Gypsum Dryer: Applications & Advancements of a Rotary Dryer for Gypsum

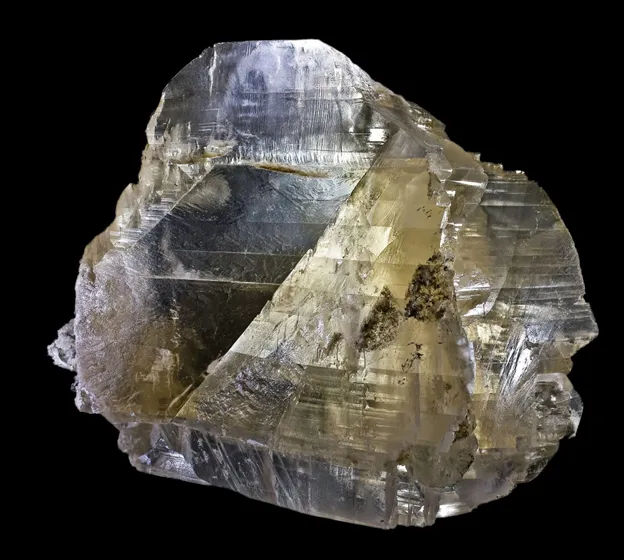

Gypsum is a sulfate mineral made out of calcium sulfate dihydrate. Mined worldwide gypsum has uses in fertilizer, pharmaceutical, construction material, etc.

However, to get the best out of this mineral, you need to dry it properly. An efficient gypsum dryer can enhance the quality and usefulness of this mineral for different applications.

This blog discusses the applications and benefits of a rotary dryer for gypsum. Before we go on, let us figure out what a gypsum mineral is.

What is Gypsum?

Gypsum is a natural mineral found in sedimentary rocks near ancient seas, volcanic vapors, hot springs, etc. It forms when water from a sea or lake having calcium sulfate evaporates and precipitates crystals. Over time, these crystals accumulate at the bottom of a water body.

Usually, gypsum is mined through open-pit mining or underground mining.

The color of the gypsum depends on the impurities inside it. In raw form, it could be anywhere from transparent to white. Sometimes it is yellowish brown.

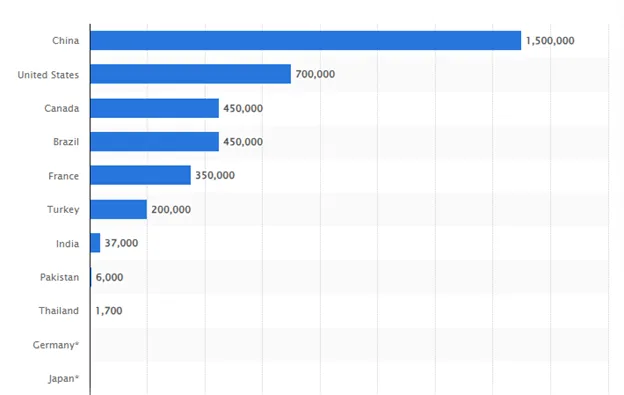

While this mineral is available in various countries, China, the United States, the Middle East, Europe, and Canada have substantial deposits.

According to Statista, China has the largest reserve of gypsum. It is about 1.5 billion metric tons.

Applications of Gypsum in Different Industries

Gypsum is a versatile mineral having applications in various industries. Some crucial applications of gypsum are as per below:

Construction

Gypsum is known as a ‘wonder mineral’ in the construction industry. It is used as fireproofing, moisture-preserving, and heating-resistant material. It is popularly used in ceiling and wall construction. Individuals also use gypsum for making noise-proofing areas.

Agriculture

Gypsum also has several uses in the agriculture industry. It is an excellent source of calcium and sulfur. Gypsum application in the soil enhances fertility and water infiltration. Agriculturists use it as fertilizer to minimize soil erosion.

Food & Beverages

Gypsum has been used in several food products as well. It is an excellent calcium source. In addition, it also acts as a firming agent and acidity regulator. Its use in canned fruits and vegetables is quite common. Besides, some ice cream, flour, and break-making companies also use it.

Cement Production

Gypsum also has a significant role in slowing down the hydration process of cement when mixed with water. Cement makers also use it in the making of Portland cement.

In addition to these industries, gypsum has several other industrial applications. For instance, it is used in the dental and medical sectors.

Drying Requirements of Gypsum

Regardless of the industry gypsum has been used in, it requires drying before its implementation. And a good quality gypsum dryer is crucial for this process.

The drying requirement of gypsum changes depending on its application. The drying process improves the quality, shelf life, and usability of gypsum. In addition, it makes its handling easier.

Some primary aspects of drying of gypsum include:

Calcination

This process involves heating gypsum to eliminate its water portion and transforming it into hemihydrate. Usually, the temperature for this process remains between 150 degrees and 165 degrees Celsius.

Control on Airflow & Temperature

Over drying can negatively impact the quality of gypsum. As a result, an individual must have proper control over temperature and airflow while drying.

Drying Time

In addition to temperature, the drying time needs to be properly optimized. It makes gypsum suitable for further processes.

There are a lot of factors to consider with the drying of gypsum. For that reason, you cannot rely on an ordinary gypsum dryer.

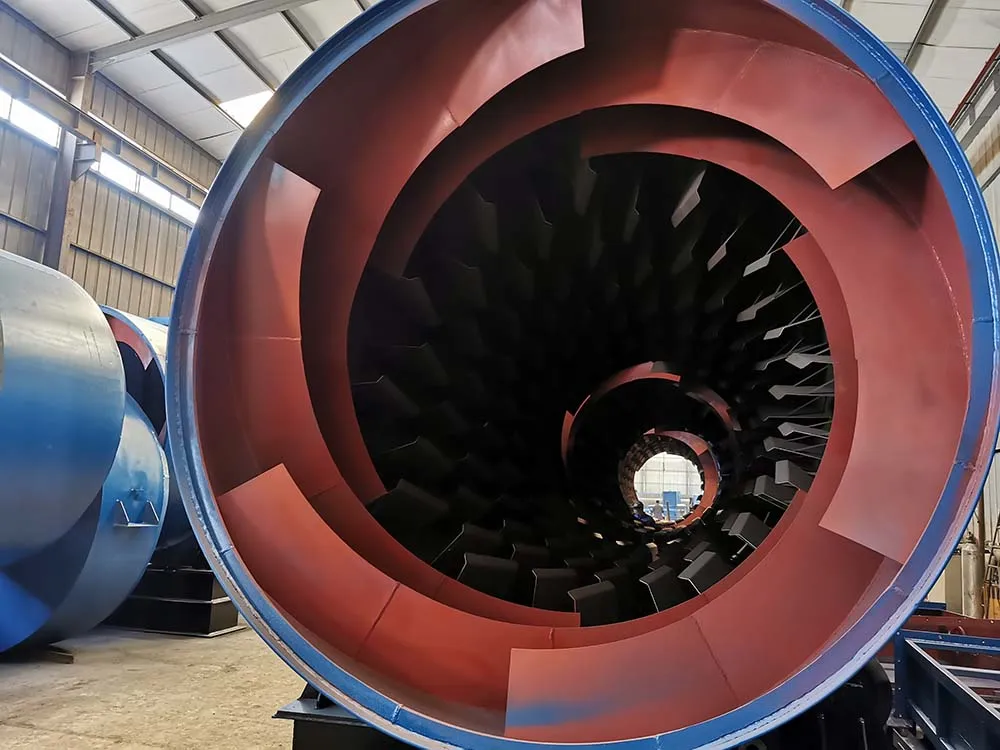

A rotary dryer is one of the most used drying systems for gypsum. This heavy-duty dryer provides a reliable drying solution.

Let’s find out why one should invest in a rotary dryer for gypsum.

Why Should We Use a Rotary Dryer for Gypsum Drying?

A rotary dryer is a highly efficient industrial drying system that can dry any mineral in bulk. It works fine as a gypsum dryer because it meets the drying requirements of this mineral.

No matter which industry you use a rotary dryer in, it can dry gypsum depending on the requirement.

For diverse applications, gypsum may have distinct drying requirements. The rotary dryer lets the operator customize the drying parameters accordingly.

Benefits of Using Gypsum Dryer

Rotary dryers are ideal machines for drying gypsum ore or processed gypsum. Let’s find out why a rotary dryer is the most suitable option to dry gypsum.

Bulk Material Handling

When you invest in a quality rotary dryer, it can handle bulk material standalone. Its belt conveyors, bucket elevators, incline conveyors and reverse conveyors can seamlessly dry tons of gypsum.

In the mining industry, you are more likely to dry gypsum in large quantities together. Therefore, you need a gypsum dryer that can handle it. And a rotary dryer can do it.

Proficient Moisture Removal

Another thing that makes a rotary dryer an ideal gypsum dryer is its efficient moisture-removing technique. The different parts of a rotary dryer, including the drum, lifters, and air/gas flow system guarantee optimum moisture removal.

Uniform Drying

One of the biggest concerns with gypsum drying is improper moisture removal. Uneven moisture can considerably affect the quality of gypsum for further processing.

This is not the case with a rotary dryer. This gypsum dryer ensures uniform drying. It distributes heat and airflow evenly inside the drying chamber.

Handles the Abrasive Nature of Gypsum

Gypsum ore is abrasive like other rocks. Consequently, it requires a sturdy dryer for reliable drying. The interior of the rotary drum can handle abrasive material. Gypsum won’t cause any wear and tear to the machine.

Customization in Drying Parameters

For different applications, gypsum may have distinct requirements. As a result, people need a gypsum dryer that lets you customize the drying parameters.

Fortunately, it is possible with the rotary dryer. It features a user-friendly control system that lets users control the speed of the drum, drying temperature, airflow, and various other drying parameters.

Complete Control over Temperature

Gypsum is quite sensitive to temperature. Over drying can destroy its mineral properties or impact its usability.

With a rotary dryer, there is no risk of thermal degradation. You can set the drying time and temperature perfectly as per the requirements.

Environmentally-friendly

Nowadays, authorities oblige industries to be as sustainable as possible. Moreover, it is ethical to be environmentally friendly.

Rotary dryer is relatively energy efficient. Companies can also install an emission control system to pass emission compliance.

How Does a Rotary Dryer Help Drying Gypsum in Different Industries

As mentioned above, people use gypsum in various industries for different applications. Let’s find out how a rotary dryer helps in drying gypsum there.

Construction

Gypsum is a commonly used material in the construction industry. You can notice its uses in wallboards, plasterboards, and similar building products.

The rotary dryer controls the moisture content in the gypsum powder. It makes gypsum easy to mix into different construction products.

For example, in wallboard manufacturing, the rotary dryer pre-conditions the gypsum. It dries gypsum so efficiently that grinders can grind the gypsum ore without much effort.

Fertilizer Production

Gypsum powder has a crucial role in improving the quality and structure of the soil. Do you know how a gypsum dryer improves the quality of this powder?

The rotary dryer helps in blending gypsum with other fertilizers. It also ensures dependable nutrient distribution.

In addition, drying helps in minimizing the risk of mold and bacteria growth in gypsum fertilizer. It naturally improves the shelf life of gypsum fertilizer.

Pharmaceutical & Food Industry

Since gypsum is rich in calcium, several food products and healthcare supplements also add it. However, before using gypsum in these industries, it needs to be in the purest form to meet certain quality standards.

Gypsum dryers help in achieving these standards. In the pharmaceutical industry, gypsum dryers can dry active pharmaceutical ingredients, such as ibuprofen, metformin, paracetamol, etc.

Cement Production

Gypsum controls the setting time of cement. It works fine only when it has an appropriate moisture level. And to achieve an accurate moisture level, a rotary dryer is the most suitable machine. This gypsum dryer lets you remove moisture from gypsum as per the requirement.

Power Plants

A gypsum dryer is also used in power plants to minimize the effect of sulfur dioxide. It attracts sulfur and counteracts its negative impact. The gypsum dryer dries gypsum before it is used in the flue gas desulfurization power plant.

Conclusion

Gypsum dryer has been transforming several industries by its efficient drying technologies. It eliminates moisture from gypsum to improve its shelf life and operational efficiency.

The rotary dryer works perfectly as a gypsum dryer. It features an advanced control system enabling the operator to dry gypsum depending on the industry requirement.

We hope the article gives you adequate knowledge about the applications & advancements of rotary dryers for gypsum. If you want a suitable dryer for gypsum, do consider a rotary dryer.

Talk to An Expert

SHARE THIS POST

Talk to An Expert