Ring Die Pellet Machine or Flat Die Pellet Machine?

A lot of consumers are interested in making their own pellets. There are many reasons for this, including the fact that it can save them money, help the environment and provide them with a great hobby. When people start to look into buying a pellet machine, they may feel overwhelmed by the number of options available. While it is important to choose a pellet mill that meets your needs, it is also important to understand what makes the different machines unique and which one is right for you.

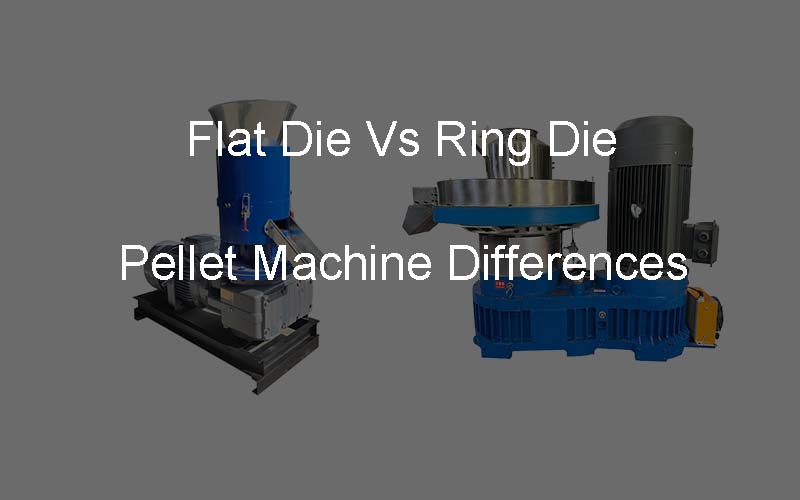

To make high quality wood pellets, we need to select appropriate pellet machine. The selection of pellet machine depends on many factors, such as the nature of raw material, the scale of production and so on. Generally speaking, there are 2 kinds of pellet machine in the market: flat die pellet machine, ring die pellet machine. Although these two types of pellets machines have similar working principle and structure, they have some differences in their details.

What is flat die pellet machine?

Flat die pellet machine is a kind of small pellet machine that can process the agricultural wastes, wood processing wastes and animal feed materials into pellets. Flat die pellet machine is a small scale pellet mill used in small businesses, farms or at home. If you want to make your own feed pellets or biomass pellets, flat die pellet machine is a good choice.

The flat die pellet mill was the first type machine to be used for the production of wood pellets. It has been around for decades and is still being used today. While this machine is not as refined or efficient as the ring die pellet machine, it is still widely used among small scale manufacturers today. The common usage of the flat die pellet machine is to produce organic fertilizer pellets. But you can also apply it in the livestock feed production, or create some wood pellets with it.

How flat die pellet machine works ?

The flat die pellet machine is composed of a press roller, a feeder and the electric motor. The press roller and the die are pressed together closely. The raw material is fed into the machine from the feeder hopper. The main working principle of the flat die pellet machine is that it puts the powdery feed into the press roller and the rotary mold through the feeder, and then the raw material is extruded from the die holes in a cylindrical shape under high pressure. At this time, if there are two or more layers of dies, there will be multiple layers of pellets at one time. After extrusion, pellets pass through a series of sieve plates arranged on both sides. There are also several small holes on these sieve plates. These small holes can separate pellets from powdery materials in order to ensure that only pellets leave from the outlet.

What is ring die pellet machine?

A ring die pellet machine is a machine for making pellets of solid biofuel. It is usually used in the pellet mill to produce wood pellets, sawdust pellets, straw pellets, grass pellets, alfalfa pellets and other biomass fuel pellets.

The first ring die pellet machine was introduced in 1960s in Germany. But it did not attract people’s attention at first. With the development of livestock industry and the growing need of high quality feedstuff, the using scope of ring die pellet machines has been enlarged gradually.

Ring die pellet machine is generally used for large scale production line of pellets which are mainly used for industrial use or the raw material of biomass fuel plant.

How ring die pellet machine works ?

The main working parts of the ring die pellet machine are a ring die and a set of rollers. Ring dies are usually made of alloy steel or stainless steel and have many small holes on it, while the rollers are cylindrical bodies. The feed enters the ring die through the feed hopper. The rotating roller rotates to squeeze and press the feed between the two rollers and the inner wall of the ring die. The pressure in this process is very large, reaching 15-25 MPa, so that the feed becomes very dense and has a certain strength, which does not break during transportation and storage. The density of feed pellets produced by flat die pellet machine can be 1.0g/cm3, while that of ring die pellet machine can reach 1.3g/cm3. The moisture content of raw materials before granulating is 13-15%, after granulating it will be 3-4%. When using pellet machine to make biomass pellets, users should ensure that they have sufficient power supply capacity and sufficient force to ensure stable operation.

Ring Die Pellet Machine or Flat Die Pellet Machine?

Capacity: The capacity of flat die pellet machine ranges from 50kg/h to 400kg/h, while the capacity of ring die pellet machine is over 800kg/h. So if you have a large scale factory and need higher output, the ring die pellet mill is the better choice.

Raw materials: Flat die pellet mill can only process soft biomass materials like sawdust, straw, grass and etc., while ring die type can process both soft and hard biomass materials like sawdust, grass, peanut shell, stalk and etc.

Quality: The quality of pellets produced by flat die pellet mill is slightly lower than that by ring die pellet machine because flat dies are less able to handle high pressure than ring dies. However, they are still good enough for domestic usage!

Application:The flat die pellet machine is suitable for small scale pellets production, what’s more, it is very convenient to move it from place to place, The ring die pellet machine has a larger capacity than flat die pellet mill. It is usually used for large scale pellets production line, which requires high automation level and large output capacity.

Price:ring die pellets mill price is higher than flat die pellet mill price by thousands dollars on average.

Conclusion

When it comes to picking the right pellet machine, choice can be a bit overwhelming. The key is determining your needs. Do you want something large scale, or do you need something more portable? Do you require specialty pellets for a particular use, or are you just getting into the hobby? These questions can help narrow down your options, but ultimately the best way to buy the perfect pellet machine is by considering price and reading reviews of different models. Neither one is better or worse than the other; they only fill different market niches. Ultimately, you will want to choose between them based on your specific needs as well as your budget.

Talk to An Expert

SHARE THIS POST

Talk to An Expert