Cost & Profit Analysis of Organic Fertilizer Production Line

With the rapid development of agriculture, large amounts of chemical fertilizers have been invested, resulting in the rapid deterioration of the soil and ecological environment. Improving the soil and increasing soil fertility have become necessary measures to ensure our food rations. Organic fertilizers, which use livestock manure and kitchen waste as raw materials and straw and garden waste as auxiliary materials, have emerged. The voice for organic fertilizers is getting louder and louder, and the prospects are getting brighter. Many people are very confident in the prospects of organic fertilizers and want to invest in the production of organic fertilizers, but they doubt if the organic fertilizer invest worth or not, and want to know the cost and profit analysis for the investment. Here we have prepared the article for you, you will know everything after reading. Let’s take you through:

Organic Fertilizer Production Cost(With Annual Output 3000tons Organic Fertilizer)

1. Raw Material Cost

The main materials of organic fertilizer are usually livestock manure, kitchen waste, etc., and the auxiliary materials are straw, garden waste, mushroom residue, etc. Since the main ingredients and auxiliary ingredients are “junk” in our usual sense, the price is very cheap.

Producing one ton of finished organic fertilizer requires 33% of auxiliary materials, and the cost of auxiliary materials is $20/ton.

Although the cost of raw materials is very low, before deciding to start production, you must first confirm whether the supply of raw materials is stable to avoid affecting production due to shortage of raw materials.

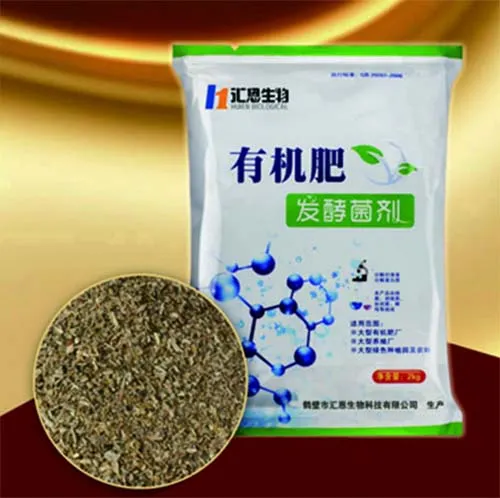

2. Fermentation Bacteria Cost

It costs about $12/kg of high-quality fermentation bacteria. What we buy is usually the original bacteria, which needs to be multiplied with brown sugar water and cornmeal. 1 kilogram of bacteria can be multiplied into 10 kilograms. Each kilogram of high-quality fermentation bacteria can ferment more than 5 tons of finished organic fertilizer, and the cost of fermentation bacteria is $2.4/ton.

3. Carbon-nitrogen Ratio Adjustment:

Superphosphate addition amount is 5%, P²O⁵≥ type market price is $170/ton, cost for the superphosphate is $8.5/ton

4. Electricity Cost

For small production lines, the power is generally around 75 kilowatts. Calculated based on an energy consumption ratio of 80%, the power consumption is 60 kilowatt hours per hour, and 3 tons of organic fertilizer can be produced per hour. The cost of electricity is $4/ton.

5. Packaging Cost

The common packaging unit of organic fertilizer is 40kg, which requires 25 packaging bags per ton. The price of each high-quality double-layer packaging bag is $0.4/bag, and the packaging fee is $10/ton.

6. Labor Costs

The salary is calculated as $40 per person per day. The production line requires 6 people (1 forklift + 1 fermentation person, 2 powder packaging people, 1 mechanic, and 1 electrician). The daily salary is $240, and each group produces for 8 hours. The production capacity is 3 tons per hour, and a total of 24 tons of finished products are produced. The labor wage to get one ton organic fertilizer is $10/ton.

7. Factory Building Cost

Organic fertilizers production do not have high requirements for factory buildings. They only require basic civil construction. The cost is about $60,000 (a conservative estimate, which varies from place to place), but the service life can reach 20 years or more, evenly divided into every ton of organic fertilizers. Fertilizer, the cost is very low.

8. Equipment Cost

According to the different shapes of the finished products, the equipment can be divided into powdered organic fertilizer production lines and granular organic fertilizer production lines.

Powdered Organic Fertilizer Production Line:

Turning Machine—Vertical Crusher—Screening Machine (optional)—Batching Machine (optional)—Horizontal Mixer (optional)—Packaging machine. The specific price depends on the machine configuration and production capacity. A complete production line generally starts at $36,000

Granular Organic Fertilizer Production Line:

Turning Machine — Vertical Crusher — Drum Screening Machine (optional) — Batching machine (optional) — Horizontal Mixer (optional) — Disc Granulator—Dryer and Cooler—Drum Screening Machine—Rounding Machine (optional)—Coating Machine (optional)–Packaging Machine. The specific price depends on the machine configuration and production capacity. A complete production line generally starts at $60,000

9. Equipment Depreciation:

The total price of a complete set of production line equipment with an annual output of 3,000 tons is approximately $36,000. The equipment has a service life of 12 years. The annual depreciation fee is $3000. With an annual output of 3,000 tons, the depreciation fee for each ton of organic fertilizer equipment is $1. .

10. Equipment Maintenance Fee:

The annual consumption of wearing parts for a complete set of equipment is about $2000, and the maintenance fee per ton of organic fertilizer is $0.7

Summary of cost to produce one ton organic fertilizer :

$20+$2.4+$8.5+$4+$10+$10+$1+$0.7=$56.6

Organic Fertilizer Production Profit

Current selling price of organic fertilizer market

The market price of packaged organic fertilizer is $140/ton;

The market price of organic fertilizer without packaging is $100/ton.

Organic Fertilizer Profit Per Ton Calculating:

$140/ton(selling price)-$56.6/ton(cost price)=$83.4/ton

with an annual output of 3,000 tons, then the annual net profit is $83.4*3000=$250,200

Cost & Profit Analysis for Organic Fertilizer Production Line Annual output 3000tons | ||

Cost&Profit | Name | Price in $ |

Cost/ton | Raw Material Cost | $20.0 |

Fermentation Bacteria Cost | $2.4 | |

Carbon-nitrogen Ratio Adjustment | $8.5 | |

Electricity Cost | $4.0 | |

Packaging Cost | $10.0 | |

Labor Costs | $10.0 | |

Factory Building Cost | $0.0 | |

Equipment Cost | $0.0 | |

Equipment Depreciation | $1.0 | |

Equipment Maintenance Fee | $0.7 | |

Total cost/ton | $56.6 | |

Selling Price/ton | Organic Fertilizer Selling Price | $140.0 |

Profit/ton | Profit/ton | $83.4 |

Annual Profit | Capacity 3000ton/year | $250,200.0 |

In the initial stage of investment, the cost of equipment accounts for the majority, but the equipment can usually be used for about 12 years through routine maintenance. When divided equally into each ton of organic fertilizer, the cost is relatively low. In the initial stage, you can also choose equipment according to the actual situation. It is not necessary to invest in the entire production line at the beginning. Above is our local cost, this is only for your reference, you can calculate that based on your local charges.

What You Should Prepare to Start An Organic Fertilizer Production Plant?

An organic fertilizer production plant with an annual output of 10,000 tons can process 22,000 to 25,000 tons of livestock and poultry manure every year. It needs to make the following investments and construction and supporting facilities:

Fermentation Workshop:

One fermentation workshop: area not less than 60㎡×6=360㎡

Factory building requirements:

The conditions of the fermentation workshop must be sheltered from wind and rain. No other conditions are required, and the height is 2.5m;

Raw Material Space:

It depends on the situation, usually between 80㎡ and 120㎡;

Processing Workshop:

processing granular organic fertilizer, with a construction area of about 200 square meters;

Small organic fertilizer factory granulation processing workshop

Warehouse:

Depending on the actual situation, a warehouse of more than 300 square meters should generally be built. According to the above requirements and the requirements of laboratory, logistics, office, dormitory and other conditions, it is more reasonable for a bio-organic fertilizer production plant with an annual output of 10,000 tons to cover an area of 5 acres to 8 acres.

Staffing:

On the premise of completing the output of 10,000 tons, about 8 production workers need to be allocated, including 1 production technician and 1 laboratory technician. Management and marketing will depend on the actual situation.

Conclusion:

Above is our cost and profit analysis of the organic fertilizer production for your reference, and some support building to start the organic fertilizer production, hope this can be helpful for you. If you want to start your own organic fertilizer business, contact with our technician to know more.

Related Articles:

How Much A Complete Organic Fertilizer Production Line Cost

Organic Fertilizer Production Line Ultimate Guide in 2023

How to Start a Fertilizer Business Plan in 2023?

Talk to An Expert

SHARE THIS POST

Talk to An Expert