Enhancing Sawdust Dryer Performance: Causes and Solutions

Introduction

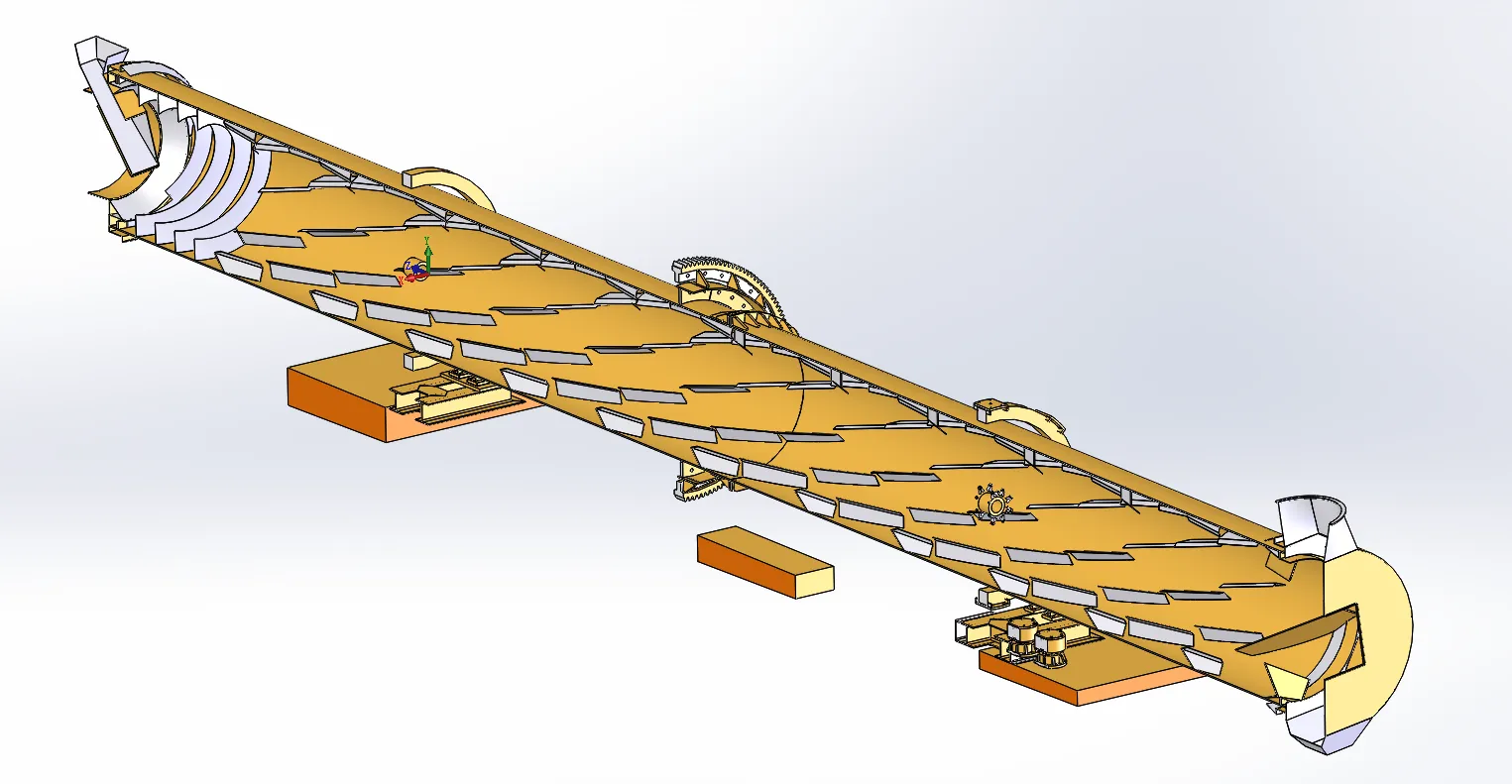

In the world of wood processing, sawdust dryers play a vital role in efficiently reducing moisture content from wood chips and sawdust, enabling their transformation into valuable products. However, like any machinery, sawdust dryers also face performance issues that hinder their effectiveness. In this article, we delve into the reasons behind incomplete sawdust dryer performance and provide practical solutions.

Common Challenges in Sawdust Dryer Performance

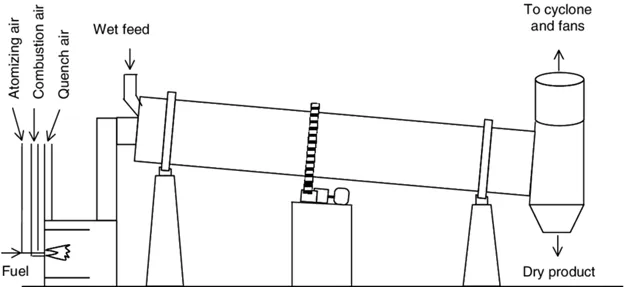

Insufficient Heat Generation

Inadequate heat generation is a primary factor leading to incomplete drying. When the dryer fails to reach the required temperature, moisture removal becomes inefficient. This can occur due to malfunctioning burners, thermocouples, or improper fuel combustion.

Improper Airflow

Efficient airflow is essential for uniform drying. Blockages in air vents, damaged fans, or poorly designed ducts can disrupt airflow, resulting in uneven moisture extraction.

Material Buildup and Uneven Distribution

Accumulation of sawdust within the dryer can impede the material’s movement and create hotspots. Uneven distribution prevents consistent drying, leading to incomplete results.

Overloading the Dryer

Overloading the dryer beyond its capacity might seem like a shortcut, but it hampers the drying efficiency. When the dryer is packed with sawdust, airflow and heat distribution are compromised, resulting in incomplete drying. Maintaining an optimal load ensures consistent and thorough drying.

Insufficient Pre-processing of Sawdust

The moisture content of sawdust before entering the dryer significantly impacts the drying process. If the sawdust is not adequately pre-processed to remove excess moisture, the dryer must work harder to achieve the desired results, potentially leading to incomplete drying.

Inadequate Monitoring and Control Systems

A lack of advanced monitoring and control systems can hinder the optimization of drying parameters. Without real-time data and adjustments, the dryer may not perform at its best.

Poor Maintenance

Neglecting routine maintenance can exacerbate drying issues. Dust, debris, and residue can accumulate over time, affecting the dryer’s performance and efficiency.

Solutions to Enhance Sawdust Dryer Efficiency

1: Regular Maintenance and Inspection

Scheduled maintenance, including cleaning, lubrication, and component checks, can prevent heat generation issues. Regular inspection ensures timely detection of faulty parts.

2: Optimize Airflow Management

Improving airflow involves maintaining clean vents, repairing or replacing fans, and optimizing duct designs. Proper airflow guarantees even drying across the material.

3: Effective Material Handling

Implementing systems to prevent material buildup and ensuring uniform distribution within the dryer promotes consistent drying. Vibrating conveyors or rotary feeders can aid in this process.

4: Avoid Overloading

Adhering to the recommended load capacity is essential for optimal drying. Avoid overloading the dryer and ensure an even distribution of sawdust. This approach allows for proper airflow and efficient moisture removal.

5: Enhancing Pre-processing Techniques

Pre-processing sawdust to reduce initial moisture content lessens the burden on the dryer. Employing techniques such as air drying or moisture extraction before entering the dryer chamber enhances overall drying efficiency.

6: Integration of Advanced Monitoring Systems

Incorporating advanced sensors and control systems enables real-time adjustments based on moisture content, temperature, and other critical variables.

7: Regular Maintenance

Regular maintenance is key to preventing incomplete drying. Establish a maintenance schedule that includes cleaning, lubrication, and inspection of all components. This proactive approach can prolong the dryer’s lifespan and maintain its effectiveness.

Conclusion

A well-functioning sawdust dryer is vital for efficient wood processing. By addressing challenges related to heat generation, airflow, material distribution, and monitoring systems, manufacturers can ensure optimal performance and quality output.

FAQs

Q1: How can I tell if my dryer’s airflow is compromised?

A1: Uneven drying or prolonged drying times are indicators of airflow problems. Visual inspection of vents and fans can also reveal blockages or damage.

Q2: What role does moisture content play in drying efficiency?

A2: Moisture content directly affects drying efficiency. Higher moisture levels require more time and energy for complete evaporation.

Q3: Are advanced control systems worth the investment?

A3: Yes, advanced control systems offer precise adjustments, leading to better drying results, energy savings, and overall cost-effectiveness. Advanced ventilation systems, temperature controls, and monitoring technologies can significantly enhance sawdust drying efficiency and effectiveness.

Q4: How can I prevent inadequate heat distribution in my sawdust dryer?

A6: Proper maintenance of heating elements and ventilation systems is crucial to prevent inadequate heat distribution. Regular inspection and cleaning can address potential issues.

Q5: What should I do if my sawdust remains damp after drying?

A5: Check for factors such as temperature settings, airflow, and load capacity. Ensure proper adjustments are made to optimize the drying process.

Q6: Can I increase the load capacity of my sawdust dryer for higher productivity?

A6: It’s recommended to adhere to the manufacturer’s load capacity guidelines to maintain efficient drying. Overloading the dryer is not recommended, as it compromises airflow and heat distribution, leading to incomplete drying and potential damage to the dryer.

Q7: How often should I perform maintenance on my sawdust dryer?

A7: Regular maintenance should be performed according to a schedule provided by the manufacturer. This can help prevent issues and prolong the dryer’s lifespan. Observe the drying effect of the dryer every day and make timely adjustments. Generally, it is necessary to check the important components of the dryer every week, such as transmission gears, pipelines, lubricating oil, and current conditions. If there is any problem, professional technicians are required to repair and adjust.

Q8: Can burstiness affect the quality of the dried sawdust?

A8: Excessive burstiness might lead to non-uniform drying and uneven moisture removal, impacting the overall quality of the dried sawdust.

Q9: What role does pre-processing play in drying efficiency?

A9: Pre-processing, such as reducing initial moisture content, resize the sawdust before feeding with hammer mill, significantly enhances drying efficiency by reducing the workload on the dryer and ensuring more effective moisture removal.

Talk to An Expert

SHARE THIS POST

Talk to An Expert