Pellet Machine 101: Various wood pellet making equipments

You may have heard a lot about establishing a wood pellet manufacturing plant or understanding about various wood pellet making equipment.

This article will discuss what a wood pellet machine actually is and why we use it and how this is an eco-friendly solution for energy production.

If you live in a village and also want to know why wood pellets are something that you need in your daily life, this article is going to be a very helpful guide.

Moreover, it is also an important informative article for manufacturers and business owners who want to establish a wood pellet manufacturing plant.

Pellets Business Ideas:

Pellet Production Profit Analysis: Is it a Profitable Business?

Top 10 Pellet Machine Manufacturers in The World

Wood Pellet Making Equipment: The Basics

We have started from scratch as it is important to understand how the wood pellet manufacturing equipment works. It is important as it will give you an idea of the equipment even before you have any experience or you do not know what the product actually is.

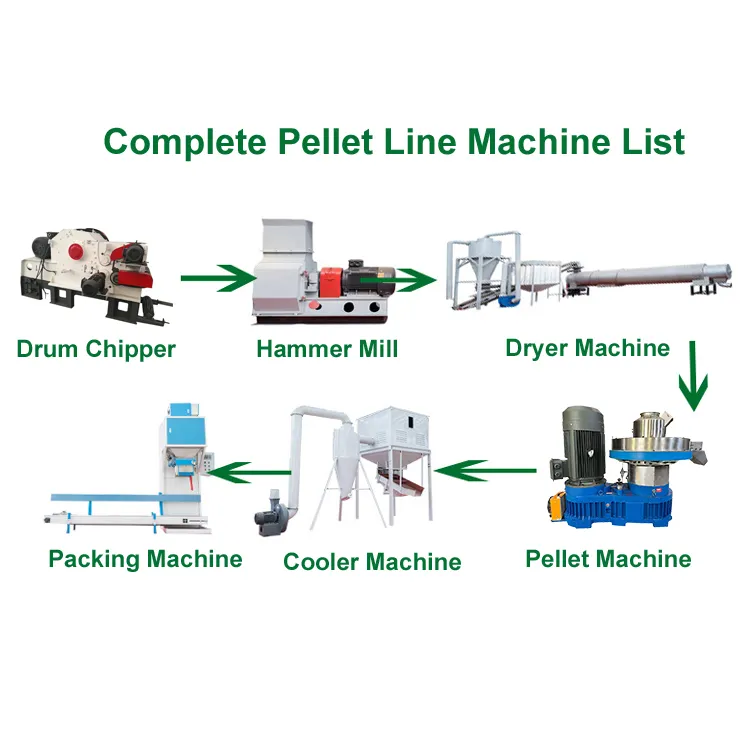

Basically, there is not only one method of creating the wooden pellet and they require very careful handling. This is basically a long step process that requires the usage of a pellet mill and different types of drying, cooling, and packaging equipment.

Here it is worth mentioning that the quality of the wood pellets directly depends on the quality of the wood. If you use high-quality wood, you will obtain very high quality wood pellets.

Moreover, it is also important to sieve them properly so that you get the pellets with equal sizes and they look stunningly amazing and useful [1].

Overview of the Wood Pellet Making Process

Before we dive into the specific equipment used in wood pellet production, let’s take a moment to understand the overall process.

Wood pellet making involves converting raw wood materials into compacted pellets that can be used as fuel.

The process typically includes the following steps:

Brief Explanation of Process

Raw Material Preparation:

First of all, you must have very high quality pellet making raw material including the wood chips or something that can be collected and prepared for the process of wood pellet making.

Saw-dust and some other similar materials are also used for making wood pellets. It is not necessary to be very expert in creating an environment where you can create wood pellets.

However, staying respectful and utilizing all the possible means to wait for making wood pellets after the process is something that you can do.

Size Reduction:

As we know the manufacturing of wood pellets is all about creating a very small size of the wooden pieces, a hammer mill or a wood chipper is used to break them down into smaller, more manageable pieces.

The conversion of the wood into these small pieces creates pellets that need to be dried in order to be useful for different purposes[2].

Drying:

It is important to understand that the manufacturing of a wood pellet does not stop at drying them only. If they do not have a specific moisture content we can never obtain high quality wood pellets.

Moreover, for the processing of wood pellets is also necessary and just stuff is more important that make them would pellets.

Pelletizing:

As the name indicates, this is the major step that converts these small wooden pieces into highly shaped and compressed pellets. This is where the role of pellet mills comes into the picture that creates the environment which is suitable for the particular moisture level of wooden pieces.

You also need to understand what happens at the whole process set up. When you use the pellet mills, you actually utilize this equipment to obtain a very high pressure.

More over the presence and creation of the heat in this whole process buyings these particles together and converting them into very useful wood pellets.

However, as it is the main step, the process does not end here and we have to cool and sieve them in order to use them.

But it is worth mentioning that this is the main step where the wood materials are compressed and shaped into pellets. Pellet mills, the central equipment in this process, apply high pressure and heat to bind the wood particles together.

How to Tutorial:

How to Make Wood Pellets-The Ultimate Beginner’s Guide

How to Make Wood Shavings? The Ultimate Guide in 2023

Cooling and Sieving:

Now that we have heated them a lot, we also need to cool them and sieve them. So if you have just created the wood pellets and took them out of the pellet mill, it is the time to let them cool down and reduce the temperature.

Moreover, it is also necessary to make sure that they do not have any extra moisture.

We can also merge another step here and that is sieving. It is the process of removing access under sized pilots or any fine particles that are present there.

So in a nutshell, the freshly made wood pellets are cooled to reduce their temperature and remove excess moisture. Sieving is also performed to separate any fines or undersized pellets[3].

Here it is worth matching that there is also specialized sieving equipment and you can never use any regular equipment that is designed for any other sieving purpose.

Packaging:

Once the pellets have cooled and been sieved, they are ready for packaging. This can be done in various forms, such as bags or bulk shipments, depending on the intended use.

Now that we have a general understanding of the wood pellet making process, let’s explore the key equipment involved and their functions.

Key Equipments in Wood Pellet Production

If you will understand the usage of key equipment in the wood pellet production, you will be able to make better decisions. It will help you in deciding what type of equipment you should purchase and how it works.

Raw Material Preparation Equipment:

The very first process in making the wood pellets is gathering the raw material and then preparing it with the help of machines. This includes machines like wood chippers, shredders, and crushers.

Their role is to break down the raw wood materials into smaller, uniform pieces suitable for pelletization. Perhaps this is the major step that requires a lot of energy expenditure.

Moreover, you should also use high quality wood if you want to see the best results[4].

Drying Equipment:

It is also important to make the best use of the equipment that removes the moisture because it is important to retain the particular moisture level and not have to dry them entirely.

To achieve the optimal moisture content in the wood materials, dryers or drying machines are used. These remove excess moisture, ensuring the quality and combustion efficiency of the pellets.

Pelletizing Equipment:

Pellet mills are the major pelletizing equipment. The heart of the wood pellet production process lies in the pellet mills. These machines compress the prepared wood materials under high pressure, forcing them through small holes in a die. The result is dense, cylindrical pellets that are durable and efficient.

The quality of the pellet mill is also important because it must be able to perform the function efficiently and provide you with the most accurately shaped and wonderful pellets that you can use for different purposes, especially energy production.

Cooling and Sieving Equipment:

After pelletizing, the newly formed wood pellets require cooling to ensure their integrity and reduce moisture content. Cooling machines, such as pellet coolers, provide this essential function. Sieving equipment is also used to remove any fines or undersized pellets.

Packaging Equipment:

To prepare the final product for distribution and use, packaging machines are employed. These machines can handle different types of packaging, including bags, boxes, or bulk containers[5].

With these key equipment pieces, you can establish a reliable and efficient wood pellet production line.

However, when it comes to choosing the right equipment for your specific needs, there are certain factors to consider.

Evaluation and Buying Tips for Wood Pellet Making Equipment

Criteria to Consider

● Capacity and Output: Assess your production requirements and choose equipment that can handle the desired pellet production volume.

Consider factors like hourly output and overall capacity. If you are a business owner or investor and want to invest in establishing a wood pellet manufacturing plant, you need to carefully analyze all the statistics related to capacity and output and you will surely get the results.

● Quality and Durability: Look for equipment that is built to last and can withstand the demands of continuous operation. High-quality materials and robust construction contribute to long-term reliability.

So if you want to purchase online, you need to see the warranty of the product and the credibility of the platform from where you are purchasing.

● Energy Efficiency: Opt for equipment that maximizes energy efficiency, helping you minimize operational costs and reduce environmental impact. It is an important step because the manufacturing of the wood pellets is also for energy creation purposes.

If the maximum energy is wasted during the manufacturing process, you will never be able to get the high quality yield. Moreover, the wood pellets that are generated after a lot of energy expenditure will cost a lot of money and you will not be able to benefit from them. This is an important aspect that the business owners, investors and expert manufacturers must consider if they want to establish their setup.

● Ease of Use and Maintenance: Consider equipment that is user-friendly and easy to maintain. Features like automated controls and easy access for cleaning and servicing can greatly enhance operational efficiency.

How to Choose the Right Equipment

Choosing the right equipment is an important thing that requires careful handling and experience of the whole process.

If you want to purchase anything online, you need to get in touch with the reputable platform that provides you with the most functional equipment that does not come with any issues.

If you are a professional person and want to establish a wood pellet manufacturing plant, you need to purchase different types of devices, tools and machines one by one and ensure that each of the tools in the equipment works efficiently.

When it comes to selecting equipment for generating wood pellets, TCPEL stands out as the clear-cut superior option.

TCPEL provides customers with a diverse selection of wood pellet machines that are developed to fulfill a variety of manufacturing requirements. Our machinery is renowned for its remarkable quality as well as its great efficiency and long-lasting nature.

TCPEL offers the optimum mix of price and quality, making it the ideal choice whether you are constructing a brand-new pellet mill or replacing the machinery you already have.

Visit TCPEL’s website to explore its range of pellet machines and learn more about its commitment to delivering top-notch equipment.

Conclusion

Now that you have read the article you can easily understand how the process of manufacturing the wood pellet works and what is the necessary equipment.

This article is useful for the people who know nothing about how the pellers are created and whether or not the procedure is cost-effective.

Moreover, it is also helpful and useful for the people who want to establish their food pellet manufacturing plant and want to see what equipment is and how it works.

And when it comes to finding the best price and quality combination, TCPEL emerges as the preferred choice. To take your wood pellet production to the next level, explore TCPEL’s wood pellet machines at tcpel.com.

Talk to An Expert

SHARE THIS POST

Talk to An Expert