes the powder under pressure through the slots in the die. Simultaneously, a cutter at the other end chops the ends of the pellet into the right size as it emerges from the slot.

- Pellets must be thoroughly cooled and dried before they are stored. Otherwise, they will not burn properly and disintegrate back into powder form.

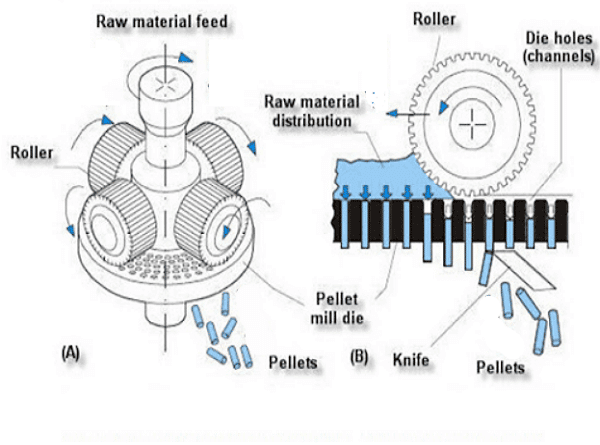

Ring Die Pellet Machine: A more sophisticated pellet maker is needed for larger quantities. This is known as a ring die, pellet maker. It is a high-capacity machine that produces anything between 800kg and 2 tons of pellets per hour. Ring die pellet machines are larger, require more space, and are much more expensive than the household or flat die machine. For quantities smaller than 800kg, it’s wiser and more economical to use a flat die machine. However, if you run a pellet-making business, you would rather invest in a large capacity machine like this one instead of smaller and less economical ones such as the flat die machine.

The ring die machine is more complex than the flat die:

- It comprises a screw feeder, roller and ring die, conditioner, electric motor, discharge portal, gears and gearbox, and pedestal.

- In this, the raw materials are mixed with vapor or oil, which help to bind the materials together more firmly.

- The dough is pressed against the sides of the ring die and pressed through the holes.

- The pellets are formed under high pressure and temperature according to the size and amount required.

- Initially, they emerge as long sticks, and they are cut to size by a cutter installed just outside the ring die.

- The formed pellets then fall into a tray and are thoroughly cooled and dried before being stored.

Additionally, other machines include the mobile pellet plant that can be moved if required. It has a small footprint but a large capacity for biomass pellet production. Smaller and larger pellet plants can also be purchased if you’re going into commercial production and starting a wood pellet-making business.

Important Tips

- While purchasing a pellet-making machine, it is important to first analyze your goals and needs thoroughly.

- Access to raw material is the next item on your list. If you don’t have easy access to either organic or natural raw material, you should purchase ready-made material at a reasonable price.

- The space and location of your pellet machine have to be evaluated so that you purchase the right type of machine.

- Ensure that the manufacturer or dealer offers post-purchase support.

- If you plan to set up a commercial business, do a detailed market survey so that you can offload your produce easily.

Talk to An Expert

SHARE THIS POST

Talk to An Expert