Organic Fertilizer Production Line Ultimate Guide in 2023

Opening an organic fertilizer factory is not a easy thing. Maybe this will be our career in the next few years, ten years or even decades, so many people will consider many issues. According to Reuters, Russia, India’s largest organic fertilizer supplier, has stopped supplying diammonium phosphate (DAP) and other fertilizers to India at discounted prices. So now is a very good time to invest in organic fertilizer projects. Here we will briefly introduce the various organic fertilizer production line and the characteristics of all the machines involved. After reading this, everyone can choose the most suitable organic fertilizer production line for them based on their own funds.

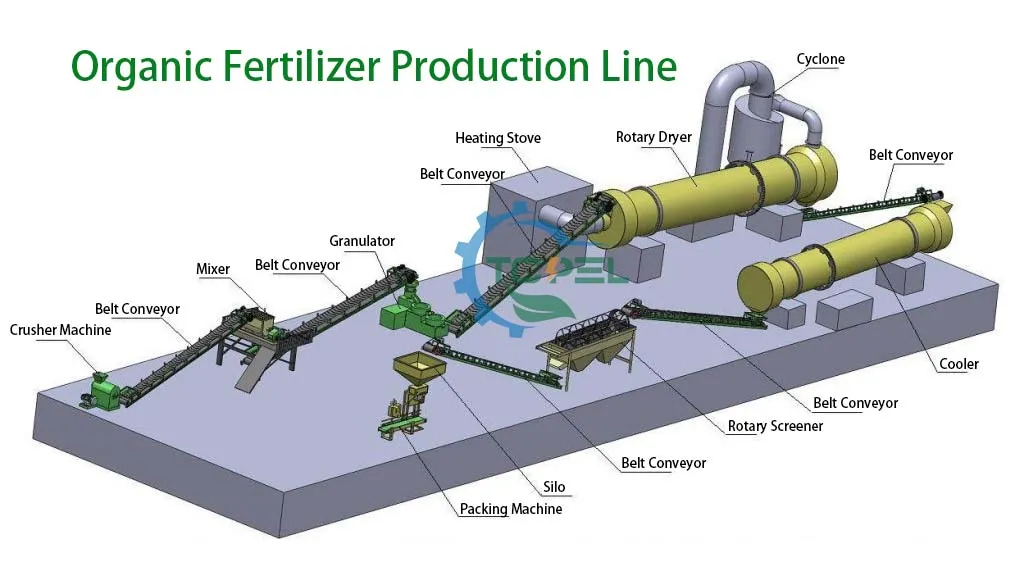

The organic fertilizer production line includes fermentation equipment, granulation equipment, crushing equipment, mixing equipment, screening equipment, cooling equipment, drying equipment, coating equipment, automatic packaging equipment and other related processes.

First, let’s take a look at the various equipments and characteristics in the organic fertilizer production line.

1. Fermentation equipment

Trough type turning machine

Trough-type turners are often also called guide-rail turners, track-type turners, pile turners, etc. It can be used to ferment and turn organic waste such as livestock and poultry manure, sludge garbage, sugar factory filter mud, residue cake meal, straw sawdust and other organic waste. It is widely used in organic fertilizer plants and compound fertilizer plants. It includes a portable fermentation tank body, a guide track, a power-taking device, a turning and heaping part, and a tank transfer device (also called a transfer vehicle, mainly used when multiple tanks are used). The working part of turning and turning piles adopts advanced roller transmission, and there are two types: lifting type and non-lifting type.

Roulette turning machine

The roulette type turner is suitable for the fermentation and composting of livestock and poultry manure, sludge garbage, sugar factory filter mud, residue cake meal, straw sawdust and other organic wastes with large span and high depth. It is widely used in organic fertilizers. Fermentation, decomposition and moisture removal operations in factories, compound fertilizer plants, sludge waste plants, gardening fields and Agaricus bisporus planting plants. Compared with traditional turning equipment, its advantages are

(1) High turning depth: its turning depth can reach 1.5-3 meters;

(2) Large flipping span: its maximum flipping width can reach 30 meters wide;

(3) Low energy consumption for turning and throwing: It adopts a unique energy-saving and high-efficiency transmission mechanism, which reduces energy consumption by 70% compared with traditional turning and throwing equipment under the same workload;

(4) Tossing without dead ends: The wheel is symmetrically tossed, and there are no dead ends under the displacement of the speed-regulating shift trolley;

(5) High degree of automation: Equipped with a fully automated electrical control system, no human operation is required during the operation of the equipment.

Forklift turning machine

The forklift turner is a multifunctional composter that integrates fermentation, mixing, crushing and shifting. The machine adopts a four-wheel walking design and can move forward, backward, and turn, and can be driven by one person. The rotating knife shaft inside the bucket mixes, fluffs and moves the pile of raw materials, leaving a new strip pile after the car passes. The operation can be carried out in an open field or in a workshop greenhouse. The outstanding technology of this machine is that it integrates the crushing function in the later stage of material fermentation. As the material gradually dehydrates, the installation of a crusher greatly improves the crushing efficiency, reduces costs, and fundamentally solves the problem of production volume being restricted by the crusher.

【Application Scope】

The forklift turner is suitable for aerobic fermentation and turning of organic waste such as livestock and poultry manure, sludge garbage, sugar factory filter mud and straw sawdust; it is widely used in organic fertilizer plants, compound fertilizer plants, sludge Fermentation, decomposition and moisture removal operations in garbage plants, Agaricus bisporus planting plants, etc.

【Machine advantages】

- Use a forklift turner to turn the fermentation materials, which can be freely transported to any location with no restrictions on the moving distance. It can be poured from one fermentation tank to another for fermentation, which saves costs.

- Transport the materials to the designated location, turn on the crushing function, and the raw materials will leak out from under the forklift to achieve the effects of crushing, mixing, and turning, which improves the powder fineness and uniformity of the compost materials and reduces nutrient volatilization.

- This machine is specially used for the process of microbial aerobic fermentation of materials, and can effectively fully decompose the viscous fermentation materials. This machine can mix 200-400m3 of fermentation materials per hour, which is converted into 100-200t of finished fertilizer. It is suitable for use in organic fertilizer plants with an annual output of 30,000 to 50,000 tons. The actual mixing time of this machine is about 1 hour per day, with an average fuel consumption of 0.03L per cubic meter. It only requires one driver, giving the finished fertilizer a clear price advantage. .

Crawler type turning machine

The crawler-type turning machine adopts a four-wheel walking design, which can move forward, backward, and turn, and can be controlled and driven by one person. During driving, the entire vehicle rides on the long-shaped fertilizer machine and is stacked in advance. The rotating knife mounted under the machine mixes, fluffs, and moves the raw materials of the fertilizer machine. After the vehicle passes, a new strip-shaped stack is formed, that is, The operation can be carried out in open areas or in workshop greenhouses.

The crawler-type turner is equipped with a drum and knife-shaped teeth. It is mainly used for flat stacking fermentation. It has the dual functions of stirring and crushing. It can not only uniformly stir the feces base material, sludge and other materials and bacteria, but also can It is an indispensable special machine in fertilizer making operations to effectively break the agglomerates in the fermented material.

【Features】

(1) The crawler-type turning machine is more suitable for the mechanism and process requirements of microbial fermentation of stored manure into fertilizer. It can effectively mix the viscous stored manure with microbial preparations and straw powder. Not only is it much faster than deep tank fermentation, it also effectively prevents the generation of harmful and odorous gases such as hydrogen sulfide, ammonia, and indole during the fermentation process. It not only meets environmental protection requirements, but also produces high-quality organic fertilizer.

(2) The overall power balance of the crawler-type turner is appropriate, low energy consumption, and high output, which reduces the survival cost of bio-organic fertilizer.

(3) The overall structure of the crawler type turner machine is reasonable. The whole machine has good rigidity, balanced force, simple, strong, safe and reliable performance, easy to control, and strong usability in the yard. Except for the rough frame, all parts and components are It is a standard part and is easy to use and maintain.

(4) The crawler-type turning machine does not need to build a trough, and can just pile the fertilizer into long strips on the ground. Ground stacking fermentation is currently the most advanced and most economical method of making fertilizers in terms of civil engineering and human resources. The materials are regularly stirred and broken by a compost turner, and the organic matter is decomposed under aerobic conditions.

Chain plate turning machine

The chain plate compost turner is suitable for trough-type aerobic composting of livestock and poultry manure, sludge garbage, straw and other organic solid waste. The walking system of this machine adopts variable frequency speed regulation, has good adaptability to different materials, stable operation, high pile turning efficiency, and can perform deep groove operations. It can effectively shorten the fermentation cycle and improve production efficiency and product quality. It adopts variable frequency speed-adjustable walking system, which can adapt well to changes in workload. The walking speed can be flexibly adjusted according to the resistance of the material, making the equipment more adaptable and flexible. An optional moving vehicle can be used to implement multi-trough equipment. If the equipment’s capacity allows, just add a fermentation tank to expand the production scale and increase the use value of the equipment.

Organic fertilizer fermentation tank

The organic fertilizer fermentation tank can be used to process organic waste such as pig manure, chicken manure, cow manure, sheep manure, mushroom residue, traditional Chinese medicine residue, crop straw, etc. It can complete the harmless treatment process in 10 hours, occupies less space, and requires no It can eliminate pollution (closed fermentation) and completely kill disease and insect eggs (can be adjusted to a high temperature of 80-100℃). It is an ideal choice for the majority of breeding enterprises, circular agriculture, and ecological agriculture to realize the utilization of waste resources.

2. Crushing equipment

Semi-wet material crusher is a professional crushing equipment for crushing high-humidity and multi-fiber materials. The semi-wet material crusher uses high-speed rotating blades to crush fibers with good particle size and high efficiency. The semi-wet material crusher is mostly used for crushing biological organic fermentation compost, urban domestic waste compost, grass mud carbon, rural straw waste, industrial organic waste, livestock and poultry manure and other biological fermentation high-moisture materials.

Vertical crusher

The new vertical crusher is a screen-less, adjustable fine crushing equipment optimized and designed on the basis of absorbing advanced fine crushing equipment. It is one of the equipment that can be widely used for crushing organic fertilizers.

Vertical crusher has the following features:

(1) Especially for materials with high moisture content, it has strong adaptability, is not easy to be blocked, and can discharge materials smoothly.

(2) The crushing blade is made of special material and has a service life three times longer than that of similar products.

(3) The crusher has high crushing efficiency and is equipped with an observation window. It only takes ten minutes to replace wearing parts.

Cage crusher

Cage crusher is a medium-sized horizontal cage crusher. This machine is designed based on the principle of impact crushing. The two sets of inner and outer cage bars rotate in opposite directions at high speed, and the materials are crushed from the inside out by the impact of the cage bars. It has a simple structure, high crushing efficiency, good sealing performance, stable operation, and is convenient. Features include easy cleaning and maintenance. The cage crusher can crush various single fertilizers with a moisture content of less than 6%, and is especially suitable for materials with higher hardness. It has a simple and compact structure, small floor space, easy maintenance, good crushing effect, smooth operation, and easy cleaning. It is the nemesis of hard granular materials such as monoammonium, diammonium, and urea.

3. Mixing equipment

Horizontal mixer

When the horizontal mixer is mixing, the material in the machine is affected by two rotors in opposite directions and undergoes compound motion. The paddle drives the material to rotate counterclockwise along the inner wall of the machine tank. On the one hand, it drives the material to turn left and right. When the two rotors cross, Overlapping shape weight loss zone, in this area, regardless of the shape, size, and density of the material, the material can float up and be in a state of instant weight loss, which causes the material to form an all-round continuous cycle in the machine tank, turning and shearing with each other. This achieves fast, gentle and even mixing.

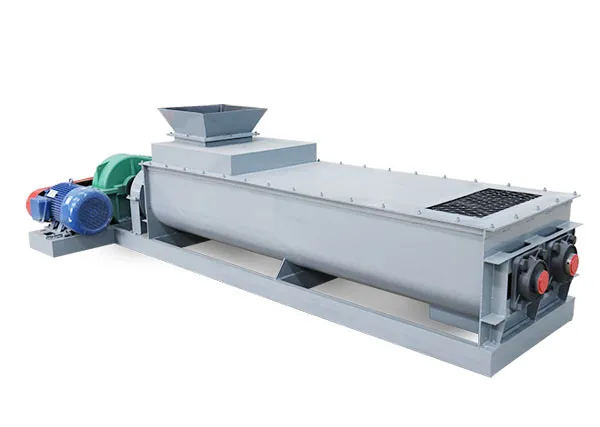

Twin shaft mixer

The twin-shaft mixer uses the synchronous rotation of two symmetrical spiral shafts to transport dry ash and other powdery materials while adding water and stirring, and evenly humidifies the dry ash powdery materials, so that the humidified materials do not emit dry ash and do not seep out. The purpose of water droplets is to facilitate the loading and transportation of humidified ash or transfer to other conveying equipment. It is mainly suitable for humidifying and loading of fly ash or similar materials in thermal power plants, mines and other industries. The twin-shaft mixer has fast mixing speed and good uniformity. It can mix and add 30% of liquid viscous materials. When working, there are two oppositely rotating paddle rotors for stirring in the middle. Because the blades have multiple special angles, they can be used regardless of the shape of the material. What about size and density. can be mixed quickly and effectively. The lower opening door has a fast discharge speed and less residue.

Pan mixer

A pan mixer is a machine mainly used for mixing raw materials. The machine is lined with polypropylene plate or stainless steel plate, which is not easy to stick to materials and is wear-resistant. It uses a cycloidal pinwheel reducer to have the advantages of compact structure, easy operation, uniform mixing, and convenient unloading and transportation. The materials are fully mixed, thereby improving the mixing uniformity. A novel rotor structure is adopted, so that the minimum gap between the rotor and the shell can be adjusted to close to zero, effectively reducing the residual amount of materials. The inside of the plate is made of polypropylene plates. Lining or stainless steel plate, so it is not easy to stick to materials and wear-resistant. It adopts cycloidal pinwheel deceleration and has the characteristics of compact structure, easy operation, uniform mixing, convenient discharge and transportation. The overall structure is more reasonable, the appearance is beautiful, and the operation and maintenance are convenient.

4. Conveying equipment

Mobile belt conveyor, fixed belt conveyor, etc. This is easier to understand

5. Granulation equipment

Disc granulator

The disc granulator (also known as the ball disc) is a volumetric metering feeding equipment. It can feed materials to the next process evenly and continuously, and can withstand large warehouse pressures. As a fine-grained material feeding equipment, it is suitable for transporting various non-sticky materials in powdery, solid or small pieces, such as coal powder, cement, clinker, limestone, shale, gangue, clay and other powdery and granular materials. or small pieces of material.

The angle of the granulating disc of the disc granulator adopts an overall arc structure, and the granulation rate can reach more than 93%. The granulating plate is equipped with three discharge ports, which facilitates intermittent production operations, greatly reduces labor intensity and improves labor efficiency. The reducer and motor are driven by flexible belts, which ensures smooth starting, slows down impact force, and improves the service life of the equipment. This machine has the advantages of uniform granulation, high granulation rate, smooth operation, sturdy and durable equipment, and long service life. It is the ideal equipment chosen by the majority of users.

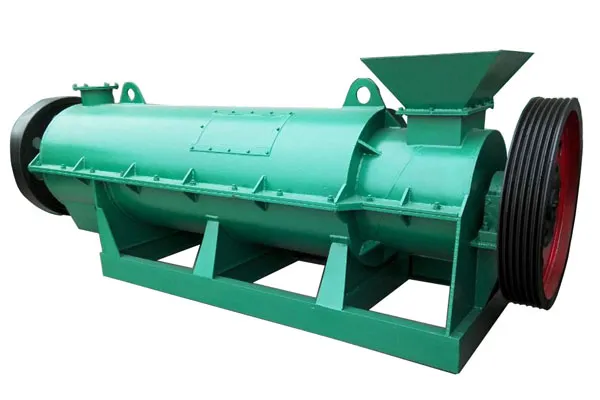

Stirring teeth granulator

Stirring teeth granulator. It is widely used in the granulation of organic fertilizers. Due to its high granulation rate, smooth operation, sturdy and durable equipment, and long service life, it is chosen as an ideal product by the majority of users. The shell of the granulator is made of thickened seamless steel pipe, which is strong and durable and will never deform. Coupled with the stable base design, it operates more smoothly.

The stirrer granulator produces bacteria at room temperature and has a reasonable structural design. It can produce spherical granular products. The granules produced have the characteristics of low moisture content, easy drying, high molding rate, good granule strength, and beautiful appearance. It is today’s ideal Bio-organic fertilizer, organic inorganic fertilizer, organic fertilizer and inorganic compound fertilizer granulation equipment.

[Application range of this machine for granulation]

Organic wastes such as peat, sludge, chicken manure, livestock manure, lignite, sugar factory filter mud, papermaking sludge, wine waste, straw, bean dregs, peat, etc. can be directly granulated after fermentation treatment, completely solving the problem of disc (turning) Drum) The key technical problems that traditional granulation technology cannot solve are fermentation, etc., and bio-organic fertilizer granulation as raw materials.

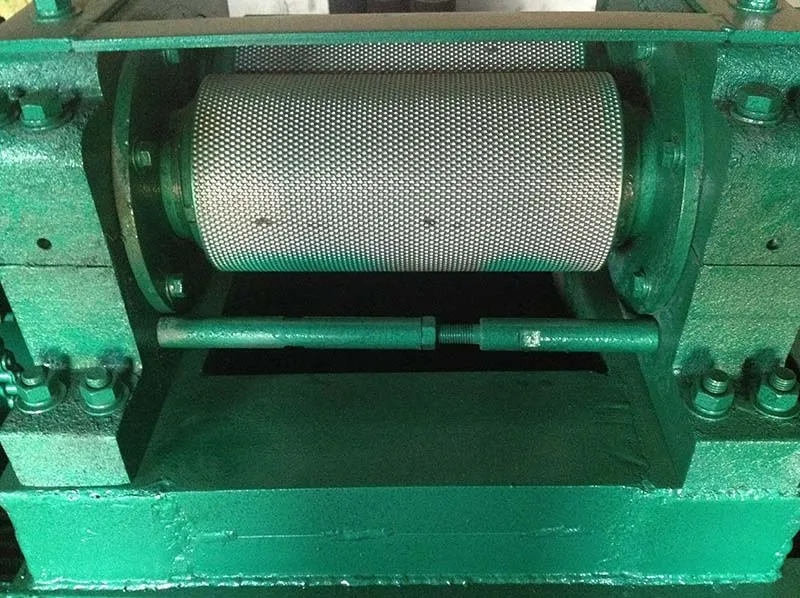

Double roller extrusion granulator

The double-roller extrusion granulator is produced using a non-drying and room-temperature process and is formed in one go. This equipment has low investment, quick results and good economic benefits. The complete set of equipment has a compact layout, scientific and reasonable layout, and advanced technology. Energy saving and consumption reduction, no three wastes discharged, stable operation, reliable operation and easy maintenance. The raw materials have wide adaptability and are suitable for granulating various raw materials such as compound fertilizers, medicines, chemicals, feeds, etc. The product granulation rate is high. It can produce compound fertilizers of various concentrations and types (including organic fertilizers, inorganic fertilizers, biological fertilizers, magnetic fertilizers, etc.). Especially rare earth, potassium fertilizer and ammonium bicarbonate series compound fertilizer granulation,

[Features of double roller extrusion granulator]

- The double-roller extrusion granulator adopts drying-free process, granulates at room temperature, and forms in one step. It has the characteristics of low investment, quick results and good economic benefits.

- The structure of this machine integrates granulation, molding and screening. It has the characteristics of simple operation and low energy consumption. The main components such as the roller body are made of a new type of metal with anti-corrosion, wear resistance and impact resistance characteristics.

Rounding machine

The round polishing machine has high output and can be flexibly arranged in the process. It can be used together with the organic fertilizer granulator and the disc granulator. The round polishing machine consists of two or three polishing cylinders arranged in sequence. After several rounds of rounding, the finished product is discharged from the discharge port. The finished product has consistent pellet size, roundness and smoothness, and a yield of up to 97%. A small amount of fertilizer falls from the gap at the edge of the organic fertilizer rounding machine and flows out along the waste port; throwing The round granulator has beautiful appearance, simple structure and working principle, is safe and reliable, small in size, light in weight, and easy to operate and maintain. The machine has adaptability and can adapt to work in various environments, and the organic fertilizer rounding machine can maintain continuous It operates for a long time, consumes little power and energy, saves electrodes, has low production costs and high economic benefits.

Drum granulator

The transfer granulator is a granulation equipment commonly used in the production of compound fertilizers, organic fertilizers, biological fertilizers, controlled release fertilizers and other fertilizers. It is suitable for cold and hot granulation as well as large-scale production of high, medium and low concentration compound fertilizers. Production. The main working method is pellet wet granulation. Through a certain amount of water or steam, the basic fertilizer is fully chemically reacted after the humidity is adjusted in the cylinder. Under certain liquid phase conditions, with the help of the rotation of the cylinder, the material pellets are The extrusion force is generated to form a ball.

- The balling rate reaches 70%, the balling strength is high, there is a small amount of returned material, the pellet size of the returned material is small, and it can be re-granulated;

- Introduce steam for heating to increase the temperature of the material, so that the moisture content of the material after it is pelletized will be low and the drying efficiency will be improved;

- The machine barrel is lined with a special rubber plate or acid-resistant stainless steel lining, which is corrosion-resistant and wear-resistant. It also realizes automatic scar removal and tumor removal, eliminating the traditional scraper device.

6. Drying and cooling equipment

Rotary dryer

Rotary dryer – also known as drum dryer, bio-organic fertilizer dryer, because the temperature cannot exceed 80° when drying organic fertilizer, so our dryer adopts hot air drying mode.

- The dryer has strong overload resistance, large processing capacity, low fuel consumption and low drying cost;

- The operating parameters can be changed according to different material properties, so that the sawdust and sawdust materials can form a stable full-fragment curtain in the dryer barrel, and the mass and heat exchange is more sufficient;

- The new feeding and discharging device eliminates clogging, discontinuity, unevenness and return of materials in the drum dryer, and reduces the load on the dust removal system;

- The new internal structure strengthens the cleaning and heat conduction of dispersed materials, eliminates the sticking phenomenon on the inner wall of the cylinder, and is more adaptable to the moisture and viscosity of materials.

Rotary cooler

Cooler, also known as drum cooler, is the main configuration equipment of the rotary kiln production system. The heat-exchanged waste gas can be introduced into the rotary kiln, thereby improving the thermal efficiency of the entire system. In the production of compound fertilizer, the fertilizer with a certain temperature and pellet size is cooled and used in conjunction with the dryer. It can greatly increase the cooling speed, reduce labor intensity and increase yield, further remove part of the water and reduce the grain temperature of the compound fertilizer. At the same time, the cooler can also be used to cool other powdery and granular materials. The cooling machine has a simple structure, good stability and reliable operation. It looks similar to a dryer, but has different materials and performance. The main machine of the dryer is made of boiler steel, and the main machine of the cooler is customized with carbon steel plates.

7.Screening equipment

Drum type rotary screener

The drum rotary screening machine is a commonly used equipment in the production of organic fertilizers and compound fertilizers. It is mainly used for separation of finished products and returned materials. It can also be used to classify finished products so that they can be classified evenly. The combined screen is used for easy maintenance and replacement. The machine has a simple structure, easy operation and smooth operation.

The drum screening machine is another new generation of self-cleaning screening equipment after the electric vibrating screen and the ordinary mesh drum screen produced by major domestic companies. It is widely used for screening various solid materials with pellet sizes less than 300mm. It has many characteristics such as high screening efficiency, low noise, low dust volume, long service life, low maintenance, and convenient maintenance. Its screening capacity is 60 tons/hour~1000 tons/hour. Comprehensive utilization of electricity based on burning low-quality coal (mainly circulating fluidized bed boilers) is rapidly emerging in China. Fuels based on coal ore and coal slime usually have characteristics such as sticky, wet, dirty, and miscellaneous, and the coal transportation system is ordinary. There are phenomena such as clogging of the screening machine, low screening efficiency, large wear of the crusher, and high energy consumption.

Vibration type screener

The vibrating screen uses a cylindrical eccentric shaft exciter and an eccentric block to adjust the amplitude. The material screen has a long flow line and multiple screening specifications. It has a reliable structure, strong excitation force, high screening efficiency, low vibration noise, durability, and easy maintenance. , safe to use and other characteristics, this vibrating screen is widely used in product classification in organic fertilizer, compound fertilizer, mining, building materials, transportation, energy, chemical industry and other industries.

8. Coating equipment

Fertilizer coating machine–the main machine has a similar appearance to a dryer and a cooler, but the internal structure is very different. The complete set of rotary coating machine equipment consists of a screw conveyor, a mixing tank, an oil pump, a main engine, etc. It adopts powder coating or liquid coating technology, which can effectively prevent the agglomeration of compound fertilizers. It is an effective special equipment for compound fertilizers.

9. Automatic packaging machine

Automatic packaging scales are specially designed for quantitative packaging, this machine is divided into double-bucket packaging scales and single-bucket packaging scales. Adopting an integrated structure, the scale has small height, compact structure, energy saving and high efficiency, novel appearance, simple installation and convenient maintenance.

Conclusion

The configuration of organic fertilizer production line can be configured according to your actual needs and operating funds

Simplest organic fertilizer production line

The simplest organic fertilizer production line only requires fermentation equipment-raw material bin-conveyor belt-crusher-conveyor belt-screening machine-storage bin. The final product is unpackaged powdered organic fertilizer with low economic value and is recommended for personal use. On this basis, a packaging machine can also be added for packaging and sale.

Disc granulator production line

Fermentation equipment – Crusher – Conveyor belt – Mixer – Conveyor belt – Disc granulator – Conveyor belt – Dryer – Conveyor belt – Cooler – Conveyor belt – Screening machine – Conveyor belt – Packaging Film machine – elevator – packaging scale

Among them, at the screening machine, the poorly granulated materials can be sent to the granulator via a conveyor belt.

Double roller extrusion organic fertilizer production line

Fermentation equipment – crusher – conveyor belt – roller extrusion granulator – conveyor belt – screening machine – conveyor belt – coating machine – elevator – packaging scale

Above are all the organic fertilizer production line machines list and introduction, hope this can be helpful for your fertilizer production. If you want to enter the organic fertilizer making business, we can always supply satisfying solutions to you. Contact with us to know more.

Related Articles :

How Much A Complete Organic Fertilizer Production Line Cost?

Cost & Profit Analysis of Organic Fertilizer Production Line

How to Start a Fertilizer Business Plan in 2023?

Talk to An Expert

SHARE THIS POST

Talk to An Expert