6 Main Rotary Dryer Moisture Issues and Solutions

Introduction

In the world of industrial processes, rotary dryers play a vital role in efficiently drying various materials. However, there are instances where the moisture content of the dried material does not meet the desired requirements. This article delves into the factors contributing to this issue and offers insights into how to address it effectively.

Understanding Rotary Dryers and Moisture Control

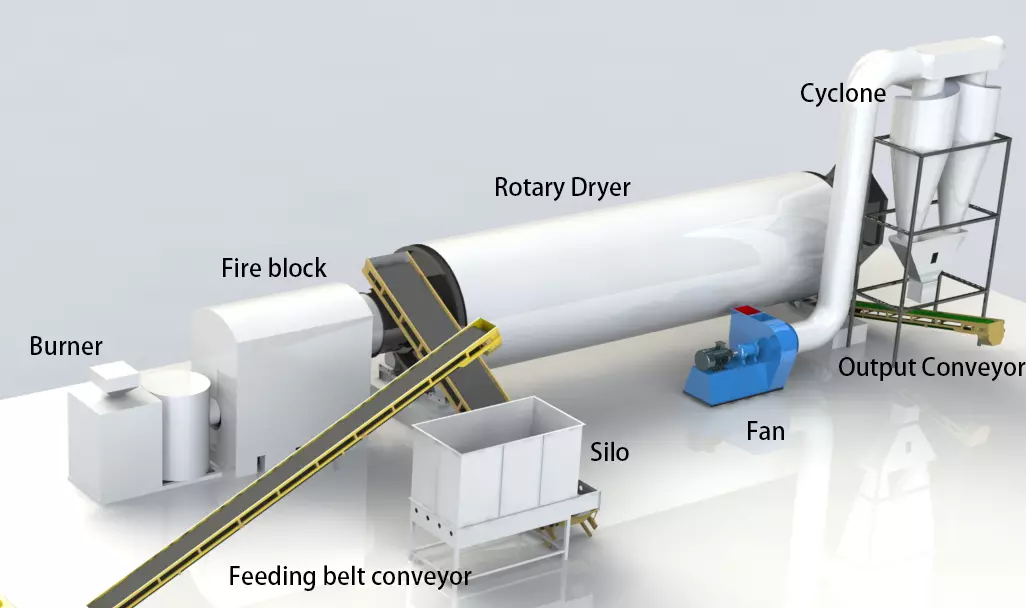

A rotary dryer is a specialized industrial machine used to remove moisture from a variety of materials through the application of heat. It consists of a cylindrical drum, which rotates while the material is fed into it. As the drum rotates, the material is exposed to hot air or gases, allowing moisture to evaporate.

Importance of Moisture Control

Moisture control is crucial in many industries, including agriculture, chemicals, and minerals, as excessive moisture can lead to product degradation, clumping, and decreased shelf life. Rotary dryers offer an effective solution for moisture removal, but at times, the desired moisture content is not achieved.

Reasons Behind Insufficient Moisture Removal

The irregular moisture distribution within the rotary dryer arises from several primary factors:

To begin, a substantial variance exists in the innate moisture levels inherent to the diverse raw materials.

Subsequently, the operational process of the rotary dryer introduces instability in the temperature of the hot airflow. This volatility manifests as frequent and wide-ranging fluctuations, encompassing both elevated and diminished temperatures. Consequently, this erratic thermal environment contributes to the irregular moisture distribution.

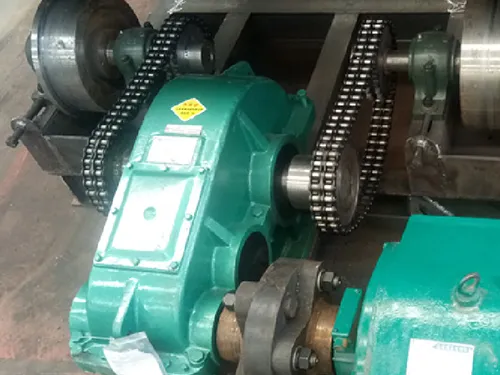

Moreover, a deficiency in the uniformity of the dryer’s mechanical mechanism compounds the issue. Inconsistencies in the dimensions and alignment of the gaps between components result in disparate drying outcomes, characterized by uneven moisture levels.

Furthermore, the feeding mechanism encounters partial blockages, thereby impairing its ability to consistently dispense materials. As a direct result, the drying quality is adversely affected, leading to disparate moisture distribution patterns.

The distribution of the heated airflow exacerbates the situation by its uneven coverage. Certain regions receive the forceful impact of the hot air, while others remain untouched, thus instigating imbalanced moisture levels across the material.

Additionally, the exhaust port of the exhaust gas chamber confronts obstructions that impede the efficient discharge of moisture-laden air. Alternatively, the exhaust port’s inadequately sized area hampers proper moisture removal. Both scenarios compromise the quality of drying and contribute to the uneven moisture distribution phenomenon within the rotary dryer.

Solutions to Solve the Rotary Dryer Moisture Issues

Regular Maintenance and Inspection

To ensure optimal performance, regular maintenance and inspection of the rotary dryer are necessary. This includes cleaning the drum, checking heat distribution mechanisms, and verifying airflow rates.

Proper Loading Techniques

Loading the dryer with the right amount of material is essential. Following manufacturer guidelines and avoiding overloading or underloading can help achieve better moisture removal.

Adjusting Parameters

Fine-tuning parameters such as temperature, airflow rate, and rotation speed can significantly impact moisture removal. Experimentation and adjustments can lead to better results.

Material Preconditioning

In some cases, pre-treating the material before entering the rotary dryer can enhance moisture removal. Techniques like size reduction or exposing the material to certain conditions can make it more receptive to drying.

Conclusion

In the realm of industrial drying, rotary dryers are invaluable tools for moisture removal. However, achieving the desired moisture content can be challenging due to factors such as heat distribution, airflow, and material properties. By addressing these issues through proper maintenance, loading techniques, parameter adjustments, and material preconditioning, industries can optimize their drying processes and ensure consistent and efficient moisture removal.

FAQs

Q1: Can any material be effectively dried using a rotary dryer?

A1: While rotary dryers are versatile, certain materials may require specific considerations for optimal drying results.

Q2: How often should a rotary dryer undergo maintenance?

A2: Regular maintenance should be performed according to the manufacturer’s recommendations and the dryer’s usage frequency.

Q3: Are there alternatives to rotary dryers for moisture removal?

A3: Yes, other methods like fluidized bed dryers or spray dryers can also be used depending on the material and desired outcome.

Q4: What safety precautions should be taken when operating a rotary dryer?

A4: Operators should follow safety guidelines, including proper ventilation, protective equipment, and monitoring of temperature and pressure.

Q5: Can moisture content be too low after rotary drying?

A5: Yes, excessively low moisture content can lead to issues such as brittleness or undesirable changes in material properties.

Talk to An Expert

SHARE THIS POST

Talk to An Expert