Wood Pellet Manufacturing – The Ultimate FAQ Guide

Are you thinking of getting yourself a new source of heat in your home during winters?

Or are you wondering about getting a reliable fuel source for your renowned industry?

If these are your major concerns, you have landed on the right platform so far!

After comprehensive research, we have compiled the commonly asked questions about the wood pellet manufacturing and wood pellet manufacturing plant.

So, let’s explore the below guide without any further ado!

Table of Content

- Are Wood Pellets Renewable?

- Which Industries Use Wood Pellets?

- How Much Does a Ton of Wood Pellets Cost?

- How Do You Make Wood Pellets Out of Wood Chips?

- What Type of Wood Are Wood Pellets Made Of?

- What Machine is Used to Make Pellets?

- What is a Pellet Mill Machine?

- How Does a Wood Pellet Mill Work?

- Can You Make Wood Pellets from Leaves?

- What Keeps Wood Pellets Together?

- Is Selling Wood Pellets Profitable?

- How Do You Make Sawdust into Pellets?

- How Much Sawdust Makes a Ton of Pellets?

- Which Industries Use Wood Pellets?

- Are There Any Harmful Chemicals in Wood Pellets?

- Why Is There a Shortage of Wood Pellets?

- How Long Does 10kg of Wood Pellets Last?

Are Wood Pellets Renewable?

Yes, almost all wood pellets are pretty renewable. Scott Pruitt, also known as the administrator of EPA, has now revealed that wood pellets are entirely renewable.

Similar to many other sources of energy such as solar systems or wind-driven energy systems, wood pellets are now regarded as the most efficient yet renewable type of energy.

Trees are naturally regenerated when the previous ones are cut and used as fuel.

So, if you burn out the old trees and plant new fresh trees in their place, the process isn’t harmful or less beneficial.

Wood pellet manufacturing plant in every state has taken the benefit of renewable source of energy to run their processing.

Which Industries Use Wood Pellets?

Fuel generating industries and domestic places are the two commonest industrial places where wood pellets are mainly used to meet the energy value.

In industries associated with wood pellets, they are used as the primary fuel source, with the processes having low thermal value. The low thermal value of this fuel in this industry isn’t associated with the high greenhouse gas emission.

Furthermore, using wood pellets as a significant fuel source has solved all problems related to air pollution.

Not only this, but wood pellet manufacturing also decreases the production of biomass waste material while heating the fuel.

Besides these applications, wood pellet plants are mainly common in the domestic heating systems and hot water supplies of homes.

It is also common in many fuel-burning industries where it successfully meets the GHG emission policies.

How Much Does a Ton of Wood Pellets Cost?

No doubt, the price of the wood pellets per ton depends on the quality of the wood pellets and their efficiency.

But on an average estimate, the price of wood pellets per ton ranges up to $250.

Not only this, but the price of the wood pellets for a conventional wood stove is estimated at around $200.

But, the price of this efficient source of fuel also differs with the variety of suppliers.

You can purchase the highest quality wood pellets at a reasonable price by approaching a reliable manufacturer or supplier.

However, the cost of the wood pellets per ton also varies from region to region.

How Do You Make Wood Pellets Out of Wood Chips?

You can make the highest quality of wood pellets out of wood chips by following the given tips:

- The first step in the production of the wood pellets is gathering the low-grade Roundwood.

- The collected wood is then passed through the process where it barked it removed for further manufacturing.

- The debarked wood is then exposed to some machines, which are then chipped into small pieces.

- After the production of the wood chips, they are further screened to maintain the quality.

- The wood chips are then dried to remove the moisture

- The steam process is applied to remove the moisture contents of the wood

- The wood chips are then shredded into a thin fiber material

- The wood fiber is then converted into the highest quality of pellets by exposing them to the pellet mill

What Type of Wood Are Wood Pellets Made Of?

A wide variety of biomass or organic materials, including the highest quality of wood chips, bark, and sawdust, are used to make a reliable quality of wood pellets.

Other than this, sawdust is one of the most critical materials used to make versatile wood pellets.

Many other waste products obtained from sawmilling or wood pellet manufacturing machines are further used to make wood pellets.

However, the type of wood used to manufacture wood pellets depends on the category of the manufactured fuel.

High-density sawdust remains are used to make the hardwood pellets, while softwoods are used to make softwood pellets.

Almost every wood pellet manufacturing plant prefers manufacturing hardwood pellets because it produces many other by-products simultaneously.

What Machine is Used to Make Pellets?

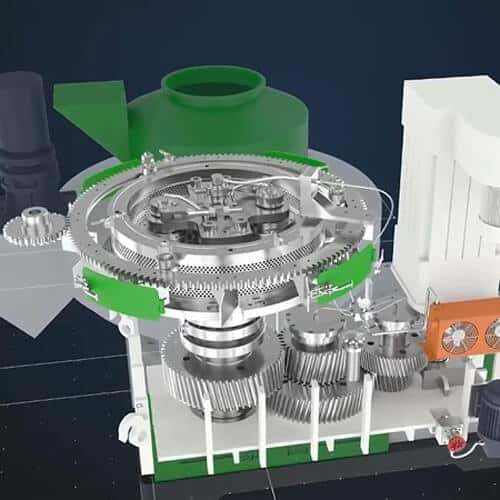

The commonest machine used to make the reliable quality of pellets is known as the pellet mill.

It is integrated into many pellet manufacturing plants, where it plays the leading role in converting raw wood into pellets.

Furthermore, it is included in the equipment category that is mainly used to manufacture wood pellets for varying industries.

This machine is available in two different types: ring die pellet mill and flat die pellet mill.

Both these pellet mills are used in the production of wood pellet materials.

Other than this machine, some other equipment that is used to make the wood pellets are given as under:

- Debarker

- Hammer mill

- Dryer

- Screener

- Cooler

- Baghouse

You can get all this efficient equipment from TCPEL since they provide the highest pellet manufacturing machines in the region.

What is a Pellet Mill Machine?

A pellet mill machine is defined as the commonest type of equipment used in producing versatile wood pellets.

It helps the manufacturers to produce wood pellets from powdered materials.

It is used in many industries depending on the production of wood pellets. It is used in grinding mills to combine all raw materials into an accurate wood pellet.

Furthermore, large and homogenous masses of wood pellets are conveniently created with the help of this wood pellet manufacturing equipment for sale.

The primary function of this machine is to pelletize the raw materials into wood pellets which are then used as a substantial source of fuel in different industries.

How Does a Wood Pellet Mill Work?

The wood pellet mill works by feeding all the raw materials into the feeding part of the machine with the help of a special opening called a hopper.

With the help of a hopper, the raw materials fall on the flat die, which then spreads them on the surface of the roller.

The rotating press machine in the pellet mill is used to put pressure on the raw materials to push them towards the holes present on the flat die.

Furthermore, the pellet mill machine is also equipped with special molds that help convert the raw materials into pellets within no time.

Can You Make Wood Pellets from Leaves?

Yes, you can use the leaves to make the reliable quality of wood pellets.

Almost all types of leaves are the most substantial sources of high-fiber material. That is why it is pretty easy to make pellets from them.

The pellets manufactured from leaves come with high intensity.

Furthermore, leaves are known to burn sufficiently and evenly.

Thus, they can be the most potential source to generate energy by burning them.

Leaves are also used to make pellets because they are available with a high calorific value.

What Keeps Wood Pellets Together?

Wood fiber is the only material in wood pellets that helps to keep them together.

During the manufacturing of wood pellets, high pressure is implemented on the wood materials to stick together for a longer duration.

Not only this, the high pressure keeps the wood pellets together by passing them through the die.

Thus, the manufacturers don’t have to worry about the inefficiency of the wood pellets when they are processed.

Is Selling Wood Pellets Profitable?

Yes, selling wood pellets is a pretty profitable business in today’s world.

The use of wood pellets in industrial and domestic areas is increasing to a substantial extent.

Due to the increased extent in the use of wood pellets as the fuel source has made the businessmen start their business.

It’s pretty reasonable to bring wood and process it into pellets. But almost all different types of wood pellets are pretty expensive when they are sold.

So, you can generate a substantial return on investment by starting a wood pellet business.

How Do You Make Sawdust into Pellets?

You can make sawdust into pellets by following tasks:

- Prepare the sawdust that you want to convert into the pellets

- Make sure to crush the sawdust into smaller parts if it is large

- Now fed the crushed sawdust into the pellet mill where it can be processed into pellets

- When the machine yields the highest quality of pellets, cool the hot sawdust

- Bring the manufactured pellets to room temperature, and they are ready to go

How Much Sawdust Makes a Ton of Pellets?

A large quantity of sawdust is used to make a ton of pellets.

However, the rough estimate of the bulk amount of sawdust ranges up to 7 m3 with normal moisture content.

The amount of moisture present in the sawdust needed to make pellets should be around 50-55%.

This amount of sawdust is then used to convert it into one ton of pellets.

Which Industries Use Wood Pellets?

Fuel-burning and domestic places are the major industries that use the highest quality of wood pellets.

The primary reason behind the use of wood pellets in these industries is their affordability as an energy source.

These industries can generate a substantial amount of energy by using a minimal quantity of wood pellets.

Are There Any Harmful Chemicals in Wood Pellets?

Carbon monoxide can be regarded as the only harmful chemical present in wood pellets.

The main reason behind the harmful nature of carbon monoxide is its ability to build up to toxic levels.

Not only this but carbon monoxide is also observed to be present in the areas where wood pellets are either transported or manufactured.

Almost all the workers present in such manufacturing plants should be addressed to take all necessary precautions for minimizing the risks produced by carbon monoxide.

Why Is There a Shortage of Wood Pellets?

The primary reason for the shortage of wood pellets around the globe is the reduction in the building rate of trade.

Moreover, there is a very minimal extent of manufacturing the scrap by-products used in the manufacturing of pellets.

All these problems are due to the increased propane levels in the market, which increases the heating cost of the pellet stoves in pellet mills.

Thus, the increased expense of the pelletizer has resulted in the decline of the wood pellets.

But, still, there are some manufacturers like TCPEL make sure to provide the essentials for the wood pellet industry at pretty reasonable rates.

How Long Does 10kg of Wood Pellets Last?

A large pack of wood pellets weighing 10kgs can last from one to three days.

However, the lifespan of the manufactured wood pellets depends on the extent of the usage.

If you’re using your stove all day long, then the life of wood pellets can decrease.

In addition to this, the lifespan of the wood pellets depends on the quality of the sawdust used in its construction.

Talk to An Expert

SHARE THIS POST

Talk to An Expert