Sawdust Dryer – The Ultimate FAQ Guide

Are you looking to integrate an efficient drying system that speeds up the drying process?

In that case, sawdust dryer machine can be the best solution.

This ultimate FAQ guide about sawdust dryer will help you understand the functionality, choosing the best quality and the right manufacturer.

So, let’s not waste more time and explore the guide below:

Table of Content

What is Sawdust Dryer?

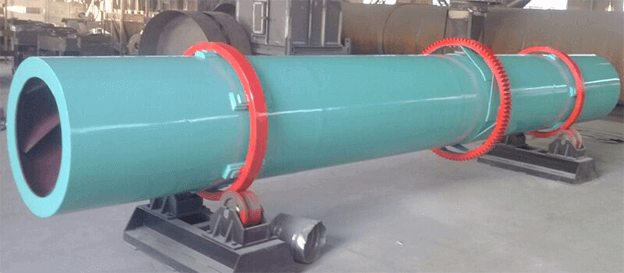

A sawdust rotary dryer is defined as a particular type of drying equipment used to design biomass material.

It is one of those devices implemented to treat the biomass material in large wood pellet plants and factories that deal with charcoal briquette factories.

When treating solid raw materials like wood pellets or materials having good flowability, a sawdust dryer is the best option.

The majority of the industries maintain the moisture content in wood pellets at a ratio of about 8 to 17%. Thus, the wood sawdust dryer is used to maintain this ratio.

Furthermore, the wet wood particles are transferred into the drum with the help of a screw conveyor, where they are exposed to high heat flow.

The subjected high heat flow with a substantially high speed plays the leading role in drying off all the moisture in the wood contents.

What are the Applications of Sawdust Dryer?

The common applications of small sawdust dryer or sawdust flash dryer are listed as under:

- Burning of the wood content is related to the use of a sawdust drum dryer

- It helps to let the wood content produce sparks while burning them through the collection bag

- It helps to produce biomass materials with a high combustion value

- The optimized working structure increases the drying efficiency in many industries

- It speeds up the drying process of the sawdust

- It is used to make the drying process of wood pellets a clean mechanism

- These machines are also used to manufacture the highest quality of artificial boards

- Sanitary ware and interior decoration pieces are also manufactured with the sawdust dryer machine

- The majority of the manufacturers treat the worse slag with the highest quality of sawdust dryer machine

- Other than this, high humidity materials are treated with the help of this device

- Many different wood materials, including wood chips, bamboo shavings, and wood shavings, are treated with a sawdust drum dryer

- This machine is also mainly used to treat the wood pellets that are implemented in the mill for the processing of wood contents

- Almost every sawdust dryer manufacturer tends to produce this item for better combustion activity of the wood pellets and shavings

- A wide range of fiber materials are also treated with the help of sawdust dryer machines in many industries

How Does a Sawdust Dryer Work?

The sawdust dryer machine works on the principle of two-time heat circulating system.

It helps to strengthen the heat and mass transfer rate while drying out the wood pellet materials.

Thus, the working mechanism of the sawdust dryer is used to dry off almost 50% of the moisture content from the biomass materials.

When the wet sawdust enters this device through an opening called a feeding hopper, these contents are mixed with the extremely hot air inside this machine.

The feeding hopper of the sawdust dryer pushes the material into the rear end of the machine, which is known as a spiral shoveling plate.

The rear end of the machine is known for rotating the wooden content under the action of gravity.

However, at the same time, the dried material is then taken up with the help of the shoveling plat, which is present on the upper portion.

Furthermore, the hot air flow is blown through the passing material to take the moisture from it.

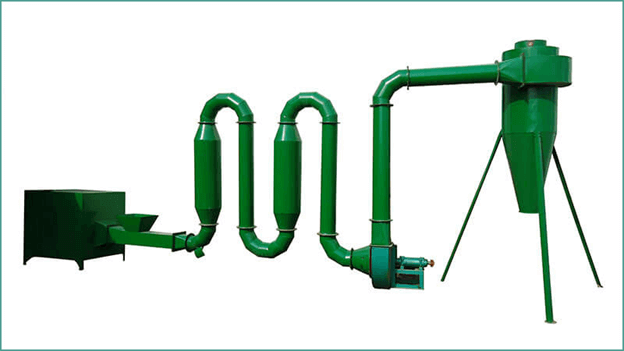

There are some curved paths or pipes inside this machine which led the material to pass through the cyclone-like structure.

The biomass material is then passed into the hot air pump, where the water vapors are taken away, and the dried materials are then released from the outer part of the cyclone in the sawdust dryer.

Different models of the sawdust dryer machine have other working mechanisms, but the overall working principle for this machine to remove the moisture from wood contents remains the same.

Not only this, but the working of the sawdust dryer also depends on its features.

What is the Structure of Sawdust Dryer?

A sawdust drum dryer is a pretty concise machine used to take off the moisture contents of the sawdust.

However, there are many essential parts in the structure of the sawdust dryer machine. Some of these parts include:

- Hot Wind Stove

It is an important part of the structure of the sawdust dryer machine. It helps to expose the heat to the wood pellets to absorb the moisture content from them.

- Material Feeder

This part of the sawdust drum dryer structure is used to retain the material contents where they are subjected to high heat.

- Drying Pipe

Besides the hot wind stove, the material contents of the wood pellets are also passed through the drying pipe, where further absorption of the moisture is carried out.

- Dying Cyclone

This part of the sawdust dryer machine is used to rotate the material contents in all directions to ensure the moisture’s proper absorption.

- Cyclone Separator

Another essential part of the small sawdust dryer is the cyclone separator, which separates the dried material.

- Controlling System

Last but not least, part of the sawdust dryer system is known as the controlling system that is responsible for maintaining the speed of the equipment.

Tcpel is one of those manufacturers that support the continuous supply of the different parts of sawdust dryer machines.

How to Use a Sawdust Dryer?

Some important instructions to use a sawdust dryer properly are given as under:

- Carry out the installation of the sawdust dryer machine in a well-defined way

- When using the sawdust dryer, make sure about the proper rotation and no leakage of the material in the machine.

- Rise the temperature of the hot windmill of the sawdust dryer to about 150 degrees centigrade

- Start feeding the wet sawdust in the machine once the desired temperature is reached.

- Make sure to select the appropriate moisture hot air temperature of the device.

- Try to adjust the air volume of the fan before using it to remove the moisture from the wood pellets.

- Don’t forget to tighten the dryer patrol to avoid leakage during its working.

- Make sure to install a bag filter in the device for dealing with the exhaust gas dust content.

How to Choose the Best Sawdust Dryer for Pellet Production?

You can choose the best and most demanded sawdust dryer for pellet production by acting on the following instructions:

- Check the Marking Speed

A wide range of small sawdust dryers is known for their speed. That is why it is suggested to make sure about choosing the item that supports the wood pellets’ high marking or drying speed.

- Look for the Price

Sawdust dryer price is one of the major concerns of the buyer when they are on their hunt for a reliable sawdust drier. Thus, try to evaluate your budget before getting your hands on this device.

- Check the Design of the Sawdust Dryer

As discussed earlier, there are many options for the best sawdust dryer design. Try to invest your money in the equipment that comes with R&D technologies.

- Durability Over All

You don’t have to spend your money on purchasing the highest quality of sawdust dryers. But make sure to purchase a product that lasts longer than usual.

- Availability of Features

The purchased sawdust dryer must be available with all demanding features such as an efficient drying mechanism and a higher working speed.

- Select the Best Manufacturer

Another essential factor to keep in mind when selecting the right type of sawdust dryer machine, always to choose the right manufacturer. Tcpel can be the best choice in this regard.

How to Maintain a Sawdust Dryer?

You can maintain the sawdust dryer by following the given steps:

- Make sure to lubricate all bearings of this drying equipment since they are responsible for controlling the load of the machine

- Check the proper working of different parts in the sawdust dryer machine

- Don’t forget to regularly check the newly installed tires of the sawdust dryer

- Stop the working of the sawdust dryer when the temperature of the oil increases

How to Dry Sawdust?

You can use the sawdust dryer machine to dry the sawdust in an efficient and fast manner.

The highest quality of sawdust dryer machines takes about 7-8% moisture content from the wood pellets.

The sawdust is slowly fed from top to bottom in the machine, thereby leading to the production of the dry contents of wood.

Talk to An Expert

SHARE THIS POST

Talk to An Expert