A Comprehensive Guide to Biomass Dryer: Types, Operating Principles, and Applications

A crucial step in the creation of renewable energy is the drying of biomass. The necessity for an effective biomass dryer is becoming more critical as the demand for renewable fuel sources rises.

These dryers are essential for dehydrating biomass materials, enabling their application in a variety of sectors including power plants, pellet mills, and biofuel production facilities.

In this piece, we’ll talk about how important biomass dryer is and how it helps build a more environmentally friendly and sustainable future.

We’ll look into the several kinds of biomass dryers that are out there, their operating concepts, and the advantages they provide for the environment and the sectors that use biomass as a renewable energy source.

Importance of Biomass Drying

The biomass sector relies heavily on biomass drying, which has many advantages and benefits. The quality and energy content of biomass fuel is improved by biomass drying by lowering the moisture content in biomass and materials like wood pellets and agricultural waste.

For effective combustion and storage, moisture levels must be optimized, making biomass dryers a crucial part of the biomass processing process. These dryers remove excess moisture using a variety of technologies and techniques, allowing biomass facilities to select the best drying option for their particular requirements.

The benefits of drying biomass are extensive. It not only cuts operating costs and energy use during combustion, but it also helps make sure that the biomass fuel business will be around for a long time. Reduced moisture content maximizes the utilization of waste resources while reducing greenhouse gas emissions.

The optimal use of biomass as a renewable fuel source and its critical role in maximizing energy production and environmental impact make biomass drying of the highest importance in the biomass business.

Types of Biomass Dryers

Biomass dryers come in a variety of designs, each created to satisfy certain drying needs. The most typical varieties include:

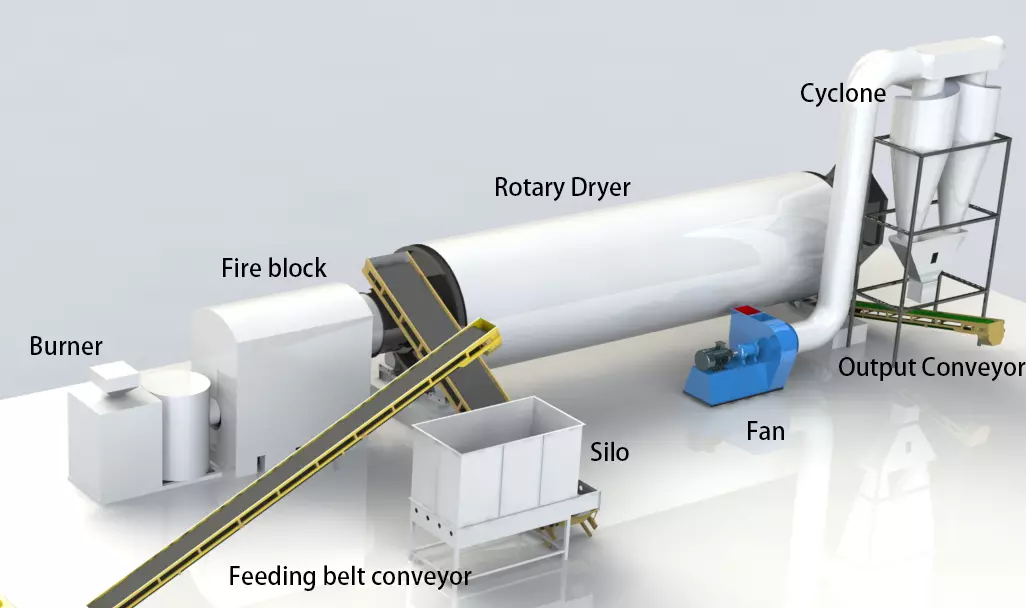

- Biomass Rotary Dryer: The first type of dryer used for biomass is the rotary biomass dryer. They have a spinning biomass rotary drum dryer that evenly distributes heat across wet biomass, such as wood chips or agricultural waste. With this effective drying procedure, excellent drying capacity and low moisture content are guaranteed.

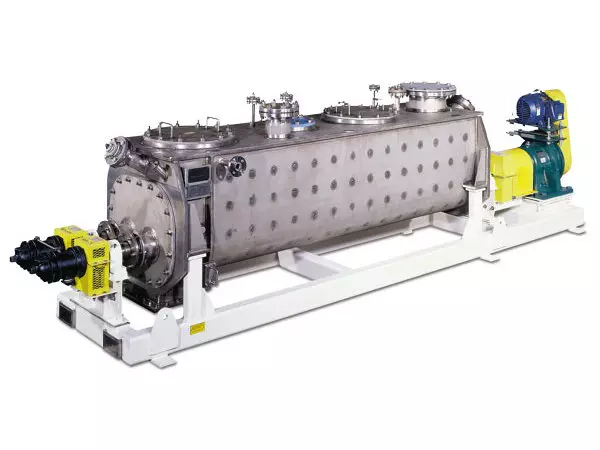

- Biomass Paddle Dryers: Also known as agitated dryers, paddle dryers constantly mix and move the wet biomass, enabling a quicker and more even drying times process. This kind of drier is frequently used to dry biomass materials that are sticky or fibrous.

- Biomass Fluidized bed dryers: These dryers move and suspend biomass particles using a stream of hot air or gas. Turbulence produced by the fluidized bed inside the drying chamber encourages quick and equal drying. Fine biomass powders or particles can be dried using this sort of drier.

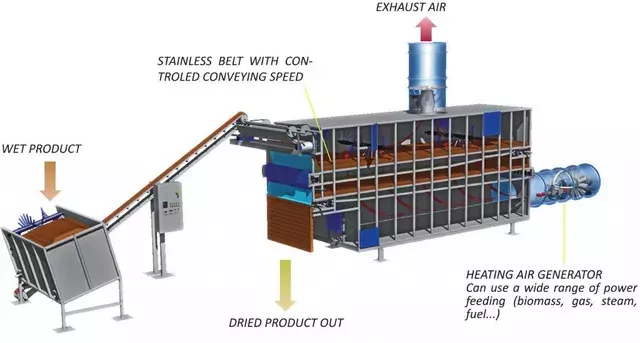

- Biomass Belt Dryer: In a biomass belt dryer, wet biomass is spread out on a moving conveyor belt, and moisture is evaporated by hot air that circulates above and below the belt. It is possible to dry biomass on a large scale using this continuous drying method, which offers a high drying efficiency.

- Tray Dryers: Tray dryers are made up of several trays stacked on top of one another. On these trays, wet biomass is thinly spread, and hot air is pushed over them to dry the biomass. Tray dryers can process a range of biomass sources and are appropriate for smaller-scale operations.

Each kind of biomass dryer has distinct benefits and is appropriate for various applications. The best sort of drier to use will depend on the moisture content, drying speed, and unique needs of the biomass being dried.

Key Components of a Biomass Dryer

An essential piece of machinery used in enterprises that depend on the drying of diverse biomass products is the biomass dryer machine. The main elements of a biomass dryer are as follows:

- Drying Chamber: The wet biomass is placed in the drying chamber to begin the drying process. It gives the biomass the room it needs to interact with hot air or other heated gases, allowing moisture to evaporate.

- Heat Source: The energy required to heat the drying chamber is supplied by the heat source. Common heat sources include electrical heaters, waste heat from other processes, and direct combustion of biomass fuel. For the best drying outcomes, a dependable and effective heat source is essential.

- Air or Gas Circulation System: The drying chamber of a biomass dryer machine needs to be circulated with heated air or gas. By doing this, it is made certain that the biomass is continuously exposed to the ideal drying temperature. Speeding up the drying process is also made possible by proper air or gas circulation.

- Exhaust system: An exhaust system is required to keep the correct drying temperature and eliminate moisture from the drying chamber. In order to ensure optimum ventilation and prevent the buildup of moisture, it aids in the evacuation of the humid air or gas produced during the drying process.

- Controls and Monitoring: To regulate and optimize the drying process, contemporary biomass dryers are outfitted with controls and monitoring systems. With the ability to precisely manage ambient temperature and airflow, these systems guarantee effective drying while reducing energy use and maintaining product quality.

Industries can select industrial drying solution that meets their unique requirements by comprehending the essential elements of a biomass dryer machine. A well-designed and well-maintained dryer may greatly increase drying efficiency, save running costs, and boost overall output whether it is used for wood chips, agricultural waste, or other biomass materials.

Biomass Dryer Selection Criteria

For drying processes to be successful and efficient, choosing the correct biomass dryer is essential. Here are some important factors to take into account when selecting a biomass dryer machine:

- Moisture Content: Evaluate the biomass material’s moisture content and compare it to the dryer’s drying capacity. Make that the dryer is capable of handling the necessary moisture removal.

- Drying Technology: Take into account the various drying techniques, such as rotary biomass dryer or high-temperature drying, and select the one that best fits the properties of the biomass material.

- Energy Efficiency: Look for a dryer that uses little energy and has low running costs. To cut energy costs, take into account things like electricity consumption and fuel supply requirements.

- Drying Capacity: Based on the volume of biomass material to be processed, determine the necessary drying capacity. Make sure the dryer’s capacity satisfies the need for production.

Whether it’s wood chips, agricultural waste, or biomass fuel, make sure the dryer is appropriate for the particular biomass material. Think about things like size, form, and density.

- Sustainability: Choose a biomass drying machine with low greenhouse gas emissions and renewable fuel sources. Look for ecological and energy-efficient drying options.

- Lifespan and Maintenance: To ensure durability and lifespan, choose a dryer constructed of high-quality materials like stainless steel. Think about the spare parts supply and ease of maintenance.

- Monitoring and Control Systems: Seek dryers with sophisticated monitoring and control systems. These systems enable exact control of the drying process by regulating the temperature, airflow, and moisture content.

You can choose a biomass dryer that satisfies your unique drying requirements, lowers your energy costs, and provides high-quality dried biomass material by taking these factors into account.

Operating Principles of Biomass Dryers

In order to effectively remove moisture from biomass, biomass dryers operate according to specific principles.

- The dryer circulates hot air or steam through it in order to transmit heat to the wet material, which causes the moisture to evaporate. This is known as the first principle of heat transmission.

- The second fundamental is ventilation, which makes sure that heat and moisture are distributed properly throughout the dryer and promotes uniform drying.

- The third principle is moisture removal, in which the dryer’s evaporating moisture is removed via a variety of techniques like condensation or ventilation.

Biomass dryers may effectively and efficiently dry biomass materials, making them ready for additional processing and use, by comprehending and putting these operational principles into practice.

Applications of Biomass Dryers

A variety of businesses can employ biomass dryers to swiftly and effectively remove moisture from biomass products. Biomass drying is necessary for the efficient processing and exploitation of a variety of materials, including wood chips used as fuel in commercial boilers and agricultural waste used as animal feed.

Here are a few typical uses for biomass dryers:

- Fuel Production: Before being used as fuel in commercial boilers and furnaces, wood chips, sawdust, and other woody biomass materials are dried.

- Agriculture: To lower the moisture content, agricultural waste materials including hay, straw, and animal manure is dried. This makes it simpler to store and handle the material for later use.

- Animal Feed: The production of animal feed requires the drying of biomass resources such as grains and grasses.

- Biomass Energy: Dry biomass is utilized to generate electricity by gasification, burning, and other processes.

- Production of fertilizers: Dried biomass can be utilized to make organic fertilizers for use in agriculture.

These are only a handful of the numerous uses for biomass dryers in different sectors.

Benefits of Biomass Dryers

Businesses and industries working with wet biomass resources might profit greatly from biomass dryers. By lowering the moisture level of materials like wood chips and agricultural waste, this specially created biomass drying system helps make them more effective for a variety of purposes.

The ability of a biomass dryer machine to dramatically enhance drying capacity is one of its main advantages. These dryers can handle huge volumes of wet materials thanks to high-temperature drying technologies and effective operation, which eliminates the need for additional drying stations and boosts total production.

Additionally, biomass dryers support sustainability by relying less on fossil fuels and using sustainable fuels like biomass fuel. This is a green solution because it not only aids in cutting energy expenditures but also lowers greenhouse gas emissions.

Ultimately, stainless steel is used in the design of biomass dryers to ensure endurance and dependability. They are cost- and energy-efficient because they also use waste heat, low-pressure steam, or extra energy from biomass plants.

Future Trends and Innovations in Biomass Drying

The need for effective and environmentally friendly drying methods is growing, and biomass drying technology is constantly developing to satisfy this need. A number of trends and developments are starting to emerge in the biomass drying industry as we look to the future.

The creation of sophisticated drying systems with increased drying intensity and efficiency is one of the major trends of biomass drying machines.

To reach the ideal moisture content in biomass materials, these systems combine drying procedures such as steam drying and air-induced drying. This enhances the drying process and raises the quality of the finished product as a whole.

The emphasis on eco-friendly drying techniques is another trend in biomass drying. Biomass drying is changing to employ renewable energy sources as the world adopts more sustainable methods. Systems for drying biomass are being developed that make use of biofuels, minimizing the need for fossil fuels and lowering greenhouse gas emissions even more.

Future-proofing drying stations is a key goal of advancements in biomass drying technology. Container drying stations that can be quickly placed in various locations are being developed by businesses.

These integrated batch drying stations make the most of available space and resources by providing a small and effective biomass drying solution.

Improvements are also being made in the biomass drying equipment. In order to increase drying capacity and lower operational costs, new technologies are being adopted. Additionally, work is being done to create large-scale, industrial-scale biomass drying systems that can process enormous amounts of wet biomass. The biomass drying system will increase productivity and eliminate the need for several drying stations.

With ongoing research and development efforts targeted at improving the effectiveness and sustainability of drying processes, the future of biomass drying appears bright. The demand for effective biomass drying technology is anticipated to increase as agricultural waste continues to be a key fuel source.

We can attain more drying capacity, lower energy usage, and a greener and more sustainable method of drying biomass by adopting these upcoming trends and developments.

Conclusion: The Potential of Biomass Dryers

The enormous potential of a biomass dryer machine to satisfy the growing need for effective and environmentally friendly drying solutions. The future of biomass drying is bright because of the creation of cutting-edge drying equipment and the emphasis on environmentally friendly processes.

Innovative drying techniques are increasing drying effectiveness and intensity to ensure that biomass materials have the ideal moisture content. The transition to renewable energy sources, such as biofuels, is lowering greenhouse gas emissions and enhancing the drying process’ sustainability.

The development of biomass drying is being further fueled by efforts to future-proof drying stations with cost-effective container solutions and increase drying capacity. These developments position biomass dryers to be a key player in the shift to a more sustainable and energy-efficient future.

So, if you’re looking for a biomass dryer for sale, look no further than one of the best biomass dryer manufacturers, visit https://www.tcpel.com/ now to learn more!

Related Articles:

Talk to An Expert

SHARE THIS POST

Talk to An Expert