Rotary Dryer Installation Precautions and Misunderstandings

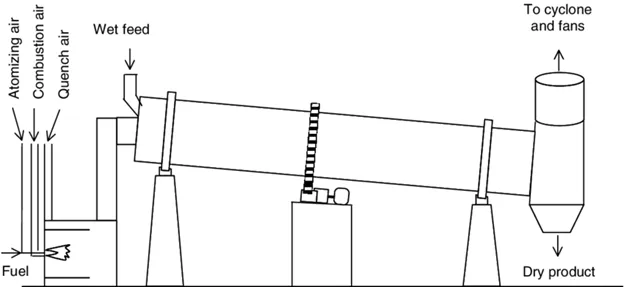

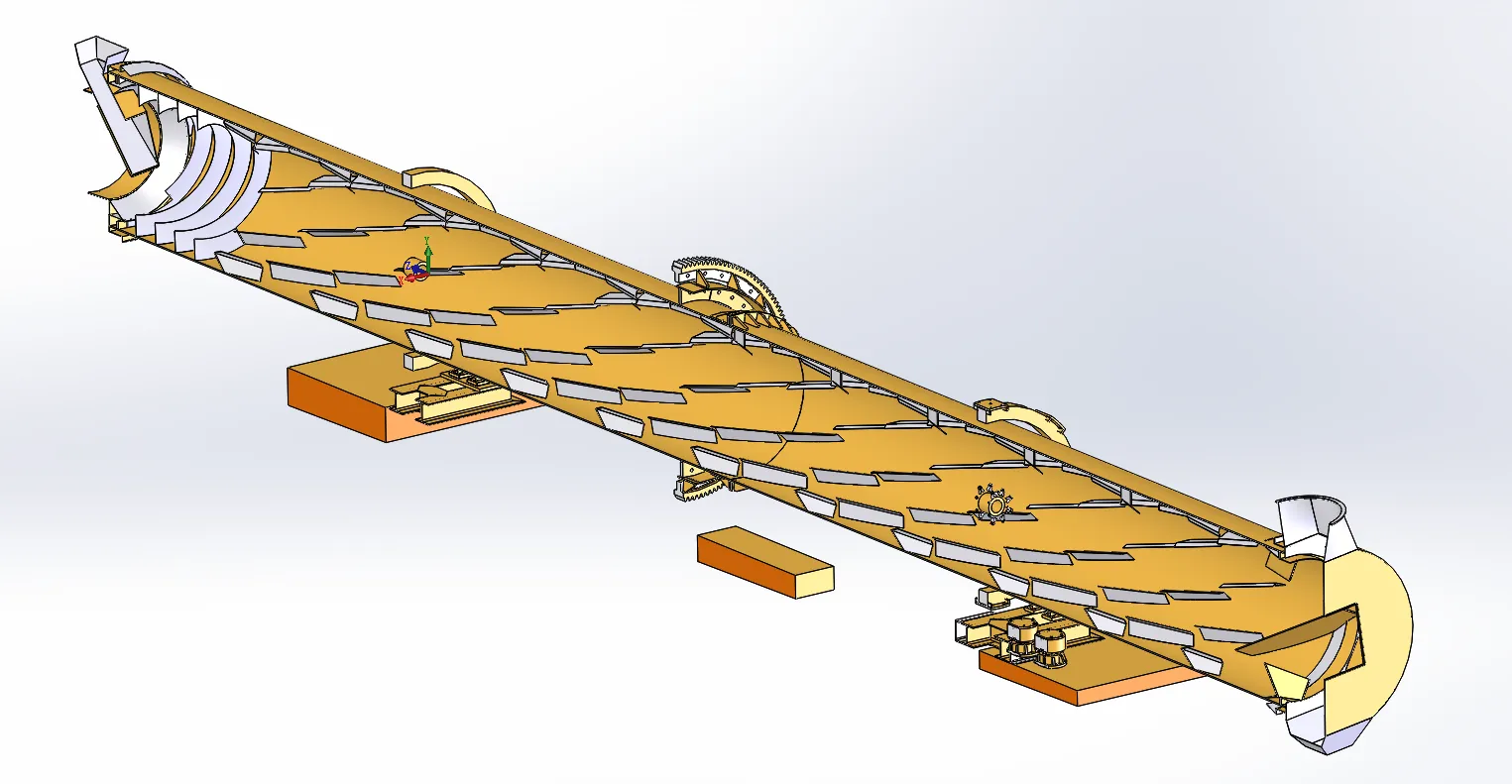

Rotary dryer is widely used in various industries, including biomass, chemical, agricultural, food, cement, sand, metal concentrates etc. The rotary dryer installation matters a lot on its performance and the whole investment success or not. Today we will talk about the precuations and misunderstandings during rotary dryer installation. And teach you the rotary dryer drum tilt correction method, hope our article can make your rotary dryer installation much easier and correct. Keep on reading .

Inspections Before the Rotary Dryer Installation

Rotary dryer must be installed before the construction of a strict inspection and acceptance process, first we will show you about the rotary dryer machine basic inspection and acceptance before the installation, and focus on the acceptance of the rotary dryer drum inspection with you.

Foundation check and acceptance

First of all, we should carry out the foundation acceptance, one is to check if the rotary dryer placed on the ground and the surrounding environment, and the next is to accept the size of the foundation of the rotary dryer machines. To check the foundation concrete pouring quality and size position deviation. Appearance requires that the surface of the foundation is clean, no oil, dust, debris, no exposed steel, no cracks and corners, no residual shell plate in the expected retention holes, as well as other casting defects.

For the foundation size and position deviation should meet the following requirements: external dimensions and foundation coordinates position, longitudinal and transverse axis error is less than 20mm. different plane elevation error is less than 20mm, only allow negative not allow positive; slope error is less than 20mm in the whole length of the discharge end allow negative not allow positive; on the plane the unflatness is less than 5mm/m, the whole length is less than 10mm.

Next is to check the rotary dryer quality. Based on the rotary dryer packing list provided by the rotary dryer manufacturer, parts, components, standard parts, random documents, etc. to inventory, check whether there is no wrong missing parts, deformation damage, etc., and make a good record, so as to be purchased or prepared before installation. Remove the protective coating and dust, oil, rust and corrosion, etc., and check and repair the damage and deformation caused in the process of transportation and loading and unloading. Pre-inspection and pre-assembly of components and key mating parts are carried out to avoid reworking during installation and to ensure the progress and quality of installation.

The rotary dryer, its parts and special tools should be properly stored, and should not be deformed, damaged, corroded, misplaced or lost. The accessory structural materials, finished products, semi-finished products and supporting parts of the dryer must have the quality certificate of the manufacturer, and their quality should be in accordance with the design documents and the current national standards.

Rotary Dryer Drum Inspection Experience

(1) Before assembling the rotary dryer drum on site, the geometry and manufacturing quality of the dryer drum should be inspected according to the requirements of drawings, and the unqualified ones should be submitted to the manufacturer to make timely processing opinions.

(2) Unroundness at the same section of the dryer drum should be less than or equal to 1%Dg, and not more than 25Dg (Dg is the inner diameter of the cylinder).

(3) The permissible deviation of outer circumference at the end face of the rotary dryer cylinder is ±15mm.

(4) The deviation of endface unevenness at the cylinder segmentation should be no more than 1/100Dg and no more than 2mm.

(5) Measurement of out-of-roundness should be measured on the surface of the dryer drum plate through the centerline measurement in 4 places. Dryer drum straightness check is along the round 0 ℃, 90 ℃, 180 ℃, 270 ℃ four parts of the pull 0.5mm fine steel wire for measurement, the measurement of the location from the longitudinal seam distance of not less than 100mm. when the dryer drum thickness is different, the calculation of straightness should be subtracted from the thickness difference.

(6) Bevel size should be in accordance with the requirements of the drawings, the bevel surface shall not have cracks, delamination and other defects.

Do a full inspection, acceptance of qualified dryer equipment before you can formally start the installation work, Special reminder for you, during installation you need to set up a cordon around the perimeter, avoid personnel access.

Precautions in the Installation Stage of the Rotary Drum Dryer.

1, The preparation of the installation process, including the basic installation procedures, installation process methods, safety technology requirements.

2, Set the mat board, to determine the reasonable layout of the mat board, pay attention to the mat board should be as close as possible to the ground bolt and arranged in the center of gravity of the load position, in order to prevent the mat board uneven force. The number of pads per group shall not exceed 5, thicker pads on the top and bottom, thin put in the middle, stacked neatly in perfect contact, when the adjustment can not be completely overlap, the contact area should be greater than 80%. The bottom of the pad and the foundation should have enough contact accuracy to the foundation contact is dense, placed in a stable, not empty corner shaking phenomenon, and to ensure that the pad up and down in the longitudinal direction of the slope and the foundation of the same, the direction of the cross should be basically horizontal.

3, The base line, the use of optical latitude and longitude, laser collimator or poor accuracy of the pull-line method, the base of the wheel transverse leveling, longitudinal find the obliquity of the repeated times, until the coordinate position, transverse level, longitudinal obliquity to meet the requirements shall prevail.

The above content hope to help you better carry out the acceptance and installation of the rotary dryer, as a rotary drum dryer efficient use of the premise, buyers should do a good job in the implementation of the specific work to ensure that the production of safe and efficient.

The Main Misunderstanding During Rotary Dryer Installation

We have been in constant and in-depth contact with customers, guiding customers and friends of the installation and maintenance work for the rotary dryer installation, so as to find a lot of misunderstanding. Today, we will first talk to you about the near fire end and the far fire end.

In the installation process of rotary dryer, most of them are installed in the form of tilted installation with high inlet fire end and low far fire end, however, such installation is a very serious mistake, if rotary dryer installed in such a way, it will only speed up the flow of materials to the far fire end, which will make the materials in the wood chip dryer drum inside the storage capacity is reduced once again. Thousands of lifting boards are lifting materials at the same time, but not much material is lifted. In order to limit the flow speed in the direction of the exit of the rotary dryer machine, it is often the case that only the rotational speed of the rotary dryer drum is limited to a very low speed, in which case the number of times the material inside the drum is lifted up is also greatly reduced. Because of this, it caused the material box hot air dynamic contact number has been greatly reduced. And at the same time by the downstream drying, and rotary dryer in the process of drying saturated water vapor and did not carry out timely discharge, this time, the water vapor in the rotary dryer drum runs too long distance, resulting in the material moisture is reabsorbed by the dry material.

Rotary dryer installation matters, customers and friends can communicate with our technical team, according to the actual use of the site, the environment, to develop the best installation program, to ensure that the next use of equipment is not affected.

Rotary Dryer Drum Tilt Correction Method

The first installation of the rotary dryer needs to be corrected by the technicians, that is, the rotary dryer drum tilt adjusted to the appropriate range. Dryer drum tilt to find the right to meet certain technical requirements, below is the detailed explain on this :

(1) According to the requirements of dryer drum tilt, calculate the center elevation of the front and rear cylinder wheels, use the flat, inclined pad iron and tilt gauge, frame type level meter, adjust the tilt of the wheels.

(2) The center line of the rotary dryer pallet should be installed parallel to the center line of the drum body, and the tolerance of parallelism is 0.1mm/m.

(3) The center height of the same group of pallet wheels of the dryer is equal, and the tolerance is not more than 0.1mm.

(4) Longitudinal and transverse axis error is less than 20mm, the different plane elevation error is less than 20mm, only negative is not allowed.

(5) Slope error of the whole length is less than 20mm, the discharge end is allowed to not allow positive.

(6) The upper plane not flatness should less than 5mm/m, the whole length is less than 10mm.

Here we want to remind you, for the rotary drum dryer, in the installation of the roller ring can be installed on the rotary dryer first, the concave joint for fixing in the form of a positive and a negative staggered configuration, do not forget to adjust the thickness of the pad iron, so that the roller ring and the concave joints to maintain a proper gap between.

If you come across any questions during rotary dryer installation, welcome to discuss with our technician, as a proforssional rotary dryer manufacturer in China for more than 15 years, we are sure we can offer you useful suggestions.

Talk to An Expert

SHARE THIS POST

Talk to An Expert