Pellet 101: A Comprehensive Guide to the Pellet Line

Pelleting Industry: The basics

The wood pellet market had a total valuation of USD 9,630 million, expected to reach around USD 23,892 million by 2028. The growth rate is projected at a CAGR of 12.1% from 2020 to 2028. This makes it one of the fastest-growing markets of recent times.[1]

Wood pellets are used efficiently for both residential and commercial purposes. Europe is one of the leading continents where wooden pellets are used. You will also find significant use of wooden pellets in North America and other countries.

Because of the increased demand for wood pellets, there has also been an increased need for highly advanced machinery for pellet manufacturing. Consequently, the demand for pellet manufacturing machines has also increased.

Today, it’s not just wood which is made into pellets. In fact, you will find a wide range of pelleting materials being used in different industries.

So, if you are in the pellet manufacturing business and you are looking forward to improving the productivity of your business to a great extent, then it is high time that you invest in a high-quality product for yourself so that the pelleting process can pellet be carried out smoothly and the pellet production rate can also be increased. You will also be able to give your business an excellent boost.

The Pellet Line

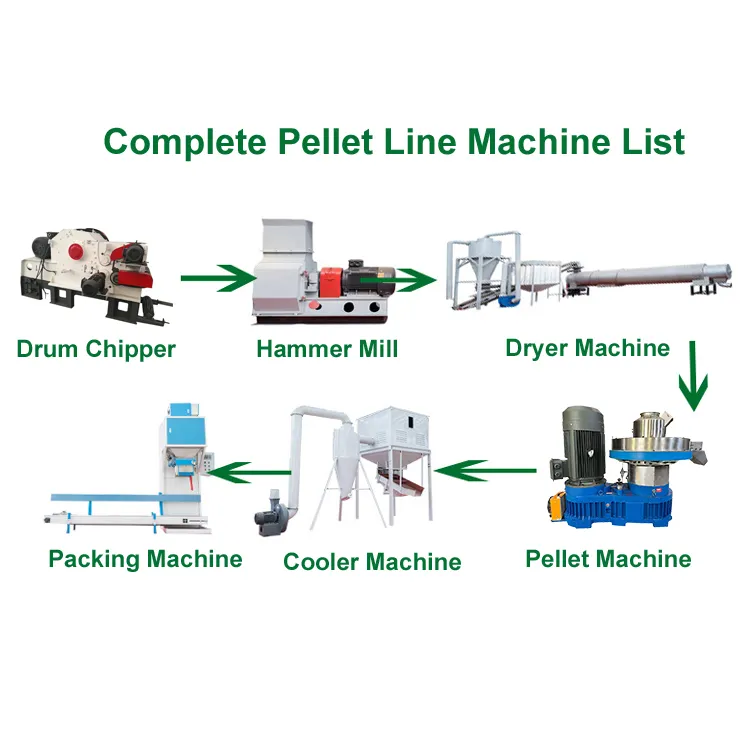

Step-by-step explanation of the process

Let us have a look at some of the crucial stages of the pelleting process:[2]

Preparation of raw material: The first thing that requires to be done is to prepare the raw wooden material. Very little raw material is required to make small wooden pellets.

These small wooden pellets are meant for personal use. The raw material is mostly crop waste which does not require additional processing.

However, for large wooden pellets, it becomes important for you to have sufficient quantities of raw material. The large pellet plants mostly use wooden branches and logs as their raw material. They also try to acquire their raw materials from a nearby factory.

Also, it is important to note that it is not just wood which is used in pelleting. The raw material will depend on your exact industrial needs.

Reduction of size: In large wooden pellet plants, once the raw material is ready, the first thing that needs to be done is to reduce the size of the raw material. The raw materials should be made under 5 mm in diameter. So, the branches and logs are cut into small pieces. Drum chippers are used quite effectively to reduce the size of raw materials.

In the manufacturing process of small wooden pellets, the size reduction process does not need to be done as crop waste is used to manufacture these pellets. However, this phase is really important in the case of large wooden pellet manufacturing processes.

Drying: After the size reduction place comes the drying phase. Here, the raw material will have to be dried. Drying the pellets properly is important to produce good quality pellets. The raw material should have a maximum of 8 to 12 % moisture. A rotary dryer can be used to extract the moisture from the wooden pellets.

Initial sieving: Next comes the initial sealing process. Here, the raw material is separated from contaminants like dust and dirt. The contaminants may otherwise interfere with the manufacturing process, and the quality of the pellets will be compromised.

Magnetic separators are used for the initial sieving process. For small wooden pellets, this step is again not necessary.

Grinding: The grinding stage is also known as the size reduction phase. This phase is equally important for both small and large pellets. During the grinding stage, the raw materials will be put into a hammer mill and converted into small pieces.

However, the hammer mill only works for raw materials with a diameter of less than 50mm. The logs and branches must be processed and cut down into wood chips before grinding.

Pelletizing: In the pelletizing stage, the raw materials are converted to wooden pellets. For pelletizing, a pellet machine is used. You will find different kinds of pellet machines available in the market.

So, your choice of machine would depend on how you would want to use the wooden pellets.

Cooling: The wooden pellets are highly vulnerable after the pelletizing process. So, they will have to be cooled before they acquire rigidity. The wood pellets are inserted into a pellet cooler to be brought down to the right temperature. The pellets can then be processed for industrial use.

Final sieving: This stage is mainly required to manufacture commercial wood pellets. The pellets will be sieved to remove all the fine particles from them to enhance their quality. This makes the pellets suitable for commercial purposes.

The level of sieving will depend on the exact industrial purpose for which the pellets will be used.

Key components involved in the pellet line

Here are some of the key components used in the pelleting process:

Drum chippers: Drum chippers are mostly used in reducing the size of wooden pellets. These drum chippers also remove unwanted materials from the wooden pellets.

Wood shaving machine: A wood shaving machine shaves raw materials like logs and branches into uniform sizes. They are mostly used for converting large-sized raw materials into a form perfect for wood pelleting.

Hammer mills: Hammer mills are an important part of the pelleting process. These hammer mills are used for grinding the raw materials so that wood pellets can be made from them conveniently.

Rotary dryers: Rotary dryers reduce the moisture content from the raw materials. These machines have a big role in ensuring that the wooden pellets are of the best possible quality.

Pellet machines: The pellet machines are responsible for pelleting the wooden chips. There are a huge variety of pellet machines available. So, you can pick the right pellet machine depending on your business needs.

Types of Pellet Machines

Flat Die Pellet Making Machines:

Flat die pellet-making machines are one of the most frequently used pellet-making machines. These pellet-making machines can produce a wide range of granulated materials. They have a simple structure and are also quite convenient to work on. The energy consumption of the pelleting process is quite yet the efficiency is high.

These machines consist of the main body, feeding device, cutting device, and an electrical control system. The main body comes with a heating chamber and cooling chamber to enhance the pellets’ quality. Each of these components has got a different role to play in the pelletizing process.

Various advantages of flat die pellet-making machines:

● The structure is quite compact, and the operations are relatively simple.

● The energy consumption is low while the efficiency is high.

● The noise production is quite low. So they can be used in residential areas.

Horizontal Ring Die Pellet Making Machines:

The horizontal ring die pellet-making machine produces pellets from organic materials and biomass. This machine has a fixed ring, a moving ring, and a hydraulic machine. Each of these components functions quite effectively and produces high-quality pellets.

The fixed ring is located at the bottom of the machine, while the moving ring is present at the top of the machine. The hydraulic machine acts as a connector between the two rings and allows the device to function efficiently.

Various advantages of horizontal ring die pellet-making machine:

● The labour required is low as there is no need for frequent manual interventions.

● You have complete control over the size of the pellets.

● The pellets produced are highly consistent in terms of size and quality.

Vertical Ring Die Pellet Making Machine:

The vertical ring die pellet-making machine is another highly efficient machine used in commercial pellet-making. This kind of machine is found in various industries, including food processing, chemical, construction, and much more.

These machines mainly compress the raw material to produce pellets. They are highly energy efficient. The power consumption is quite low. They are also suitable for processing raw materials for pellet production. The pellets produced through these kinds of machines are of really high quality.

Various advantages of vertical ring die pellet-making machine:

● The energy consumption is much lower as compared to other pellet-making machines.

● The machines have a high level of energy efficiency.

● These pelleting machines are quite easy to operate. Even an individual with few days of training will be able to work on these machines.

So, if you are willing to invest in the best quality wood pellet machines for your pellet factory, then it is high time that you reach out to TCPEL and pick the right product for yourself.

TCPEL has always been one of the premium pellet machine manufacturers in China. The company has the widest selection of pellet machines available for various factory operations. The company has a highly experienced team of professionals devoted to releasing the best quality products to solve various problems associated with millet manufacturing and production. [4]

TCPEL follows a strict quality control process to ensure the machines run efficiently. The products are also priced competitively. The company also offers excellent after-sales services.

So, if you face any kind of problems after making your purchase, then you may reach out to the technicians at TCPEL, and they will offer you the exact services as per your requirements.

Importance and Applications of Pelleting

Industries benefiting from pelleting

Food processing: The food processing industry is one of the primary industries where pelleting is used. Pellets are mainly used to produce different snack items and breakfast cereals.

Pelleting in food processing can be used to improve the digestibility and nutritional value of food. Sometimes, they also have a big role in increasing the shelf life of different food items.

Agriculture: The pelting process is used quite frequently in the agricultural industry. The pellets are used for the preparation of fertilisers. They can also be used to produce animal feeds to improve digestibility.

Pelleting the agricultural residue can convert them into biomass, a highly sought-after energy source.

Biomass: Pelleting is important in the biomass sector as well. Various raw materials like branches, logs, and wood chips can be converted to biomass pellets, which are converted to energy.

Biomass pellets are used in various industries as a source of renewable energy. The pellets are also used for various residential purposes.

Chemical industry: The chemical industry also largely benefited from producing pellets. Pellets are mainly used to manufacture items like detergents, pigments, catalysts, and various other pharmaceutical intermediates.

By pelleting the chemical substances, you can improve the ease of handling the products. The solubility is also improved to an extraordinary level.

Pharmaceutical industry: And here’s another industry which frequently requires pelleting. The pellets are mainly used to produce different types of medicines. Because of pelleting, controlled drug delivery can be implemented in the pharmaceutical industry.

Importance of quality and efficiency

Quality and efficiency are driving factors of the pelletizing process. You need to ensure that the pellets produced are of extremely high quality.

Only then can they be used for different industrial and residential purposes. The pellets have to undergo strict quality checks before they are used for commercial purposes.

The hardness, appearance and texture of the pellets mainly reflect the quality. It is also important to maintain proper efficiency during the pellet manufacturing process.

Only then will you be able to get the desired economic benefits from the pelleting process. The efficiency of pelleting can easily be improved by using high-quality pellet machines for the pelleting process.

Conclusion

And this is all that you require to know about the pelleting process. For more details on how the entire pelleting process is carried out, you may get in touch with our experts at TCPEL and they will offer you with the desired information on the same.

Also, for any kind of machinery or equipment required in the pelleting process, you may browse through the products section on our website and pick the products that meet your industrial needs.

Talk to An Expert

SHARE THIS POST

Talk to An Expert