Advantages of Sand Dryer & Stone Rotary Dryer

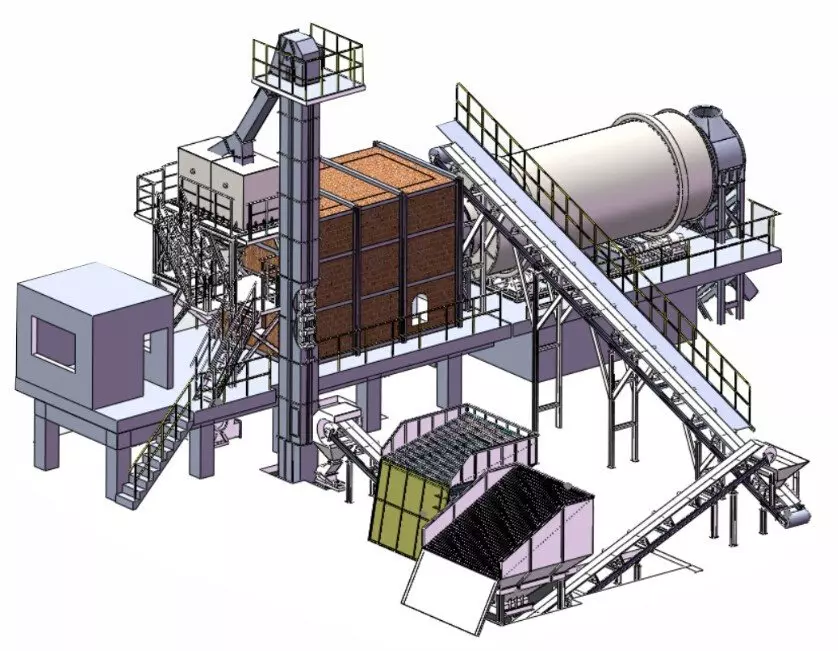

An industrial rotary dryer has been used in several industries. And the sand and stone mining industry is no exception. From the extraction of material to the end product, drying is a crucial process in mining. And the sand dryer and stone rotary dryer facilitates this process conveniently.

The blog discusses the versatile role of sand dryer and stone dryer. Also, you will learn how to choose a perfect rotary drying machine.

Rotary Dryer Applications in Mining Industry, Sand Dryer and Stone Rotary Dryer

While the mining of sand and stone relies on numerous machines for different operations, the rotary dryer has an important role. It eliminates moisture content from sand & stone so that people can use them for other applications.

Let’s quickly learn about situations when people use sand dryer and stone rotary dryer.

Drying of Stone Aggregates

In the stone mining industry, stone aggregates like basalt, limestone, etc., need drying at a certain stage. The use of a rotary dryer helps individuals eliminate the required moisture content in comparatively less time.

Drying of Wet Sand

Encountering wet sand during sand mining operations is a common scenario. Sand dryer can help you dry sand before processing it for blending, sorting, or screening. The drying process evaporates the moisture from sand, making it suitable for transporting.

Drying of Sand as Construction Material

Sand is a primary material used for building construction. Individuals use it for plastering, bricklaying, and other applications. However, for each application, it needs a specific moisture content. A sand dryer is the most suitable machine to ensure optimal moisture content.

Drying of Silica Sand

People associated with the mining industry know the importance of silica sand. This sand needs proper drying before you bring it into use.

Since mining companies need to dry silica sand in bulk, using a silica sand dryer is a suitable choice.

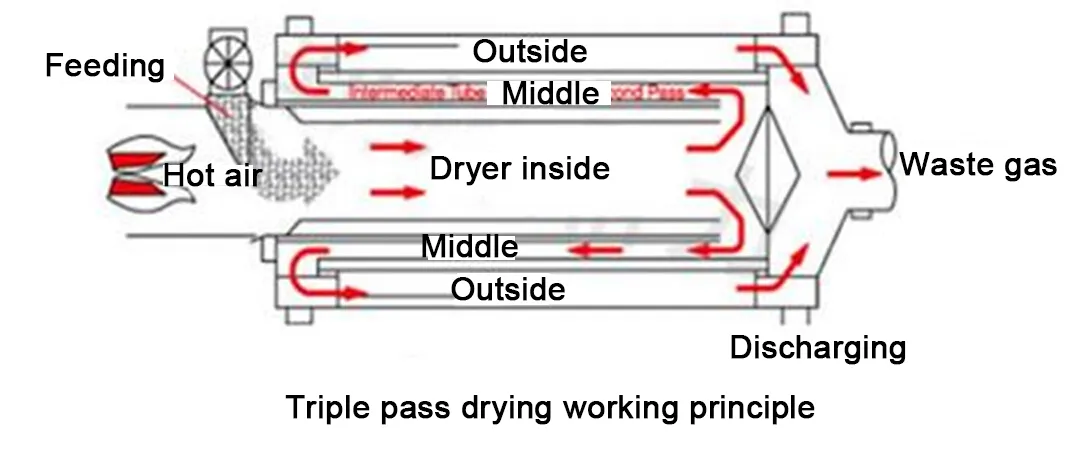

What’s the complete sand drying process ?

When drying sand, the triple pass rotary dryer is widely used. The so-called triple pass dryer is a high-efficiency dryer equipment with three-layer heat insulation effect and a circulating self-insulation structure, that is, a high-efficiency combined dryer, which adopts a new European energy-saving technology-a mosaic structure. The three cylinders are reasonably inlaid according to a certain mathematical relationship, which effectively prevents the dissipation of heat, and the utilization rate of its calorific value can reach more than 90%. It is a kind of industrial drying equipment with a high utilization rate of heat energy at present. The main advantage is that the heat preservation effect is better than that of the traditional single cylinder dryer. This dryer forms a self-insulation cycle structure by the inner cylinder, the middle cylinder and the outer cylinder, which has higher working efficiency, more energy saving, environmental protection and stability.

The triple pass rotary dryer is used to dry raw materials such as yellow sand, river sand, machine-made sand, quartz sand, slag, fly ash, mineral powder, etc. Gas, alcohol-based, biomass and other fuels.

The drying material (sand) is firstly fed evenly to the belt conveyor through the feeding hopper and disc feeder, then the sand is transported by the belt conveyor to the sand flow pipe which passes through the hot air furnace, and then the sand enters into the cylinder of the main machine of the three return journeys through the sand flow pipe. First of all, the sand reaches the inner cylinder of the three-way first, and under the action of the fixed mixing impeller and forward rotating blade in the inner cylinder, the sand is pushed forward very quickly and reaches the other end of the three-way, which is a return journey. The inlet port of the inner cylinder is small, and the outlet port is large, which is favorable for the material to be pushed forward. The size of the inner cylinder is large, and the lifting plate lifts up the material sufficiently to form a uniform material curtain, which is favorable for the contact between the material and the hot air, so as to take away the moisture.

The material arrives at the other end by the baffle gear back to the middle cylinder, in the discharge port end, the middle cylinder is slightly longer than the inner cylinder with the baffle, also under the action of the rotary blade, the sand in the middle cylinder is rotated back to the inlet end, which is the second return; in the middle cylinder material is from the large mouth discharge end to the small mouth inlet end of the flow of the material. Because the middle cylinder is slightly shorter than the outer cylinder at the feeding end, coupled with the role of the outer cylinder forward rotating blades, the sand enters into the outer cylinder and is pushed forward in the third return;

At the discharge port, the middle cylinder back gear plate and the outer cylinder are set vertically with steel plate, which can effectively make the sand dispersed and discharged, and there are dust removal and exhaust port supporting the discharge port, so that the moisture and part of the dust can be discharged and filtered, and the sand can reach the moisture content demanded by the users after the three backward frying and turning and drying, and the dry sand is finally transported to the finished product silo through the belt conveyor.

Special note: the internal structure of the three return dryer is particularly important, the design requirements need to make the material can be fully lifted and spread, conducive to the full heat exchange with the hot air, in order to improve the output and drying effect. The output of the three return dryer is closely related to the initial moisture of the material, final moisture, sand particle size, heat source, induced air and other factors.

Triple Pass Rotary Dryer Advantages for drying sand

1. The investment required for the triple pass dryer is about 20% of that of imported products. It is made of 16Mn steel plate, and its service life is about 3-4 times longer than that of ordinary steel plates.

2. The initial moisture of the material is 5-25%, and the final moisture is guaranteed to be below 0.5-1%. The triple-pass rotary dryer is the ideal choice for various drying projects such as the cement plant slag powder dry powder mortar production line.

3. Compared with the traditional single pass dryer, the thermal efficiency is increased by about 40%, and its thermal utilization rate is about 90%.

4. The fuel can be white coal, bituminous coal, coal gangue, oil and steam. It can dry lumps, granules and powder materials below 20-100mm.

5. Compared with the single cylinder dryer, it reduces the occupied area by about 50%, reduces the civil construction investment by about 60%, and is more convenient to install and operate.

6. There is no air leakage phenomenon, which completely solves the difficulty of sealing.

7. The discharge temperature is less than or equal to 60 degrees, and it can be directly fed into the warehouse without cooling in the cooling shed.

8. The temperature of the outer cylinder is ≤60 degrees, the temperature of the exhaust gas is less than 120 degrees, and the service time of mature dust removal equipment is more than 2 times longer.

9. The coal consumption is about 1/3 of that of the single cylinder dryer, the electricity saving is about 40%, and the natural gas consumption per ton is less than or equal to 10 cubic meters.

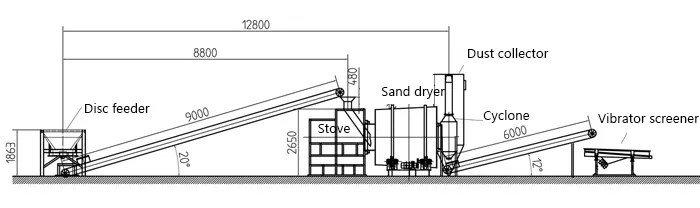

Installation and commissioning of triple pass dryer

1. The installation of the dryer should be carried out in strict accordance with the requirements of the upper assembly drawing and the basic drawing. Before the installation of the dryer, its parts and auxiliary parts should be checked, wiped, cleaned and complete.

2. Since the sand dryer is a long and large-scale equipment, it should be installed in this order and method:

(1) Draw the base line: Correctly make cross lines and elevation lines on the base mark plate, and embed the center mark plate to achieve convenience and accuracy, and consider that the machine base will not be covered after installation. the

(2) Install the base and the tugboat: Level the position of the pad iron, draw the center line of the base and the tugboat, find out the installation position of the base and the tugboat according to the requirements of the drawing, level and place it, and first grout the foundation hole until the concrete reaches a certain level. When the strength is high, tighten the anchor bolts, and install the cylinder after the recheck is qualified.

(3) Install the cylinder and the rolling ring: first install the rolling ring on the cylinder, and the concave joints required for fixing should be arranged in a positive and negative staggered manner, and adjust the thickness of the shim to make the contact between the rolling ring and the concave joint Keep the corresponding gap, do not be consistent, and spot weld the concave joint bolt head and the cylinder body.

(4) Install the large gear: Before installation, check that there are no collision marks on the interface of the docking surface, clean the contact surface between the large gear and the cylinder, and then carefully align the two halves of the gear and tighten the interface bolts, then install the large gear on the on the barrel. Rotate the cylinder, check the radial runout and lateral swing of the large gear until the adjustment is qualified.

(5) Install the pinion, reducer and motor: According to the installed large gear, adjust the meshing parameters of the large and small gears to meet the requirements of the equipment, and fix the positions of the pinion and the reducer motor. the

(6) Install the gear cover: make it evenly spaced from the edge of the gear. the

3. After the above work is completed, carry out secondary grouting, and the requirements for grouting should be carried out in accordance with the relevant regulations of civil engineering design. The installation review and commissioning work related to grouting are carried out simultaneously to ensure the installation quality of the dryer.

Triple pass sand rotary dryer maintenance

The maintenance of the triple pass sand dryer equipment is an extremely important and regular work. It should be closely coordinated with the operation and maintenance of the equipment, and there should be full-time personnel on duty for inspection.

1. The bearing bears the full load of the machine, so good lubrication has a great relationship with the life of the bearing. It directly affects the service life and operating rate of the machine. Therefore, the injected lubricating oil must be clean and the seal must be good.

The main oiling places of this machine are (1) rolling bearings (2) roll bearings (3) all gears (4) movable bearings and sliding planes.

2. The newly installed hoop is easy to loosen and must be checked frequently.

3. Pay attention to whether all parts of the machine are working normally.

4. Pay attention to check the wear degree of wearable parts, and replace worn parts at any time.

5. The plane of the bottom frame where the movable device is placed should remove dust and other objects to prevent the movable bearing from moving on the bottom frame when the machine encounters unbreakable materials, resulting in serious accidents.

6. If the bearing oil temperature rises, stop the machine immediately and check the cause to eliminate it.

7. If there is an impact sound when the rotating gear is running, it should be stopped immediately for inspection and eliminated.

Why Invest in Rotary Dryers to Dry Sand & Stone

In different industries, drying sand and stone is a crucial process. While there are several traditional ways to remove moisture from these two, a rotary dryer is the most preferred option for industrial applications.

Let’s explore some advantages of employing a sand dryer and stone rotary dryer.

Super Drying Efficiency

Industrial rotary drum dryers are known for their high efficiency. They release hot gasses that dry the material 360 degrees. As a result, the machine gives uniform drying all over the material.

The source of heat can be coal, oil, or gas, depending on the type of dryer you buy. The sand dryer features a rotating drum that ensures material gets heated and dried from all directions.

The revolving tube of the dryer creates a cascading effect ensuring proper heat transfer and moisture removal.

Minimal Maintenance Cost

Less maintenance is another primary reason industries engaged in mining prefer rotary dryers over other sand and stone drying mediums.

Although a rotary dryer is a large-sized machine, it is easy to maintain. Moreover, you won’t require a significant budget for its maintenance.

If you invest in a modern, feature-rich rotary dryer, it would require less maintenance comparatively. It has a built-in lubrication system that automatically greases the filtration and an injection system.

Nowadays, sand dryer and stone rotary dryers have automatic monitoring and control systems to ensure the proper operation of the machine.

Energy Saving

Rotary dryers are not only easy to maintain but also energy-efficient. Unlike traditional drying methods, they optimize heat transfer and consume minimum energy.

Since the machine ensures perfect contact between material and heat, it reduces energy wastage. In the long run, these small savings become a significant cost saving.

Improvement in Product Quality

Using a rotary dryer to dry sand or stone improves quality in several ways. It lets you control the moisture content precisely.

You can keep the moisture level of sand and stone depending on their intended applications, such as brick-making, asphalt production, etc.

The good thing is that the rotary dryer’s drying process does not cause harm to the integrity of stone and stone elements.

How much it cost to dry 1ton wet sand?

The cost of drying 1ton wet sand varies according to the moisture content and the fuel used, and also the sand dryer efficiency. Today we have listed 3 common fuels for example: raw coal, natural gas and biomass pellets, to explain to you the cost of drying 1 ton sand,

The initial moisture of 1ton wet sand is calculated as 30%, and the final moisture is calculated as 8%. The evaporation of one ton of sand is 220kg.

1. Raw coal with a combustion value of 5000 kcal can evaporate 9 kg of water per kg of combustion. If it needs to be dried to remove 220 kg of water, 24 kg of raw coal is required. If the price of raw coal is $140/ton, the total drying cost is $3.36 .

2. Natural gas with a combustion value of 8700 kcal can evaporate 17 kg of water per cubic meter of combustion. If 220 kg of water needs to be dried, 13 cubic meters of natural gas will be consumed for drying. The price of natural gas per cubic meter is about US$0.18, and the total drying cost is about US$2.34.

3. Biomass pellets with a combustion value of 4000 kcal can evaporate 7 kg of water per kg of combustion. If 220 kg of water needs to be dried, drying will consume 31 kg of biomass pellets. If the price of biomass pellets is US$170/ton, the total drying cost is US$5.27.

Below is our summary of the cost of different fuels for drying 1ton wet sand for your reference. You can calculate according to your local cost

30% initial moisture content, 8% final moisture content, to dry 1ton wet sand, the Evaporation is 220kgs | ||||

Fuel | Burning Calorific | Unit Cost | Consumption | Total Cost |

Coal | 5000kcal | $140/TON | 24KGS | $3.36 |

Natural Gas | 8700kcal | $0.18/CBM | 13CBM | $2.34 |

Biomass Pellets | 4000kcal | $170/TON | 31KGS | $5.27 |

How many tons of wet sand need to be dried to produce 1 ton of dry sand?

If the initial moisture is 30% wet sand and the final dry sand moisture content is 8%, then 1.28 tons of wet sand is required to get 1 ton dry sand using a sand dryer.

How to Choose Rotary Dryer for Drying Sand & Stone

Consider Your Drying Requirements

Consider the amount and type of sand and stone you will be drying. It will help you choose the specification you need in your rotary dryer. Also, you can decide the size of the machine you want.

Choose the Machine’s Features

While various types of rotary dryers are available in the market, get the one that is best for you.

The machine should be capable of bearing the coarse nature of stone and sand. Ensure it features a lifting plate to move the wet sand inside the rotating drum to dry it with hot air. Also, check for speed and drying intensity controller.

Safety Features

The rotary dryer must have basic safety features, such as an emergency stop button, a transition tube between the hot blast stove and dryer, overload protection, and more.

Besides this, you can also look for features like drying temperature monitoring, ventilation monitoring, and electrical safety.

Learn the Maintenance Requirement

Maintenance alone can be an enormous investment in the long run. Therefore, look for the rotary dryer model that supports easy inspection, cleaning, and maintenance.

Look for the Right Supplier Partner

Remember, if you have chosen the right sand dryer manufacturer, you have won half of the battle. Working with a reputed manufacturer/supplier is crucial. It ensures that you will get a dryer meeting different quality standards.

Evaluate the manufacturer’s reputation by reading their reviews and analyzing their track record. Get an insight into their after-sales service.

A reliable manufacturer helps you with the setup and maintenance of the dryer.

If you do not know how to buy a perfect rotary drum, read the buying guides.

Final Words

So these are some possible usages and advantages of using a rotary dryer to dry sand and stone. We hope this guide helps you choose the perfect rotary drying machine for your sand and stone mining business.

Talk to An Expert

SHARE THIS POST

Talk to An Expert