How to Make Wood Shavings? The Ultimate Guide in 2023

Do you want to learn how to make wood shavings? You have come to the right place. Whether you want to produce wood shavings for animal bedding or use them as raw material for board making, you must learn a proper making process.

Do not worry, this article will help you make quality wood shavings. However, before we proceed with the process, let us learn what wood shavings are.

What is Wood Shaving?

The scraps left over after shaping the wood are known as wood shavings.

You can produce wood shavings with the use of a wood shaving machine.

Wood shavings are not uniform in size or shape like wood pellets. As they are peeled from a wood surface, they look like a thin curl.

Generally, wood shavings are soft and have a cushioning effect. As a result, they become excellent bedding for animals. Individuals also use them as bedding for delicate goods during transportation.

Additionally, wood shavings are used to produce paper and as fuel.

The wood shavings market is expected to continue steady growth in 2023. The market size is projected to reach $21.7 billion in 2023 from $19.2 billion in 2020, growing at a CAGR of 3.8%.

The increasing demand for wood shavings as bedding for poultry, livestock and horses is driving market growth.

How to Make Wood Shavings?

To make wood shavings, you need to prepare the materials first, the materials can be log branches, waste pallet, waste furniture, etc, then put the materials into wood shaving machine, press the materials with hydraulic press of the wood shaving machine ,press the wood shaving machine button and it will make wood shavings automatically.

It is simple to make shavings out of wood. Let’s take a step-by-step look at how to make wood shaving.

Choose the Right Wood Shaver Machine

A wide range of wood shaving machines is available in the market. You may buy a small wood shaving machine, large shavings mill, or handy carpentry tool based on your requirements.

If you want to make wood shavings for commercial use, invest in a professional wood shaving machine.

A commercial wood shaver machine can peel off shaving out of wood of various types. It consists of a roller and spiral shaft, driven by a motor.

Generally, a professional wood shaver machine comes with two kinds knives: a Spiral knife and Straight Knife. The spiral knife produces small-size shavings, while the straight knife roller helps you get large-sized wood shavings.

Use Appropriate Raw Materials

Choosing a suitable raw material is crucial for making quality wood shavings. You may use a variety of raw materials, including locust wood, logs, and tree branches.

Choose the diameter and size of raw material depending on the specification of your wood shaving machine.

It is advisable to use peeled logs to produce high-quality wood shavings. You will get less debris and better uniformity.

Wood Shaving Making Process

Professional shaving mills can shave wood of lengths between 800mm to 1400mm in diameter. Based on the capacity of the machine, you can process up to 1500 kg of wood.

Therefore, it should not be an issue if you have branches, wood logs, or timber as raw materials.

Start the Machine

Switch on the machine and leave it running. Put the raw material into the inlet of the machine. Ensure all wood logs have the same length.

Next, the wood shaver will process the wood log or branch and shave its surface to make wood shavings.

There is a hydraulic stick inside the wood shaving machine. As soon as the wood is placed inside, the rotating knife roller begins to cut it into uniform shavings. Shavings discharge through an outlet on the other side.

An advanced wood shaving machine uses a powerful motor to drive a rotary knife and make shavings out of wood.

Wood Shaver Machine Troubleshooting

Your wood shaving machine might experience technical issues just like any other machine. As a result, you must learn some troubleshooting.

Low Output

There could be plenty of reasons your machine is not giving desirable output. However, in most cases, a blunt knife is the culprit. So, check it out. If required, get it sharpened.

Additionally, adjust the blade in the right place. The cutting process might be compromised by the gap in the blade. It should not be too large or too small. Ideally, it should be between 2 to 3mm.

Jamming of Belt

Sometimes the belt of the wood shaving machine gets jammed due to the eccentric position of the rotor.

If you notice such an issue, adjust their concentricity. To fix cylindricity, you might try inserting the pads underneath the motor. Adjust the belt after every use.

Provide your wood shaving machine with proper maintenance from time to time. Clean it properly after every use. After three to four hours of working, grease the bearing seat.

What Wood Shavings are Safe for Chickens?

A lot of discussions are happening on this over the internet. However, most people consider pine shavings safe and suitable for chicken bedding.

They do not smell as strongly as cedar and are easy to clean. According to experts, people should avoid cedar shavings as bedding due to their natural oil.

Chickens, especially the young ones, have a weaker respiratory system. As a result, you must pay special attention when choosing bedding for them.

Choose a reliable animal bedding machine that can provide uniform and soft shavings.

How to Dry Wood Shavings?

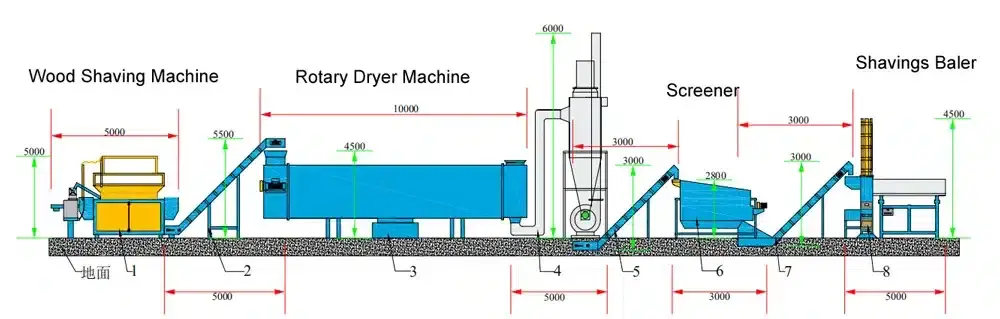

If you produce wood shavings in bulk, use a professional rotary dryer. The rotary dryer dries the wood shavings with hot air.

In the presence of drying air, the machine spins the wood shaving inside the spinning drum. The machine lets you control the frequency of drying as per the requirement.

For a small batch of wood shavings, use the natural drying method. Let moisture evaporates automatically in open air and sun.

How to Store Your Wood Shavings

If you produce wood shavings commercially, you must have a proper storage system for them. Once your wood shavings are dry. You can use a wood shavings baler to pack them and store them in a shed or shelter.

Choose the location where there is no moisture and wind. Place a tarpaulin sheet beneath the wood shavings. It will prevent dampness from the ground. Moisture from the ground can ruin your wood shavings.

Also, keep your wood shavings away from dust and dirt. Otherwise, it might impact the quality of your wood shavings.

So this is our quick guide on how to make wood shavings for animal bedding. We hope it gives you adequate knowledge of making wood shavings.

Talk to An Expert

SHARE THIS POST

Talk to An Expert