Applications of Rotary Dryers in Metal Concentrates: The In-depth Guide

A rotary dryer is a robust industrial drying machine. It helps in removing moisture from a wide range of materials.

As the dryer is versatile in operations, people use it in several industries. One important industry that employs this machine for various processes is – the metallurgical industry.

Metal concentrates are a source of raw materials for the metallurgical industry..

These metals get extracted using different processes. However, before these metal concentrates undergo any process, they require drying. This process prepares metal concentrates for further processing.

This blog post guides you through different applications of rotary dryers in metal concentrates. In addition, you will learn why this machine is better than other drying methods.

So without further delay, let’s get started.

Advantages of Using a Rotary Dryer for Metal Concentrates

Metal concentrates come from the mining process, containing components like iron ore, silver, gold, nickel, zinc etc.

Let’s learn some advantages of using a rotary dryer for metal concentrates.

Efficient Moisture Removal

Metal concentrates may come in contact with moisture during the extraction. The dampness can trigger microbial growth and affect the quality of the metal.

Consequently, before conducting any further processing, drying of metal concentrates is crucial.

A rotary dryer is an efficient moisture removal machine that lets you dry metal ores in large quantities. Its high-temperature drying ensures quick evaporation of water content.

Minimizes The Chance of Oxidation & Corrosion

Some metal concentrates can rust when they are in contact with moisture. A rotary dryer can help prevent this.

The dryer removes excessive moisture from metal concentrates to prevent corrosion and oxidation.

Easy Storage & Handling of Metal Concentrates

When you dry metal concentrate, their weight gets reduced to a certain extent. It makes their handling and storage more comfortable.

In large-scale mining, metal ore concentrates are extracted in large amounts. The rotary dryer helps minimize their weight and makes them easy to handle, transport, and store.

Versatile

During mining, you can’t be sure about what metal you will get. As a result, you need a drying technique that accommodates various metal concentrates.

The rotary dryer can set the drying temperature depending on the nature of the material being dried.

The dryer lets you get control over drying temperature and airflow. No matter what metal you get during mining, you can dry it with the rotary dryer.

Low Material Degradation

One fear that often bothers people during the drying of metal concentrates is their degradation.

Uncontrolled heat can degrade the metal significantly. Fortunately, a rotary dryer minimizes this risk.

The rotary dryer dries metal concentrates so gently that they do not break.

Dust Collection

Applications of rotary dryers in metal concentrates are not just limited to drying metal ores. It helps the industry in various ways.

Metal concentrates contain a lot of dust. Their fine particles may mingle in the air with other drying techniques.

The rotary dryer collects all the dust in its dust collection system. It naturally maintains a safe environment for machine operators and machine workers.

Low Maintenance

Rotary dryer for metal concentrates has low maintenance requirements. This powerful machine has a straightforward design making it easy to clean and maintain.

Modern rotary dryers come with a built-in lubrication system that minimizes downtime.

Cost Effective

While the initial investment of a rotary dryer may look expensive, it is cost-effective in the long run. The high drying efficiency and low energy consumption make it cost-efficient.

In addition, rotary dryers can dry metal concentrates in large quantities at a time. It lowers the overall drying cost.

Most rotary dryers are either fully automated or semi-automated systems. The machine reduces labor costs and operation time.

Energy Efficiency

Rotary dryers are energy efficient compared to conventional drying methods. The design of their drum supports better heat transfer. There is negligible heat loss with this dryer. Consequently, it requires low energy to provide high heat.

The operator can control the speed of the drum to achieve perfect drying. It not only prevents over-drying but also extra energy consumption.

Customization Options

There are various types of metal concentrates. Each has different moisture content and drying requirements.

The rotary dryer is one machine that lets you set drying temperature and residence time as per the type of metal concentrates.

All-in-all, the applications of rotary dryers in metal concentrates bring several benefits.

Rotary Dryer Applications in Metal Concentrates: Different Metal Sulfide Concentrates

Applications of rotary dryers in metal concentrates are broad. They can enhance the market value of metallic minerals, such as copper, iron ore, nickel, etc.

Let’s learn their usages in drying different metal concentrates

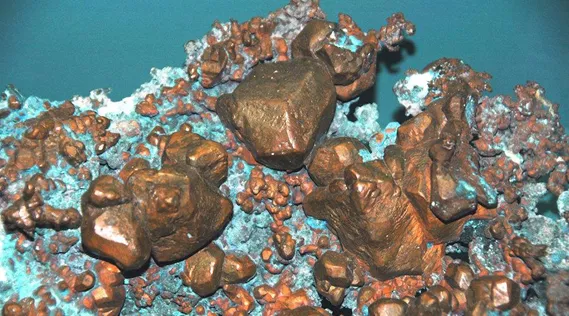

Drying of Copper Concentrates (Copper Concentrate Dryer)

Using a rotary dryer is one of the convenient copper concentrate drying techniques. Copper concentrate is obtained from copper ore and contains a high amount of copper mineral.

However, before the copper concentrate is processed further, it needs drying. Drying improves the flow capacity of copper and prevents it from solidifying during transportation.

A Copper Concentrate Dryer is the most suitable machine for this job. It enables the operator to control drying temperature and time precisely.

It dries copper concentrates without overheating. Moreover, the dryer does not destroy the crucial minerals of copper concentrate.

When it comes to buying a copper concentrate rotary dryer, options are endless. You can purchase different sizes of rotary dryers depending on your needs.

Drying of Iron Ore Concentrates(Iron Ore Dryer)

Drying iron ore concentrates makes it easy to handle, transport, and store. In addition, it makes the subsequent processes, such as melting and pelletizing convenient.

The iron ore dryer lets you control the drying time and efficiency. Therefore, you do not need to worry about overexposing to temperatures and losing the quality of a final product.

Drying of Nickel Concentrates

Nickel concentrates are obtained from nickel ores. These concentrates contain minerals and impurities from nickel ores.

Nickel ores go through mining, crushing, flotation, drying, smelting, and refining to get a pure nickel metal.

Drying nickel concentrates offer several advantages. For example, it minimizes the growth of fungi and bacteria during storage and shipment. In addition, it helps in the smelting and refining of nickel ore.

There are various nickel concentrate drying solutions. However, rotary dry is widely used for nickel ore processing, including the laterite nickel ore

This heavy-duty drying machine dries a large amount of nickel ores at once. It is designed for industrial-scale drying operations.

Furthermore, the machine can dry different grades of nickel concentrates regardless of their particle sizes and moisture level.

Drying of Zinc Concentrates(Zinc Ore Dryer)

Because of the wide applications of zinc ore uses, the zinc ore processing process have been upgraded generation by generation. Rotary dryers have been playing a vital role in drying zinc concentrates. Companies use them to remove moisture from zinc ores so that they are perfect for further processing.

Zinc Dore Rotary dryer features rotating drums that give zinc ores 360° drying. Additionally, these dryers can deal with the abrasive nature of zinc concentrates during zinc ore processing.

Drying of Gold and Silver Concentrates(Gold Concentrates Dryer and Silver Ore Dryer )

Gold and silver concentrates are derived from complex ore bodies. They often require multiple extraction processes for both gold ore processing and silver ore processing.

Since silver and gold concentrates hold high market value, they need special attention while drying.

They require precise drying temperatures to avoid any losses. Improper drying might cause the decomposition of silver and gold.

A rotary dryer is an excellent choice for such situations. They offer precise control over drying temperature.

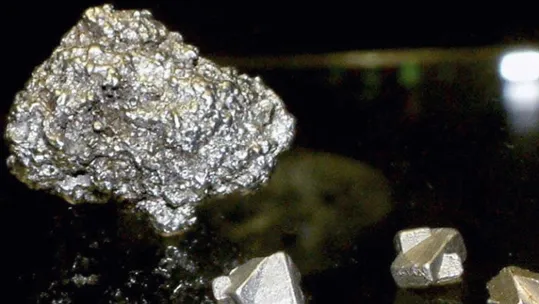

Platinum Group Metal (PGM) Concentrates

Platinum group metal concentrates include minerals having high market value and several industrial applications. PGM concentrates contain minerals, including palladium, rhodium, osmium, ruthenium, and osmium.

These concentrates require proper drying to meet the requirement of subsequent metallurgical processes.

A rotary dryer is a perfect choice to dry PGM concentrates. Its consistent and precise drying temperature preserves different characteristics of PGM ores.

Things to Consider When Buying a Rotary Dryer for Metal Concentrates

To ensure well-organized and lucrative metal concentrate processing, choose the right rotary dryer. Below are some points to consider when buying a rotary dryer.

Capacity

Rotary dryers are available in different models. Choose the diameter, speed, power, and evaporation capacity based on your requirements.

The market has rotary dryers with different ranges of power options. From 2.2KW to 30 KW, rotary dryers are readily available.

Similarly, you can choose an internal diameter ranging from 800mm to 2800mm. Select it based on how much metal concentrates you want to dry at a time.

Drying Method and Technology

Rotary dryers have different configurations—for example, direct rotary dryers, indirect rotary dryers, and steam tube rotary dryers.

– Direct rotary dryer dries the material that comes into contact. It uses hot gas/air to dry material.

– Indirect rotary dryer features an external heat chamber from which air/gas enters into the rotary drum to dry material.

– Steam tube rotary dryer uses steam to dry the material. The steam goes through a series of tubes before entering the chamber.

Determine what machine better aligns with the nature of your metal concentrates.

Heat Source

Generally, rotary dryers operate on heat sources such as electricity, steam, and natural gas. Find out which one is going to be energy-efficient and affordable for you.

Drying efficiency and Temperature Control

Choose a rotary dryer that comes with lifters. It ensures proper material movement and heat transfer.

Some metal concentrates are sensitive to high temperatures. Therefore, invest in a rotary dryer that lets you set the temperature precisely.

Safety Features

Do not forget to look for crucial safety features when selecting a rotary dryer. Your dryer must have features like emergency shut-offs, fire detection, automatic lubrication, etc.

Reputation of Manufacturer

Find a rotary dryer manufacturer that is experienced and reputable in the market. The manufacturer must have a track record of supplying quality rotary dryers for metal concentrates. In addition, they have compliance with certifications like CE, ISO 9001-2000, and SGS.

Conclusion

Applications of rotary dryers in the metal concentrate industry are vast and diverse. It removes moisture from metal concentrates and makes them ready for subsequent processing.

The dryer significantly improves and speeds up the downstream processes. What makes rotary dryers better than other drying equipment is their sustainability.

We hope this guide helps you make informed decisions about rotary dryers for metal concentrates.

Talk to An Expert

SHARE THIS POST

Talk to An Expert